We have gathered 10 examples of 3D printing in real-world applications that can be seen today in this post. You can virtually create anything you can think of with 3D printing, such as medical devices, aircraft parts, and shoes. In the near future, 3D printers will be available for many households all over the world as they become more affordable to purchase.

In Linquip, We offer you access to the best additive manufacturing and 3D printing tools available to help you perform your duties more efficiently. By visiting Linquip’s website, you can find a wealth of information about 3D printers and the factors that you should consider when purchasing a 3D printer. The “What Is Additive Manufacturing and 3D Printing?” page explains what Linquip offers based on its intended use.

You can find the perfect product for your needs with Linquip’s wide selection of Additive Manufacturing and 3D Printing Products. We provide 3D printing quotes from a variety of companies and suppliers if you’re interested in purchasing a 3D printer. Fill out our online form to receive quotes from multiple Additive Manufacturing and 3D Printing Companies and Suppliers.

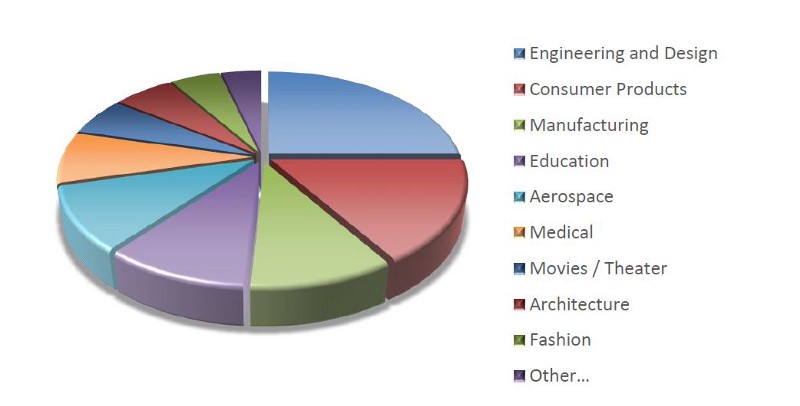

In addition to the powerful capabilities these machines provide businesses and their production processes, manufacturers are also paying attention to them. Almost daily, new developments in 3D printing expand the possibilities.

Let’s take a look at some of the interesting objects that can be created with 3D printers today.

Buildings

You can actually build entire houses using 3D printing, believe it or not. Three-dimensional printing enabled the construction of a 400-square-foot house in a suburb of Moscow in less than 24 hours. When time is of the essence, 3D printing can be used to quickly erect houses and other structures, such as emergency shelters, for areas affected by natural disasters. Design innovations will also result from the ability to realize new architectural visions that were previously unimaginable with current manufacturing methods.

The 3D printing of a two-story house from concrete in Beijing was completed in 45 days, while German researchers even 3D-printed a house from glass for the first time.

There is no end to design innovations. It will soon be possible to live in a neighborhood made up entirely of 3D-printed houses in Holland.

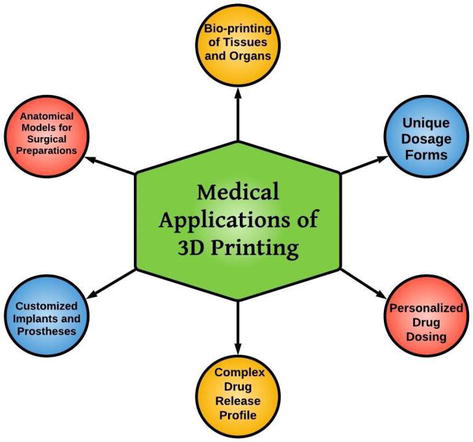

Health Science

Researchers have developed a 3D bioprinter that produces organs, tissues, and bones that can theoretically be implanted into living humans. By using bioplastics and cells from humans, rabbits, rats, and mice, researchers have created muscles, bones, and ears. The living cells survived the process of 3D printing. Additionally, the researchers were able to implant 3D-printed structures into rodents, which proved to be successful. The technology may one day allow doctors to print bones, muscles, and cartilage from a patient’s own cells, leveraging patient-derived models, if it proves successful on rodents.

After this, a printer was used to print artificial skin. Various types of cells were placed in the wells of an actual ink cartridge; then, a printer was programmed to arrange the cells in an ordered manner. An adaptable version of ink-jet printing technology is currently being used to print skin on-site for soldiers suffering from life-threatening burns. According to this technology, skin cells and essential materials would be placed directly into a print cartridge and printed directly onto wounds.

An implanted skull might seem like science fiction, but Chinese doctors saved a baby’s life last year by printing a titanium skull and implanting it in three pieces. It is easy to design titanium 3D printed to fit the patient perfectly, and it is strong and lightweight.

Manufacturing

It is possible to use 3D printing in manufacturing across a wide range of industries, including automotive, aerospace, and more. It can be used to print replacement parts for machinery, prototype new products (with the added advantage of recycling the models when you’re done), to create moulds and jigs to improve production efficiency. 3D printing has been used by manufacturers to lower costs and produce products more quickly. Electric cars and other cars are 3D printed.

Another example is 3D bicycle printing. Several construction challenges, including the cost and size of the printer needed, limit the possibility of a 3D bicycle coming to a retail market. However, companies offering 3D-printed titanium bike parts and ETT Industries offering 3D printable bicycle parts that can be printed at home are improving the lives of bike riders despite these initial hurdles. Cycling enthusiasts who are interested in incorporating new 3D printing technology into their own rides will be thrilled to hear this news.

3D-printed shoes have an appeal. Who wouldn’t want a pair of shoes tailored to their exact measurements? However, 3D-printed shoes are still limited to either shoe parts or limited editions.

The world of shoes outside of sports seems to be dominated by highly artistic offerings. Customers see these offerings being printed right before their eyes at the store. Another interesting concept is Feetz, which 3D prints shoes based on photos of your feet.

Drug Printing

Aprecia Pharmaceuticals has recently released Spritam, the world’s first 3D-printed drug used to treat seizures in epileptic patients. The printing is accomplished by MIT-developed technology using ZipDose, the company’s trademark. In order to dissolve quickly in liquids, the printed pills are made by sandwiching a powdered form of the drug between liquids and bonding them at the microscopic level with technology.

A 3D drug printer is a huge step forward in personalized medicine because it allows the size, dosage, appearance, and rate of delivery of a drug to be customized to suit the individual. On-demand drug-printing facilities may soon be available in clinics, hospitals, and pharmacies, as well as in patients’ homes.

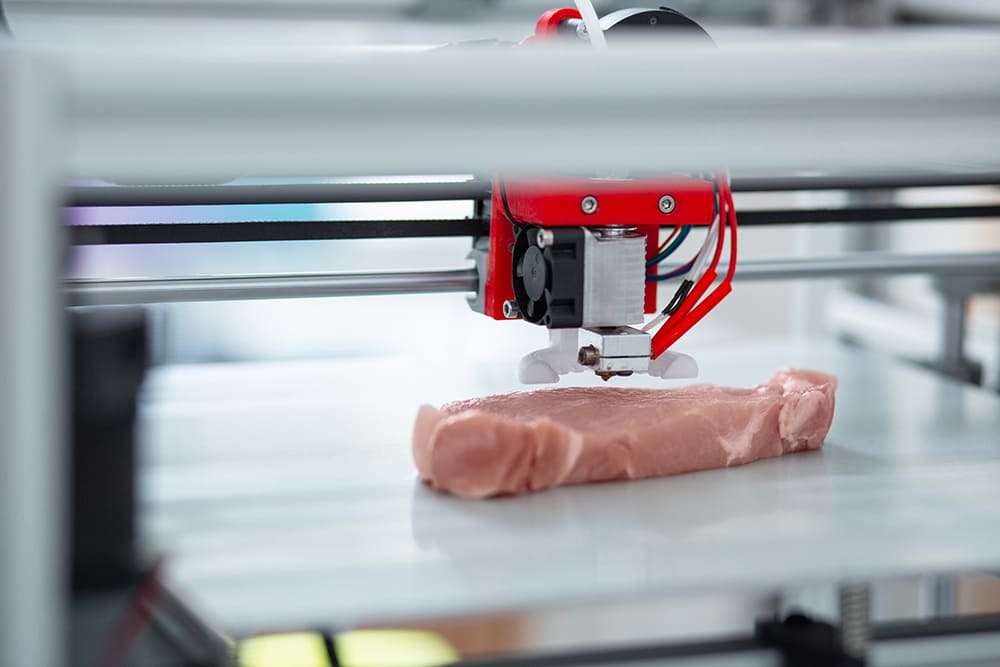

Food

The advent of 3D printing is even breaking down design barriers in the world of culinary arts. With the use of a plastic 3D printer, chocolate can actually be printed by users from 3D software. Ice cream, cookie dough, marzipan, and hamburgers are just a few of the edible foods that can be printed with a 3D printer.

A food 3D printer uses the same concept as traditional 3D printers: it heats edible ingredients before printing them, layer by layer, on a build plate. Alternatively, the food 3D printer can solidify ingredients in the form of a powder, similar to SLS 3D printing.

Firearms & Military

3D printing of fully functional firearms has been a very controversial topic for quite some time. Defense Distributed’s “Liberator,” a working plastic gun manufactured using 3D printing, has been the focus of a lot of discussions. The ability to make guns with 3D printers and design blueprints is viewed by many as extremely dangerous since anyone can make their own guns with just a 3D printer and design blueprints.

Musical Instruments

A number of instruments, including violins, flutes, banjos, and more, have already been manufactured with additive manufacturing techniques. In the first-ever live concert featuring all 3D printed instruments, Lund University hosted the show, and it was a rousing success. The process of 3D printing is not only used for creating complete instruments but also for creating accessories, such as custom mouthpieces.

Drawing

3Doodler, a handheld pen that allows you to “draw” 3D printed objects, provides perhaps the most entertaining example of 3D printing.

A 3Doodler is similar to a hot glue gun. It is controlled through a button, where you can start, pause, and stop it. When you begin your drawing, you press the pen tip on a flat surface; then, you draw your 3D object.

Artwork for the Blind

The technology is even being used to turn classic paintings into 3D-printed sculptures, so that blind art lovers can appreciate classical paintings.

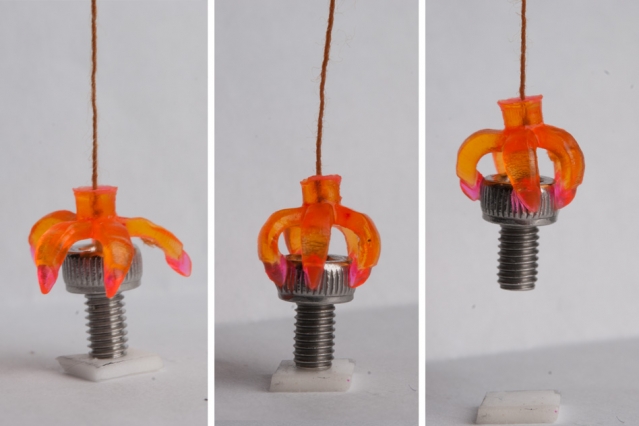

Shape Memory Materials

Although 4D printing is less common than 3D printing, one example illustrates how it may prove useful in the future in a variety of applications. Lawrence Livermore National Laboratory researchers have printed silicone that is flexible and adaptable to heat. In this way, it would be possible to create truly customized, form-fitting shoes that would adapt to the wearer’s feet.

Why is 3D Printing So Popular?

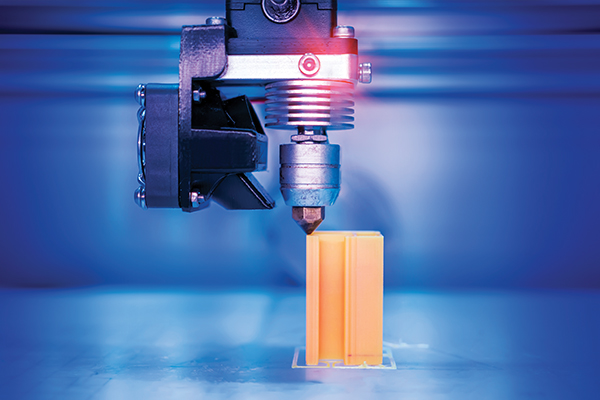

It involves building up a 3D object layer by layer using a digital file. Imagine you slice open a finished 3D-printed object and get a glimpse of the thin layers, like the rings on a tree trunk.

The first step to printing anything is creating a 3D model of the object you’re trying to build. After that, the computer model is “sliced,” which means that it is divided up into hundreds (or possibly thousands) of layers. By feeding this data to the 3D printer, the object is printed slice by slice.

A major advantage of this approach is that it enables the creation of even the most complex of shapes much more easily, and it uses less materials in comparison to traditional methods of producing things (which is less harmful to our environment and better for the bottom line).

It is possible to print parts and products on-site, thus reducing transportation costs. In addition, it is possible to make one-off products in a very fast and easy way, without the worry that there will be any economies of scale – which could be very helpful for rapid prototyping, custom manufacturing, and the creation of highly personalized products as well. Further, 3D printing can be done with pretty much any material – not just plastic but also metal, powder, concrete, liquid, and even chocolate.

Download the PDF for 10 Examples of 3D Printing

You can download the PDF of this article by clicking on the link below.

linquip.com-10 Examples of 3D Printing

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- The 10 Best Large 3D Printer

- The 10 Best FDM 3d Printer + Buying Guide

- The 6 Best 3D Printer for Home + Buying Guide

- The 6 Best 3d Printer for Beginners + Buying Guide

- The 9 Best 3D Printer for Under $300

- The 10 Best 3D Printer for Under $500

- The 7 Best 3D Printer for Under $1000

- The 10 Best Industrial 3D Printer

- 10 Types of 3D Printing: A Comprehensive Guide

- What Is 3D Printing and How Does It Work? + Applications