In the industry of heavy equipment, they need reliability and efficiency at its finest. These machines are used widely for construction, mining, agriculture, and transportation industries, among others. Managing these machines, therefore, comes with a need to focus on hydraulic systems that power such equipment. Hydraulics are a must-use on this equipment as they provide the necessary force that is needed for tasks such as lifting, excavation, and movement. As a result of this, hydraulic services are required to be conducted frequently as a way of preventing machinery breakdowns. Here are five hydraulic services one should not overlook in helping to ensure the overall health and performance of your heavy machinery.

1. Regular Hydraulic Pump Maintenance

Every hydraulic system comes with this component, which plays a very crucial role of increasing the hydraulic pressure as machines transform mechanical power into hydraulic power. It is important to always service the hydraulic pump and be keen on maintenance to enhance its performance and expected lifespan. This is a process of checking on the pump to see if it has signs of corrosion or depreciation, and also, the level of the fluid is checked to see if it is low or if there is a leakage. The hydraulic fluid must be clean and should be properly filtered as well because it defines how efficiently the pump will work and how long it will last. Maintenance is not only important in optimising efficiency but also fundamental in identifying some complications that would require expensive repairs later in the future.

2. Hydraulic Fluid and Filter Replacement

Hydraulic fluid can be regarded as the life force of hydraulic systems since it determines the capability of those systems. This fluid gets exposed to dirt, metal particles, and other debris and thus leads to a reduction in the efficiency of working and, in the worst scenarios, causes harm to the system. Another key service that needs to be carried out is the changing of hydraulic fluid and filters frequently. This service entails the removal of the old fluid, followed by its replacement with a new one with uncontaminated fluid. New filters are fitted to enable filtration of any undesired materials from entering the system. This maintenance task is not only improving the hydraulic drive power and efficiency but also increasing the service life of the hydraulic parts.

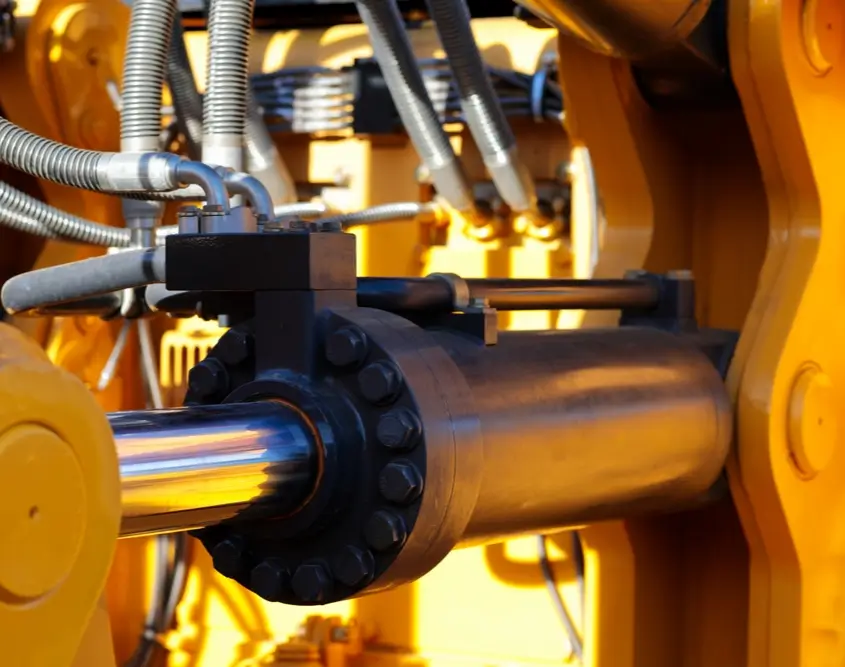

3. Hydraulic Pump Repairs

Hydraulic pumps, like any other equipment, require a certain degree of maintenance at some point in time and may develop some problems. Hydraulic pump repairs are an important service to deal with such issues since they are fixed as soon as possible. Some of these problems relate to leaks, pressure loss, or turbulences created by the pump. It can involve worn seals or even some specific part complications and such skilled technicians have to fix it. Maintenance is important to avoid small problems becoming huge breakdowns, which will cut on productivity of the machinery and other materials. The repair of hydraulic pumps offers a good solution to ensure constant availability of the heavy equipment as an investment.

4. System Pressure Testing

Pressure testing can be described as checking the hydraulic system to ensure that it is operating within the set pressure limit that is recommended by the designer. In this service, certain points of the process are pressurised in order to detect any leaks or potential problem areas. Pressure testing is the capacity to detect problems like leaks, blockages, or problems in different sections that may not be noticed during inspection. Pressure testing allows for the identification of such problems and such issues will be solved before they cause the machinery to break down, thus giving the hydraulic system and pressure system a work-as-intended guarantee.

5. Comprehensive Hydraulic System Inspection

A complete hydraulic system check is a service provision that analyses all the hydraulic systems as a comprehensive check for possible problems. The inspection should also cover the hoses, fittings, valves, and their actuators, the hydraulic pump, as well as the fluid. They check for signs of wear, corrosion, and other forms of damage that may affect the system, therefore. In addition, thorough inspection helps in checking the status of the system and its readiness to serve clients as well as diagnosing the health of the machines. This approach can help to avoid a failure of the equipment at unexpected times and enhance their life span.

Conclusion

The reliability of heavy machines is dependent on the proper care of the hydraulic systems of the machines. About hydraulic pump maintenance, hydraulic fluid and filter replacement, hydraulic pump repairs, system pressure testing, and comprehensive hydraulic systems check, your operations will not be interrupted by machinery failure. These services are not merely about solving problems; rather, they are about painful things that are done to keep your heavy machinery ready that should be ready to work at any time. It is important to note that the conditions of your hydraulic systems are critical to the efficiency and the bottom line of your business. It is also important to emphasise that hydraulic services should not be treated as an emergency spare part to have with you when something breaks down, but rather as a necessary step that should be done periodically to have properly functioning equipment.