Gas turbines and reciprocating engines are a type of internal combustion engine widely used to generate power for several applications including institutional and industrial applications. While both of them are used to provide motive power, some differences make them advantages over each other. In this article, Linquip will take a closer look at the difference between gas turbines and reciprocating engines. Read on to find out more about each and their differences.

On Linquip’s website, you can find the whole range of information you need regarding different types of power generation equipment, such as turbines and engines, depending on your needs. Linquip has a team of experts available to answer any questions you may have regarding any of these industrial terms or anything else you may have regarding Linquip’s services. To begin with, we suggest that you take a look at Linquip’s article, “What is Power Generation?“. This link will provide you with access to a wide range of power generation tools and devices, companies, and manufacturers, as well as many other options.

Furthermore, if you want to be able to access all the services that Linquip has to offer, it is highly recommended that you register as a Linquip Expert. Would you be interested in publishing a Guest Post on Linquip? We invite you to submit your content for publishing on Linquip’s platform as a guest.

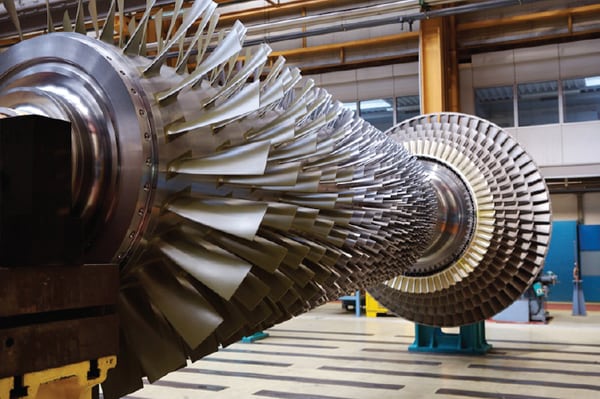

What Is a Gas Turbine?

A gas turbine, also called a combustion turbine, is a type of continuous and internal combustion engine. It transforms the chemical energy in the fuel, for example, natural gas or similar fuel into mechanical energy. The mechanical energy generated by the turbine’s exit shaft is then transferred through a gearbox to the generator’s shaft. The generator then creates electrical energy.

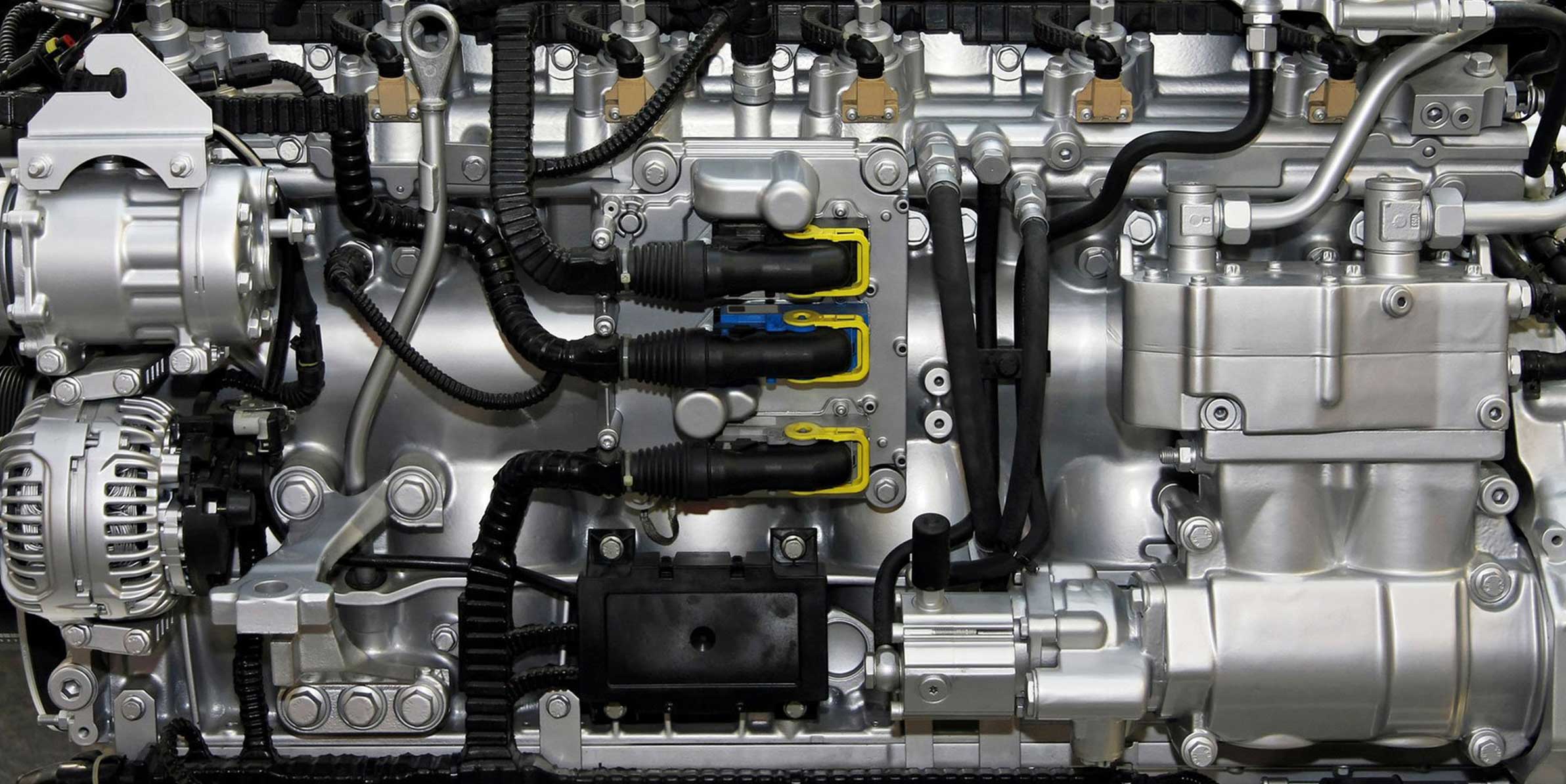

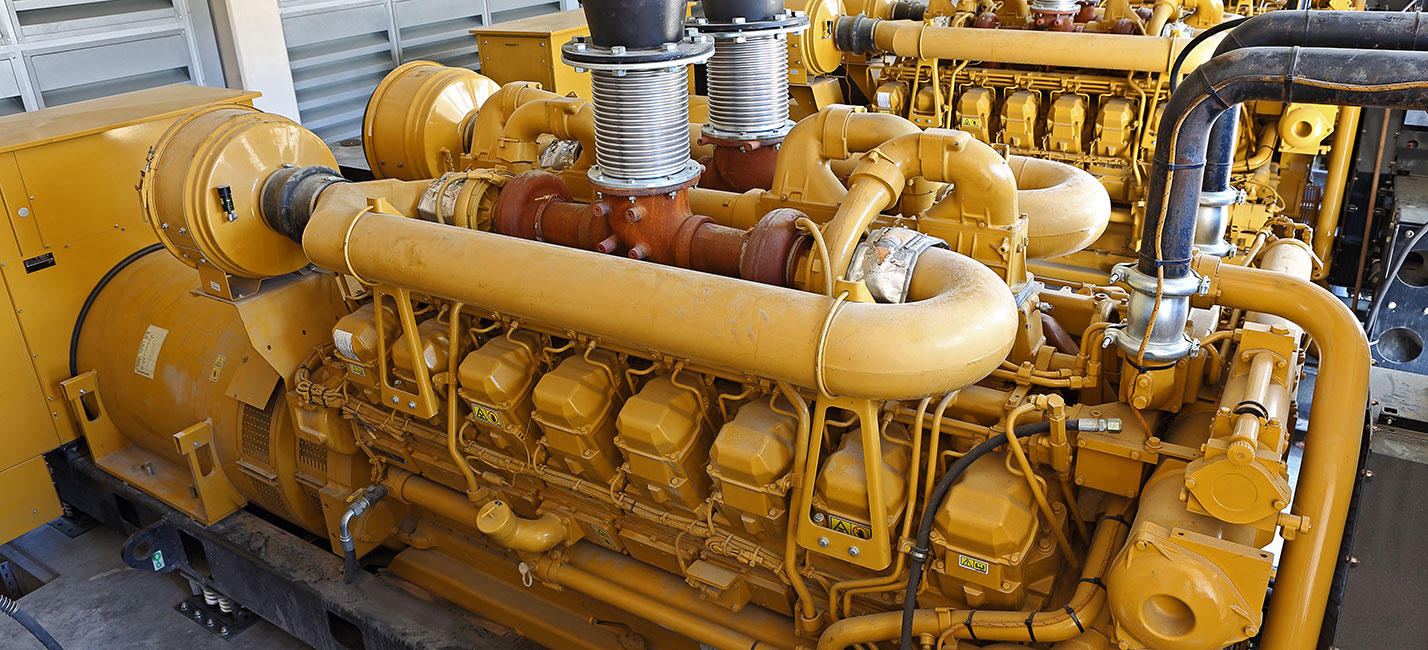

What Is a Reciprocating Engine?

A piston engine, also commonly referred to as a reciprocating engine or, recipe, is an internal combustion engine that uses one or more reciprocating pistons to convert pressure into a rotational motion.

The power created by reciprocating engines comes from pressurizing fuel using pistons to create combustion and, in turn, produce a circular, rotating motion. This process is called the four-stroke cycle as, like a rotary engine, reciprocating engines rely on a repeating pattern of intake, compression, combustion, and exhaust to function which leads to creating energy.

The Difference Between Gas Turbine and Reciprocating Engine

The primary difference between a gas turbine and a reciprocating engine is that reciprocating engines convert pressure into rotating motion using pistons, while a gas turbine engine, or a combustion turbine, uses the pressure from the exploding fuel to turn a turbine and produce thrust. There are several factors taken into account while selecting a gas turbine or a reciprocating engine. The following factors show the main differences between these two.

-

Application

A gas turbine, either in the simple or combined cycle, is the equipment of choice if you require high-pressure steam (e.g. over 100 PSIG) and in large quantity, where a reciprocating engine may be more appropriate for a CHP (combined heat and power) application where you need a lot of hot water (e.g. for sanitation, process, etc.).

Besides, gas turbine engines power large and powerful aircraft such as military jet fighters or commercial airliners, but reciprocating engines are being used in smaller and short-range aircraft.

-

Load following

Reciprocating engines in general are better for load following if you have an electrical load that varies as their efficiency does not vary significantly as you reduce their load, unlike gas turbines which become far more inefficient at lower loads.

-

Installation

Gas turbines are small and modular, therefore, they can be transported, installed, and commissioned in as little as 3 months, compared to 12-18 months for reciprocating engines. Gas turbines can be installed outdoors with minimal foundation requirements, making them an advantageous energy solution for any region that needs fast, clean, reliable power.

-

Plant size

There are few gas turbines below about 3,000 kW and they are pretty inefficient. That doesn’t matter so much if you are capturing the waste heat but it does if you aren’t. Gas turbines would be the choice for larger (typically 7,000 – 10,000 kW and above) plants and either reciprocating engines or gas turbines in the 3,000 – 7,000 kW range, again depending on the thermal requirements and balance between thermal and electrical.

In a CCHP application, as a general rule of thumb, a 5,000 kW combustion turbine can produce about 2,600 – 2,800 RT (refrigeration tons) of chilled water using an absorption chiller. An equivalently sized reciprocating engine plant would be able to produce about 900 – 1,000 RT.

-

Capital cost

From a capital cost perspective, a reciprocating engine CHP plant is likely to be less expensive than a gas turbine-based plant. However, its operating costs will typically be higher on a per-kilowatt-hour basis as reciprocating engines require more routine maintenance, lube oil changes, etc.

-

Maintenance

Gas turbines need maintenance only once a year, or when they have been in operation for 4,000 hours. Compared to reciprocating engines which require 50 times more maintenance events per year. aero-derivative engines save more than 13,000 man-hours over a 3-year maintenance cycle.

Maintenance of the reciprocating engines is simpler while maintenance of the gas turbine engines is complex.

-

Lube oil costs

A highly efficient gas turbine in a combined cycle consumes only about 2 mL/MWh of lube oil per year which is 200 times less than a reciprocating engine. That can translate to savings of more than $1 million per year for a 100 MW gas turbine power plant.

-

Availability

Gas turbines have the highest availability of any thermal power technology. A gas turbine can be replaced in a power plant within a few days for a major inspection, which translates to higher availability which is 98.2% as compared to power generated by reciprocating engines, with an average availability of 93%.

-

Fuel flexibility

With the ability to operate on a wide spectrum of fuels including natural gas, LPG (propane and butane), isopentane, ethanol, diesel, and Coke Oven gas, gas turbines can allow power customers to switch between fuels to save money, all without stopping, and without a power reduction. Using diverse fuel sources doesn’t just increase reliability, it also results in significant fuel savings from $12 million up to $43 million per year as compared to the fuel costs of a high-speed reciprocating engine.

-

Response rate

Gas turbines feature a power turbine and high-pressure shaft that work together to respond quickly to grid frequency fluctuations, helping create a more stable and reliable grid than reciprocating engines.

-

Emissions

Equipped with best-in-class combustion systems, gas turbines can offer 15 or 25 ppm NOx without needing SCRs (selective catalytic reduction) or the use of ammonia.

-

Enabling renewables

Gas turbines allow renewables to operate when needed, saving fuel and maintenance and maintaining a stable grid as compared to reciprocating engines, to allow the integration of more renewables in the future.

-

Footprint

Because gas turbines have about 22 times more power output per unit than comparable high-speed diesel reciprocating engines, gas turbine power plants take up less space which is a real advantage where real estate is expensive.

-

Design

Gas turbines are sophisticated in design and manufacture, while reciprocating engines are simpler in design and easier to manufacture.

That was everything you needed to know about the difference between a gas turbine and a reciprocating engine. As you see, from higher efficiency and lower costs to faster, cleaner, higher-quality power generation, gas turbines have many advantages over reciprocating engines. Comment below and let us know what you think about these two and their differences. And if you have any questions about gas turbines or reciprocating engines, feel free to sign up on Linquip and we will help you right away!

Download Gas Turbine vs. Reciprocating Engine PDF

The article can also be downloaded as a PDF file to your computer so that you can access it whenever you need it. Please click on the link below to start downloading.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

- The Practical Guide To The Difference Between Gas Turbines and Steam Turbines

- Difference Between Pump and Turbine

- Top Gas Turbine Manufacturers In the UK in 2022

- Top 15 Gas Turbine Manufacturers In India In 2022

- Top Gas Turbine Manufacturers In the US (2022 Update)

- Open Cycle Gas Turbine: A Detailed Overview

- Closed Cycle Gas Turbine: An Easy-To-Understand Explanation

- Combined Cycle Gas Turbine

- Quick Guide: The Difference Between Gas Turbine and Diesel Engine

- Gas Turbine Cycle: Everything You Need to Know About Gas Turbine Working Principle

- Gas Turbine Types: Overview of Types and Profitable Applications

- Gas Turbine Parts: Fast Basic Guide about Components

- How do Valves Work in an Engine?

- The 10 Best Diesel Engines

- Efficiency of Stirling Engine (Formula & Diagram)

- Beginner’s Guide: The Difference Between Gas Turbine and Gas Engine

- Differences Between Motor and Engine

- Differences Between Engine and Transmission

- The Difference Between Diesel Engines and Gas Engines: Discover the distinction, decide the best

- The Difference Between Diesel Engine and Petrol Engine: which one best works for you?

- Diesel Engine Working: everything you need to know