Polarized Capacitor– Capacitors with particular positive and negative polarities are known as polarized capacitors. It is critical to ensure that these capacitors are linked in precise polarities when utilizing them in circuits.

Polarized capacitors are capacitors with specific positive and negative polarities. When using these capacitors in circuits, it’s vital to make sure they’re connected in the correct polarities. Polarized Capacitor is an important Product to use in industrial applications. Polarized Capacitors are provided by several Suppliers and Companies, different manufacturers, and a lot of distributors and there are a lot of Polarized Capacitors for Sale on Linquip.

There is a complete list of Polarized Capacitor services on the Linquip website that covers all of your needs. Linquip can connect you with a number of Polarized Capacitor service suppliers and experts. Linquip provides a list of Polarized Capacitor Professionals who can help you with equipment testing.

What is a Polarized Capacitor?

A capacitor that utilizes an electrolyte to achieve a higher capacitance than other capacitor types is known as an electrolytic capacitor. An electrolyte is a gel or liquid that contains a large number of ions. Almost all electrolytic capacitors are polarized, which indicates that positive terminal voltage must always be larger than the negative terminal voltage. The advantage of large capacitance in electrolytic capacitors is accompanied by a number of disadvantages. Large leakage currents, value tolerances, comparable series resistance, and a short lifetime are only a few of the disadvantages.

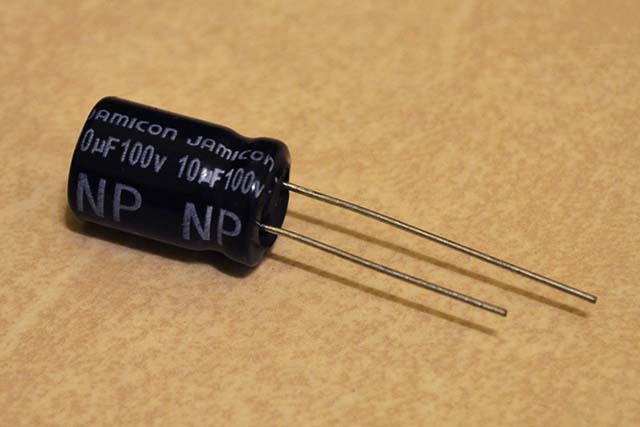

Wet-electrolyte or solid-polymer electrolytic capacitors are available. Tantalum or aluminum are the most typical materials utilized, but other materials may also be employed. Supercapacitors, also known as double-layer electrolytic capacitors, are a type of electrolytic capacitor with capacitances in the hundreds of thousands of farads. Aluminum electrolytic capacitors will be the focus of this article. These typically have a capacitance of 1F to 47mF and may operate at up to a few hundred volts of DC. Aluminum electrolytic capacitors are utilized in a variety of applications, including power supply, computer motherboards, and a variety of household goods. They can only be used in DC circuits since they are polarized.

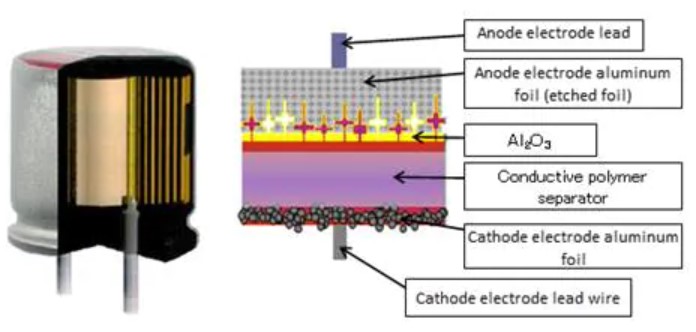

How are Electrolytic Capacitors Made?

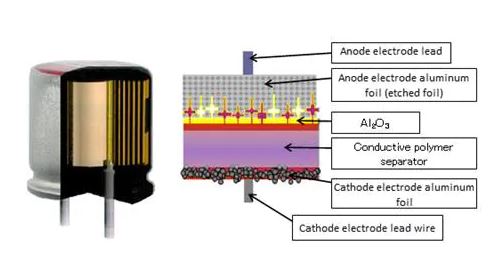

A capacitor is made up of two conducting surfaces separated by a dielectric in concept. Air, paper, ceramic, or a specific electrolytic chemical film can all be used as dielectrics. Most electrolytic capacitors are made up of two very thin layers of metal foil (aluminum, niobium, or tantalum), one of which is coated with a dielectric oxide layer, and the entire assembly is then rolled up.

The completed device is sealed with a specific coating, which can be made of plastic, epoxy, metal, or another material, to keep moisture out while keeping the electrolytic material contained inside in the event of chemical “leakage” or case failure.

Why We Use Electrolytic Capacitor in Power Supply?

The resulting capacitor is non-polarized and may be used with AC waveforms; it can also be put either way in the circuit with a non-chemical dielectric. Electrolytic capacitors, on the other hand, have a polarity of installation and use due to the chemical composition of the film and structure utilized. Reversing the voltage on such a device will cause it to deteriorate and eventually break.

Why use polarized electrolytic capacitors at all, given this constraint? The answer is straightforward: to get a high capacitive density and value. Most AC/DC power sources require capacitance in the range of several hundred to ten thousand microfarads (F), which can only be done with electrolytic capacitors in a component of practical size. Using ceramic or air as the dielectric would necessitate a capacitor volume of 100 to 1000 times greater.

A larger capacitor would necessitate more material, resulting in a greater direct cost as well as the higher “cost” of employing more PC board space or a larger overall power supply. Although supercapacitors appear to be a better and smaller option since they can readily produce farad ratings, they cannot withstand the ripple current or charge/discharge nature of a power-supply regulator and its load.

Choosing an Electrolytic Capacitor: Design Parameters

Of course, the capacitance of these bulk storage devices is the most important metric. Electrolytic capacitor values range from 1 to tens of thousands of F. Of course, if more capacitance is required than a single component can give, the capacitors can be connected in series.

The working voltage, which is commonly indicated as WVDC, is the next parameter that the designer must pick (working voltage DC). This is a function of the design and housing and is the maximum DC voltage rating at which the capacitor will operate reliably. To survive internal arcing and punch-through, a greater WVDC necessitates a larger physical-size device, which is more expensive; therefore, the designer must be careful not to over-specify this aspect. To account for any ripple or transients on the capacitor from the source, most designers employ a 2-volt safety margin on WVDC; thus, a 25-volt WVDC capacitor would be utilized with a nominal 12-volt DC power supply.

Although a capacitor should be just that, every capacitor contains some equivalent series resistance (ESR) and self-inductance in reality. A high-quality capacitor has an ESR of 0.1 to 1; the greater the ESR, the less the capacitor will perform like an ideal device, and it may even cause the regulator circuit to fail. The ESR of lower-quality electrolytic capacitors may increase with time and temperature and may even reach tens of ohms, causing problems. Due to the imperfect dielectric, capacitors have a small amount of leakage current.

Furthermore, every genuine component has parasitic inductance, which is typically on the order of a few millihenries for capacitors (mH). While this low value is usually not a problem at AC-line frequencies, it can become a problem as the working frequency of the power supply grows, causing circuit instability and even failure.

Types And Features of Electrolytic Capacitors

Comparison of Electrolytic Capacitor Types

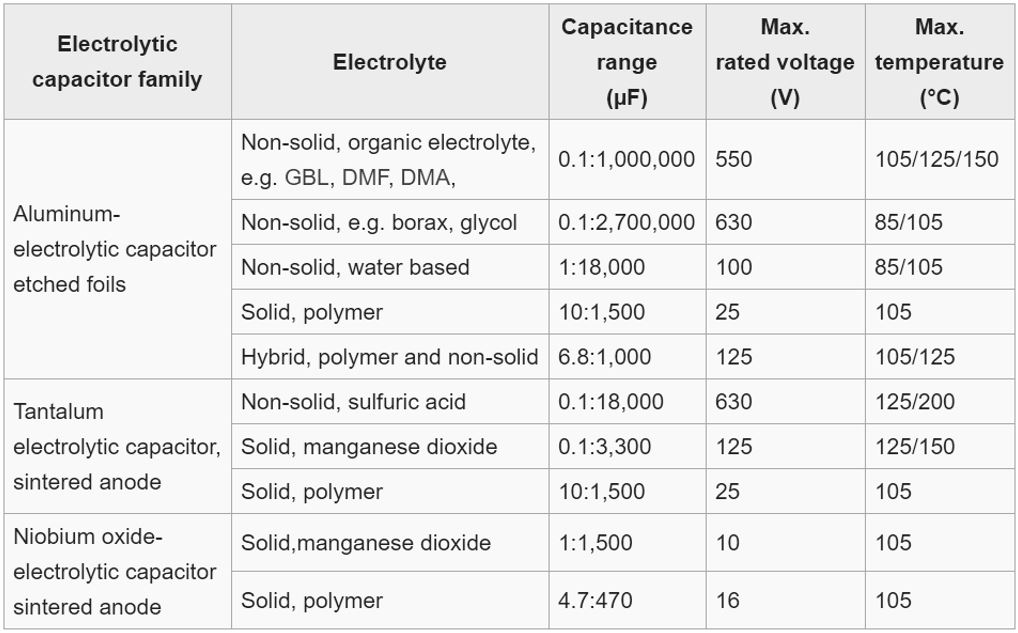

Electrolytic capacitors feature a large range of anode materials and electrolytes, resulting in a vast range of capacitor types with diverse attributes. The table below provides an overview of the main characteristics of the various varieties.

Among all conventional capacitors, non-solid or “wet” aluminum electrolytic capacitors were and are the cheapest. They are not only the most cost-effective choice for high capacitance or voltage values for decoupling and buffering, but they are also unaffected by low ohmic charging and discharging as well as low-energy transients. With the exception of military applications, non-solid electrolytic capacitors can be found in practically all fields of electronic devices.

Surface-mountable chip capacitors made of tantalum electrolytic capacitors with solid electrolytes are commonly employed in electrical devices with limited space or a low profile. They perform consistently throughout a wide temperature range with minimal parameter variation. Only tantalum electrolytic capacitors have the requisite clearances for military and space applications.

Because niobium is more commonly available, niobium electrolytic capacitors compete directly with industrial tantalum electrolytic capacitors. Their characteristics are similar.

The polymer electrolyte has substantially enhanced the electrical characteristics of aluminum, tantalum, and niobium electrolytic capacitors.

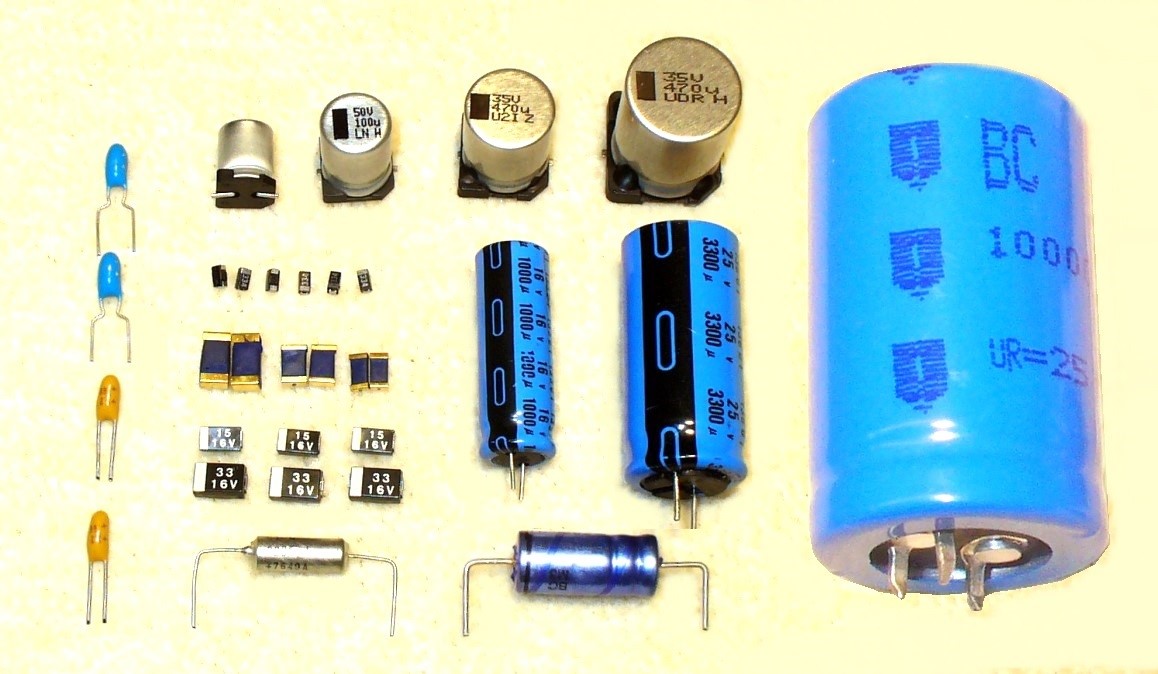

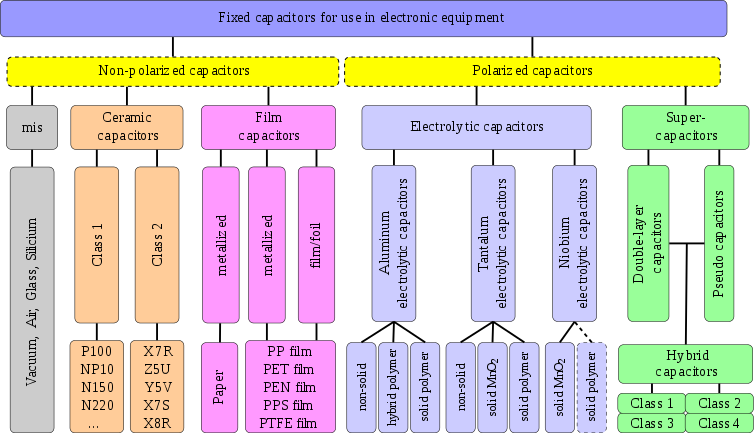

The following figure shows a comprehensive illustration of various types of capacitors:

Comparison of Electrolytic Capacitor Types

The ESR and ripple current load values are the essential characteristics in such a comparison for electrolytic capacitors in modern electronic equipment. The lower the ESR, the greater the ripple current per volume and the better the capacitor’s functionality. Better electrical properties, on the other hand, come at a cost.

Styles of Aluminum and Tantalum Electrolytic Capacitors

Aluminum electrolytic capacitors account for the majority of electrolytic capacitors used in electronics due to their wide range of sizes and low cost of production. Tantalum electrolytic capacitors have a higher specific capacitance than aluminum electrolytic capacitors and are utilized in products with limited space or a flat design, such as laptops. They’re also employed in military technologies, usually in an axial, hermetically sealed configuration. Niobium electrolytic chip capacitors are a relatively new product on the market, designed to replace tantalum electrolytic chip capacitors.

Electrolytic Capacitor Tolerance

All components, including electrolytic capacitors, have tolerance ratings; a tolerance of 20% is normal, however, some are specified with tighter tolerances. While this may appear to be a high tolerance allowance, it is appropriate in this case.

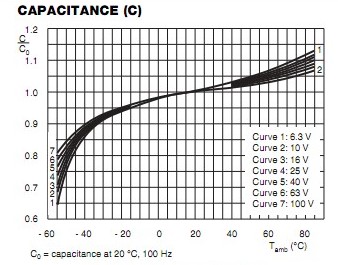

Most capacitor vendors provide models that contain the ESR, inductance, leakage resistance, and any other non-ideal properties to aid the designer’s performance and stability studies (See the following figure). They may exhibit characteristics at the line and higher frequencies, as well as at different temperatures.

Electrolytic Capacitor Degradation

Electrolytic capacitors are typically expected to work to specification for many thousands of hours, while they are frequently used with acceptable results beyond their maximum “to spec” lifetime. (Imagine a power supply in a long-running desktop PC that is constantly “on.”)

Electrolytic capacitors, like all electronic components, are prone to factors that affect their reliability and working life, in addition to evident operation outside of the authorized values.

Heat is the most common cause of capacitor failure: a capacitor certified for 10,000 hours at 250 degrees Celsius will need to be derated as the temperature rises and may only be rated for 1,000 hours at 850 degrees Celsius, and even less at 1050 degrees Celsius. Because the majority of these capacitors are utilized with power supplies, which run hot and have localized temperature rises over the overall enclosure, their lifespan will be shortened. To address this issue, vendors offer capacitors that are rated for long life at higher temperatures.

The ripple current that electrolytic capacitors must withstand is the second reason that shortens their life. This current is caused by an unavoidable fluctuation in the voltage regulator’s output, which the capacitor is charged to smooth out. The ripple current shortens the life of the capacitor and its electrolyte for complicated electrochemical reasons; the larger the ripple current, the greater and faster the deterioration. The susceptibility to ripple current depends on the construction and materials used; suppliers offer varied ripple-current levels for operating life.

After selecting the proper capacitor and the accompanying vendor model, there is one non-technical issue that designers must consider. Substandard, replacement or outright counterfeit parts are relatively easy to find their way into the production and assembly process. This is due to the fact that it is extremely simple to construct an appropriate capacitor that will function satisfactorily for a short period of time. However, the product’s life in the field will be cut short, but by then, it will be too late and a significant issue.

Keep in mind that the purchasing department at the manufacturing site may be tempted to substitute a “similar” capacitor for the one specified on the BOM by the designer, as long as the top-level specifications remain the same: capacitance, WVDC, and size. However, it may have different secondary but still significant standards, like ESR or ripple-current tolerance, and a change in the BOM could impact system performance or reliability. Engineers must collaborate with the production supply chain to ensure the capacitor’s integrity and traceability back to the designated source vendor.

Electrolytic capacitors between the power supply regulator and the load may appear uninteresting and even commonplace. Nonetheless, they are necessary for the circuit to have a reliable DC rail. As a result, designers must specify and choose them based on their primary and secondary criteria, as well as their operating environment and less-obvious supply-chain concerns. For more information about polarized capacitors visit this link.

FAQs

What Is the Function of Polarized Capacitor?

Due to its structure, this capacitor is commonly referred to as an electrolytic capacitor or simply “electrolytic.” It is critical in ensuring that a power supply’s output can give the required current at the rated DC supply voltage.

What Is the Function of Polarized Capacitor?

A non-polarized (“non-polar”) capacitor is one that has no implicit polarity and can be used in either direction in a circuit. A polarized (“polar”) capacitor has an inherent polarity, meaning it may only be connected in one direction in a circuit.

What Does It Mean When a Capacitor Is Polarized?

Polarization is seen in the majority of electrolytic capacitors. This means that only when they are charged in line with their marked polarity can they achieve their rated maximum operating voltage, capacitance, and internal resistance.

What Is the Difference Between a Polarized and Non-Polarized Capacitor?

The capacity, or how much voltage a capacitor can store, is the major difference between polarized and non-polarized capacitors. Non-polarized capacitors can also operate at considerably higher frequencies than polarized capacitors.

Where Are Polarized Capacitors Used?

They give enormous capacitance values in tiny, cost-effective packaging. Their primary function is to filter power supplies (storage). They’re also utilized to prevent DC in amplifier stages when they’re coupled together. A film or ceramic capacitor is an alternative, although they are physically larger and do not come in high capacitance values.

Download Polarized Capacitor PDF

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

- What is Non-Polarized Capacitor? Types & Function

- Difference between Capacitor and Inductor- Capacitor vs. Inductor

- Difference Between Condenser and Capacitor in a nutshell

- What is a Paper Capacitor?

- What is Paper Capacitor Used for?

- What is Mica Capacitor Used for?

- What is Electrolytic Capacitor? Usage & Application

- What is Film Capacitor & What is it used for?

- What is Capacitor and How it Works?

- 7 Types of Capacitors and Their Uses

- What is Ceramic Capacitor Used for?

- What is Mica Capacitors? Comprehensive Overview

- What is Electrolytic Capacitor?

- What is Film Capacitor? Different Types & Working

- What is Ceramic Capacitor? A Basics Description

- Types of Capacitors: All You Need to Know