Globe valve types fall into three main categories although there are some ways to divide them. Globe valves are designed for regulating flow, up and down within the valve, disc, and seat, typically broken into the body of the valve. Globe valves are created by a disk translating against a seat. The seats are parallel to the plane or bent towards the flow line. You will read in this article, at Linquip, about globe valve types (briefly), their diagram, their common application, and the advantages and disadvantages they have.

⇒ View a List of Globe Valves for Sale and Their Suppliers ⇐

Globe Valve Types

As mentioned above, globe valve types are mainly three categories, Wye (Y), Tee (T), Z, and angle valves; based on the type of body. But this is not the only way of categorizing the globe valves. They also can be divided into external thread types and internal thread types. Also, a globe valve can be divided into a straight flow type and a flow direction angle. Moreover, we can separate globe valves according to the shape of the sealing by product size and type of bellow dressing.

Tee Pattern globe valves, as the first globe valve types, have the lowest flow rate and a higher pressure drop. This is used in extreme throttling systems, for instance in bypass lines around a control valve. For applications where pressure drops are not an issue and throttling is required, tee-pattern globe valves can also be used.

The Wye pattern globe valves give the least flow resistance among globe valves. When completely open, the seat and stem are at a 45° angle, resulting in a straighter flow path with the least resistance to flow. Despite extreme erosion, they are broken open for long periods. They are commonly used in seasonal or start-up operations for throttling. When used in drain lines usually close, they can be barred to avoid debris.

Z-type Globe Valves. A Z-body is the simplest and most frequent sort of globe valve types. The seat is contained within the globular body by a Z-shaped wall. Because of the seat’s horizontal sitting configuration, the stem and disk can wander perpendicular to the pipe axis, resulting in a very large pressure loss. The valve seat is easily accessible via the bonnet, which is coupled to a big aperture at the valve body’s top. The stem acts as a gate valve, passing through the bonnet. This design makes production, installation, and repair easier. When pressure drop is not a problem and throttling is necessary, this style of valve is employed.

Angle Globe Valve

The third type among globe valve types is the angle globe valve that represents a shift in the configuration of the Z-shaped basic glove valve. The entry and exit ends are located at the right angles. The diaphragm may be a plain flat plate with its ends at right angles. The fluid can flow down more symmetrically than discharge from the ordinary globe with just one turn in 90. The angle body style has a particular benefit as it can be used as both a valve and a pipe elbow. The angle valve closely resembles the ordinary globe for moderate pressure, temperature, and flow conditions.

The angle globe valve can be used to control the slugging effect in fluctuating flow conditions. In terms of fluid mechanics and erosion, the release conditions of the angle valve are favorable. In high-pressure applications, these features are extremely important. The valve operates more or less like the Z Shaped Valve under mild conditions.

Y Type Globe Valve

Categorizing globe valve types does not end with only three types. There are more types of course. The valve configuration of the Y-bodies is a solution to the pressure drop problem typical in globe valves. The seat and stem in Y type globe valve are angled at about 45 ° to the axis of the pipe in this form. The angle allows a straighter flow path (at maximum opening) and gives the stem, bonnet, and packing a fairly pressurized container.

The Y-body valves are primarily suitable for applications with high pressure in which pressure dropping problems are common. But the pressure resistance cannot operate efficiently in case of a throttling, in particular when the valve is smaller in size. That is because the flow movement is not as complex in smaller valves as in large containers.

Globe Valve Types based on Body Bonnet Connection

Screwed bonnet: This is the most basic design possible, and it is utilized for low-cost valves.

Watch Video about Globe valve types

Bolted-bonnet: This is the most common design and is seen in the majority of globe valves. A gasket is required to seal the junction between the body and the bonnet.

See All Knife gate Valve for Sale

Welded-Bonnet: This is a common design that does not need disassembly. They weigh less than their bolted-bonnet equivalents.

Pressure-Seal Bonnet: This kind is commonly employed in high-pressure, high-temperature applications. The greater the pressure in the body cavity, the greater the strain on the gasket of a pressure-seal valve,

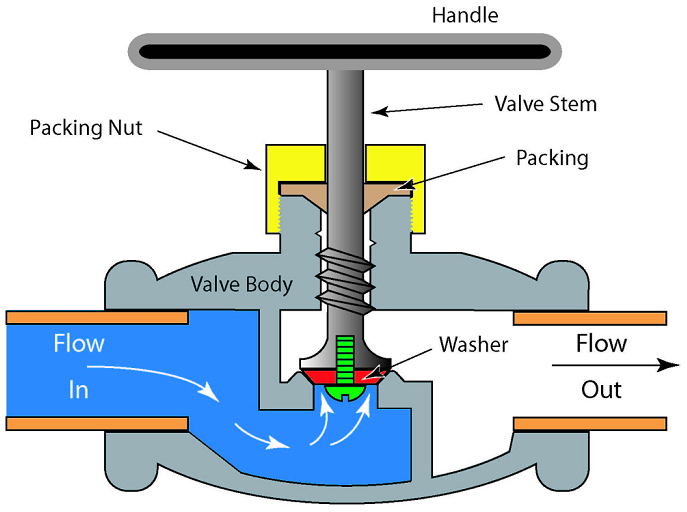

Globe Valve Diagram

Globe valves may be designed to close the disk against the flow or in the same flow direction. The kinetic energy of the fluid helps to close, which prevents opening as the disk closes in the direction of flow. The kinetic energy of the fluid obstructs the closure but helps to open the valves if the disc closes against the flow path. If a quick start is required, this feature is preferable.

See All Air release Valve for Sale

Talking about the globe valve diagram, a globe valve has a bulb-like a valve-seat body that can be fitted with a screw-down or a valve disk. The main part is made up of the surfaces of the valve and valve seat. With the help of light interference and a grub screw, the seat is secured in the valve chest. Within the valve plate, the spindle is held with a nut. To avoid leakage, a stuffing box with a suitable gland is connected to the spindle. The fluid flow path change cannot be controlled by all forms of globe valves. The reverse flow valve is called the “angle valve.” With reverse flow, the flow is from below the valve seat. Thereby, when the valve is closed, the valve is not subjected to increased static pressure. With the support of a piston or a stem attached to a wheel handle outside the valve, the disk is directed on the seat.

Globe Valve Advantages and Disadvantages

All globe valve types are applied for specific purposes. Generally, the valve of the globe valve is the one pushing the plate along the central seat axis. The change of seat opening is proportional to the valve stroke, depending on this type of valve movement. Due to its relatively short opening or closing stroke and its highly efficient cutting feature, it is well suited for flow control. Let’s read more about their pros and cons.

Globe valves have the following advantages:

- Great capacity to shut off.

- Moderate to strong valve throttling

- A shorter stroke compared to a gate valve

- Offered in Tee, WYE and Angle styles, each with exclusive ability

- Easy to machine or resurface the seats

- The valve can be used as a stop-check valve if the disk is not connected to the stem.

- Simple structure, easy production, and maintenance

- Small working schedule and limited time to open and close

- Effective sealing, low friction between long life, and the sealing sheet.

Globe valves also have several disadvantages. They are inconvenient due to:

- Higher drops in pressure in contrast to a gate valve.

- More force (with pressure under the seat) or more actuators to seat a valve

- High resistance to fluids, the higher force required to open and close

- A medium with high viscosity and clear coking of particles is not right for the globe valve

- Poor efficiency of control

- Flow under the seat throttling and flow off over the seat

- The high head loss from two or more right angles of moving fluid is the most noticeable defect in a globe valve. Flow route obstruction and discontinuity give to head failure. The fluid dynamic effects from pulsation, impact, and pressure drops in a long high-pressure line will damage cutting, stem packing, and actuators.

- Particular noisıness for applications with high pressure.

- Wide opening for the disk mounting, heavier weight, and the cantilevered mounting of the disc to the stem than other valves with the same flow rate.

In this blog, we discussed briefly the globe valve types, advantages, disadvantages plus the diagram of globe valves. We also mentioned that globe valves can be divided into several types. If you feel you want to know more globe valve types, register at Linquip and let our experts give you more information.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What is Butterfly Valve

- What is Check Valve

- What is Control Valve

- What is Diaphragm Valve

- What is Flap Valve

- Gate Valve Manufacturers

- Ball Valve Manufacturers

- Other Valves Manufacturers

- Globe Valve Manufacturers

- Knife gate valve Manufacturers

- Check Valve Manufacturers

- Types of Pneumatic Valves: Specifications and Working Principles

- Types of Hydraulic Valves and Their Working Principles

- Globe valve parts 101: All you need to know in one place

- globe valve vs ball valve; Which One Is the Best for You?

- A Comprehensive Guide To Different Types Of Air Valves

- Types Of Solenoid Valves: Everything You Need To Know

- A Complete Tutorial To Learn About Different Types Of Check Valves

- Types of pressure relief Valve: All you need to know about PRVs

- Types of non return valve: Introducing 6 types and more!