Pressure relief valves are devices that control and manage the pressure in a system. These devices are extremely vital for the safety of industrial processes and without them, catastrophic events occur every day in every corner of the world! But does your field of work require PRVs? And if so, which type of PRV should you use? What characteristics should we consider before buying a PRV? You need to know the answers to these questions to ensure the safety of your work and avoid catastrophes. So stick around with Linquip until the end, as we study various types of pressure relief valve and learn tips to choose the right one.

What are pressure relief valves?

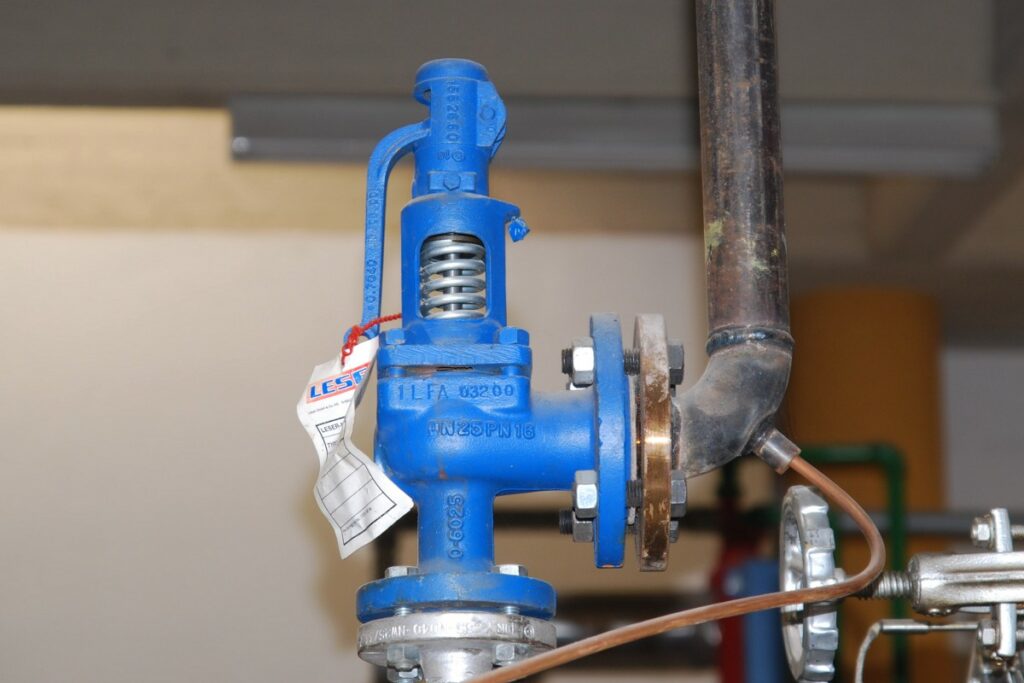

Pressure relief valves are a kind of specific safety valve system. This system is designed to restrict the pressure that’s built up in a system. There is a vast variety of types of pressure relief valve, that are controlled either manually or automatically from a piping system or a pressurized vessel. The excessive pressure of the maximum allowable working pressure (MAWP) has to be released. This task is done by discharging pressurized gas or fluid into the atmosphere or a tank.

PRVs have the main purpose of safety. They protect the system or pressure vessels from calamitous incidents. The system’s failure could cause irreversible damage during an overpressure phase.

Pressure relief valves are extremely useful in different parts of the industry including petroleum refining, petrochemical, and chemical manufacturing industries. Water supply and power generation industries, as well as industries that process natural gas, are other examples of pressure relief valve usage. The pressure relief valve (PRV) could also be referred to as a pressure safety valve (PSV), relief valve, and relief valve. The naming of this device depends on its application. Although they’re all basically the same, slight differences in operation and design can be seen among these valves.

Types of pressure relief valve

Balanced Spring Loaded

A balanced spring-loaded is designed exclusively for the purpose of decreasing the backpressure effects and protecting the bonnet spring and guide from released fluids. The disk area of these valves is unloaded into the air and a separate disk is subjected to backpressure. These two disks are equal.

Conventional Spring Loaded

Conventional spring-loaded valves consist of the bonnet, guide, and spring in the released fluids. As the bonnet vents into the atmosphere, the relief-system back pressure lowers the set pressure. However, as the bonnet vents inward to the outlet, the process is reversed and the relief-system backpressure makes the set pressure higher.

Conventional spring-loaded valves are commonly in noncorrosive services and used where backpressure is lower than 10% of the setpoint.

Safety Valve

A safety valve is one of the types of pressure relief valve. Its mechanism functions by inlet static pressure and it’s designed to open continuously with a pop action. Safety valves can be seen mostly in air and stream services. Safety valves are made in 2 forms:

- Low-lift safety valve: In these types of valves, the disc is lifted automatically, and the disc’s position defines the actual discharge space.

- Full-lift safety valve: Just like low-lift safety valves, the disk lifts automatically are full-lift safety valves as well; however you can’t recognize the actual discharge area by the disk’s position.

Pilot Operated

Pilot-operated valves are managed by an auxiliary pressure pilot. While the operation through an orifice is happening, a pressure is produced that provides the resistance force on the main valve’s piston. As the process pressure closes in on the setpoint, the net seating force on the piston starts to rise.

Safety Relief Valve

Among the types of pressure relief valve, safety valves are widely popular. These valves are known for their brisk opening or pop action. Safety relief valves have a system of opening ratio that’s determined by the pressure increase over the opening pressure base. These valves are utilized for compressible fluid or liquid. Safety relief valves have multiple types including balanced and conventional safety relief valves. You’re now familiar with these valves, as we studied them earlier.

Relief Valve

Relief valves are another type of pressure relief device. These devices have an inlet static pressure in their design. As the pressure over opening pressure increases a measured and gradual lift operates accordingly. Relief valves are surrounded in spring housing, which makes them ideal for close discharge systems.

Power-Actuated Pressure Relief Valve

As one of the types of pressure relief valve, power-actuated pressure relief valves consist of a relieving device. A distinct device is combined with these valves and controls them that requires an external energy source.

Temperature-Actuated Pressure Relief Valve

As the name suggests, temperature-actuated pressure relief valves are similar to power-actuated pressure relief valves, with the exception that they are actuated by external temperature or by the pressure that’s applied on the inlet side.

Vacuum Relief Valve

As a type of pressure relief device, vacuum relief valves are devices that have the job of resisting an exceeding internal vacuum. These valves are designed to stop the redundant fluid flow following the restoration of regular conditions by reclosing.

Watch Video about Types of pressure relief Valve

Choosing among the types of pressure relief valve

Selecting the right pressure relief valve for your field of work requires knowledge and attention. While choosing the right PRV it’s better to consider the things below:

- Each relief load should be defined.

- There are tons of various devices that each have unique characteristics. You should scan them all and seek the best one available.

- Consider the installation process.

- Reactive forces.

- Rapid Cycling.

- Note the liquid discharge process.

- Investigate design traits such as the material, size, and complexity.

- Overpressure causes.

- Multiple components should be studied to make sure they suit the relieving device’s capacity. These components include backpressure, set pressure, dual relief valve, multiple relief valves.

- Piping (Inlet and discharge)

- Scan the tailpipe

- Note the resonant chatter. This happens at the valve inlet with exceeding loss that is produced by the inlet piping.

What type of pressure relief valve do you need for your project? Did you learn everything you need to know about PRVs? If you have any more questions about types of pressure relief valve, simply register at Linquip and submit your questions to us. Also, don’t forget to share your thoughts with us and other readers in the comments.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Types of shut off valve: Your ultimate guide

- Types of plumbing valves: A complete guide

- Types of isolation valve: All you need to know!

- A Comprehensive Guide To Different Types Of Air Valves

- Types Of Solenoid Valves: Everything You Need To Know

- A Complete Tutorial To Learn About Different Types Of Check Valves

- Types of Water Valves: The Ultimate Guide

- Types of non return valve: Introducing 6 types and more!

I am a woodworker trying to set up a dust collection system using a 20-gallon plastic drum and a shop vac. When I use it the drum collapses. I need a valve to place on top of the drum lid to open when the pressure increases to prevent the drum from collapsing. Can you help?