Simple open cycle gas turbine plants consist of a compressor, combustion chamber, and turbine. The air is compressed through the compressor, fuel is added to the combustion chamber, and then the hot gases are expanded in the turbine. Two pressures are to be considered, and these are often expressed as a pressure ratio. On the T-S and P-V diagrams, these pressures are shown by the constant pressure lines. Since the compressor and turbine are located on a common shaft, some of the work generated by the turbine is lost in running the compressor.

With the advancement of technology in the fields such as internal combustion engines and steam turbines, gas turbines were developed. As a result of the operations in both of these fields, gas turbines were developed in the 1940s. Between 1500 and 1870, researchers developed various models that used steam or hot gas to create motion. This article provides a comprehensive understanding of a particular type of gas turbine, namely, the open cycle gas turbine, its working principles, advantages, and applications.

Basics of Open Cycle Gas Turbine

Open cycle gas turbines are combustion turbines fired up by liquid fuel that trigger a rotor generator to generate electricity. The remaining heat will be exhausted to the atmosphere at nearly 5500 degrees. Generators and turbines are located in noise-reduction enclosures, which occupy an area of almost 75m by 75m per unit. The exhaust stack is almost 30m tall, while the intake structure is 20m tall.

Working Principle of Open Cycle Gas Turbine

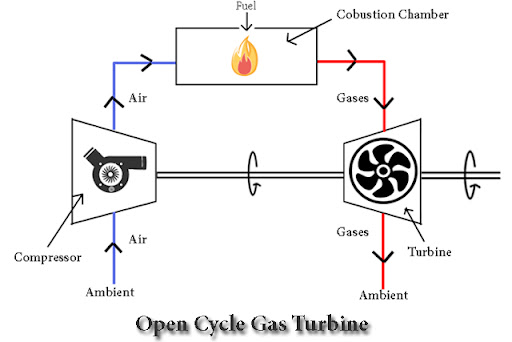

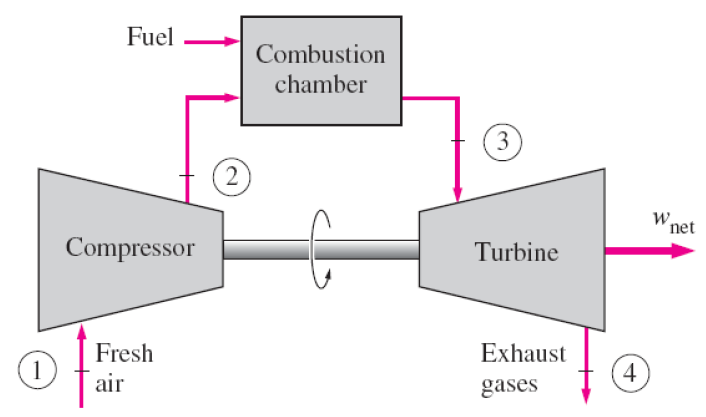

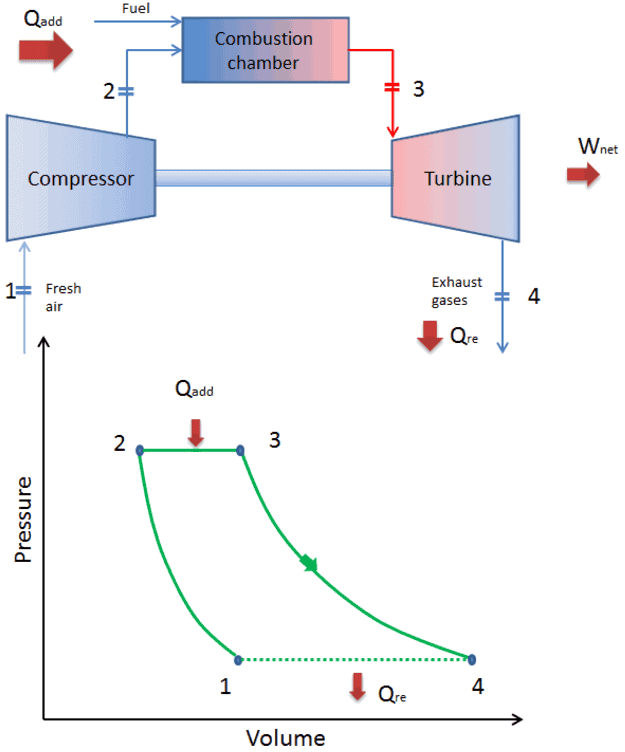

Below is a diagram of an open cycle gas turbine:

Open cycle gas turbines consist of three components: a compressor, a power turbine unit, and a combustor.

An open cycle gas turbine works by drawing in fresh atmospheric air and compressing it using either centrifugal or axial flow compressors.

The compressor takes the atmospheric air and compresses it through a series of compressor stages. Compressed air is mixed with fuel once it is injected into the combustion chamber. High-pressure hot gases are used to drive the turbine. As soon as the mixture is ignited, velocity gas is generated. As the velocity gas passes through turbine blades, it turns the shaft that is connected to the rotor section of the generator. The power created by turning the turbine shaft can power a variety of industrial devices and be used to generate electricity.

Emissions from turbines are released into the atmosphere. Due to the fact that the exhaust gases aren’t recirculated but instead released into the atmosphere, the system is classified as an open cycle.

The turbine uses some of its power to drive the compressor and other equipment, while the remainder is used to generate electricity. The compressor is supplied with fresh air, and the turbine’s gases are exhausted into the atmosphere, so the working medium is continually replaced. This is the working principle of an open cycle gas turbine plant.

Fuel

In an open cycle gas turbine, combustion products are in direct contact with the turbine blades. It is recommended to use fuels whose combustion products produce no corrosion or depositing of high-temperature ash and whose residual solids are small enough not to cause erosion. Fuels suitable for gas turbines include natural gas, refinery gas, blast furnace gas, and distillate oil. Residual fuel oils may contain contaminants.

The main components of ash that cause corrosion and deposit between 670°C and 815°C are vanadium pentoxide and sodium sulfate. In order to overcome this problem, gas scrubbing to remove sodium as completely as possible with a fuel additive of magnesium oxide, magnesium sulfate, and aluminum silicate seems to be the most effective procedure. Treatment systems of this type are in operation and seem to be economically feasible. It should be a requirement that gas turbine bids include an in-depth fuel analysis.

Efficiency

The thermal efficiency of an open-cycle gas turbine power plant can be expressed as:

{\eta }_{th}=\frac{W_{net}}{Q_{HV}}

Sometimes, this engine is modeled by a closed cycle gas turbine engine. Assume that air is the working fluid and replace the combustion process with the addition of heat (qcc). The thermal efficiency can then be expressed as:

{\eta }_{th}=\frac{W_{net}}{Q_{cc}}

Therefore,

{\eta }_{th}=\frac{W_{Turbine}-W_{Compressor}}{(h_3-h_2)}

The following expressions can be established according to figure above:

W_{turbine}=h_3-h_4=c_p\left(T_3-T_4\right)

W_{compressor}=h_2-h_1=c_p\left(T_2-T_1\right)

q_{cc}=h_3-h_2=c_p(T_3-T_2)

Thus,

{\eta }_{th}=\frac{\left(h_3-h_4\right)-\left(h_2-h_1\right)}{{(h}_3-h_2)}

or

{\eta }_{th}=\frac{\left(T_3-T_4\right)-\left(T_2-T_1\right)}{{(T}_3-T_2)}

Open Cycle Gas Turbine Plant

Open cycle gas turbine plants are agile, fast-acting power units that can be put into service quickly and removed again immediately. Because of this, it has become one of the major sources of peak power on power grids around the world. The units are typically relatively expensive to build and less efficient than a base load plant such as a combined cycle plant.

Applications of Open Cycle Gas Turbine

Simple open-cycle gas turbines, which run on either natural gas or light fuel oil, are usually used in small and medium industrial applications. There is little difficulty accommodating dual fuel arrangements, and automatic fuel switching between the two can be provided in some cases.

Machines can be of a simple single-shaft design where the turbine power, compressor, and output drive are on the same shaft, or of a twin-shaft design where the compressor and its driving turbine are on one shaft, and the turbine power is on the output drive shaft.

While both types are suitable alternator drives, they have slightly different power-control characteristics. Additionally, they may be developed from engines initially intended for aircraft use or units that are designed specifically for land applications. Among the two, the former is touted as lighter, more compact, and more efficient, while the latter is considered as more robust, but there is a great area of land.

At full load, electrical-generation efficiency is only 14 to 20% for small industrial units, but it is over 30% for larger units. The specific fuel consumption of a typical 1.25 MW set can range from 0.51 kg of gas oil per kWh at full load to 0.63 kg at half load at an ambient temperature of 15°C but increases with elevated ambient temperatures particularly on partial load.

Among the applications where open cycle gas turbines are commonly used are:

- Generally, open cycle gas turbines are used in aviation, where they provide motive power for jet propulsion.

- Open cycle gas turbines can be used for electric power generation.

- Among their uses are locomotive propulsion, marine industries, and automotive.

- Their use can be incorporated into mechanical drive systems.

Advantages of Open Cycle Gas Turbine

The following are the main advantages of open cycle gas turbines:

- Warm-up time: After the starting motor accelerates the turbine to its rated speed and the fuel is ignited, the gas turbine can be accelerated from a cold start to a full load without a warm-up time. Open cycle plants are favored when used as peak load plants due to their quick start times and the ability to take up load quickly.

- Low weight and size: The weight per kW generated is low. Open cycle plants require less space than closed-cycle plants.

- Fuels: Hydrocarbon fuels of any type can be used in the combustion chamber, from heavy diesel oils to high-octane gasoline.

- Refinements: Component and auxiliary refinements can usually be implemented in open cycle gas turbine plants to improve thermal efficiency. They can also provide the most economical overall cost depending on the load factors and other operating conditions.

- No cooling medium is needed: There is no need for cooling water for open cycle gas turbines except those with intercoolers. Therefore, the plant becomes self-contained and independent of a cooling medium.

Disadvantages of Open Cycle Gas Turbine

Here are the disadvantages of an open cycle gas turbine:

- Lower efficiency at part load: Since a considerable portion of the power generated by the turbine is used to drive the compressor, the efficiency of the open cycle gas turbine plant decreases rapidly at part load.

- Sensitivities: Component efficiency plays an important role in the system, especially that of the compressor. Changes in atmospheric temperature, pressure, and humidity affect the open cycle gas turbine.

- Heat loss from exhaust gas: Since the open cycle plant has a higher air rate than the closed-cycle plant, it results in an increase in heat loss in the exhaust gases and a need for large diameter ducts.

- Erosion: Keeping dust from entering the compressor is essential to preventing erosion and deposition on the compressor blades and passages. In doing so, their profile is damaged. The carbon and ash deposited on the turbine blades are not desirable at all since they reduce the open cycle gas turbine plant’s efficiency.

Difference between Open Cycle and Combined Cycle Gas Turbine

The popularity of natural gas in power generation has prompted many inquiries about Combined Cycle Gas Turbine (CCGT) plants and Open Cycle Gas Turbine (OCGT) systems. Every product has its pros and cons, and these systems are not different. OCGTs are rather straightforward machines that start with fresh ambient air entering the compressor and end with power generation. The simplicity of these machines makes them more advantageous than CCGTs. Do not, however, get it all wrong; this cycle also has some drawbacks that may make it unusable under some circumstances.

In order to choose between OCGT and CCGT, it is worthwhile to compare the two in terms of efficiency, economics, and environmental impact.

Efficiency

CCGT technology is, without a doubt, a popular option for many natural gas-fired power plants. Efficiency is a driving force for this device, and it appears to be improving. Recent advancements have resulted in an efficiency of over 60%. Owners of power plants, particularly those that operate combined cycle power plants, must be thrilled at the recent developments. Open cycle gas turbine manufacturers are working hard to increase the efficiency of their products, but the figures they have achieved thus far are considerably less than the 60% plus of CCGT.

Economics

The fiscal factors must be considered carefully when choosing the CCGT. As compared to OCGT, the technologies required to build a combined cycle power plant are complex and expensive. There are times when O&M and initial capital costs outweigh the savings realized from greater efficiency. Taking current fuel prices and equipment prices into account, this technology would still make sense for a new facility. In both economic and technical terms, CCGT is very flexible.

Historically, these plants aren’t continuously operated. They are only switched on during peak load periods. This is why this technology has been widely adopted in wind power and other renewable energy sources. In renewable energy production, there are usually peaks and troughs. Moreover, it uses virtually any fuel type, including methane gas, oil, and biogas.

Environmental Impacts

The construction and operation of power plants may affect the environment. Space is taken up, pollutants are emitted, and water is used up. Additionally, the height of the facility may hinder aviation activities. Any power plant may have environmental effects, but most people prefer combined cycle power plants over open cycle gas turbines. In general, power plants that have taken this route report fewer emissions.

Several pollutants have been reduced significantly, including sulfur dioxide (SO2), carbon dioxide (CO2), and nitrogen oxides (NOx). Open cycle gas turbines emit waste heat into the atmosphere, which can negatively affect the environment. The combined cycle gas turbine plants do not have such an issue because they re-use waste heat to generate more energy.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Raed More on Linquip

- Combined Cycle Gas Turbine

- Closed Cycle Gas Turbine

- Hydrogen Gas Turbine: All You Need to Know

- Gas Turbine Types: Overview of Types and Profitable Applications

- Top 15 Gas Turbine Manufacturers In India In 2022

- Top Gas Turbine Manufacturers In US (2022 Update)

- More Information about GE Frame 7 Gas Turbine

- See List of Gas Turbine Products

- See List of Siemens Gas Turbine Products

- See List of General Electric (GE Power) Gas Turbine Products