Knowing the parts of water pump helps to better understand how it works. Everyone who understands how contemporary engines function realizes how important water pumps are to the running of cars. Without a competent water pump, your engine would be as hot as Phoenix’s blacktop during the summer—not a good thing. However, few individuals comprehend the complexities of water pumps. Mechanical water pumps include five major components, all of which are crucial to the pump’s performance and dependability.

⇒ View a Comprehensive List of Pumps for Sale and Their Suppliers ⇐

Basics of Water Pump

A water pump serves an incredibly important task in ensuring that your car’s engine runs as smoothly as possible. The water pump is a part of a vehicle’s cooling system, supplying a steady coolant stream to the motor. The constant flow of fluids prevents the engine from overheating. In other words, if the water pump malfunctions, the engine fail, which you do not want.

It is beneficial to learn more about the water pump as a component of the vehicle’s cooling system. If it fails or has a problem, you should have a rudimentary understanding of all of its parts and which one to replace.

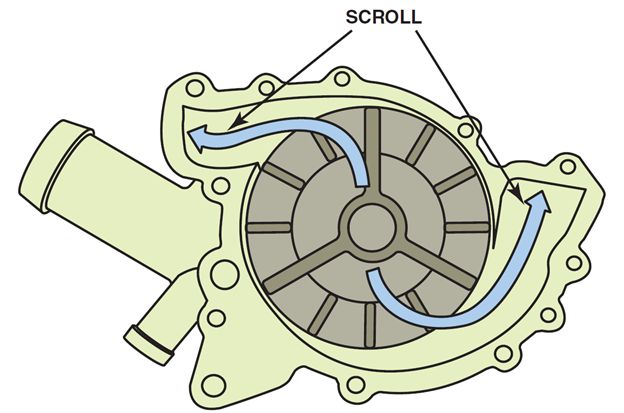

The water pump is the engine cooling system’s beating heart. It is necessary to understand how your car’s cooling system works in order to comprehend its purpose. The coolant enters the pump body via the radiator outlet, and the centrifugal force created by the pump impeller propels the coolant around the cooling circuit via the radiator. The radiator dissipates the heat produced by the engine.

Working Principle

A belt connected to the engine’s crankshaft powers the water pump, which is a simple centrifugal pump. The pump circulates fluid when the engine is running.

While spinning, the water pump employs centrifugal force to send fluid to the exterior, causing fluid to be sucked from the center continually. The pump’s inlet is towards the center, such that fluid returning from the radiator strikes the pump vanes. The fluid is pushed to the exterior of the pump by the pump vanes, where it can enter the engine.

The fluid that exits the pump goes through the engine block and cylinder head, then into the radiator, and ultimately back to the pump.

Purpose of a Water Pump

Basically, the car’s water pump is essentially the heart of the cooling system. It is used to circulate the engine cooling water to the cooling system continuously. The cooling system returns from the radiator to the engine and then to the radiator.

This system enables drivers to enjoy a comfortable and quiet ride. The pump is driven by the engine, usually by a belt and pulley system, but a gearing chain can also be used. The most crucial component of the pump is the impeller.

The impeller must spend and circulate the coolers throughout the vehicle. It appears to be identical to the propellers that push the boat. Only when acting on a sealed bearing, can the impeller be effective. The water pump will fail fast if the sealed bearings start to leak.

A normal water pump will transfer around 750 gallons of coolant per hour. The water pump may also circulate coolant through the engine’s components more than twenty times per minute.

Did you know that your water pump can drain the whole pool in one hour at these speeds? I’m sure you had no idea how strong a water sump pump is. It’s also worth noting that your water pump will function in connection to your engine. This implies that it pumps less at slower rates and more at faster ones.

When the engine speed is high, there is a greater quantity of heat produced, and the water pump is supposed to compensate for the rapid increase. As a result, rotating speed will be required.

As a result, it is critical to test the coolants, water pump, and belt drive system at each car service to ensure that the cooling system does not malfunction during the trip, leaving you stuck.

Coolant is removed from the engine block to the water pump, where it is rapidly routed to the radiator. The coolant in radiators flows via short, thin tubes to give a larger surface area for cooling the hot fluid in the engine.

This coolant then returns to the engine block and cylinder head to remove the excess heat created by the engine. This operation is repeated by pumping water until the engine stops operating.

Your water pump will finally fail, and you must replace it immediately to prevent permanently harming your engine. Remember that changing a car engine is highly expensive and will cost a great deal of money. On the other hand, water pump replacement is inexpensive and takes only an hour or two.

Car Water Pump Types

To understand water pumps in-depth, it is necessary to learn how to distinguish between the many varieties that exist.

On the one hand, water pumps for trucks/industrial vehicles and passenger cars may be distinguished, with each responding to the unique characteristics of each vehicle. However, they can be categorized as follows:

Mechanical Water Pumps

The coolant in mechanical water pumps collects heat from the engine block and cylinder head and discharges it to the ambient air via the radiator. Mechanical water pumps can be mounted in the pump housing on the engine’s exterior or directly on the engine block, depending on the construction type. Mechanical water pumps are usually powered by V-belts, timing belts, or straight from the engine.

Variable Water Pumps

The fundamental feature of a variable water pump is that it allows the flow to be adjusted based on the demands of the engine, which is accomplished via a vacuum technique, i.e. the water pump only functions on the cooling system when required.

As a result, it leads to enhanced engine efficiency, which results in reduced fuel consumption and, consequently, a considerable decrease in polluting emissions into the environment.

Electric Water Pumps

Electric water pumps make contributions to decreasing emissions from early contemporary-day engines. A supply flow that is independent of the number of rotations of the motor allows for on-demand cooling. This minimizes the amount of power necessary, diminishing friction losses, fuel usage, and pollutant emissions.

Auxiliary Water Pumps

The primary role of the auxiliary water pump is to provide support to the main water pump. The auxiliary water pump, on the other hand, is more concerned with comfort since it is placed in a by-pass hose of the main cooling system and feeds the coolant to the heater within the vehicle.

Depending on the nature of the cooling system, certain cars will have more than one auxiliary pump.

The auxiliary water pumps are also utilized in hybrid and electric cars to provide coolant to all sides of the system because the batteries and electric motors are both cooled.

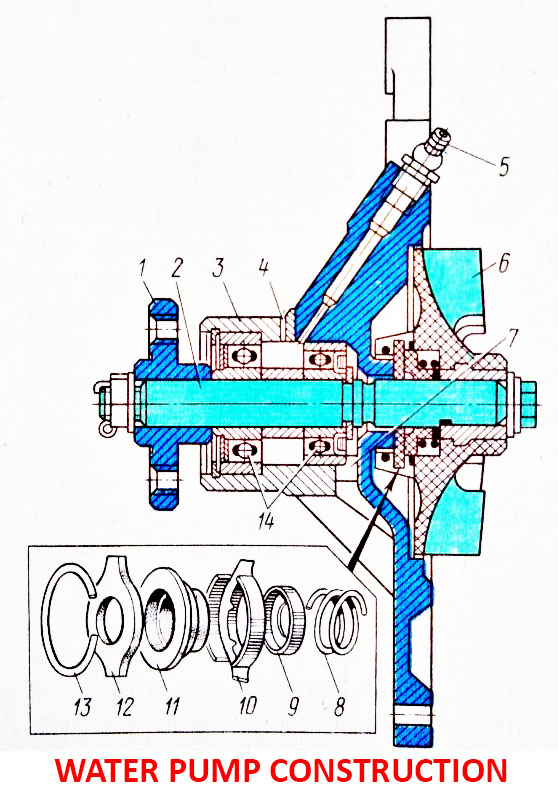

Components of Water Pumps

The water pump includes five primary components:

Hub or Pulley

This is basically the impeller’s power source. As a result, it contributes to the spinning of the impeller and is highly valued. The hub or pulley also contains the V-belt, timing belt, and engine serpentine.

This is accountable for transmitting the turning of the power belt to the bearing spindle. The pulley absorbs engine traction and acts as a bridge between the two, reducing the amount of torque that passes through. Because the pulley is exposed to a great deal of pressure and force from the drive belt, it must be constructed of sturdy materials. Steel, cast iron, or sheet metal are commonly used materials for pulleys. The goal is to build a sturdy, lightweight, and long-lasting pulley.

If the pulley fails or malfunctions, it will probably cause overheating and damage to other components.

A water pump pulley’s design is a common source of issues, especially when utilizing water pumps that aren’t constructed to OEM standards. This is due to the fact that minor differences in the size/configuration of the pulley may create fitment, noise, or severe wear issues.

Body/Housing

It is the structural part of the pump that supports the other elements and connects to the cooling circuit. It is constructed of aluminum or cast iron. However, there are cases where its housing is constructed of stamped steel. What is stated as a weeps hole in the housing enables coolant to escape through a defective seal.

The housing is necessary to the water pump’s performance because:

- The housing material must be thick enough to handle the pressure exerted by the drive belt and the internal pressure of the coolant system.

- The housing is subjected to high temperatures, it must be suitably designed and produced.

A manufacturing defect in a water pump housing may result in early bearing structural failure, fracture, or even disastrous rupture.

The body is connected to the pulley on one end and to the car’s cooling system on the other.

Bearing

It is the component that transmits the Hub / Pulley’s spin to the impeller. Its design and quality provide a direct impact on the pump’s lifetime. Bearings are divided into two types: roller-ball and ball-ball. The Roller-Ball design offers increased durability as well as the ability to withstand higher weights.

The bearing is the mechanical support keeping the impeller rotating. To distribute coolant throughout the system, the impeller must rotate continuously. Bearings can fail in several ways, including:

- Lubricant oxidation on the bearing surface

- Drive belt overtightening

- Faulty Manufacturing techniques

- Design flaws

Though all bearings ultimately wear out, a properly constructed water pump bearing should last the life of a vehicle (or beyond) under typical operating conditions.

Seal

Because the bearing is constructed of metal balls, there is a significant possibility of corrosion. Consequently, the component must be shielded from any liquid exposure. The seal is installed to prevent the bearing from contamination and to guarantee that the pump shuts securely. So, its primary function is to protect the bearing by minimizing coolant leakage and contamination, as well as to guarantee that the pump is tightly sealed.

It is composed of two separate sections, one of which is attached to the body and the other of which turns with the bearing axle.

If there is a leakage, the water pump will not provide sufficient pressure, causing it to fail. As a result, the seal is essential to preserving the water pump in working order. The quality of the seal, together with an adequate coolant, ensures the proper operation of the water pump.

Bearing seal design will vary depending on the requirements; however, all bearing seals must:

- Function properly at the pump’s extreme edges, which means it will operate just as effectively at top speed under WOT (Wide Open Throttle) as it does when the motor is starting at idle.

- Not deform or worsen as fluid pressure fluctuates.

- Prevent any dirt or silt from entering the pump from the cooling system.

- Be a part of a system that is designed to operate well together.

Perhaps the most important point is that a good bearing seal is part of a system. When water pumps are manufactured by a single company (particularly one with extensive expertise in constructing water pumps), the seals tend to mesh rather well with the bearing, bearing shaft, and so on.

Impeller

The impeller rotates in a water pump to raise the pressure and flow of fluids. The impeller can be considered the heart of a water pump, and if it fails, the whole system will fail. It collects the liquid in its fins and turns to boost the velocity. The pulley and bearings provide the torque. The specifications of the impeller determine the efficacy of a water pump. The flow and pressure of the coolant in the cooling circuit are governed by its diameter, as well as the quantity and height of the fins. A decrease in flow might significantly impact the engine’s lifespan.

Inside the housing, the impeller is attached to the bottom of the shaft. The engine’s RPM determines the rate of rotation of the impeller.

It is often made of plastics or metal. Metal impellers endure longer than plastic impellers and are favored by most manufacturers when constructing water pumps.

Impeller failure is uncommon, but it can occur when the impeller vanes slide when the engine starts. Impeller corrosion can also take place as a result of insufficient or poor coolant. The best method to avoid this is to begin performing regular coolant maintenance.

Gasket

This is the component that provides the watertight connection between the pump and the engine. It can be constructed of rubber, paper, or sheet metal coated with rubber.

Signs of a Faulty Water Pump

A vehicle’s water pump failure can be associated with a number of reasons, including:

- Leaking coolant

- Overheating engine

- Leaking coolant

If you see any of the signs stated earlier, it is probable that the water pump has broken or is on its way out. If this happens, you should take your car to a technician and have the water pump inspected for flaws.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- The 8 Best Water Pumps with Pros. and Cons

- What Is a Water Booster Pump and How Does It Work?

- Types of Water Pumps and Their Principles

- Parts of Oil Pump

- 7 Parts of Gear Pump and Function + Diagram & Applications

- 10 Parts of Reciprocating Pumps + Function, Application and Working

- 10 Parts of Hydraulic Pump + PDF & Function

- 8 main Parts of Piston Pump and Function + Work & PDF

- 12 Parts of Sump Pump + Diagram

- 16 Parts of Heat Pump and Functions (Clear Guide)

- Types of Centrifugal Pumps: All Classification & Working Principles

- Centrifugal Pump Working Principle with Diagram

- 7 Best RV Water Pump (Clear Guide & Review)

- 13 Parts of Concrete Pump with Name & PDF

- 6 Parts of Pool Pump + Diagram & PDF

- 20 Parts of Submersible Pump + PDF

- 7 Parts of Screw Pump: Advantages and Disadvantages

- Diaphragm Pump Parts List + Function & Application

- Parts of Centrifugal Pumps

- The 10 Best Electric Air Pump (Clear Guide)

- The 8 Best Water Pumps with Pros. and Cons

- The 5 Best Air Source Heat pump (Clear Guide)

- 12 Types of Water Pressure Pumps with Applications & Characteristics

Thank you for explaining the parts of the water pump in your blog. as you said, it is essential to understand each piece. If it fails or has a problem, you should know its parts and which one to replace. My uncle is expanding his bakery and plans to have an ACP-2500HMF-100 Coolant Pump to help him produce a large amount of dough since it is a multi-staged high-head pump for large quantities with high precision & efficiency.

Thanks for sharing your experience with us! You can also visit our industrial directories, where you can find thousands of various industrial equipment based on your application and demand.