Parts of Reciprocating Pumps – The plunger pump, piston pump, and diaphragm pump all belong to the reciprocating pump family of positive-displacement pumps. Reciprocal pumps, if properly maintained, may endure for decades. They can, however, succumb to wear and tear if not properly maintained. A reciprocating pump is a positive displacement pump that collects a particular volume of liquid in an enclosed container and discharges it to the desired application under pressure. Reciprocating pumps are better for low flow rates and high pressures.

Linquip’s website is your best source of information about reciprocating pumps. You can find out all you need to know about them on the site. In case you have any questions about reciprocating pumps, our experts are on hand to answer them. If you are interested in gaining a basic understanding of these types of positive displacement pumps, you may want to read Linquip’s article, “Reciprocating Pump: Working Principles, Function & Diagram.“

Have you ever used reciprocating pumps before? You will find a wide selection of Reciprocating Pump Products that will allow you to find exactly what you are looking for. Have you decided which reciprocating pump you are currently looking for? Linquip provides free access to all available Reciprocating Pumps for Sale available on this platform. By using Linquip, you are given the opportunity to ask for a free quote/inquiry from all of the reputable Reciprocating Pump Companies and Suppliers.

⇒ View a Comprehensive List of Reciprocating Pumps for Sale and Their Suppliers ⇐

What is a Reciprocating Pump?

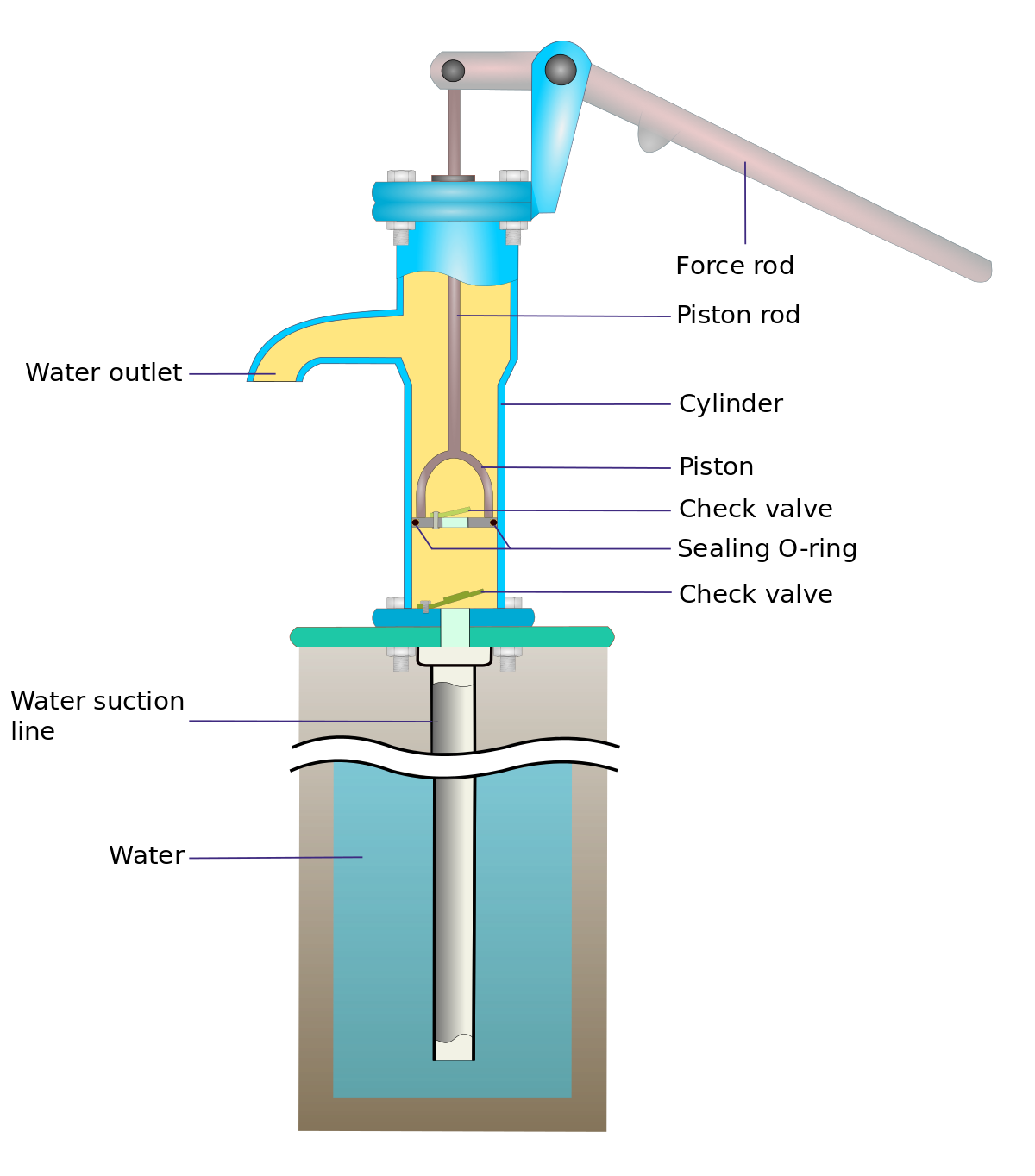

A reciprocating pump is a mechanical device that converts hydraulic energy from mechanical energy into a fluid (pressure energy). The fluid is pumped from one area to another using a piston or plunger. A reciprocating pump is often known as a piston pump since it employs a piston or plunger for pumping functions.

The piston of this pump reciprocates in an upward and downward position within the pump cylinder. The piston sucks fluid as it advances toward BDC, then pressurizes the fluid as it goes toward TDC. A reciprocating pump is most commonly seen as a hand pump. The most common types of reciprocating pumps are bicycle pumps and syringe pumps.

The reciprocating pump operates by the downward and upward movement of the piston. Dynamic pumps, on the other hand, employ an impeller and diffuser to move fluid from low to high head locations. Ctesibius, a Greek discoverer, devised the reciprocating pump in approximately 200 BC.

The reciprocating component of these pumps is completely responsible for their operation (i.e., piston, plunger, or diaphragm). Reciprocal pumps cannot transmit fluids if the reciprocating piston is damaged. As a result, with these pumps, the piston’s appropriate operation is critical. The piston turns the kinetic energy of the fluid into pressure energy while the pump is in operation.

When a small amount of fluid is transported under high pressure, the reciprocating pump is used. In comparison to centrifugal pumps, this type of pump is better suited for low flow rates at high pressure.

When employing a plunger or piston pump, a specified volume of liquid (usually sump) must be applied and transferred from the lowest to the highest location. If you go to a bike water service, for example, you may make sure that the water required for servicing is retrieved from the sump and sprayed onto the bike by applying pressure to the nozzle.

It’s frequently utilized when only a tiny amount of liquid needs to be handled but the delivery pressure needs to be high. The liquid is trapped in reciprocating pumps by a stationary cylinder containing a piston or plunger. A reciprocating pump is a mechanical device that converts hydraulic energy from mechanical energy into a fluid (pressure energy). The fluid is pumped from one area to another using a piston or plunger. A reciprocating pump is often known as a piston pump since it employs a piston or plunger for pumping functions.

Parts of Reciprocating Pump

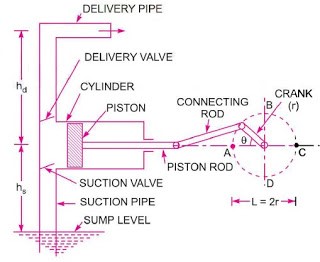

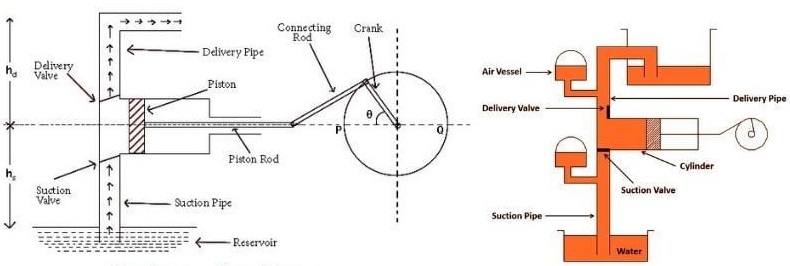

The key parts of reciprocating pump are detailed here:

- Section Valve

- Delivery Valve

- Suction Pipe

- Delivery Pipe

- Cylinder

- Connecting rod

- Crank

- Piston and piston rod

- Air Vessel

- Strainer

Suction Valve

It includes the reciprocating pump’s most important components. The intake or suction valve is a one-way valve. In other words, this sort of valve only allows one-way flow. Between the cylinder and the suction pipe, the suction valve is inserted. This valve opens when the liquid is discharged and shuts as the liquid is suctioned. Suction valves are non-return valves, which means that only one direction of flow is available. This is situated between the entrance of the suction pipe and the cylinder. It is opened during liquid suction and closed during liquid discharge.

Suction Pipe

Water is drawn from the storage tank into the pump cylinder through the suction hose. The inlet valve is connected to the reservoir via this portion of the reciprocating pump. It links the water tank to the pump intake. The suction pipe links the liquid supply to the reciprocating pump’s cylinder. This pipe transports liquid from the source to the cylinder.

Pressure Valve

The discharge valve is one of the reciprocating pump’s most important components. It also functions as a one-way valve. The delivery pipe and the cylinder are connected by this valve. This valve shuts during the suction phase and opens during the fluid delivery procedure.

Cylinder

The pump cylinder is made from either cast iron or alloy steel. In the pump cylinder, the piston rod and piston are arranged. The suction valve’s liquid sucks into the cylinder. The piston within the cylinder rotates forward and backward to increase the pressure. The cylinder is connected to a discharge valve, which directs fluid into a discharge pipe.

A hollow cylinder is composed of cast iron or steel alloy. Inside this cylinder is a piston and piston rod arrangement. This cylinder is used to suction and release liquid, and it is equipped with suction and delivery lines as well as valves.

Delivery Pipe

Fluids are delivered from the pump cylinder to the desired height or position using the delivery pipe. It is directly connected to the piston pump’s cylinder delivery valve. The delivery pipe links the pump’s cylinder to the output source. This pipe transports the liquid to the specified output position.

Crank

The positive displacement pump’s crankshaft is a critical component. It’s a solid disc with a connecting rod that links it to the piston. The electrical motor is directly linked to the crank. When the electric motor is turned on, it revolves.

Connecting Rod

The piston and the crankshaft are linked via the pressure valve. The piston is connected to the crankshaft via this component of the pump. The connecting rod spins in tandem with the crankshaft. It converts linear crankshaft rotation into linear piston motion.

Piston and Piston Rod

The reciprocating pump’s most important components are the piston and piston rod. A piston is a piece of solid metal. It suctions the fluid by moving back and forth inside the cylinder.

The piston takes air into the cylinder as it goes backward, and it provides fluid when it moves forward. The movement of the crankshaft causes the piston to move. The piston rod allows the piston to travel in a straight path. A piston is a solid cylinder element that rotates back and forth inside a hollow cylinder to accomplish liquid suction and delivery. The piston rod aids in the piston’s linear motion.

Air Vessel

The discharge and suction pipes are attached to this reciprocating component. Friction heads are no longer required. It also ensures a consistent discharge rate.

Strainer

A filter at the suction pipe’s end prevents solid particles from the water supply from entering the cylinder. Solid particles will obstruct delivery otherwise. It functions as a mesh, allowing all dirt, dust particles, and other debris to be filtered out of the sump. If there is no strainer, debris or dust will enter the cylinder, clogging the area and interfering with the pump’s operation.

Working of Different Parts of Reciprocating Pump

The following is how different parts of reciprocating pump work:

- When a power source is linked to the crank, the crank will begin to rotate, and the connecting rod will be moved as well.

- The piston, which is attached to the connecting rod, will move in a straight line. When the crank rotates outwards, the piston travels to the right, creating a vacuum in the cylinder.

- This vacuum forces the suction valve to open, forcing liquid from the source into the cylinder through the suction pipe.

- The piston advances to the left as the crank moves inwards or towards the cylinder, compressing the liquid in the cylinder.

- The pressure now causes the delivery valve to open, allowing liquid to flow through the delivery line.

- The whole liquid in the cylinder is supplied through the delivery valve when the piston reaches its extreme left position.

- The crank rotates outwards again, and the piston advances to the right to generate suction, and the process is repeated.

In a single action reciprocating pump with only one delivery stroke per one rotation of the crank, the procedure described above may be witnessed. When it comes to a double-action reciprocating pump, however, one crank turn will result in two delivery strokes. If you have any question about the different parts of the reciprocating pump and their working principle, visit Linquip Platform or contact Linquip Pump Experts.

Advantages of Reciprocating Pump

- A reciprocating pump can exactly supply the appropriate flow rate.

- It provides a constant discharge rate.

- It can deliver fluid at extremely high pressures.

- The reciprocating pump does not require priming.

- A reciprocating pump’s efficiency is ten to twenty percent higher than that of a centrifugal pump.

Disadvantages of Reciprocating Pump

- The pump is really expensive (The capital cost is high).

- Pumping viscous liquids using a reciprocating pump is tough.

- The pump’s maintenance costs are quite expensive due to the enormous number of components.

- The rate of flow is lower.

Reciprocating Pump Application

The following are some examples of how reciprocating pumps are used:

Pneumatic pressure applications.

Vessel, pipe, tank, tube, condensate pipe, heat exchanger, etc.

Vehicle cleaning.

Oil drilling, refineries, production, disposal, injections.

Hydro testing of tanks, vessels, etc.

Sewer line cleaning.

Wastewater treatment system.

Boiler feeding

Wet sandblasting

High-pressure pumps for the RO system (Reverse osmosis)

Fire Fighting system.

FAQ Section about Parts of Reciprocating Pump

Who Is the Inventor of the Reciprocating Pump?

Ctesibius, a Greek discoverer, devised the reciprocating pump in approximately 200 BC.

What are the types of Reciprocating Pumps?

The primary types of reciprocating pumps are as follows:

- Single-stage Pump

- Single Acting Pump

- Multistage Pump

- Double Acting Pump

- Diaphragm Pump

- Piston Pump

- Plunger Pump

What are the Parts of Reciprocating Pump?

The reciprocating pump is made up of the following parts:

- Air Vessel

- Strainer

- Piston rod

- Piston

- Delivery Valve

- Section Valve

- Suction Pipe

- Crankshaft

- Connecting rod

- Compression Cylinder

- Delivery Pipe

Download Parts of Reciprocating Pumps PDF

For your convenience, we have included an option to download the PDF version of this document to your computer. Please click on the links below to begin.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Reciprocating Pump: Working Principles, Function & Diagram

- Parts of Water Pump

- Parts of Centrifugal Pumps

- Diaphragm Pump Parts List + Function & Application

- 7 Parts of Gear Pump and Function + Diagram & Applications

- 10 Parts of Hydraulic Pump + PDF & Function

- 8 main Parts of Piston Pump and Function + Work & PDF

- 12 Parts of Sump Pump + Diagram

- 16 Parts of Heat Pump and Functions (Clear Guide)

- 20 Parts of Submersible Pump + PDF

- 6 Parts of Pool Pump + Diagram & PDF

- ULTIMATE GUIDE TO TYPES OF RECIPROCATING PUMPS

- The 5 Best Air Source Heat pump in 2022 (Clear Guide)

- 7 Best RV Water Pump In 2022 (Clear Guide & Review)

- The 10 Best Electric Air Pump in 2022 (Clear Guide)

- The Best HVAC Vacuum Pump in 2022 (Clear Guide)

- The 5 Best Well Pump in 2022 (Clear Guide)

- The 10 Best Condensate Pumps of 2022: A Complete Guide

- 13 Parts of Concrete Pump with Name & PDF

- 5 Types of Concrete Pumps + PDF

- 6 Type of Sump Pump and Which Are Better to Buy?

- Types of Pump Casings (In Centrifugal Pumps & Others) + Pros & Cons

- 7 Parts of Screw Pump: Advantages and Disadvantages

- 3 Types of Positive Displacement Pump + Name & PDF

- 5 Types of Vacuum Pump and Applications + PDF

- Types of Centrifugal Pumps: All Classification & Working Principles