Knowing the parts of pool pump, as well as a broad grasp of how the pump and motor work, will aid you in rapid diagnosis and repair. In this post, we’ll disassemble a sample pool pump so that next time your pump needs repairs, you can quickly do it yourself, or at the very least, find anything wrong so you can tell the repairman exactly what needs fixing so you don’t get stuck with a big payout for parts that didn’t require repairing in the first place.

In order to learn all the information you need about pool pumps, the Linquip website is a perfect place for you to go. If you have any questions regarding pool pumps, we have a group of experts at your disposal to assist you. The first place you may want to start gaining a basic understanding of these pumps is to read Linquip’s article titled “What is a Dynamic Pump & How Does it Work?“.

Did you ever work with any pool pumps before? At Linquip, there is a comprehensive list of Dynamic Pumps Products with which you will be able to find exactly what you are looking for. So, what type of pool pump are you looking for right now? In addition, Linquip provides you with free access to all available Dynamic Pump Devices for Sale on the website. With Linquip, you will have the opportunity to request a free quote or inquiry regarding the prices of pool pumps from all Dynamic Pumps Suppliers and Companies.

⇒ View a List of Pumps for Sale and Their Suppliers ⇐

Basics of Pool Pump

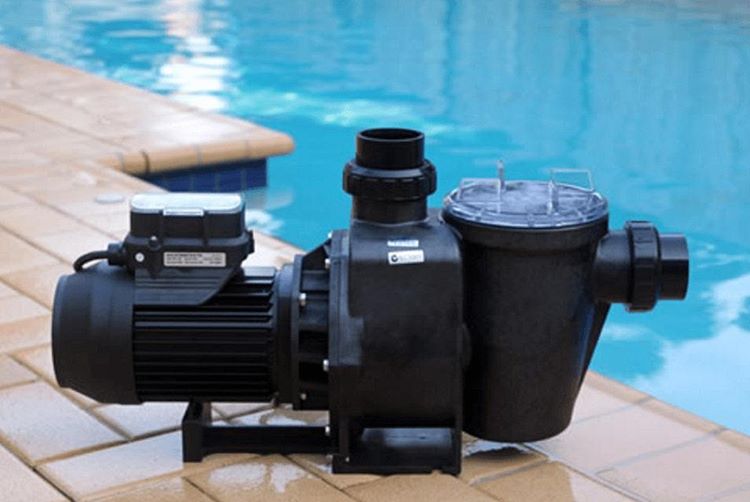

If you’ve ever pulled a pool pump apart for maintenance on your own or seen someone else do it, you’ll realize that it appears much simpler than other types of machinery equipment. The rationale for this is simple: the fewer moving parts there are, the less likely it is to fail. Pool pumps are made to run for long periods of time; thus, this is the idea behind them.

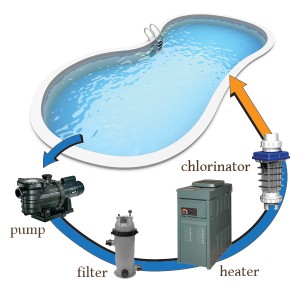

The pool pump is the heart of any pool’s circulation system, running non-stop every day of the pool season. The most important consideration of pool maintenance is to keep your pool pump working. If the pump is not working, then nothing works – so it must be fixed immediately.

The pump provides the flow of water that properly distributes chemicals throughout the pool, allowing it to disinfect the water efficiently. It pulls the liquid from the pool via the skimmer and main drain, filters it, and afterward, sends the water to the pool through the main returns.

With an efficient pool pump, you can turn over your water a number of times per day, depending on the size of your pool. This helps eliminate debris from your pool while improving the efficacy of your pool chemicals, which battle the formation of algae and germs in your water, allowing you to enjoy your swimming pool experience while being healthy.

Components of Pool Pump

Pool pumps are very basic machines that consist of two different primary categories:

- The external structure

- The drive train

Let’s go through these two categories.

The External Structure

The simplest way of explaining this is to compare the pool pump to a vehicle. The external component is visible at first look and is what keeps the pump together.

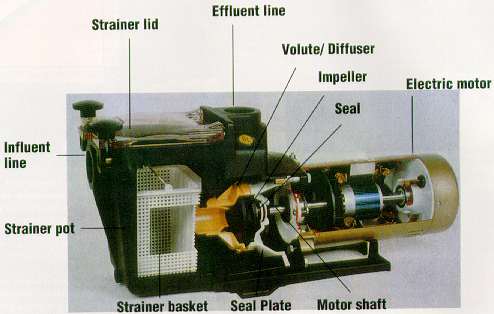

Housing

All of the pump’s internal components – including impeller, diffuser, seals, and motor – are housed in or attached to its outer casing. The housings of modern pool pumps are constructed of a high-impact plastic composite called Noryl, which makes them light yet highly robust. Unless your pump is over 20 years old (in which case we recommend replacing it soon), it will have this plastic composite casing. This is rust-proof and can withstand heat, pressure, water, and the environment for years.

Older pumps (the early 1980s and before) were manufactured of brass or bronze, which proved to be exceedingly robust but expensive to maintain. A plastic injection molded impeller will be far less expensive than a brass one that must be smelted and forged. Your back should also thank pump makers for converting to plastic because metal pumps may weigh up to 100 pounds. Metal pumps were tough workhorses that may still be found on pools today.

Lid

The strainer lid is the main inspection point for the pump, from which a professional or owner may check the performance of the system. If we detect enormous air bubbles or no water in the strainer lid while the pump is working, we may have an air leak on the suction side. The lid is composed of transparent or colored Lexan glass due to its usefulness as an inspection point. Lexan is the substance used in bulletproof windows and other glass-like materials.

The lid assembly consists of the lid (or cover), o-ring, and clamp. Common concerns are damaged o-rings, fractured pump lids, malfunctioning clamp bands, or simply loose lids. To achieve an airtight seal, the pump cover must be very tight. You can apply a Teflon-based pool grease to the pump lid o-ring to help seal and preserve it.

Baskets

This is positioned just beneath the strainer lid. The strainer basket’s key purpose is to filter out larger debris before it reaches the more sensitive components of the drivetrain. Small stones, leaves, and other debris get lodged in here before causing clogs in the drivetrain or, worse, chipping the impeller.

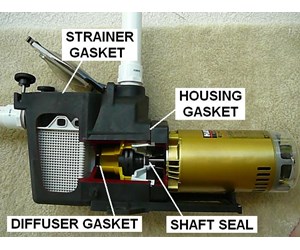

Gaskets and Seals

They include the o-rings, gaskets, and seals that keep air out that shouldn’t be there and water in where it belongs. A defective seal might cause floods or the pump to stop working altogether. Bubbling around seams and apertures in your pump is an indication of damaged gaskets. Here are several areas to inspect your pump for seal and o-ring performance:

- Lid Gasket or Lid O-ring: It is located on the strainer lid. Sand and other debris can become lodged on this gasket as a result of repeated opening and closing of the strainer lid, causing leaks. Before shutting the pool pump strainer lid, make sure it is clean and clear of debris.

- Diffuser Gasket or Diffuser O-ring: It is situated on the diffuser’s cone tip; it’s a fairly difficult part to find, but it’s rarely damaged because the diffuser is infrequently accessible.

- Seal Plate Gasket or Seal Plate O-rings: The housing gasket is another name for this. This substantial gasket connects the housing with the motor seal plate. Because most seal plate gaskets are designed to match the shape of the housing, it’s challenging to acquire replacement seals for them other than those made by the manufacturer.

- Shaft Seal or Shaft Seal O-rings: It is the most critical seal in the pump. This is located beneath the impeller and the motor’s shaft. Be cautious that this is a critical seal. Before reattaching the impeller, make sure it is not damaged and has no debris sticking to it. A leak in this area might cause serious flooding of your pump’s motor.

Seal Plate

The seal plate is a mounting flange for a motor that enables it to be attached to the pump housing. The seal plate is so given the name because it houses the shaft seal, which encircles the shaft and prevents water leaks into the motor. This is constructed from the same Noryl plastic as the housing, making it lightweight and long-lasting.

A shaft seal, which is positioned behind the impeller, is a unique two-piece system that enables the motor shaft to pass via the seal plate, rotate at high RPMs, and not leak water down the shaft, so protecting the motor and avoiding leaks. Shaft seal leak and failure due to excessive heat, poor water composition, salt or ozone corrosion, and water-hammer damage are common issues. Shaft seals are cheap; however, just one size suits your specific pump.

Note that there is only one right way to install the shaft seal. The soft rubber side of the bigger spring-half of the shaft seal faces the impeller, while the hard plastic side faces the motor.

The Drive Train

The drive train houses all of your pool pump’s moving parts and is in charge of pushing the water around. Your pump is a worthless lump of plastic without the Drive Train.

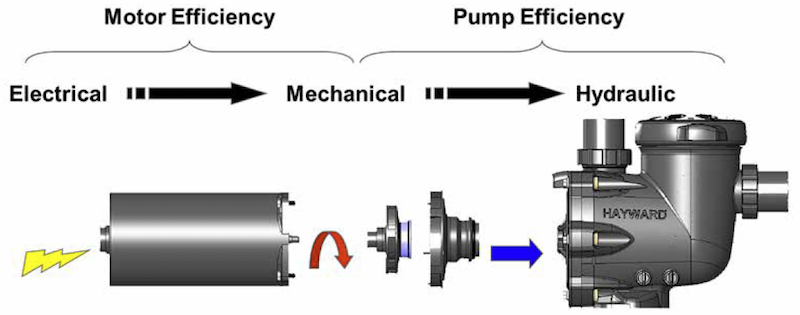

Motor

The pool pump motor is the engine that drives your pool pump. The motor generates the necessary force for the impellers to rotate and circulate the water. Older motors only had one on/off option; however, modern ECO types have many settings that allow them to operate at lower speeds and so save power.

Single-speed induction motors are the industry norm although they are losing market share to dual-speed and variable-speed motors. Variable- and dual-speed have risen in popularity as a result of their energy efficiency, which has been aided by electric providers giving subsidies to households who want to upgrade.

Most single-speed motors have a dual voltage configuration, allowing them to operate on either 230 or 115 volts (the user has to adjust voltage before installing). Variable-speed and the majority of dual-speed run on 230 volts; there are a few outliers in the dual-speed category that run on 115 volts.

The motor is attached to the impeller, and when an airtight supply of water is provided, it generates pressure and flow. New type variable-speed motors are permanent magnet motors that operate cooler, quieter, and have a longer lifespan than regular pumps’ less efficient induction motors.

Overheating, winding shorting, hot spots, and water damage are all common issues. Most pool pump motors have a lifespan of about eight years, or longer if you’re lucky. To protect the motor in locations with severe rain or direct sunlight, use a vented Motor Cover.

Impeller

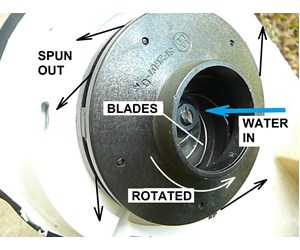

The Impeller is a rotor that is utilized to raise the pool’s pressure. In contrast to a turbine, which uses water flow to generate energy, an impeller applies power to generate water flow.

The suction and pump motion of your pool pump are created by the impeller. The impeller converts the pump’s rotating action into a vortex, sucking pool water toward the pool’s suction pipe and expelling it through the filter and back into the pool.

An impeller is made of two discs that are bonded together to sandwich fan blades (also called vanes). The front disc includes an aperture with a porthole to direct the impeller’s churning force into the pool’s suction pipe. Water is drawn into the impeller’s face and then discharged out the slotted sides — think of it as H2O’s equivalent of a merry-go-round.

Impeller wear rings are little plastic rings that prevent friction on a misaligned impeller and must be placed before installing the Diffuser.

Each horsepower motor is paired with a slightly different-sized impeller with a unique component number.

Clogging with small debris such as grass clippings, pine needles, stones, seeds, or stamens from blossoming trees is a common issue. Use needle-nose pliers to reach the eye, remove the motor, and ream the impeller vanes using a thin wire.

Diffuser

The diffuser surrounds the impeller, focusing the pull of water into the impeller eye and controlling the flow outside the impeller with a set of stationary vanes. To provide suction, the diffuser seals the impeller eye up to the rear of the pump housing.

This is a device that increases the suction force of the impeller. It forms a vacuum lock at the front of the housing and directs the suction to the front, thereby boosting the force of the impeller’s suction.

A common issue is a missing or broken diffuser gasket or o-ring, which is a vital component of the pool pump. When dismantling the motor for service, they occasionally slip off the front end of the diffuser. If the diffuser is not entirely tightened over the impeller, the impeller may not be properly seated.

Impeller Ring

The impeller ring, also known as the wear ring, is a plastic ring that fits around the impeller’s tip. A wear ring is designed to act as an extension of the impeller’s tip, ensuring a seal between the impeller and diffuser. The impeller’s centrifugal force compels the wear ring to adhere to the diffuser, ensuring a much tighter vacuum for priming and pumping. Wear rings are not seen on all pump models, but they are most common on high pressure and high head design pumps.

Impeller Screw

The impeller screw is used to fasten an impeller to a motor with an internally threaded shaft. As most manufacturers have transitioned to external thread motor shafts, the impeller screw is soon becoming obsolete. Because of the switch to external threads, the impeller may now be fastened directly to the motor shaft with no need for additional security. The new impellers’ thread type also ensures that the impeller is rotated in a direction that maintains it close to the motor and prevents slippage.

How to Use a Pool Pump

The functioning of the pump governs the overall operation of the pool. In general, the cleaning system cannot function without the main pump, and the pool water cannot be filtered without the main pump working. Thus, it is necessary to be aware of the right timetable for the functioning of the main pump.

The time of day that the pump should run is determined based on two factors: chemical requirement and energy cost. Because the Still’s UV light eliminates chlorine from the water, it stands to reason that the most considerable chlorine demand will be throughout the day. As most techniques of chlorine addition necessitate the pump to be running in order to provide the pool with the necessary quantity of chlorine, it follows that it is preferable to run the pump during the day instead of at night.

However, owing to the greater cost of electricity during the day, these two points must be considered in order to select the timetable that best suits the demands of each pool and its owner.

The ideal condition would be to operate the pump from sunrise to sunset. This schedule would be excellent in cases where the cost of power does not fluctuate during the day. However, running the pump at night may be necessary to avoid high utility bills in some circumstances. Note that the amount of chlorine delivered to the pool must be sufficient to keep the chlorine level at or above 3.0 ppm for most daylight hours, particularly in the afternoon.

The chemical demand is at its highest during the summer months, and because the bathing load is often larger during this time, the quantity of debris in the pool is also increased. This necessitates more thorough filtering of the water to eliminate the additional particles. There is a general rule that may be used to measure the length of each pumping cycle. Operate the pump for 112 hours for every 10° F increase in outdoor air temperature. This guideline should be applied conservatively because the temperature cannot be forecast exactly every month.

It is suggested that the pump operate 12 hours per day during the warmest summer months, 4-5 hours a day during the winter months, and to varying degrees throughout the fall and spring. The daily cycle can be divided into numerous cycles. However, each cycle should be no less than 4 hours long, as this is the lowest time required for all of the water inside the pool to pass through the filtration system at least once. It is also the recommended time between adding chemicals and the subsequent water test/or pool use.

Proper Size of a Pool Pump

You may be curious what size pool pump to buy if you are adding a new pool or replacing an old pump or motor. While it is tempting to be in a safe place and oversize, larger pool pumps are bad for both your pool and your budget.

A larger-than-necessary pool pump has a more powerful motor and distributes water at a greater flow rate. This requires substantially more energy to pump the same volume of water and places more strain on your pipes and filter, requiring replacement sooner. When the flow rates are so high, your filter performs less efficiently, and the quality of your pool decreases, which might indicate that the pool pump is oversized. If an installer attempts to sell you a bigger pool pump as an option, make sure to inquire if it is required for the operation of your pool.

Likewise, the rated horsepower of your present pump is not an accurate indicator of what to seek in a replacement. The prior pump may have been enlarged by the original installation, and newer ones tend to pump water more effectively, so a pump with a smaller motor may produce the same flow.

Furthermore, prior to 2021, motor horsepower rates were not standardized; therefore, manufacturers occasionally rated the same pump with two distinct horsepowers. As a result, a lower horsepower pump may be equivalent to your present pump, so don’t be startled if the installation suggests one with a smaller motor. Remember that smaller horsepower pumps consume less energy and are a better alternative if they can handle your pool’s filtration and cleaning requirements.

When comparing two pool pumps, the easiest approach to measure relative efficiency is to compare the Weighted Energy Factor (WEF), which is a statistic similar to “miles per gallon” for automobiles. A greater WEF shows that the pump is more efficient.

Variable-Speed Pool Pumps

Variable-speed pool pumps may work at a wide range of speeds, making sizing less challenging. Your technician will program the pump to run at the appropriate speed for your pool. Variable speed pumps consume far less energy than single-speed pumps and are better for your pool and filtration since they can be configured to operate at lower flow rates almost all the time.

To summarize, you should always check with a competent contractor when choosing and installing a pool pump, but if you have an option, go with the smaller pump and an ENERGY STAR type.

How Long Does a Pool Pump Last?

Pool pumps typically last between eight and 12 years before they need to be replaced. The parts will wear down over time.

Is It Possible To Repair a Pool Pump?

A majority of the new generation of pumps are already equipped with automatic controls as well as safety controls. If you spend enough time learning the manual, you might be able to fix some issues by yourself. Obviously, professional assistance is best for repairs and replacements.

Why Do Pool Pumps Malfunction?

Most often, the problem is caused by bad thread sealant, a cracked pump, an air leak in the suction line, a plumbing problem on the suction side, or a damaged valve stem.

Download Parts of Pool Pump PDF

We have included the option to download the PDF version of this document so you can have access to it. To get started, click the links below.

Conclusion

Now that you’re familiar with the parts of a pool pump, you’ll be able to recognize any possible trouble down the line and quickly obtain replacement parts without worrying about buying the wrong ones.

Furthermore, in this post, we tried to discuss various aspects of applying guidelines for pool pumps, as well as choosing a proper one for your specific application.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- 20 Parts of Submersible Pump + PDF

- 10 Parts of Reciprocating Pumps + Function, Application and Working

- Parts of Water Pump

- Parts of Centrifugal Pumps

- 12 Parts of Sump Pump + Diagram

- Diaphragm Pump Parts List + Function & Application

- 7 Parts of Gear Pump and Function + Diagram & Applications

- 8 main Parts of Piston Pump and Function + Work & PDF

- Pump: Working Principles, Function & Diagram

- Different Types of Pumps: Ultimate Guide in 2022

- Types of Fire Hydrant Systems

- Types of Piston Pumps

- 3 Types of Oil Pumps + Working Principle & PDF

- 5 Main Types of Fuel Pump & How They Works?

- 3 Types of Heat Pump + Working Principle ( Clear Guide)

- Types of Pump Casings (In Centrifugal Pumps & Others) + Pros & Cons

- 12 Parts of Sump Pump + Diagram

- How and When to Replace Your Sump Pump?

- Best Check Valve for Sump Pump: 9 of the Best Models

- What is Sump Pump and How Does It Work?

- Top Dosing Pump Manufacturers and Suppliers in 2022

- Top Water Pump Manufacturers and Suppliers in 2022

- The 7 Best RV Water Pump In 2022

- The 10 Best Electric Air Pump in 2022

- The Best HVAC Vacuum Pump in 2022

- 9 Different Types of Rotary Pumps + PDF

- The 5 Best Well Pump in 2022

- The 10 Best Condensate Pumps of 2022: A Complete Guide

- 13 Parts of Concrete Pump with Name & PDF

- 5 Types of Concrete Pumps + PDF

I find the article very informative on Swimming Pool Pumps

Thanks Francky