What are Rotary Valves? Working Principles & Types – The rotor of a rotary valve is a spinning component that controls bulk material flow from upstream to downstream devices. A drive motor linked to the valve rotor powers its rotation – several rotary valve drive connections are possible. Here, we provide sufficient information about the working principle and various types of rotary valves.

⇒ View a List of Valves for Sale and Their Suppliers ⇐

What is A Rotary Valve?

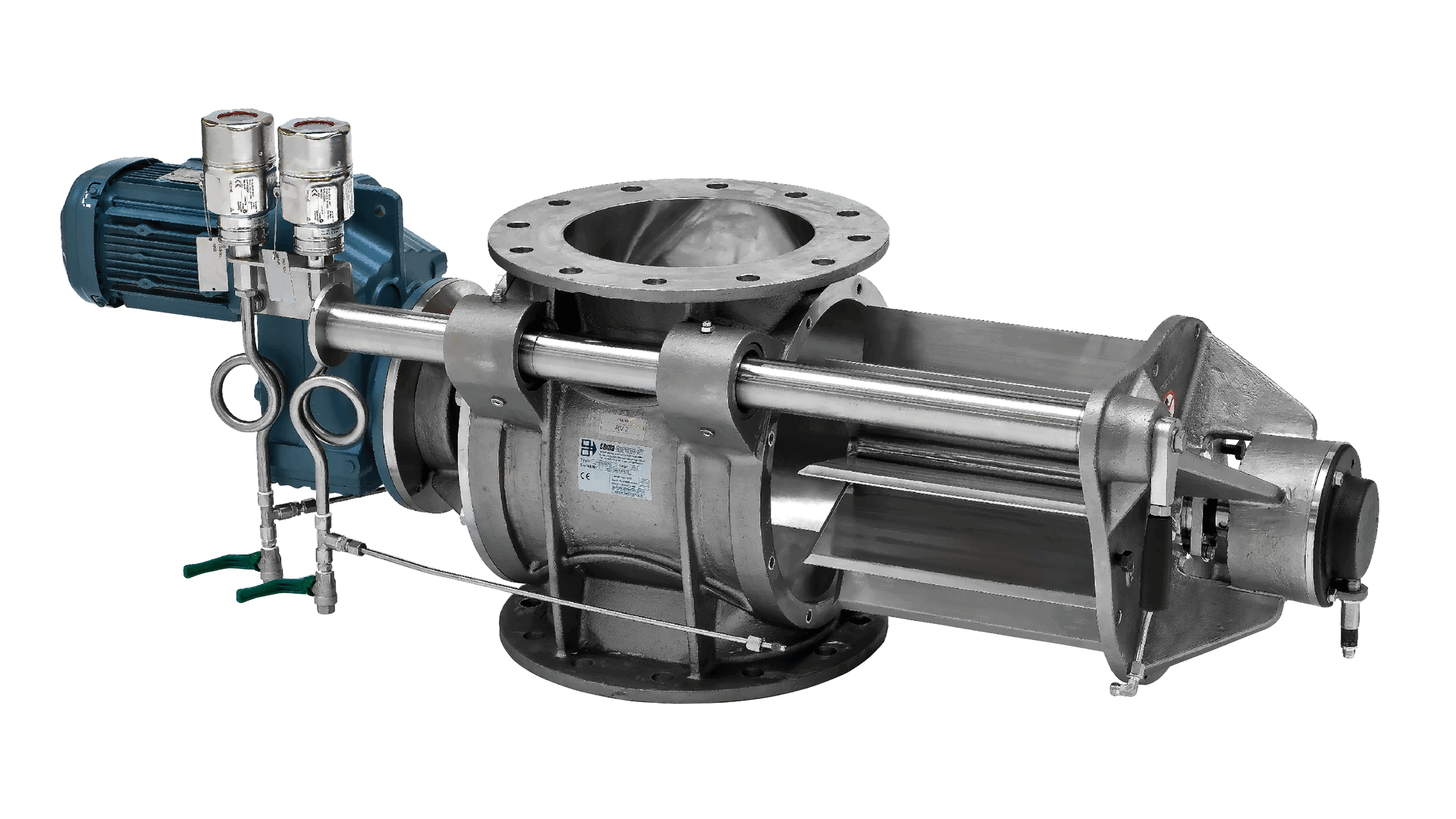

Pneumatic valves that control and meter the flow of granular bulk or powders are known as rotary valves (also known as rotary feeders, rotary airlocks, and so on). Material is supplied into the valve through a hopper or other inlets, processed by the valve rotor, and then deposited in discrete packets onto a conveyor system, all with little pressure loss. Rotary valves are most commonly employed in air conveyor systems to reduce pressure loss across the valve, but they may also be used to meter materials at a regulated flow rate. They almost solely act as airlocks, explosion/flame barriers, and process isolators, among other things, in air systems. They can transport dry to somewhat sticky goods and have a wide range of uses in the chemical and food industries, as well as pharmaceutical, plastic, and other production industries.

Rotary Valves Parts

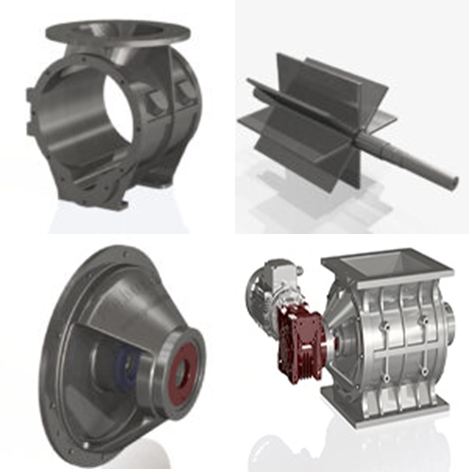

The manufacture of rotary valves is subject to general engineering perfection. A valve body (housing) with an intake port and an outlet port, a rotor (shaft with blades), two end plates (outboard or inboard), and a driving system are the basic valve components.

Housing

The bulk material flowing through a rotary valve housing is kept safe by confining it throughout the material handling process. Proper housings are made of a variety of materials, including cast iron, stainless steel, and hardox. For the food and dairy sectors, manufacturers provide specific coatings for abrasive bulk materials as well as highly polished finishes. Flow through, blow through, and offset are the three types of housing configurations available.

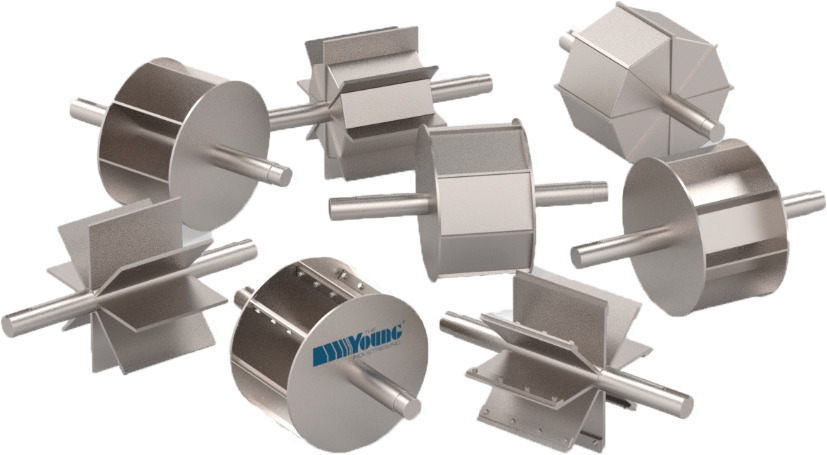

Rotors

In rotary valves, rotors serve as metering components. The design of these components differs from one another. Because it is made up of a shaft and blades (also known as vanes) that are welded or cast together, a rotor is also known as a rotor assembly. It is the spinning component of the valve. The number of rotor vanes varies depending on the rotor; 6, 8, and so on. The rotor pocket is the area between the vanes. The pocket capacity increases as the number of rotor pockets decreases.

End-Plates

The rotary valve end-plates prevent bulk materials from spilling over the rotor pockets’ sides. Outboard and inboard bearing end-plates are the two types of end-plate configurations. Outboard plate bearings are generally utilized in heavy-duty rotary valve versions, as they are relocated away from the head plates. Seals can be seen on these plates. The seals’ principal function is to prevent dry bulk material from rotor pockets from flowing into the bearing zone. It’s possible to utilize lip sealing or gland packing.

Systems of Propulsion

The valve’s driving system consists of the motor and the gearbox together. A reduction gearbox powered by an electronically induced motor drives the majority of the rotary valves. Normally, a reduction gearbox is used to receive a specified motor speed and create a low output speed. A worm gear reduction connection, a chain gear connection, and a straight coupling connection are the three drive configurations offered by Polimak.

How Do Rotary Valves Work?

An outer housing, a rotor, a rotor bearing and seal, and a drive are the four essential components of a rotary valve. The inlet/outlet ports, as well as a safe passage for material passing through the valve, are all housed in the housing. The rotor bearing keeps the rotor in place, while the bearing and shaft seal keep particles out of the valve inner housing. The driving mechanism (usually an electric motor) is mounted on the exterior of the rotor shaft and regulates the rotor’s rotation speed and direction. The product is fed into the valve, collected in equal pockets between the rotor vanes, and distributed evenly at the outlets. These rotor vanes have a tight clearance with the housing, preventing pressure/material losses via the valve and maintaining pressure differentials.

Types of Rotary Valves

The rotary valve comes in a variety of shapes and sizes, each suited to a specific use. Each component may be customized to fit specific requirements, and the sections following will describe how particular elements differ in producing various types of rotary valves.

Housing Styles

Housings are available in inline or offset configurations, depending on the application. The intake lies right above the exit in inline housings, which is more efficient and practicable in most applications. Offset housings skew the inlet and outlet to minimize product shearing and overfilling, however they’re less efficient and have a smaller market. Plow-like designs and one-off configurations are also available, all of which are intended to give the optimal valve functioning for specific applications.

Rotor Styles

The rotor design is very unique to the task at hand, and there are many different sorts of rotors. Closed-end rotors, open-end rotors, staggered pocket rotors, metering rotors, helical rotors, reduced volume rotors, adjustable rotors, radius pocket rotors, flex tip rotors, and a variety of other one-off varieties are also available. A rotor normally has at least 8 rotor pockets (and hence 8 vanes), however increasing the rotor size will reduce filling efficiency while improving sealing capacity. Because rotors wear out over time, replaceable vanes are also common, but they are rarely utilized in big rotary valves.

Drive Styles

A synchronous electric motor linked to a reduction gearbox and chain configuration powers most rotary valves, providing for accurate speed control and regulation. These drives may be equipped with additional speed monitoring devices and variable speed controls, making the rotary valves suitable as rotary automation valves. Larger rotary valves can alternatively be powered by hydraulic motors, which do not require a gearbox and are reserved for more specialized applications.

Applications of Rotary Valves

Using a Rotary Valve to Empty a Silo

The solid bulk discharge from these units and feed devices like conveyors, screw feeders, mixers, and other container systems is controlled by a rotary valve located beneath the silo, hopper, or another container system.

Rotary Valve Cyclone Discharge

Under the cyclone, a rotary valve is utilized to control the solid bulk discharge from the cyclone under pressure or vacuum, as well as feed equipment such as conveyors, screw feeders, and mixers.

Dust Collection With Rotary Valve

Dust is collected from production lines using dust collectors, filters, and jet pulse filters. To discharge the dust, rotary valves are put under dust collection systems.

Dosage Control, Mixing, Batching With Rotary Valve

Rotary valves can be used to regulate the amount of bulk materials discharged. Volumetric measurement of powdered and granule-type bulk materials is accomplished by changing the rotor speed of the airlock. Mixers and containers can be fed volumetrically.

Rotary Valve Pneumatic Conveying Systems

Pneumatic conveying lines are fed by rotary airlock valves from silos, hoppers, cyclones, and large bag discharge stations, among other places. Rotary feeders prevent air from escaping the conveying line and ensure that powders or granules are fed continuously.

Rotary Valves for Conveyor Feeding and Discharging

With the use of airlocks, conveyors may be fed from silos, hoppers, or other containers. Bulk materials dislodged from conveyors can be fed into airlocks and then transported to other equipment such as a pneumatic conveying line or a mixer. Baghouse filters and ESP systems make extensive use of this material.

Rotary Valves for Screw Feeder Feeding and Discharging

With the use of airlocks, screw feeders may be fed from silos, hoppers, or other containers. Bulk materials ejected from screw feeders can also be fed into airlocks before being delivered to another piece of equipment, such as a pneumatic conveying line or a mixer.

Rotary Valves are Used to Feed and Discharge Bulk Solids Processing Equipment

Airlocks can be used to feed or discharge bulk solid processing equipment in a variety of industrial operations. Rotary valves are used in operations such as boiling, cleaning, surface treatment, mixing, and crushing. External conditions are isolated from the process using rotary airlock valves.

Solid Filling in Bulk

Volumetric metering using airlocks fills a variety of bulk materials into bags, sacks, huge bags, containers, or drums.

What to Look for When Buying Rotary Valves

The rotary valves that regulate the flow of powder have numerous key spots inside the plants or machines. Rotary valves are completely safe and serve as a flame barrier and process isolator. However, you must choose the ideal valve based on the pipeline’s dimensions. However, several factors like type, size, pressure, temperature, and other typical product features must be considered while selecting valves.

- Type: Varied types of valves have different roles, such as airlocks, feeders, and airlock feeders. Product flow is sometimes allowed by the pressure inside the input and exit sides of valves. Airlocks are commonly used in cyclone and baghouse outlets. Then there are feeders, which aid with rate regulation. The last kind is airlock feeders, which integrate many functions.

- Size: After deciding on the kind, the size of the valves must be determined. We must consider the volumetric capacity and flag size while deciding the size. The rotary valve size includes a distinct area for mating the valve’s flange.

The feeder with long-lasting pressure is the optimum dilute conveying system. Finally, other aspects of other cleaning solutions, as well as aspects for valve performance, modifications, options, and other accessories, are in the hands of the user.

To understand better the sizing of the rotary valves, watch this nice video. You are also encouraged to see this post to find top valve manufacturers in the world.

FAQs about Rotary Valves

1. What is a rotary valve?

In dry bulk material handling, it is common to employ a rotary valve to regulate the flow of dry bulk solids between two systems, such as upstream and downstream machinery. Many other names have been given to this valve, including an airlock valve, star valve, and rotary feeder.

2. What makes a rotary feeder different from an airlock feeder?

It is possible to feed dry bulk solids from an upstream device to a downstream device using a rotary feeder, which does not need the separation of pressure differentials. When it comes to dry bulk materials, an airlock feeder is a valve that separates a pressure difference while feeding or metering the material into a downstream system.

3. Do you know the function of a rotary valve?

When a rotary valve is in use, the blades revolve within the valve’s housing. A motor powers this spin. Rotor pockets are formed while the motor turns. The valve’s intake receives dry bulk solids from upstream equipment, which settle in the pocket. After the rotor spins, the dry bulk solids are discharged from the output port. There are two forms of rotation: one on the load side and one on the return side. In the first case, the rotor pockets are rotated from the inlet to the outlet, whereas in the second, the rotor pockets are rotated from the outlet port to the inlet.

4. What is the purpose of rotary valves?

For a variety of industrial purposes, rotary valves are commonly employed. Control of dry bulk solids flows, feeding of downstream systems, and maintaining a pressure difference between an upstream, and a downstream device are only some of the functions it serves.

5. When would you use a rotary valve?

Depending on the application, rotary valves for industrial production are commonly employed in bulk material handling, dust collection, or pneumatic conveying systems. The valve controls the flow of a product or material by maintaining a constant flow rate that is appropriate for the process.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What is Solenoid Valve and How Does It Work? 2022 Guideline

- Manual Valves: everything you need to know about them

- What is Automatic Expansion Valve: A Basic Guide

- Lift Check Valve: learn the basics, get the most out of it!

- PVC Foot Valves: a brief review of everything you need to know

- Strainer Valve: a basic guide to know it better

- Backwater Valves Installation, Costs and Maintenance in 2022

- How to Repair a Gate Valve? (Clear Guide)

- Backflow Valve Installation, Costs and Maintenance in 2022

- How to Install a Thermostatic Mixing Valve? (Costs and Maintenance in 2022)

- How to Install a Water Pressure Reducing Valve? (Costs and Maintenance in 2022)

- Check Valve Installation Costs and Maintenance in 2022

- The 10 Best Water Shut off Valves of 2022

- What is Drain Valve? Working Principle, Types & Applications

- What are Coaxial Valves? Working Principles and Type

- What is Isolation Valve? Working Principle & Types

- Backwater Valves: Working Principles & Types

- What is Block Valve? Working Principle & Types

- Butterfly Valve Installation Costs and Maintenance in 2022

- How to Install a Saddle Valve? (Costs and Maintenance in 2022)

- How to Install Check Valves? (Costs and Maintenance in 2022)

- What is Pilot Valve? Working Principle & Types (Complete Guide)

- What is Poppet Valve? Working Principle, Types & PDF

- What is Balancing Valve? Working Principles,Types & Function

- What Is Linear Valve? With Example, Working Principles & Types

- What Is Actuated Valve? Working Principle & Types

- 6 Main Types of Expansion Valves: an Easy to Understand Guide