Types of CNC Machine – In the Computer Numerical Control (CNC) machining process, production equipment and tools are moved according to pre-programmed computer software. The procedure may be used to operate a variety of complicated machinery, including mills, CNC routers, lathes, and grinders. Three-dimensional cutting jobs may be completed with CNC machining in a single set of instructions. In this post, we are going to describe some basics of CNC machines and provide comprehensive information about various types of CNC machines.

Basics of CNC Machining

You will be better able to appreciate the difficulties involved in effectively utilizing your data for a CNC-controlled machining or cutting activity if you are familiar with the CNC process and how it works. This little introduction ought to be helpful.

Some Basic Definitions

CNC: Computer Numerical Control – A computer and CAM software are used to automate, control, and observe the motions of a machine using digital data. The machine might be a robot, router, lathe, grinder, welder, sheet metal stamping machine, laser or waterjet cutter, or any number of other devices. The computer is often an on-board specialized controller for bigger industrial machinery. However, the computer can be an external PC for machines that are more suited to hobbies or with certain retrofits. In order to move and control the machine axes and carry out the preprogrammed movements, the CNC controller collaborates with a number of motors and drive components. The advanced feedback system that continuously analyzes and modifies the cutter’s speed and position is often present on industrial equipment.

Desktop CNC: There are a lot of smaller desktop CNC machines designed for model makers and hobbyists. These are often less costly, slower, less accurate, less stiff, lighter, and less rigid than their industrial equivalents, but they work well for milling things made of softer materials like plastic, foam, and wax. Some desktop computers may operate quite similarly to a printer. Others may even have specialized CAM software and their own closed command system. A few will also take input in the form of regular G-code. Certain desktop industrial standard machines have specific controllers for performing fine tiny operations.

CAM: Computer-Aided Machining or Manufacturing – This is the process of using different software programs to generate toolpaths and NC code for a CNC-operated machine based on data from 3D computer models (CAD). The combination of the two is frequently referred to as CAD/CAM.

It should be noted that CAM only generates code for the CNC machine to follow. Additionally, it does not import your CAD model and automatically generates the appropriate NC code. In order to execute the program, create machining strategies, and know which tools and operations to employ in each circumstance to produce the best results, CAM programming, like 3D modeling, requires knowledge and expertise. While there are certain straightforward programs that a novice user can pick up and use without too much trouble, more complex models require time and financial commitment to become skilled.

NC code: This is a unique and relatively basic computer language that can be understood and used by CNC machines. These languages were first created to enable direct part programming at the keyboard of the machine without needing a CAM application. Along with managing other machine operations like spindle and feed speeds and coolant, they instruct the machine on what actions to do one at a time. The most widely used language is G-code, often known as ISO code, a basic alphanumeric programming language created in the 1970s for the first CNC machines.

Postprocessor: Although G-code is regarded as the industry standard, individual manufacturers are free to change certain components, such as auxiliary functions, making it possible for G-code designed for one machine to malfunction on another. Many machine makers have also created their own programming languages, including Heidenhain and Mazak. Therefore, there is a bridge software component software called a postprocessor to convert the internally determined routes of the CAM software into precise NC code that the CNC machine can interpret. Once properly set, the post processor generates the appropriate code for the selected machine, allowing any CAM system to produce code for any machine theoretically. Postprocessors may come with the CAM system for free or at an additional fee.

Types of CNC Machines

10 Types of CNC Machines are:

- CNC Milling Machine

- CNC Lathe Machine

- CNC Drilling Machine

- CNC Laser Cutting Machine

- CNC Grinding Machine

- CNC Waterjet Cutting Machine

- CNC Plasma Cutting Machine

- CNC Electrical Discharge Machine

- CNC Router Machine

- 3D Printer

CNC Milling Machine

One of the most common CNC machines are mills, which include integrated tools mostly used for drilling and cutting.

To route and travel the spindle in various ways, mills develop and convert specialized programs made up of letters and numbers (G code).

The workpiece is placed inside the milling machine, and then the computer takes over.

Every action and movement of the spindle and tools is guided and instructed by the computer code in order to accurately cut and transform the workpiece into a planned bespoke item.

Some of the typical tasks that a CNC milling machine may carry out include tapping, turning, drilling, milling the face, and milling the shoulder.

Configurations for CNC milling machines range from three to six axes.

The three axes in the simplest 3-axis CNC stand for the motions of the X axis (horizontal), Y axis (horizontal), and Z axis (depth).

In comparison to other CNC equipment like CNC routers, CNC milling machines are relatively big and costly.

In general, hard metals are machined using CNC mills, whereas soft materials like wood, plastic, and soft metals are machined using CNC routers.

Some of the well-known manufacturers of big CNC milling machines are Okuma, Haas, and DMG Mori.

CNC Lathe Machine

The capacity to rotate materials while in use defines lathe CNC machines. They are shorter and more compact than CNC milling machines because they have fewer axes.

A lathe that controls and transmits material to the computer programmatically is at the heart of CNC lathe machines. Due to its quick and precise operation, it is now a lathe that is frequently utilized.

After initial setup, a semi-skilled person may readily operate it. The capstan and turret are two examples of mass-produced items that utilize this kind of lathe. However, there is no automated feeding mechanism.

CNC Drilling Machine

Similar to conventional drilling machines, CNC drilling equipment makes holes in a stationary object using a spinning cutting tool. However, CNC drilling machines are more precise and adaptable than conventional drilling machines since they rely on CNC technology.

For instance, holes may be produced by CNC drilling equipment with tolerances as tight as 0.001mm. Additionally, they work well with a variety of materials, including wood, plastic, and metal. Additionally, many CNC drilling machines have a tool turret that can hold several drill bits and enable rapid switching between them during production.

If you want to create hubs, gear blanks, and machined shafts, you should use CNC drilling equipment.

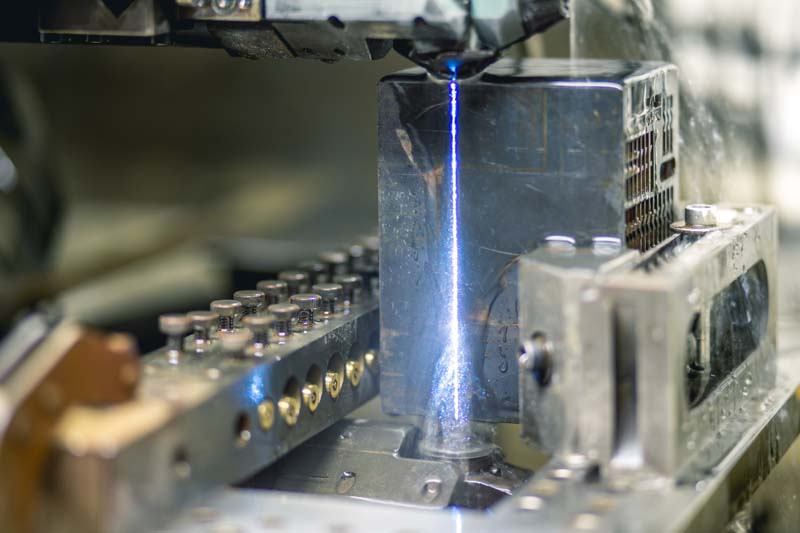

CNC Laser Cutting Machine

In their capacity to cut through strong materials, CNC laser cutters are similar to CNC plasma cutters.

But unlike a plasma cutter, which employs plasma, a CNC laser cutting machine uses a powerful and highly focused laser to do the work (ionized gas).

CNC laser cutting machines often offer a greater degree of precision and a better surface quality when compared to CNC plasma cutters since lasers have a smaller point of contact and spread than torches.

Additionally, CNC laser cutters are substantially more expensive than CNC plasma cutters with the same specifications (accuracy and cutting depth). But at a larger expense. CNC plasma cutters, however, provide greater cutting power since plasma is more powerful than lasers. They are mostly used to cut timber, metal, and plastic.

The laser power may be adjusted to readily cut through material depending on the density and toughness of the material. The material shape is frequently in the form of a sheet in CNC laser cutters. The material is then sliced precisely by the laser beam moving back and forth across it. To make the precise cut, the laser’s heating action vaporizes or melts the material.

When compared to other cutting devices, CNC laser cutters may frequently generate a range of patterns. Frequently, the cuts and edges generated are so exact and clean that they don’t need any more polishing. As a result, CNC laser engravers are frequently used to make parts and engrave machine parts.

In ornamental crafts, including sign-making, woodworking art, and glass engraving, laser engraving is widely employed. When tight tolerances and a precise output are needed, CNC laser cutting is used.

CNC laser cutting machines frequently employ lasers like CO2 and neodymium (Nd)-doped yttrium-aluminum-garnet (Nd:YAG). OMtech, Flux Beamo, and Glowforge are some popular brands of CNC laser cutters.

CNC Grinding Machine

It is a finely crafted performance tool that separates metal from metal using a revolving wheel. Camshafts, ball bearings, transmission shafts, and other functional items that need an exact and precise finish are frequently ground on CNC grinding machines.

Cylindrical objects are frequently produced with a CNC grinding machine. Other kinds of workpieces can also be produced by a grinding machine. “CNC” stands for computerized numerical control in CNC grinding machines.

CNC Waterjet Cutting Machine

As the name implies, high-pressure water jets are used by CNC waterjet cutters to cut through materials. CNC waterjet cutting is frequently chosen when working with materials like plastic and aluminum that are sensitive to temperature and might melt at high temperatures.

Despite the fact that these machines can cut with only water, extra abrasives like garnet or aluminum oxide are frequently added to the water for more effective cutting. When comparing equivalent specs, a CNC Water-jet cutting machine is more expensive than a plasma cutter. However, it is less costly than a CNC Laser cutter with the same specs.

Being slower than CNC plasma cutters and CNC laser cutters is one drawback of a CNC waterjet cutter. Brands of CNC waterjet cutters that are well-known include KMT, WARDjet, OMAX, and Flow.

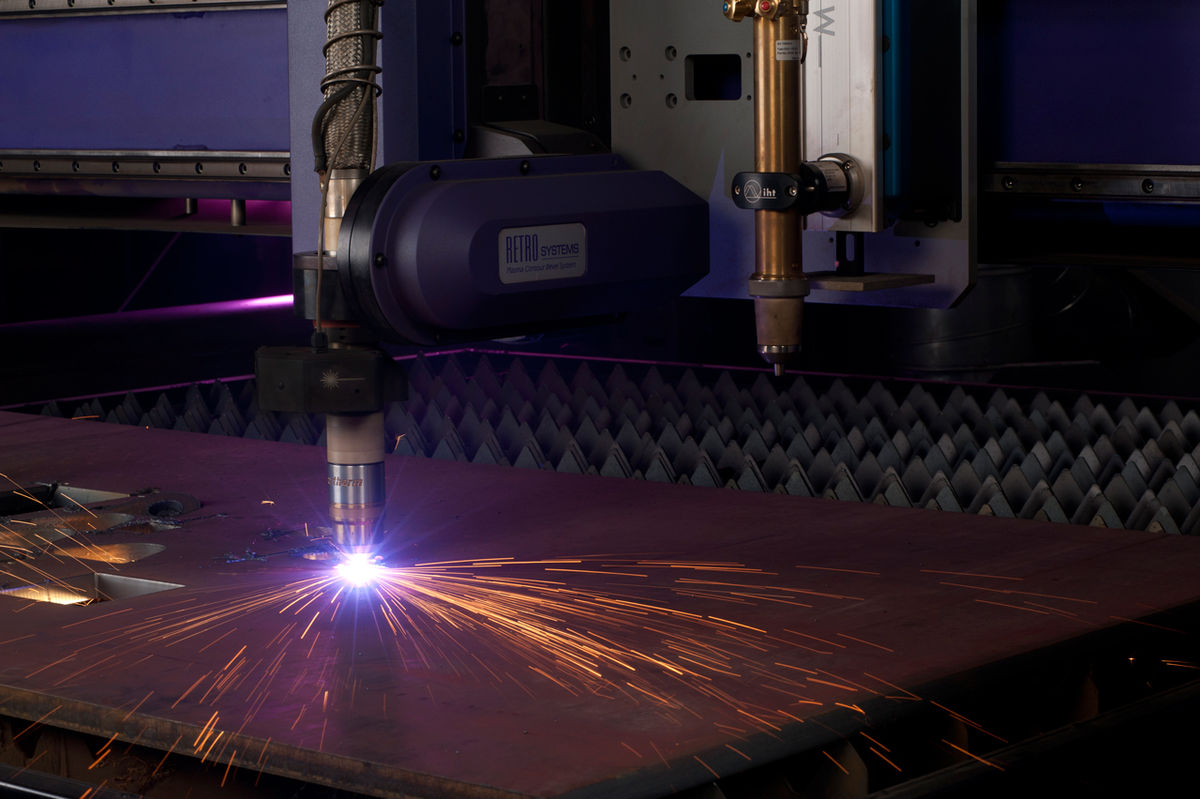

CNC Plasma Cutting Machine

Like laser cutters, CNC plasma cutting machines provide a high level of cutting precision and a wide variety of material compatibility. They only vary from laser cutters in that they use a plasma flame to do the cutting.

High-powered plasma (or charged gas) that may reach temperatures of up to 50,000°F is produced by the plasma torch. Any substance that is electrically conductive is effortlessly sliced through by this immense heat energy.

CNC Electrical Discharge Machine

These are also referred to as sparks. A unique kind of CNC machine called a CNC machine manipulates materials into the required shape using electric sparks.

Electrical discharge can damage the materials from which it is delivered since it has a temporary impact. This is used by the electric discharge CNC machines to shape materials by creating controlled sparks.

The materials are placed in the electrode’s top and bottom regions, and the computer then determines how much electrical discharge, the electrodes will create.

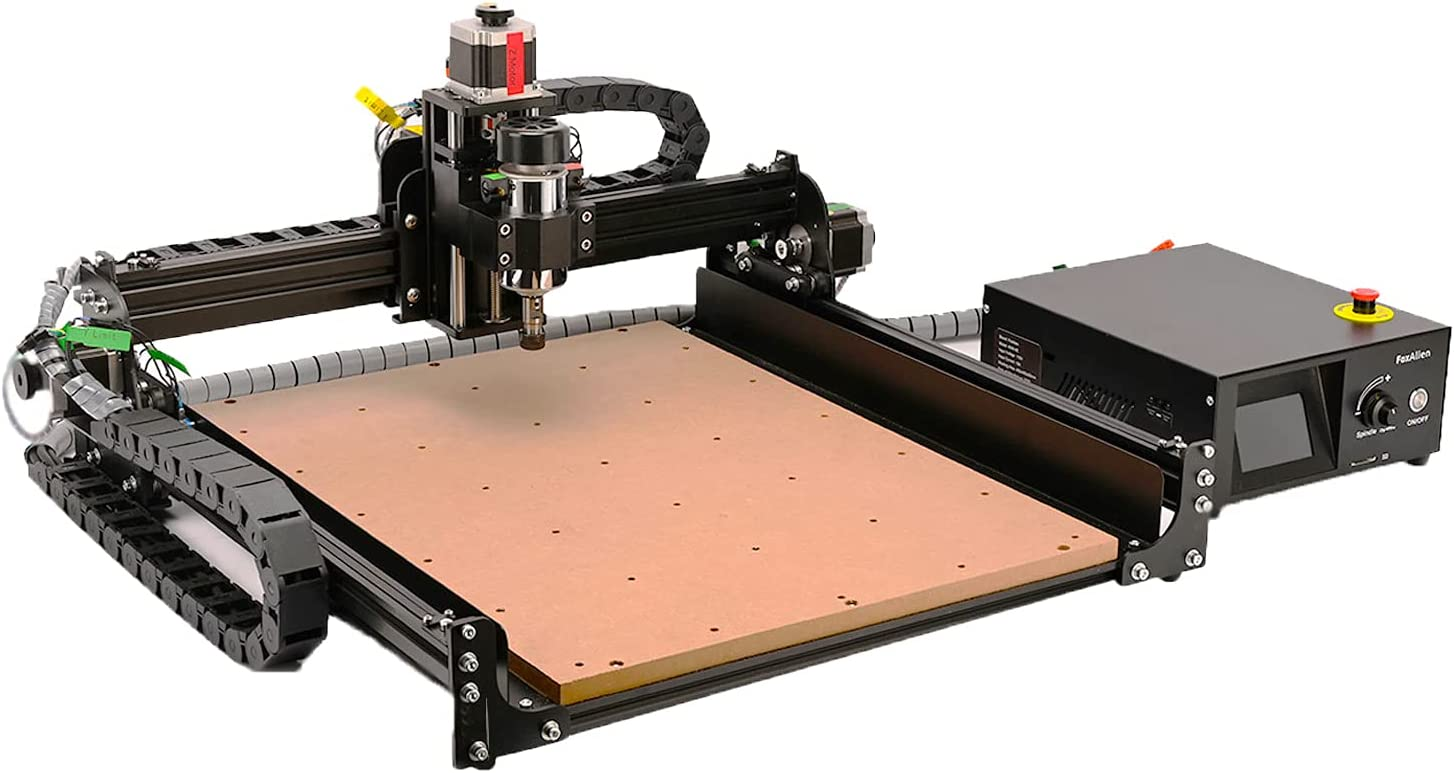

CNC Router Machine

A CNC router is a tool that is comparable to a CNC mill although it is primarily used for working with softer materials and is less accurate.

The cost of CNC Routers is much lower than that of CNC Mills. Compared to even entry-level CNC Mills, which can cost upwards of $10,000, a high-quality CNC Router can be bought for less than $2,000.

In order to create and shape materials like wood, steel, composites, aluminum, foam, and plastic to the required pattern and form, CNC routers employ computer numerical control to route spindle and machine tool paths.

A mechanical base, a spindle, stepper drivers, stepper motors, controllers, and a power supply are the basic components of a CNC router. CNC routers speed up production by decreasing waste, improving accuracy, and increasing efficiency.

The majority of CNC routers are adept at creating modest projects and working on prototypes of both basic and complicated designs in all three dimensions. Similar to CNC mills, CNC routers come in a variety of axes with a range of three to six. Carbide 3D, Avid CNC, Inventables, BobsCNC, and Onefinity are some of the most well-known manufacturers of CNC routers on the market right now.

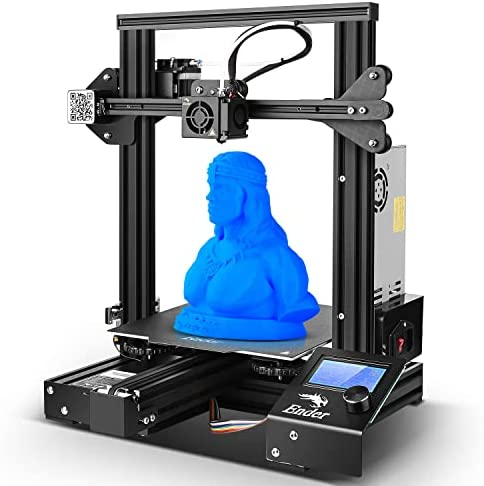

3D Printer

It is a CNC machine that prints elements one at a time. The CAD and CAM processes are utilized to develop the design and drawing, and the 3D printer is then used to reflect that design. The CNC device is used in 3D printing houses and other structures.

Advantages and Limitations of CNC Machining

Advantages

CNC machines assist manufacturers in enhancing productivity and accuracy and help lower the risk of human error by enabling them to automate various production operations that would otherwise need to be carried out manually.

Here are 5 significant ways they have changed engineering:

- CNC machining is excellent for producing lots of parts

- Various materials may be worked on using CNC machines

- CNC equipment produces items swiftly

- CNC equipment is very precise

- There are several post-processing and finishing choices with CNC machining

Limitations

CNC machines’ capabilities may be constrained by the sophistication and age of their control and drive systems. Majority of CNC controllers only comprehend circular arcs and straight-line motions. The arcs are often only allowed on the main XYZ planes in many machines. Rotating an axis can be thought of as moving linearly, only in degrees rather than in space. Two or more axes must interpolate (move precisely and synchronously together) in order to produce arc motions or linear movements that are at an angle to the major axis. Also capable of simultaneous interpolation are rotary and linear axes. Five-axis machines require that all five be precisely synced, which is a difficult undertaking.

It is crucial that the machine controller can interpret incoming data quickly, send orders to the drive system, and keep track of the machine’s speed and location. In this regard, older and less costly devices are plainly less competent, much as how an older computer would perform demanding tasks less effectively and more slowly (if at all) than a modern one.

Applications of CNC Machining

No matter what kind of material you work with—wood, metal, or pretty much anything else—you’ve definitely heard of the formidable CNC machine. While we often only think of recent years when it comes to computers, CNC technology has been around since the 1940s.

Since then, CNC technology has advanced significantly and now has a wide range of new applications, as we’re sure you can anticipate. Let’s discuss some of the top applications and advantages of CNC machining.

CNC Machines Are Repeatable

The main advantage of CNC punching is the ability to produce as many copies of a design as your materials will support after the design has been defined. Once the application is installed, you can simply save it and utilize it whenever you choose, whether you’re creating plaques, carved signs, decorations, or even automotive components.

There are just too many advantages of CNC technology to enumerate, but there are also more applications than we could ever include in one list. Here are a few that you might not be familiar with.

Dental Supplies

It may surprise you to learn that dentists frequently utilize CNC machinery, especially when placing dental crowns.

Although wood and sheet metal are frequently made using CNC services, they are capable of producing much more. Even dental crowns and implants may be carved out using CNC software since the technology is so accurate.

The nicest part about it is how simple it is to set up and how precisely it can produce crowns that fit exactly where they were intended in your mouth. Think again if you believed that the only companies who provided machining services were automakers! This technique has been utilized by dentists for many years.

Armaments

You may be aware of the debate around 3D printers because of their capacity to produce weapons without serial numbers. However, CNC machines have existed for a far longer time and have always had that potential.

Additionally, CNC machines may even modify rifles to add grips and other attachments. The quantity of material you need to start with is the sole distinction from a 3D printer. However, it is prohibited to make weapons without a license, despite the fact that many different firearm firms produce their products using CNC mills.

The military and defense sector frequently employs CNC manufacturing to produce different types of weaponry and equipment in addition to guns. The entire industry gets a lot of its equipment from CNC production.

Construction

Even if it might not come as a surprise, CNC punching can be useful quite a bit when it comes to building. You might not anticipate some of these.

Even the most accomplished carpenters would struggle to match the level of accuracy needed for some works, particularly when working on pre-existing structures.

This level of precision may be required by other trades, such as HVAC professionals, plumbers, and pipefitters. Essentially, CNC technology may give so much more than any other tool, which is the key factor. With the capacity to operate on any material you can imagine, they can perform many functions simultaneously, including those of a router, drill press, jigsaw, table saw, jointer, and even a surface planer. It’s tough to surpass.

Transportation

This is a wide word since the services provided by CNC technology to the sector are so varied. CNC technology is used in various ways by the aviation, railroad, and automobile sectors since it provides such a wide range of services.

To guarantee that every component of the plane operates as it should while you are thousands of feet in the air, every element must be made with high accuracy. For this reason, the industry has traditionally relied on machining services.

In order to assure safety, railroads and autos must also be constructed appropriately. Automakers must make sure that quality control is their first concern because more than 70 million automobiles are produced each year. There must be uniformity throughout. Because machines can provide greater regularity than people can, CNC services are very useful to the industry.

Development And Research

Prototypes are necessary for R&D across practically every sector, along with some degree of trial and error. That covers physics, chemistry, biotechnology, woodworking, and other subjects. Any notion you have in your brain may be brought to life with skilled accuracy using CNC machining.

Since its beginnings, it has been used to create precise prototypes in practically every industry you can think of, and it still does so today.

Niche Production

In actuality, CNC machines are capable of doing almost anything. A CNC machine can produce practically anything that needs to be made from the correct amount of any material.

What other machine could construct a door, a spinning wheel rim, an electronic guitar, and a dental crown in a matter of hours? CNC technology has raised the bar for manufacturing in all specialized fields and fashions and is only becoming better. Whatever your demands are for production, a CNC can meet them.

Conclusion

This post has produced a collection of data on CNC machining, its working principle, applications, limitations, and advantages. You are also encouraged to visit the Linquip website to learn more about these machines, as well as to find providers of additional industrial and commercial items. You can also visit our CNC Milling Machines Suppliers and Companies to find out a complete list of CNC machine products and suppliers.

FAQs about CNC Machining

1. How Does A CNC Machine Work Step By Step?

In order to move and control the machine axes and carry out the preprogrammed movements, the CNC controller collaborates with a number of motors and drive components. The advanced feedback system that continuously analyzes and modifies the cutter’s speed and position is often present on industrial equipment.

2. What Is g-Code and M Code?

The machine control language, often known as M code or G code, governs the whole program. M code governs the machine’s activities, whereas G instructions define locations. Although M stands for many codes, some people refer to it as machine code since it manages specific equipment functions.

3. How Many Types Of CNC Machines Are There?

CNC machines come in eight different varieties: mills, routers, lathes, plasma cutters, laser cutters, water jet cutters, electrical discharge machines (EDM), grinders, and water jet cutters.

4. Is CNC Easy To Learn?

If you have a basic understanding of technical design, computer and arithmetic skills, and manual machining expertise, you may become proficient at writing G-code and 2d-CAM programs in just one week.

5. Can You Teach Yourself CNC?

Given a rudimentary understanding of math and an understanding of how milling functions, learning very basic CNC programming is simple. Usually, you can master this within a few days. While learning advanced CNC programming might take many years, learning intermediate programming abilities can be taught in a year.

6. What Are The Main Components of a CNC Machine?

Three fundamental parts make up a computer numerical control (CNC) system: processing apparatus, often known as a machine tool, a machine control unit, and CNC software, which is a set of instructions.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What Is CNC Machining & How Does It Work? (A Comprehensive Guide)

- 13 Parts of CNC Machine + Function & PDF: A Clear Guide

- 10 Best CNC Machines & Routers for WoodWorking (Clear Guide)

- 10 Types of Molding Machinery + PDF (Clear Guide)

- A Full Explanation on Types of Servo Motors

- Types of Synchronous Motors: A Full Description

- Universal Motor: a Simple Guide to Construction, Types and Working

- The Good Guide to Types of Electric Motors

- Synchronous Motors: Definition, Working Principle, Types, and Applications

- 4 Different DC Motor Types and Their Applications

- Brushed DC Motor: A Comprehensive Explanation of Working Principle, Parts, and Types

- Types of Induction Motor: A Concise and Useful Guild

- What is AC Motor ? Types, Principles and Constructions

- 11 Types of Drilling Machines and Their Usages