Various types of crimping tools are available, each with its own advantages and disadvantages. Typically, a manually operated crimping tool will suffice for smaller crimping requirements, where precision is paramount. However, hydraulic and electrical models are also available when more power is required.

We provide you with a wealth of information about crimping tools to help you gain a broader perspective. Linquip can help you in a number of ways; you can find out more about them on our “Tools and Instruments” webpage based on your intended use.

Do you have trouble choosing the right crimping tools? Linquip offers a list of Tools and Instruments Products, so you can choose the best tool for your application. Linquip’s online form allows you to get quotes quickly from a wide range of Companies and Suppliers offering Tools and Instruments.

In order to ensure reliable terminations, good crimping requires the right tool. However, selecting the right tool can be challenging when there are dozens of options available. Take the time to learn about crimping tools so that you can perform your work more efficiently.

Basics of Crimping Tools

In crimping, metal pieces are joined through the deformation of one or both of them, and this deformation is the “crimp”. A crimping tool creates this connection.

Typically, crimping is used to connect wires together or to other connectors in electrical work. A crimp connector is a fitting that attaches to the wire using this method, usually with an insulated sleeve attached to a metal connector. Crimping tools are used to form a secure electrical connection that is tightly sealed against gas and moisture, preventing shortages or damaged connections.

Additionally, mechanics and engineers use crimping in manufacturing, where they crimp a variety of different objects.

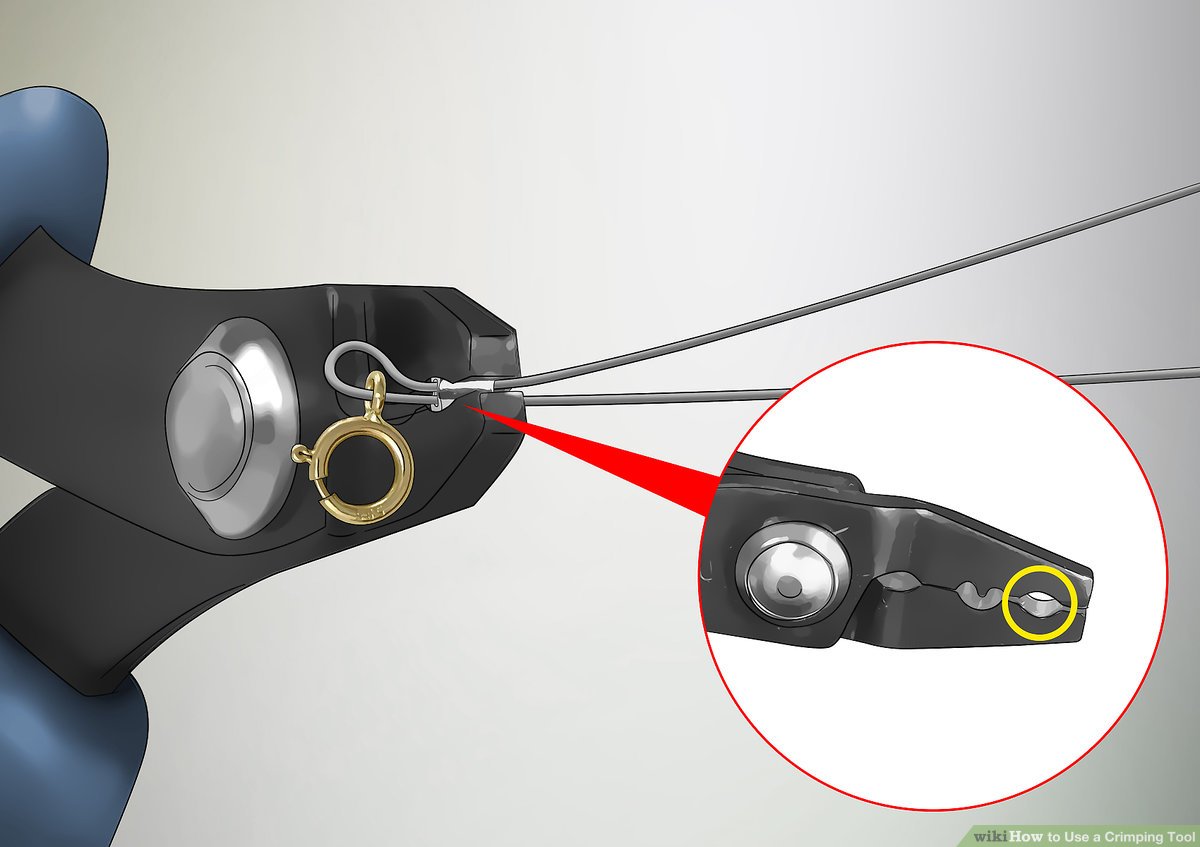

There are many types of electrical connections that rely on terminals (bolt-down or push-fit connectors) that have an open end crimped on the bare ends of wires. A crimping tool squeezes the crimp shut, forming a secure connection between the terminal and the cable. The terminals, often simply referred to as crimps, are usually made of metal and covered in PVC or nylon.

Crimping Tools: What Do They Do?

Crimp tools come in all shapes and sizes and are used in a variety of settings, but they all serve the same function – to create a strong and reliable bond.

It is common for electricians, mechanics, and engineers to use crimp tools during the installation or replacement of cables or wires. Crimp tools are often used to precisely attach the wiring heads to connectors and terminals.

As opposed to solder, electrical crimps are mechanically stronger, but they must remain gas-tight – impermeable to oxygen and moisture – in order to protect the metals within the circuit from potential corrosion damage.

Using crimp tools, electricians fix ferrite beads to wiring to prevent electromagnetic interference and control the flow of current. Ferrite beads are ceramic and iron alloy blends, which also play a crucial role in electrical insulation.

If a fine wire is being used, crimp tubes or crimp beads tend to be a very important part of the manufacturing of jewelry in terms of developing secure joints. During the process of securing a utility meter or even sealing a container containing cargo, a crimped lead appears to indicate interference graphically.

Types of Crimping Tools

AWG (American Wire Gauge) is a measurement of cable (or wire) thickness. The crimp, often called a terminal, must match correspondingly for the connection to function.

The thinnest gauge in common use is 18 gauge (0.04 inch), which measures around a hundredth of an inch in diameter. AWG 4/0, on the other hand, is about 0.5 inches across. Larger cable diameters are generally indicated as MCMs (which stand for thousands of circular mils) and are bigger than 1.5 inches.

The different sizes of cables can be attached to different terminals, so there is no one crimping tool that can handle all jobs. Crimping tools can be handheld, hydraulic, or hammer-type.

Handheld

The most common crimping tools are handheld. They’re usually cheap and versatile. The size of these crimpers varies. Some are small enough to fit in the palm of the hand and are intended for high-precision tasks (like small terminals or wire splices), while others are long enough to provide the leverage necessary for heavy-duty crimping.

Although most use a simple squeezing action, as do ordinary pliers, ratchets are often used to apply consistent, repeatable pressure. The jaws vary in size and type to accommodate terminals of different sizes and types. Some portable crimping tools have interchangeable jaws to maximize range. Also included in the tool may be wire strippers and/or small bolt cutters, making it a multipurpose tool.

Hydraulic

Although hydraulic wire crimping tools can be automated for production lines, most of these tools remain manually operated. An oil-filled cylinder is actuated by a lever, resulting in a tremendous increase in output pressure. Typically, hydraulic crimpers are rated based on the force they can apply. It is usually expressed in tons per square inch (ranging from 8 to 16), which shows how much power they can exert.

The interchangeable crimping dies of a hydraulic crimper allow it to handle medium-size terminals, although they are often used in heavy-duty applications. These steel jaws are specially designed to close the crimp firmly. It is common for tools to include a selection of these—an example might consist of 8 AWG (0.12 inch) to 0-250 MCM (0.68 inches).

It is easy to use hydraulic crimping tools, but they require some maintenance. If air gets into the cylinder, for example, it may reduce performance, so the cylinder needs to be purged. It is also necessary to change oil seals on a regular basis.

Hammer

Typically, hammer crimping tools are low-cost, so they are ideal for occasional crimping needs. As well as being robust and compact, it is also a tool that can endure tough environments and is commonly used in automotive shops and other places where heavy-duty crimping is necessary.

In a hammer crimper, there are no dies; instead, there are height-adjustable wedge-shaped rams on sliding carriages with V-shaped grooves at the base, where the crimp and cable need to be placed.

Crimping is done by hitting the wedge of this crimper with a hammer, preferably a sledgehammer, but any heavy hammer will do. A bench vise can also be used for gripping the ram.

Types of Crimping Tools Based On Applications

The following are some additional types of crimping tools that are used across many industries and environments:

Bootlace Crimping Tool

This tool is designed for crimping bootlace ferrules/crimps, which are metal tubes with a color-coded insulation collar. The wire sizes they can handle range from small to large, and they are often used in screw terminals to prevent multiple core wires from splitting.

If you want to crimp well without having to strain your hands, choose a high-leverage one. You can also opt for the plier version to fit a broader range of sizes.

Thin Cable Precision Crimping Tool

Using traditional hand crimping tools is not always possible when working with thin cables because there is little margin for error. To overcome this problem, use a crimping tool with a ratchet feature, which helps to control the crimp to eliminate human error, resulting in a perfect crimp every time, even with smaller cables.

Crimping Tool for QM & IP68 Connectors

Designed for crimping QM and IP68 connectors, these tools are ideal for connecting mains control leads as well as small transmission systems.

This tool is capable of handling QM connectors with wire sizes up to 24 AWG as well as IP68 connectors with wire sizes up to 28 AWG, which makes it a versatile choice.

Crimping Tool for Splice Connectors

Instead of using a generic crimping tool, you need a tool that is specifically designed for crimping splices, including gel-filled or butt splices.

Crimping Tool for Coaxial Cable

Coaxial cables have an inner conductor and a conducting shield, making crimping them difficult. They can be used to transmit high-frequency signals, such as broadband internet.

Coaxial cable crimping tools are generally categorized based on their impedances (calculated in ohms), so be sure to pick a tool that matches the cable type you have.

Auto Electrical Crimping Tools

There are multiple electrical connectors and cables within car engines that require sturdy joins, and automotive electrical crimping tools are intended to provide these. The tools are available in standard plier designs for non-insulated, pre-insulated, battery, and ignition terminals.

Mini Crimping Tools

Crimp pins are designed for smaller wire widths and are useful for applications that require close precision, flexibility within tight spaces, or rotatable flip-top heads.

PEX Crimping Tools

Cross-linked polyethylene (PEX), a flexible plastic material, is replacing copper or steel in the manufacture of water pipes.

Plastic tubing can be installed and joined much more easily than copper or steel tubing. It doesn’t need welding, just a specialized PEX crimping tool that grips it firmly. These tools are typically used in conjunction with steel clamps, so they’re accessible to both DIYers and professionals.

Amp Crimping Tools

Multi-pin amp connectors are typically housed in a plastic housing and can be crimped using specialist amp crimpers.

RJ45 Crimping Tool

An RJ45 crimping tool is a versatile and powerful handheld tool that is compatible with CAT5e, CAT6, CAT6A, and CAT7 connectors.

RJ9 Crimping Tool

This handheld tool has three dies (crimping heads) that accept standard connector types RJ45, RJ11, and RJ12. Due to its adaptability, engineers can perform repairs and installations with fewer tools.

Download PDF for Types of Crimping Tools

To read the article and print it out for future reference, here is the link for the PDF version.

linquip.com-Types of Crimping Tools

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- 13 Types of Adjustable Wrench: Clear Guide

- 12 Types of Industrial Sewing Machine + Advantages

- 5 Different Types of Drill Bits for Wood: A Comprehensive Guide

- 18 Types of Machining Vises (Clear Guide)

- 28 Types of Clamps: A Complete Guide

- 16 Types of Scaffolding + Components & PDF

- 27 Types of Plumbing Tools + Table of Characteristic & Usage

- 13 Types of Rivets + Applications & Working Principle

- 7 Types of Solder + Working Principle & PDF

- 9 Types of Pop Rivet + Working Principle (Clear Guide)

- 4 Types of Solid Rivets + Working Principle

- 3 Types of Magnets + Name & Applications

- 10 Types of 3D Printing: A Comprehensive Guide

- Types of Electrical Wire + Application (Complete Guide)

- 9 Types of Blind Rivets + Working Principle & Applications

- 17 Types of Hinges and Hinge Materials: A Complete Guide

- 27 Types of Screwdrivers + Names (Comprehensive Guide)

- 33 Types of Pliers & Their Names: A Comprehensive Explanation

- The 6 Best PETG Filament + Tips For Choosing

- The 10 Best Staple Guns + Buying Guide

- The 10 Best Wire Crimping Tool + Buying Guide

- Types of Drill Bits for Metal: Comprehensive Guide

- All 24 Types of Drill Bits + Video: Clear Guide

- Different Types of Bolt Heads + Benefit of Bolts and Nuts

- Different 5 Types of Fasteners: A Practical Guide

- 20 Types of Tool Kits + Table with Characteristics and Usage