In today’s article, we will discuss all types of drill bits and their uses, which will assist you in selecting the right drill bit for your project. Drill bits come in a wide variety, which can be a little overwhelming. You need to choose the right drill bit so you can save the most valuable resource of all – your time. Understanding the different types of drill bits and choosing the right one for your project is therefore essential for peak efficiency.

In order to assist you in making an informed decision, Linquip offers a wealth of information on drill bits. To make your job easier, Linquip offers you access to the best drilling tools on the market right now. On our “What Are Drilling Machines?” page, we explain what Linquip can do for you based on your intended use.

Will you be purchasing a drill bit soon? Linquip’s extensive selection of Drilling Machines Products will help you find the right tool for your application. Linquip’s platform enables you to request quotes on drill bits. You can obtain quotes directly from multiple Drilling Machines Suppliers and Companies by filling out our free online form.

Due to the increasing popularity of drills at home and at work, drill manufacturers created a wide variety of drill bits suited to specific materials and tasks. The purpose of this guide is to introduce and explain all types of drill bits and how they can be used for DIY projects.

Drill bits can be classified into the following types:

- Twist Drill Bits

- Flat Drill Bits

- Spade Drill Bits

- Brad Point Drill Bits

- Auger Drill Bits

- Straight Fluted Drill Bits

- Double Fluted Drill Bits

- Multi Fluted Drill Bits

- Countersinking Drill Bits

- Centre Drill Bits

- Counter Boring Drill Bits

- Installer Drill Bits

- Shell Drill Bits

- Step Drill Bits

- Spirec Drill Bits

- Masonry Drill Bits

- Rivet Drill Bits

- Plug Cutters

- Core Drill Bits

- Hole Saw Bits

- Glass Bits

- Hammer Bits

- Forstner Bits

- Tile Bits

A Brief Introduction

Drill bits are rotary cutting tools that make holes. A drill chuck clamps the shank – the back end – of the bit into place while the bit’s point contacts the material being drilled. Drill bits penetrate materials by rotating with downward pressure. A high carbon steel or alloy steel is used in its construction.

Professionals and DIYers use drill bits to complete a wide range of DIY projects around the home and on the job site. Among the pros who use drill bits are electricians, carpenters, and plumbers. A drill is commonly used by home DIYers to mount heavy objects, such as flat-screen televisions or shelving. You can, however, drill straight through the brick wall by using the right drill bit and drill type. You just need to caulk the hole after the wire run is complete.

Different Types of Drill Bits

Now it’s time to get into the nitty-gritty! Here is a list of the most common drill bits and what they are used for.

Twist or Standard Drill Bit

Using a screw format, the twist bit combines twin cutting edges with dual grooves (also called flutes), which pull away swarf (waste) from your workpiece. They’re the ultimate tool for DIYers and trade pros, due to their versatility, multi-medium compatibility, and multi-drill functionality. Although they aren’t the best type of drill bit for concrete, these boring heads can be used on acrylic, plastic, and sheet metal. A thin rod of alloy steel is generally used for this type of drill bit.

Flat Drill Bit

High Carbon Steel is typically used for flat drills, and their cutting edges are usually hardened and tempered. Due to their easy customization and low cost, flat drills are commonly used for drilling in soft metals and carpentry work.

A flat drill isn’t used to drill holes in iron material, but its biggest advantage is that it can drill holes in solid metals, and its cutting points can remain at a 90-degree angle, unlike any other type of drill.

Spade Drill Bit

There is a sharp point in the center of a spade bit, and material flares out on either side. Large sections of material can be removed with spade bits.

The bit’s sharp point prevents it from skating on smooth surfaces, while the flared wings score the outer perimeter of its circle as the blades chip away. Its scoring motion severs the wood fibers and minimizes tear-out in wood, making it an excellent choice for wood.

Brad Point Drill Bits

There is no doubt that these types of drill bits are the best for wood drilling. They deliver clean holes into wood, reducing the risk of splintering and cracking and differ from the twist format by their distinctive W-shaped heads.

For accurate and reliable anchorage, the center of the ‘W’ – the point – goes through the timber. In use, the wing of the ‘W’ spins around this axis while the flutes remove wood chips.

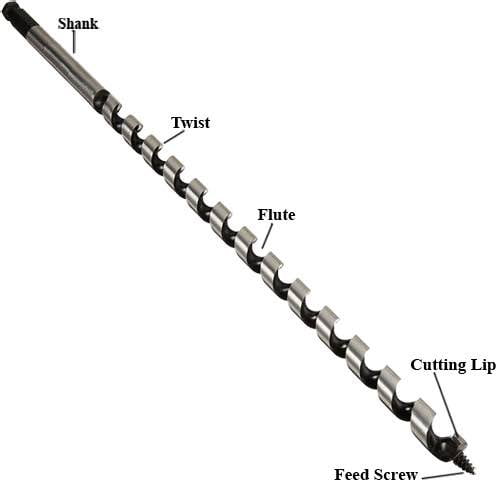

Auger Drill Bit

An auger is the best option if the brad bit lacks the grunt needed for your wood products. Auger bits are utilized for substantial woodworking tasks that require either a large borehole or dense timbers to be addressed. It begins by penetrating the wood with a screwhead at its business end. In addition to securing the anchor – like the brad point – it also aids you in driving the bit into the material with less physical energy. The twin spurs around this screw cut into the wood, while corkscrew grooves draw the detritus from the wood.

In order to use these boring heads – which come in larger diameters compared to brad point bits – you will need a 0.5-inch chuck.

Straight Fluted Drill Bit

This Straight Fluted Drill is characterized by flutes or grooves which run parallel to the axis of the drill, but it is not recommended for standard practices and cannot be automatically removed.

The Straight Fluted Drills are used primarily for drilling copper, drilling brass, and drilling other softer materials.

Double Fluted Drill Bit

The best and strongest drill is this type. In this drill, two flutes are cut opposite each other. A wide variety of tasks can be carried out with it.

Multi-Fluted Drill Bit

Special jobs require this drill. More than two flutes are present in this drill. This tool’s distinguishing feature is that it bores holes quickly and cleanly because of its larger cutting edge.

Counter Sinking Drill Bit

Countersinking involves drilling holes in places where counter head screws will be installed. In addition, the cutting point of the ground is at 60 degrees or 82 degrees.

Centre Drill Bit

As a combination drill, a Centre Drill can simultaneously countersink and drill, and it is also used for fastening.

Counter Bore Drill Bit

Counterboring drills are also called counterboring cutters. Whenever Allen Screws are fitted on the work surface, then counterboring is a working drill.

A counterboring drill is generally used to enlarge a hole, and to bore a hole as high as the screw head. Moreover, the boreholes are angled from top to bottom from 60 to 82 degrees.

Installer Drill Bit

Installer bits are among the most innovative drill bits out there. Using this drill accessory, you can install thin wiring for security alarms, CCTV, and AV entertainment equipment. Suitable for wood, plaster, and semi-dense masonry, these borers come in sizes up to 18 inches. After the bit penetrates the material and emerges on the opposite side, insert a wire into a small eye on the bit tip, then retract the bit allowing the cable to be pulled through the hole. With this method, you are able to pass electrical wiring through even the tiniest gaps for a neat finish.

Shell Drill Bit

Shell drills are a distinctive type of drill that consists of four flutes. Their tops are 1/3″ / Foot in taper shape and look like face cutters and side cutters.

It is generally used to enlarge boreholes as well as milling works.

Step Drill Bit

This boring tool is designed for metal workers, not for carpenters. Designed for boring into sheet metal – up to 0.25 inches deep – these bits feature a stepped pyramid shape. As the boring head penetrates, the hole size gradually increases – reducing the chance of slicing and damaging base materials while allowing you to drill numerous-sized holes using a single tip. The bits have an imprinted index indicating the drilling width for each step. Also, it is typically equipped with a groove for removing metal burrs and shards.

Spirec Drill Bit

A Spirec Drill is a delicate type of drill that is also used for boring holes such as spray pump nozzles. Their sizes range from 0.0086″ to 0.0984”.

Masonry Drill Bit

There is no doubt that masonry drill bits for concrete are the ultimate drill bit types due to their enormous strength.

Usually carbide-tipped, these powerful plows can penetrate concrete, brickwork, hardcore, and render. They are robust, durable, and can be used with rotating machines and hammer drills.

A rotary drill and SDS masonry head are needed to address the densest concrete.

Rivet Drill Bit

Thin metal sheets can be drilled with rivet bits due to their special design.

Plug Cutter

In professional projects, plug cutters are useful for drilling holes into the wood; if you are cutting wood plugs you need to cover recessed fasteners.

Core Drill Bit

A drill bit with this shape is probably the easiest to identify of all drill bits. There is a thin shank attached to a rounded cup in the core bit. With a hollow center, it only cuts the outside of a hole, leaving the center untouched. As soon as the cutting is complete, the cutting material can be removed in a single piece.

In masonry and brickwork, these bits are used to create substantial holes in order to accommodate sewage and drain pipes, HVAC ducts, and extractor fan flues.

You will need a rather powerful drill if you plan on drilling a big hole in such dense material. These bits can only be used with rotary drills due to their capacity and power.

Hole Saw Bit

Hole saw bits perform the same function as core bits, but they are used for masonry instead of timber. With its cup-like head and larger tenon-like teeth, it’s usually used to create wire and pipe channels.

Glass Drill Bit

A glass drill bit can be used for drilling glass, plastic, brick, hollow brick, marble, composite material, and and others. It can also withstand high temperatures.

Hammer Drill Bit

Using this Hammer Drill Bit, a precise hole can be drilled into the slab in order to ensure relative humidity and completion.

Forstner Drill Bit

Forstner bits are characterized by relatively narrow shanks and round block-cutting heads. Most drill holes have an angled bottom, but these borers produce wide, circle-shaped boreholes with flat bases. Their precision makes them ideal for creating openings for dowels, studs, and hinges.

It’s possible to use them with any rotating drill – but it is not recommended to use them with anything but pillar presses. By not using one of these precision-centric bits in a perpendicular drill, the drill will produce an uneven or less-than-level hole – defeating the purpose.

Tile Drill Bit

Home DIYers or trade professionals may find drilling into tiles challenging.

When boring a hole in ceramic or porcelain tile, these carbide-tipped cutting heads reduce the risk of chips, cracks, and breaks. These are crucial for the installation of showerheads and soap dispensers in the bathroom and kitchen. You can use them with any rotational drill to get the job done.

Although tile-specific accessories are available, they don’t provide you with the license to be reckless. The drill/driver should have a variable speed range that allows drilling at a low speed between 400 and 600 revolutions per minute.

Conclusion

By selecting the right drill bit for your project, you’ll ensure effortless operation, safe handling, and rewarding results. Furthermore, when choosing your boring head, ensure that it is compatible with your drill type, has the correct diameter, and fits the chuck. The information above will help you drill like a pro! Thank you for reading this article and we hope the information was helpful to you.

Don’t hesitate to contact Linquip Drilling Machinery Experts if you have any questions about using or choosing drill bits. You can also find Drilling Machinery Service Providers on Linquip if you are looking for any particular service for your drilling tools.

Video for Drill Bits Types

Watch this video for a more visual explanation of drill bits.

Download PDF for Types of Drill Bits

You can download the PDF format of this post from the link provided here.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More On Linquip

- The 8 Best Cordless Drills + Buying Guide

- 7 Types of Masonry Drill Bits + Applications & Features

- The 8 Best Cordless Drills in 2022 + Buying Guide

- Different 5 Types of Drill Bits for Wood: comprehensive guide

- Types of Drill Bits for Metal: Comprehensive Guide

- 6 Types of Hammer Drills with Advantages

- 3 Types of Crimping Tools + Name & Their Uses

- 33 Types of Pliers & Their Names: A Comprehensive Explanation

- 27 Types of Screwdrivers + Names (Comprehensive Guide)

- 17 Types of Hinges and Hinge Materials: A Complete Guide

- Types of Electrical Wire + Application (Complete Guide)

- 9 Types of Pop Rivet + Working Principle (Clear Guide)

- 28 Types of Clamps: A Complete Guide

- 8 Types of O-Ring + Applications (Clear Guide)

- 12 Types of Industrial Sewing Machine + Advantages

- Different Types of Bolt Heads + Benefit of Bolts and Nuts

- Different 5 Types of Fasteners: A Practical Guide