Here is another article on a technical topic and about one of the engineering items and equipment. We have already talked about heat exchangers and their types in separate articles. Today we are going to take a more specialized look at this device and its construction. We want to elaborate on the Heat Exchanger Design. How heat exchangers’ buildings are constructed and whether they are all designed under the same rules or there are different methods for designing them is the main topic of this article. Join us until the end of this journey.

An Introduction to What Heat Exchangers Are

To better understand the main topic of this article, it is best to first have a simple definition of what a heat exchanger is and what it does. Heat exchangers are devices designed to transfer heat between fluids with different temperatures. The heat transferring process based on the type of heat exchanger can be gas to gas, liquid to gas, or liquid to liquid. This exchanging is conducted through a solid separator preventing direct contact of these fluids.

The suitability and compatibility of a fluid with a heat exchanger depends on the heat exchanger type being used and its materials. Some heat exchangers are suitable for most fluids including oil, water, and even Sea Water. For some corrosive fluids such as chlorinated saltwater, refrigerants, and acids, there is a need for other materials such as Stainless Steel and Titanium.

Other characteristics, such as materials used in construction, components and parts, a different mechanism for heat transfer, and so on will help to classify different types of heat exchangers. These characteristics also help us find which one is more compatible with given applications across a wide range of industries, and general use.

Now that you know what a heat exchanger is and how it works, let’s see what is going on with the topic and how they all differ in terms of design. In the following section, we will talk about the different types of heat exchanger designs.

Different Heat Exchangers Different Designs

There are so many heat exchanger designs available to choose from such: tubular, double-pipe, flat plate, spiral, and coil designs. The selection of one type of exchanger design relies on many factors. Most heat exchangers are classified according to their construction, working principle, and surface compactness which means the amount of surface area for the heat dissipating from or transfer compared to the physical size.

Some of the more common Heat Exchanger Designs and types include:

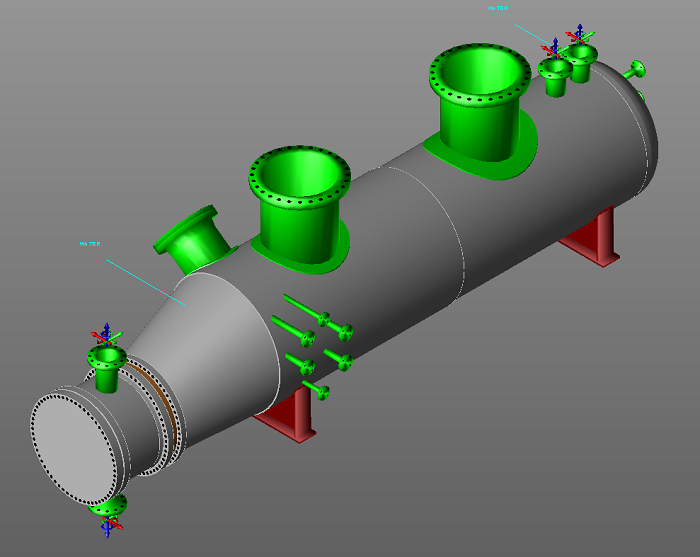

- Tubular and Shell Heat Exchanger Design

- Double Pipe or Hairpin Exchanger Design

- Flat Plate and Fin Exchangers

- Radiators and Solar Exchangers

- Spiral Heat Exchangers

- Air Coolers, Chillers, and Condensers

- Wet Cooling Towers

In the following, we will deal with only two types of designs in this regard, the tubular and flat plate designs. these two are the most common-in-use designs and types of heat exchangers so we chose these.

-

Tubular Heat Exchanger Design

The tubular heat exchanger has by far the simplest design. The primary fluid circulates through straight or concentric pipes in the form of a U-shaped tube design. these primary tubes are encased within an outer secondary tube that circulates the secondary fluid within. Their usual application is in small heat water-to-water transfer applications. The advantage of this type of design is flexibility since tubular heat exchangers can be added or removed whenever you ask.

Also, any number of heat exchangers can be connected. While being very simple and basic, the effectiveness of this type of single-pass heat exchanger design can be increased by having the directional flow of the secondary fluid in the opposite direction to the primary flow to improve heat absorption and efficiency. If both the primary and secondary fluids flow in the same direction, then this is called “parallel-flow”. If the primary and secondary fluids flow in the opposite direction, then this is called “counter-flow”.

-

Flat Plate Heat Exchanger Design

Flat plate heat exchangers are another common type of design which offers improved efficiencies for their size compared to tubular designs. Flat plate heat exchangers provide a relatively large heat transfer surface in a small space and can also operate at higher fluid pressures.

Flat plate heat exchangers are made from lots of thin metal plates joined or “stacked” together, with a small amount of space between each plate to allow the heat transfer fluid to circulate, extracting heat from the plates as it flows. These individual plates are usually joined together using rubber gaskets and seals to prevent leakage and direct the thermal fluids through alternate flow passages. Other types of flat plate heat exchangers include brazed or welded exchanger designs.

Because the surface area of flat plate exchangers is large, this allows for maximum contact between the two heat transfer fluids which provides for effective and efficient heat transfer. Just like the tubular design, the liquid flow of the two heat transfer fluids can be either parallel flow or counter flow direction with each plate having four apertures serving as inlet and outlet ports.

3. Plate-fin and Tubular-fin Heat Exchangers Designs

Plate-fin and tubular-fin heat exchangers are another more common type of thermal heat exchanger categorized as “compact heat exchangers”. They consist of plain, corrugated or louvered designed metallic fins that are bonded, brazed, or welded onto a series of flat, round, or rectangular tubes. This type of heat exchanger design has been used for many years either with individual fins or plate-fins in a wide variety of applications.

-

Compact Heat Exchanger Design

Compact heat exchangers get their name from the fact that their construction results in a very large thermal surface area within a small physical size. The compactness of the exchanger is usually given in so many m2/m3 of physical size, with surface area densities of over 1000m2/m3 now common.

Compact heat exchangers are commonly used as automotive water and oil cooling radiators, air conditioning applications, process, and waste heat recovery, ocean thermal energy conversion, geothermal, and solar thermal systems. Anywhere where there is a need for a small compact light-weight, space-saving, and economical heat exchanger.

As we mentioned before, a Heat Exchanger is a mechanical device that is used to transfer thermal energy between two or more circulating fluids at different temperatures. These fluids are usually separated by some form of the heat transfer surface, whether of a tubular, flat plate, or finned design. Heat exchangers are usually classified according to their construction, compactness, and the way they transfer the heat from the primary to the secondary fluids.

Heat exchanger technology and design have come a long way over the years and there has been steady progress to reduce the size and bring compactness of radiators, chillers, evaporators, and condensers to improve conversion efficiencies.

Conclusion

in this article, we tried to give you essential and comprehensive information about the different heat exchanger designs. we talked about the design and construction of some types of air heat exchangers which are used more commonly. Also, we elaborated on what each of these designs offers and does, and for what purpose they were designed. Besides, for better understanding, we brought some basic pieces of information about what a heat exchanger is. All we did in this article was an attempt to make choosing easier for you who are about to buy one.

If you have any experience of using different types of heat exchangers and know more about different designs, we will be very glad to have your opinions in the comments on our website Linquip. By the way, if you have any questions about this topic and if you still have ambiguities about this device in your mind, you can sign up on our website and wait for our experts to answer your questions. Hope you enjoyed reading this article.

Read More on Linquip

- Demystifying Heat Exchanger Sizing: A Comprehensive Guide

- Heat Exchanger Efficiency: Tips for Having an Efficient Heat Exchanging System

- Quick Guide On What Is Floating Head Exchanger

- Advanced Guide: What Is Tube In Tube Heat Exchangers

- What are Double Pipe Heat Exchangers and Their Working Principles?

- Types of Heat Exchangers: An Introduction to All Essential about Specifications

- Heat Exchanger vs. Chiller: Which one is the best?

Very useful information given in detail

Thank you for your attention

Nice information, but please topic wise more image provide.

Thanks for visiting our website! We also encourage you to visit the Linquip website, where you can find numerous industrial equipment, along with companies and experts.

I need to designe falling film evaporator for Chillers

We need designe knowledge