Here, we will elaborate on Temperature Sensors completely. A Temperature Sensor is a piece of electronic equipment that detects the temperature of its surroundings and transforms the incoming data into electronic output data to control record or signal temperature variations. There are several types of temperature sensors. Some of them need direct contact with the physical target that is being identified, which is introduced as contact temperature sensors. In contrast, others sense the temperature of the targets indirectly, which is described as non-contact temperature sensors.

Temperature Sensors quantify the quantity of heat energy or even coldness produced by an item or system, allowing us to “sense” or detect any physical change in that temperature, generating an analog or digital output. A temperature sensor is an important product of employing Industrial Tools. Temperature Sensors are provided by several suppliers and companies, different Manufacturers, and a lot of Distributors and there are a lot of Temperature Sensors For Sale on Linquip.

There is a complete list of temperature sensor services on the Linquip website that meets all of your needs. Linquip can connect you with a number of temperature sensor service providers and experts who can help you. Linquip offers a team of temperature sensor specialists and subject matter experts available to help you test your equipment.

Here we want to present to you what a temperature sensor is and what its working principles are, what the applications are, and what its various types are.

What is the Temperature Sensor?

Temperature sensors are simple devices that sense the degree of cold or heat and transform it into a simple unit. But, do you ever think about how the temperature of the soil, land boreholes, great concrete dams, or houses is detected? Well, this is done by using some of the particular temperature sensors. Visit here to see what is a temperature sensor clearly.

We employ them in various applications in our daily lives, such as domestic water heaters, refrigerators, microwaves, or in the form of thermometers. Generally, they have a wide range of usages, and the geotechnical controlling area is one of them. They are utilized in this field to control the condition of concrete structures, bridges on soil or water, etc., for structural variations in them according to seasonal changes.

Temperature sensors are constructed to monitor a regular check on special structures like highway bridges, railway tracks, concrete or soil dams, etc. A thermometer is the most common form of them applied to sense the degree of temperature everywhere.

A thermocouple is another common example of them. Thermocouple, or briefly T/C, is constructed from two different metals that produce an electrical output voltage in direct relation with the temperature modification. Another example of them is an RTD (Resistance Temperature Detector). RTD is a variable resistor that modifies its electrical resistance directly with the variation in the temperature. The sensing of an RTD is too repeatable, precise, and nearly linear.

Temperature Sensor Working

As discussed before, a temperature sensor is an instrument that is constructed to sense the condition of coolness or hotness in the target. The fundamental working of this sensor is based on the voltage in its diode. The temperature variation is directly related to the resistance of this diode.

The resistance of the diode is detected and transformed into simple and readable values of temperature such as Fahrenheit, Kelvin, or Centigrade and demonstrated in meaningful formats instead of readout values. These temperature sensors are employed to sense the internal temperature of various structures like power plants. Click here to see precisely how is the proportion of diode’s resistance & temperature variations.

The fundamental principle of the temperature sensors operation is the voltage modification in the MOSFET terminals. If the voltage reduces, the temperature also decreases, according to the voltage drop between the emitter in the MOSFET and terminals of the base sensor.

In addition, some devices have a type of vibrating wire in the structure of the sensor that operates on the principle of stress variations followed by temperature modifications. The vibrating wire is modeled depending upon the function of different metals. They have various linear coefficients with temperature variation in their expansion.

They fundamentally include a magnetic wire which has high tensile strength. Two sections are set to dissimilar metals that any variation in temperature influences the tension in the wire directly and, therefore, its main frequency of vibration.

In modern and high-tech temperature sensors, the basic metal is aluminum because aluminum has a greater coefficient of a thermal effect than steel. As the temperature sign is transformed into frequency, the readout values utilized for other vibrating sensors can also be used to control the temperature.

Temperature Sensors Formula

The frequency related to the temperature is also proportional to the tension ‘σ’ in the wire, can be described as follows:

f = 1/2 * [σg/ρ] / 2L (Hz)

Where:

σ = tension of the wire

ρ = density of the wire

L = length of wire

g = acceleration due to gravity

Types of Temperature Sensor

Temperature sensors are present in various types, sizes, and shapes. However, two main classifications are Contact and Non-contact sensors.

Contact Type Sensors are a group of sensors that detect the degree of temperature in an object by using direct contact with it. They can be employed to sense liquids, solids, or gases in a wide range of temperatures. Among them are thermocouples and thermistors. Thermocouples are typically cheap, as their model and basic materials are simple. The other common type of them is a thermistor. In thermistors, resistance reduces as temperature increases.

Non-Contact Sensors are not in contact with the object. So, they measure the temperature by utilizing the radiation of the heat source. The most common type of them is the infrared (IR) sensor. IRs detect the energy of an object remotely and emit a sign to an electronic circuit that senses the object’s temperature by a specific calibration diagram.

The contact and non-contact sensors are further classified into the following common sensors, which are introduced briefly.

Thermostats

A thermostat is a contact type sensor containing a bi-metallic section constructed from two different metals such as aluminum, nickel, tungsten, or copper.

The main principle of thermostats is based on the difference in the linear expansion coefficient of the metals. Therefore, it forces them to generate a mechanical movement due to heat rise.

Thermistors

Thermally sensitive resistors or briefly thermistors are particular sensors because of the modification of their physical appearance due to the change in the temperature. The thermistors are constructed from ceramic substances like oxides of particular metals covered with glass. It will allow them to form simply.

Some thermistors are NTCs and have a negative temperature coefficient. So, they will be introduced as a separate group of sensors in some textbooks. We will discuss them below completely. But there are a lot of thermistors that have a positive temperature coefficient. They are introduced as PTCs, and their resistance increases by increasing the temperature.

Resistive Temperature Detectors

RTDs are temperature sensors that are constructed from precise conducting metals like platinum covered in a coil. The electrical resistance of an RTD modifies due to the temperature variations.

Thermocouples

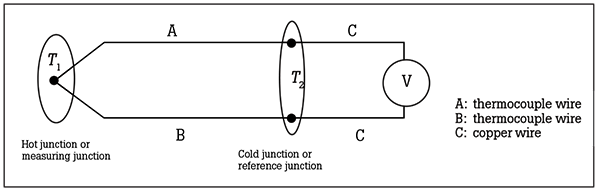

The thermocouple is one of the most popular temperature sensors because of its wide temperature range, accuracy, sensitivity, reliability, and simplicity.

A thermocouple generally includes two sections of dissimilar metals, such as constantan and copper, combined by welding. One of these sections, introduces as the Cold junction, has a particular temperature while the other one, introduced as the Hot junction, is for the measuring process.

Negative Temperature Coefficient (NTC) Thermistor

NTC is a particular type of thermistors that basically reacts directly to even a few temperature changes. The Negative Coefficient means that the thermistor presents a great resistance at low temperatures. Therefore, as the temperature increases, the resistance starts to drop immediately.

It can be said that even a small temperature variation can be detected accurately by the negative temperature coefficient thermistors according to the large resistance modification per degree Centigrade in them. Nevertheless, they require linearization because of their exponential operation principle. They normally work between -50 to 250 °C.

Semiconductor-Based Sensors

A semiconductor-based temperature sensor operates with two combined circuits or ICs. They include two similar MOSFETs with high sensitivity. They precisely provide electrical characteristics, including voltage and current, to measure the temperature variations. They approximately send a linear output but are less precise at 1 to 5 °C. They also present the slowest time responses between 5 to 60 s between temperature sensors in their temperature range.

Temperature Sensor Applications

As mentioned before, there are various kinds of temperature sensors, and the most common method to classify their application depends on the way of connection, which contains contact and non-contact sensors. Contact sensors like thermistors and thermocouples are directly related to the target they want to measure, while the non-contact sensors detect the thermal radiation emitted by the heat source. The main application of these temperature sensors is in hazardous locations like nuclear power plants.

Temperature sensors identify the heat of hydration in concrete structures in geothermal control. They can also be employed to control the migration of seepage or groundwater. One of the most usual methods of using them is in curing the concrete. It has to be warm in order to construct and cure appropriately. The seasonal modification causes structural expansion and changes its overall volume.

The other temperature sensor’s applications contain:

- The temperature sensors are employed for verifying model suppositions that will improve more economical and safer construction.

- They can detect rock temperatures in order to identify storage tanks of liquid gasses and the ground freezing process.

- Temperature sensors can also be used in land boreholes and reservoirs and to measure water temperatures.

- They are employed to interpret temperature in dams to reduce stress in volume variations and control the temperature variations on other installed instruments like curing concrete.

Why Do We Use Temperature Sensors?

When dealing with severe heat, risks, or inaccessible measurement sites, temperature sensors are used to guarantee that a process is either remaining within a specified range, providing safe usage of that application, or satisfying a mandated requirement. A thermometer includes two key components: (1) a temperature sensor (e.g., the bulb of a mercury-in-glass thermometer or the pyrometric sensor in an infrared thermometer) that changes when the temperature changes, and (2) a way of turning this change into a numerical value.

Advantages of Temperature Sensors

Temperature Sensors have some advantages in comparison with other practical instruments.

- Temperature sensors are low-cost, precise, and extremely reliable in repeated experiments.

- They are desirable for both embedded and surface mount applications.

- They have a faster response time because of the lower thermal mass.

- The vibrating wire type is normally full-interchangeable. It means that one indicator can be used for all sensors. It also has a particular technology for verifying long-term stability, simple and fast output.

- They generally have an IP-68 rate by their weather-proof body.

- They have some indicators that are suitable for direct temperature presentation. So, they can be used for remote detecting and data logging.

- Their temperature probes have precise linearity and low hysteresis.

- Finally, it should be said that temperature sensors are completely airtight. They are fully sealed by electron beam welding with a pure vacuum inside them.

Download Temperature Sensor PDF

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

- Types of Sensors Detectors/Transducers: An Entire Guide

- Transducer vs. Sensor: Basic Differences & Advantages of Them

- How to Wire Up Piezoelectric Sensor? A Comprehensive Guide

- Types of Humidity Sensor: A Full Explanation on The Most Common Types

- Temperature and Humidity Sensors: An Ultimate Guide

- what is temperature transmitters: simply find the definition, types and calibration

- Temperature Transducer: Definition, Working Principle, and Types

- Types of Temperature Sensor and Their Application

- Difference Between Actuator and Sensor: The Ultimate Guide

- What is Differential Pressure Sensor?: An Ultimate Guide

- 5 Types of Proximity Sensors (Application and Advantages)

- What is Humidity Sensor: Your go-to Guide on humidity Sensors!