A thermocouple is an instrument usually containing two different metal alloys generating a voltage based on the temperature difference between both sides of the conductors. Thermocouples are self-powered and need no external form of inducing in contrast to other methods of measurement. They have a junction part, which is the measuring point of the system, where the negative and positive parts of the thermocouple wire are combined. They are constructed from these junctions, which employ the Seebeck effect procedure to detect the temperature. They can usually be introduced as the Cold and Hot end junction, but this is a general term.

What is a Thermocouple?

A thermocouple is a sensor for temperature measurement. This sensor has two different metal wires, welded at one part and connected to a particular device at the other section. They can present measurement in a broad range of temperatures when configured appropriately.

When did the Thermocouple Originate?

Back in 1821, German researcher Thomas Johann Seebeck discovered the behavior of different metals when they are combined. He identified that temperature modifies between the parts and a particular magnetic field. This is introduced as the Seeback phenomenon.

The magnetic field was later detected to be a section of the thermoelectric process. The voltage produced from the two kinds of wire is what is utilized to detect the temperature in a wide range. The level of temperature sensing is based on the kind of wire material employed. The power can be produced from a thermocouple junction at a very low current.

Other scientists such as Michael Faraday and Georg Ohm utilized the Seeback effect to operate new experiments to understand the impact of temperature measurement further.

Thermocouples were constructed in the early 1900s from this identification and after more research throughout history. This technology has improved to what it is today. They are now utilized in many various applications, from medical manufacturing to industrial preparation.

Manufacturing of a Thermocouple

The Discovery of temperature sensing has continued the construction of the instrument to be simple but more efficient. The two metal alloys are joined to create a junction. One section of the junction is located on the main source to measure the temperature. The second section of the junction is kept at a constant temperature point. In addition, temperature sensing is based on the type of metal employed in the production of the thermocouple.

The production of a thermocouple is too simple. The manufacturers make the temperature gauges from the particular wires. Finally, a protective and insulated tube covers these wires. Designers of thermocouples sometimes decide the joining of different metals and need the new calibration for assembling. The usage of the thermocouple is based on the surroundings. The various materials and sizes are all factors noticed when production the particular type of thermocouple. However, the installation of a thermocouple is related to a pre-existing system in some cases.

They are too popular between temperature sensors for their versatility on a wide range of applications, from industrial use to common appliances. It is too considerable to know its basic features, how it operates, and its ranges, according to its broad models and technical characteristics, as to better specify what the best model and material of thermocouple for your particular application is. Visit here to see to explore more about various types of thermocouples fundamentally.

Types of Thermocouple

There are various types of thermocouples with different features based on their stability, vibration resistance, temperature range, durability, chemical resistance, and specific applications. The most common types of them are as following:

Beaded Wire

A beaded wire is the most common type of them. It contains two parts of wire combined with a welded bead. However, there are many application limitations because the bead of the thermocouple is restricted. For instance, the beaded wire should not be utilized with fluids that could oxidize or corrode the thermocouple alloy.

Metal surfaces can also have some difficulties; especially pipes are employed to ground electrical devices. The indirect connection with an electrical device could influence the sensing. Beaded wire types are generally a good option for gas temperature detection. Because they can be constructed too small, they also present response time immediately.

Thermocouple Probe

A thermocouple probe has a wire placed in a metallic tube. The sides of the tube are introduced as the sheath. Common sheath materials are normally stainless steel and rarely Inconel. Inconel supplies higher temperature levels than stainless steel, while stainless steel is usually selected due to its wide chemical adaptability. Other exotic sheath substances are also present at very high temperatures.

Surface Probe

Sensing the temperature of a solid plane is too problematic for most kinds of temperature sensors. The whole area of the sensor should be in direct contact with the surface to assure that the measurement is accurate. This is more difficult when operating with a strict sensor and a rigid plane.

They are constructed from particular metals, so the junction can be created flat to supply the maximum contact with a solid plane. They are the best options for surface measurement. The sensor can even be constructed in a process that circulates, making it desirable for sensing the temperature of a rotating surface.

Thermocouple types based on the Material

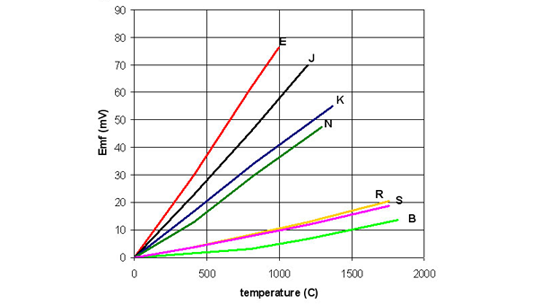

Thermocouples are present in various compositions of metals and have different calibrations. The most popular types are the “Base Metals” introduced as K, J, E, T, and N kinds. There are also Noble Metal thermocouples, which are high-temperature calibrations, including Types R, S, and B.

All calibrations have a different temperature level, whereas the maximum temperature modifies with the size of the wire applied in them . Therefore, a very small thermocouple cannot obtain the full temperature condition.

Type K (Nickel-Chromium / Nickel-Alumel)

This is the most usual form that presents the broadest operating range of temperature. Type K thermocouples typically perform in many applications because they are based on nickel and have proper corrosion resistance. They’re also precise, inexpensive, credible, and have a broad temperature range.

Key Design Attributes

- The most common base metal option for high-temperature applications.

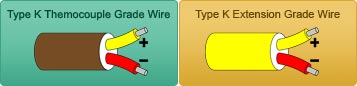

- Its Positive part is non-magnetic with a yellow sign, and its negative part is magnetic with Red sign.

- Proper for usage in corrosion or internal atmospheres at temperatures near 2500°F.

- Best operation in clean oxidizing atmospheres, while sensitive to sulfur exposing or sulfur-containing atmospheres.

- Not suggested for employ under partially oxidizing states in a vacuum.

- Its standard accuracy is +/- 2.2°C, and its Limits range of Error is +/- 1.1°C or 0.4%

Temperature Range

Its grade wire range is between –270 to 1260 °C, while its Extension wire range is between 0 to 200 °C.

Type J (Iron/Constantan)

This is the second popular type of thermocouples. It is an appropriate option for common applications when humidity is not present. It is similar to the Type K based on cost and stability while having a shorter range and a shorter life cycle than the Type K at high temperatures.

Key Design Attributes

- Proper for utilization in reducing and oxidizing atmospheres or in vacuum air up to 760°C.

- Its expected life period for the smaller wires is restricted according to the fast corrosion of the iron wire at temperatures more than 540°C.

- It should not be used in sulfurous environments of more than 540°C.

- Its Positive iron wire is magnetic with a white sign, and its negative wire is non-magnetic with a red sign.

- Its standard accuracy is +/- 2.2C or +/- .75%, and its special limits of Error is +/- 1.1C or 0.4%.

Temperature Range

Its grade wire is between -210 to 760 °C, while its Extension wire range is between 0 to 200 °C.

Type E (Nickel-Chromium/Constantan)

Type E has a higher resolution and more powerful signal than the Type K and Type J at limited temperatures.

Key Design Attributes

- Both parts are non-magnetic, but the negative part has a red sign, and the positive part has a purple sign.

- It is usually suggested for employment in oxidizing atmospheres up to 900°C.

- It is proper for low temperatures near -230°C.

- It has the highest output EMF (Electro Magnetic Field) of any common type.

- It is vulnerable to sulfur exposure.

- It can operate perfectly in clean corrosion atmospheres, while generally not suggested for use in oxidizing states.

- Its standard accuracy is +/- 1.7C or +/- 0.5%, and its special limits of Error is +/- 1.0C or 0.4%.

Temperature Range

Its grade wire range is between –270 to 870 °C, while its Extension wire range is between 0 to 200 °C.

Type T (Copper/Constantan)

The Type T is a very reliable thermocouple and is often employed in low-temperature conditions like ultra-low freezers or cryogenics.

Key Design Attributes

- Both parts are non-magnetic, but the negative part has a red sign, and the positive part has a blue sign.

- They are very reliable and humidity-resistant when used in the air.

- They are useful close to 370°C.

- They can be used in higher temperatures when employed in a vacuum or in reducing environments.

- They are proper to utilize down to -200°C; however, specific applications require particular materials.

- Its standard accuracy is +/- 1.0C or +/- .75%, and its special limits of Error is +/- 0.5C or 0.4%.

Temperature Range

Its grade wire range is between -270 to 370°C, while its Extension wire range is between 0 to 200 °C.

Type N (Nicrosil / Nisil)

Type N has similar accuracy and temperature level to Type K. However, this type is generally more expensive.

Temperature Range

Its grade wire range is between -270 to 392 °C, while its Extension wire range is between 0 to 200 °C.

Noble Metal Thermocouples (Type S, R, & B)

Noble Metal types are chosen according to their capability to tolerate high temperatures while keeping their cycle-life and accuracy. Nevertheless, they are generally more expensive than Base Metal types.

Type S (Platinum Rhodium – 10% / Platinum)

The Type S is employed in applications with very high temperature. It is usually found in the Pharmaceutical industries and Biotech technologies. In addition, it is occasionally utilized in lower temperature conditions because of its high reliability and precision. Its standard accuracy is +/- 1.5C or +/- .25%, and its special limits of error is +/- 0.6C or 0.1%.

Temperature Range

Its grade wire range is between -50 to 1480 °C, while its Extension wire range is between 0 to 200 °C.

Type R (Platinum Rhodium -13% / Platinum)

The Type R can be used in very high-temperature conditions. It has a higher volume of Rhodium than Type S, which causes it to be more expensive. This type is the same as Type S based on its performance. Its standard accuracy is +/- 1.5C or +/- .25%, and its special limits of error is +/- 0.6C or 0.1%.

Temperature Range

Its grade wire range is between -50 to 1480 °C, while its Extension wire range is between 0 to 200 °C.

Type B (Platinum Rhodium – 30% / Platinum Rhodium – 6%)

The Type B thermocouple is usually utilized in high-temperature applications. It has the highest temperature range among all of the thermocouples described before. It has a high level of precision and reliability at high temperatures. Its standard accuracy is +/- 0.5%, and its special limits of error are +/- 0.25%.

Temperature Range

Its grade wire range is between 0 to 1700 °C, while its Extension wire range is between 0 to 100 °C.

How a Thermocouple Works?

A Thermocouple works like an electrical instrument that employed to sense the temperature. They can tolerate high temperatures, heavy vibrations, and extreme pressure because of their accuracy and quick time response. These features make them suitable for various applications. Nevertheless, how does a thermocouple work?

Thermocouple Working Principle

The working principle of a thermocouple is based on the thermoelectric effect, or, Seebeck effect. It is the particular phenomenon of converting thermal energy into electrical output. The effect explains the process of electrical voltage when two different metals are combined and how the generated voltage changes with temperature.

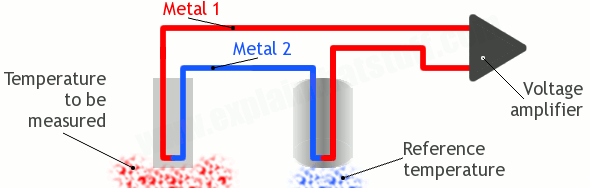

Their fundamental design includes two dissimilar wires which are touching, twisted, or welded in one part with different electrical characteristics at various temperatures. This part is introduced as the measuring point. The other part connecting to the voltage detector is the connection point. The electron density of both metal wires differs when the temperature varies at the measuring point. This modification of electron density is the voltage difference, which is sensed at the connection point.

It is important to consider that they do not sense the absolute temperature. They detect the temperature difference between the measuring and the connection section. As a result, they also require a cold junction alternative, which guarantees that the temperature sensing at the connection terminals does not vary the measuring result and allows more accurate sensing.

What you see above is the function of a thermocouple that detects the unknown temperature. It’s joined into a larger system with some feeding outputs and an electronic amplifier practically. This raises the very small voltage values between different parts of the circuit, such as the upper and lower section. So, it can sense the temperature more precisely.

Thermocouple Diagram

The diagram shows the features and properties of temperature vs. mV output for all types of base metal and Nobel thermocouples. It can be concluded that these sensors have a linear output approximately.

Thermocouple Selection and Special Features

Thermocouples are always utilized in industries because they operate in wide temperature levels. The following matters are considered in choosing a particular thermocouple:

- The chemical resistance or sheath substance

- The temperature ranges

- Installation considerations because they should be compatible with existing systems

- Vibration resistance and atmospheric pressure

You should notice the features and costs of the different detectors and particular systems. They can usually sense the temperatures in wide ranges, but they are not as precise as thermistors and RTD’s. Thermistors are the most accurate transducers, but they do not have a wide temperature range. They also have a self-heating problem.

RTD’s are more reliable and have a broad temperature state but are not as cheap as thermocouples. They need an electric current to sense the temperature. Nevertheless, have some inaccuracies due to self-heating. Infrared Sensors can be employed to sense temperatures higher than any of the other transducers. They can operate without direct contact with the devices being measured. Nonetheless, they are normally not precise and have reactions with the radiation efficiency. They can detect devices that have not a direct sign of sight by using fiber optic cables.

Response Time of a Thermocouple

A time coefficient has been introduced as the time needed by a detector to reach 63.2% of a step modification in temperature under particular conditions. Five-time coefficients are required for the sensor to be 100% in the step variation value.

The exposed junction type presents the most immediate response between all types. In addition, it should be said that the smallest sheath diameter probes can provide the fastest responses, but the maximum temperature should be reduced. However, the probe sheaths cannot tolerate the full temperature state generally.

Thermocouple Accuracy

They are not always used to present high accuracy and perfect performance in industries and science. Many thermocouple designers apply particular wires and techniques to supply the accuracy levels that are near the low-cost thermistors. Nevertheless, some applications need thermocouple wire with special grades that provide an interchangeable probe precision better than ±0.9°F in the range of 32°F to 212°F. This is more appropriate than most thermistors over the same range.

The accuracy of them can be increased by assembling the probe to a particular electronic circuit and evaluating them in a “system calibration”. This phenomenon reduces the problematic error of the individual thermocouple and helps reduce the measurement accuracy to a few tenths of a degree. New manufacturers present accuracies more proper than ±0.5°F in some thermocouple sensors.

Thermocouple Tolerances

Thermocouple wire is generally presented to tolerate temperatures more than 0°C. Some particular requirements and testing may be needed for their substances for them to operate within the sub-zero specific tolerances.

Thermocouple Wire Temperature Limits

Some limitations are provided to protect the systems. For instance, some thermocouples are constructed in protecting tubes and conventional closed-end sheaths.

Thermocouple Junctions

Thermocouple junctions are classified into 4 groups:

Grounded Thermocouples

This is the most usual form of junctions. A device is known as grounded when both thermocouple parts and the sheath are combined to create one junction on the probe. These kinds have an immediate response time because the thermocouple is in direct contact with the target, transferring heat simply.

The problematic matter is that it is more sensitive to electrical noises. This is owing to the fact that the sheath usually has contact with the surrounding section, causing interference.

Ungrounded Thermocouples (Ungrounded Common Thermocouples)

A thermocouple is known as ungrounded when its wires are combined, but they are separated from the sheath. The wires are usually insulated by mineral methods.

Exposed Thermocouples (Bare Wire Thermocouples)

A device is introduced as an exposed type when its wires are combined and inserted into the system directly. Their response time is too fast, but they are more sensitive to oxidization and corrosion. As a result, this form is not generally suggested.

Ungrounded Uncommon

An uncommon ungrounded type includes a dual thermocouple arrangement that is separated from the sheath. Each of the parts is also separated from the other one.

Should We Use a Grounded or Ungrounded Probe?

It is based on particular systems. For instance, in controllers with non-isolated inputs, there is a chance to be a link to the ground, so an ungrounded probe is necessary. Otherwise, in the instruments with a handheld meter, a grounded type should be used.

Advantages and Applications of a Thermocouple

Thermocouples are utilized in various scientific and industrial applications. They can be seen in all industrial markets, including Mining, Paper, Biotech, Cement, Power Generation, Oil/Gas, Pharmaceutical, Glass, and others. They are also employed in common usages like furnaces, stoves, pizza ovens, and kilns.

Why We Use a Thermocouple?

Thermocouples are normally chosen due to their 1-high-temperature limits, 2-low cost, 3-wide temperature level, and 4-natural stability. They are usually utilized in biotech and industries because they’re naturally too precise and can perform over a great range of actually cold and hot conditions.

They produce electric currents, so they’re beneficial for operating automatic senses. It’s easier to use an electronic circuit or a computer to detect a temperature at constant processes than to do it manually with a thermometer. They are also inexpensive compared to other transducers and durable enough to tolerate harsh surroundings because they are separated from metal strips arrays like other sensors.

Thermocouple Production Cost

The production of a thermocouple is too complex and is based on different requirements. There are various metals and materials for using to make the perfect type of them from low to the high-temperature range. Nevertheless, the total cost of their production depends on some variable and fixed costs during the process.

Between these variables, machine investment, staff salaries, cost of basic substances, and testing spending are the main subjects that should be considered in the completion of product making. Designers are often trying to decrease the production cost and obtain the final product quality more durable. But sometimes, the result is lower precision and immediate wire corrosion even under normal usage.

Finally, when we want to select the perfect one, the research and your constructor’s knowledge are more important. The correct temperature range of any production is essential for the operating of all temperature sensors.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Thermistor vs. Thermocouple: Complete Comparison & Practical Selection Guide

- Thermocouple vs. Thermopile: A Complete Comparison & Advantages of Each Type

- Thermocouple Types: A Complete Comparison Between Them

- Thermocouple for Water Heater: How does it Work?

- The Only Guide You’ll Ever Need For Different Type of Industrial Measuring Tools

- working principle of thermocouple: the operation is governed by 3 effects

Thanks a lot for your consideration

We encourage you to visit other posts in our blog.

One of the most engaging blogs i have come across. Very valuable and accurate information about thermocouple provided here. Yes they are in types and also with different properties.

Thank you for your consideration. Please check our other posts and comment.