Electric motors are everywhere, from the gadgets we use at home to the machines that power industries. But did you know that even the most efficient electric motors experience some level of energy loss?

Thankfully, there’s a way to reduce this to as low as possible, and it happens via a process termed electric motor lamination.

But what is lamination, and how does it help in saving energy? Let’s explore.

What is Electric Motor Lamination?

In the process of electric motor lamination, thin sheets of metal are incorporated inside the motor. Commonly, these are made of silicon steel. These are insulated from each other.

The primary aim is to minimize energy loss, which happens from overheating; therefore, the efficiency of the motor improves.

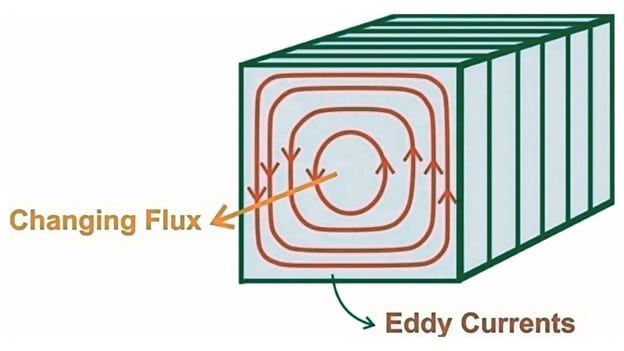

Unlike its solid core of metal, laminated cores reduce what is commonly known as ‘eddy currents’.

Eddy currents arise when a motor’s magnetic field induces electrical currents in the core material. Unless checked, such currents convert into heat, which then translates into wasted energy.

The lamination of a motor core in that case breaks such currents and increases efficiency.

With the quest for any business to ensure that motor efficiency is achieved, lammotor.com provides quality laminations.

They are involved in ensuring that motors will perform better by minimizing the loss of energy.

Why Does Energy Loss Happen

When some energy is lost in the production of heat, the efficiency at which a motor operates is lessened. This is because, within the core of the motor constructed from metal, electric currents flow.

If the core isn’t laminated, those eddy currents generate more heat and cause inefficiency. Over time, the efficiency of the motor depletes, while the electricity bills rise.

That’s where companies like Lam Motor come in. By applying advanced techniques of lamination, they reduce this energy waste and ensure that motors run cooler and last longer.

How Does Lamination Reduce Energy Loss

Here’s the cool part: when a motor’s core is laminated, it interrupts the flow of eddy currents. If these are not laminated, such currents would circulate in a current through a solid metal core. They would heat up and waste energy.

In such a case, laminating the core breaks these currents into pieces and makes it more difficult for such currents to form.

This, in turn, does the work by making the working of a motor more efficient, and energy-saving, and reduces the dissipation of unnecessary heat.

Another important factor is the silicon steel used in these laminations. It possesses unique characteristics that enhance its ability to minimize both electrical and magnetic losses.

Role of Silicon Steel

Silicon steel has the excellent characteristic of minimizing energy losses. It is less conductive; hence, eddy currents hardly take place in such materials. It even makes motors more efficient.

The lamination sheets come in different thicknesses, and they offer better performance. However, they can be rather expensive.

Business enterprises can re-balance between cost and performance with the help of companies like lamnow.com.

Where is Motor Lamination used

Motor lamination for an electric motor is used in every kind of motor. You could find it in small home appliances or large industrial machinery. For high-performance areas like electric vehicles, lamination is important.

Efficiency in the motors means cars can run on one charge for a longer distance. This will also involve very powerful motors operating with minimal loss of energy; this will increase their overall output and reliability.

Brands like Lam Motor and Lam Now supply lamination materials to a wide class of industries. They help in the smooth running of the motors, thereby helping save energy.

Conclusion

Lamination of electric motors is a rather simple but effective method for reducing energy loss. It cuts down the formation of eddy currents, thus allowing motors to run more efficiently and cooler.

More importantly, besides saving energy, the motor sustains longer life and becomes rather cost-effective for consumers and business customers alike.

Accordingly, for enterprises willing to enhance motor efficiency, companies like lammotor.com and lamnow.com provide quality laminating services.

These services can actually help you save energy and money in the long term.