Welcome to Linquip Blog. Today and in this article, we are going to have a look at Types of Synchronous Motor. As you may know, generally in electrical construction there can be two main types of mostly used motors. An electrical system can benefit from one of these electrical motors. The first one is called the synchronous motor and the second one is called the induction motor. We will explain the differences between these two electrical motors later and in another article. Here, we are going to discuss the types of synchronous motors and talk about their features.

Depending on your application, Linquip can assist you with all the information you will need to make an effective decision about the synchronous motors you require. We at Linquip will be able to provide you with any information you may need regarding the construction of a synchronous motor. You can begin by reading the Linquip article “What Is Synchronous Motor?“.

Are you looking for synchronous motor devices? You can browse a wide range of Synchronous Motor Products for free at Linquip. Where do you intend to buy synchronous motor products? Linquip offers free access to all Synchronous Motor for Sale. You can also contact Linquip to inquire about synchronous motors equipment or device prices and receive free quotations from Synchronous Motor Suppliers and Companies.

To have an overview of what you are going to encounter in the following, we have to say that in this article for those who are not familiar with the Synchronous motor, we have prepared a simple definition of what it is and how it works very concisely and briefly. In the 3rd section of this article, we are going to elaborate on the different types of synchronous motors and how they differ in construction and operation.

Our team gathered all of the necessary information on this topic to eliminate the need for reading diverse content on other websites. Stay with us until the end to find the answer to your question on this topic. We have a long journey ahead of us, so take a deep breath, sit back, and keep reading this article until the end.

⇒ View a List of Synchronous Motor for Sale and Their Suppliers ⇐

What Does a Synchronous Motor Do?

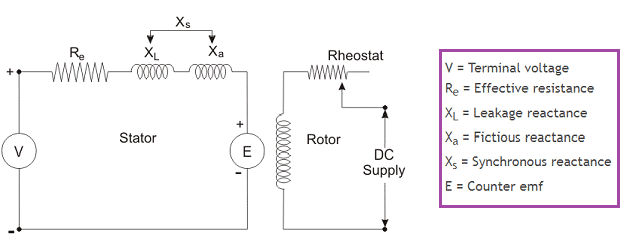

Electrical motors are an electro-mechanical machine converting electrical energy to mechanical energy. Electrical Motors have been classified into single-phase and three-phase motors based on the type of input. The most common types of three-phase motors are synchronous motors and induction motors. When three-phase electric conductors are placed in certain geometrical positions which means at a certain angle from one another, an electrical field is generated. The rotating magnetic field rotates at a certain speed known as the synchronous speed.

If an electromagnet is present in this rotating magnetic field, the electromagnet is magnetically locked with this rotating magnetic field and rotates at the same speed as the rotating field. This is why we call this type of motor synchronous motors, as the speed of the rotor of the motor is the same as the rotating magnetic field.

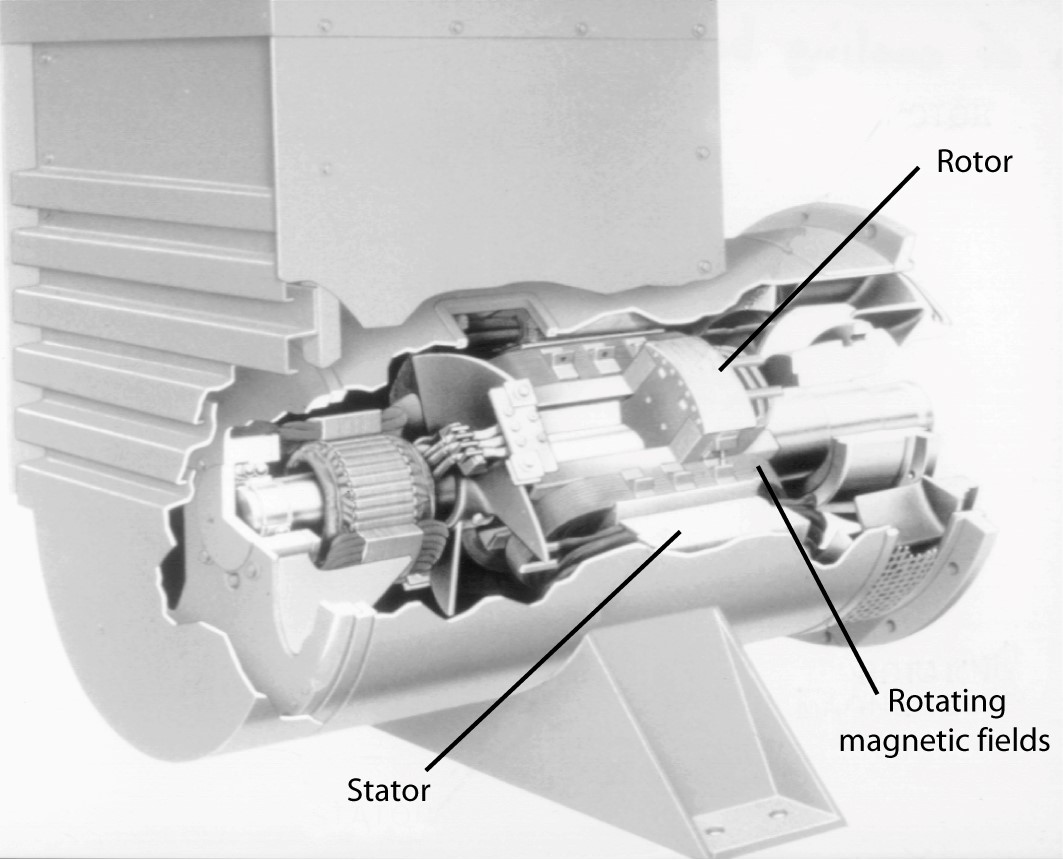

The Construction of Synchronous Motors

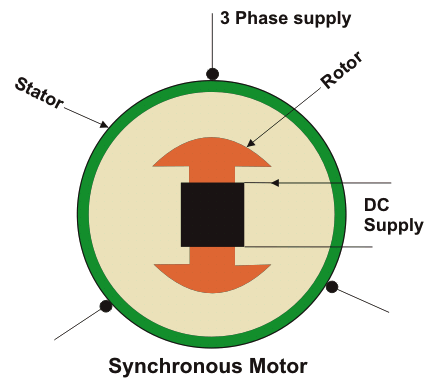

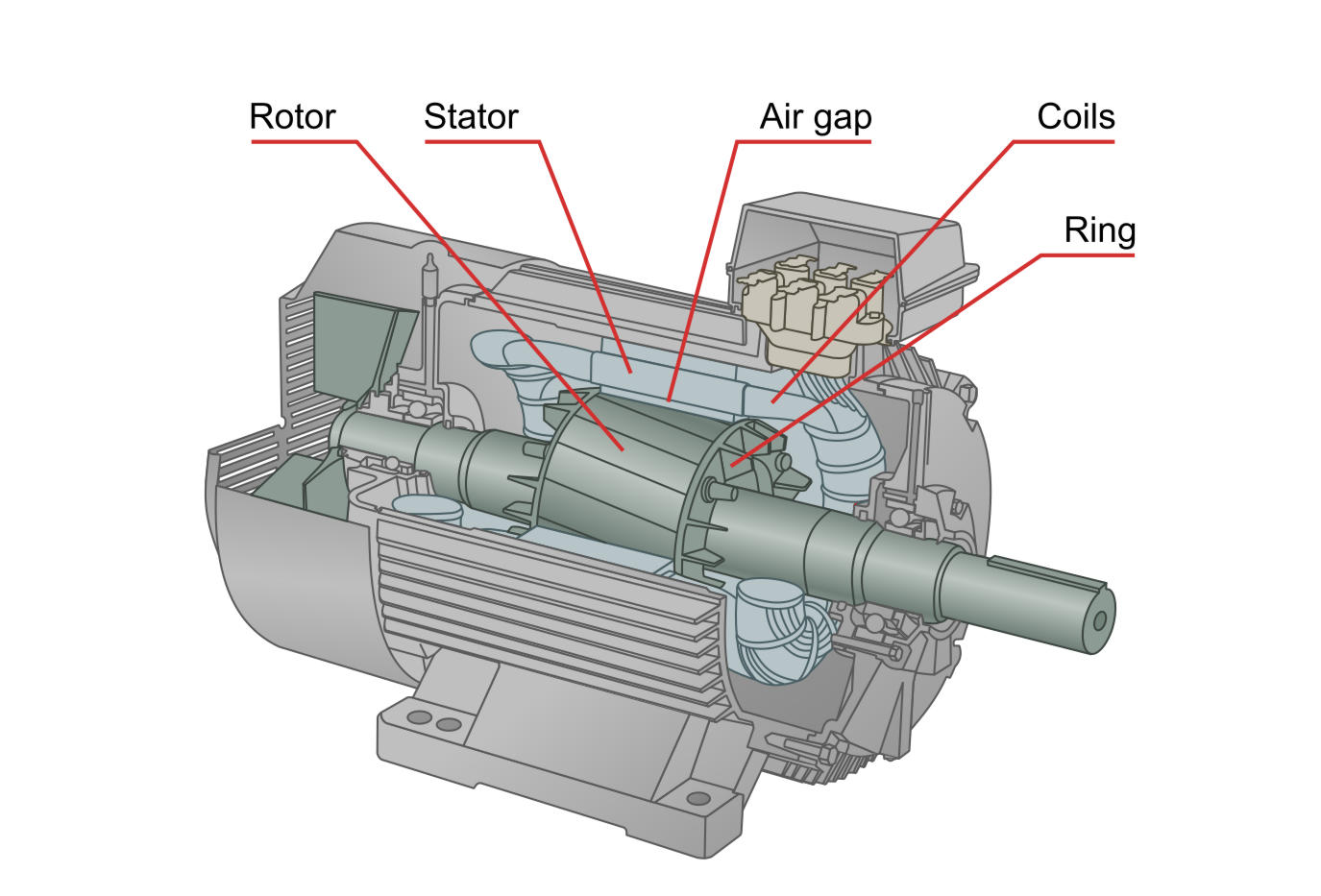

A synchronous motor is generally made up of two parts, a stator the stationary part of the machine that carries the armature winding in which the voltage is generated, and a rotor the rotating part of the machine that produces the main field flux. Of course, this motor has other parts and components. But electric motors are generally known by these two parts. In the following, we will get acquainted with all these components and parts, and we will mention the function and role of each in the motor.

1. Stator Construction

The stationary part of the machine is called Stator. It includes various parts like stator frame, stator core, stator windings, and cooling arrangement. They are explained below in detail.

1.1. Stator Frame

It is the outer body of the machine made of cast iron, and it protects the inner parts of the machine.

1.2. Stator Core

The stator core is made of silicon steel material. It is made from many stamps which are insulated from each other. Its function is to provide an easy path for the magnetic lines of force and accommodate the stator winding.

1.3. Stator Winding

Slots are cut on the inner periphery of the stator core in which 3 phase or 1 phase winding is placed. Enameled copper is used as a winding material. The winding is star connected. The winding of each phase is distributed over several slots. When the current flows in a distributed winding it produces an essentially sinusoidal space distribution of EMF.

2. Rotor Construction

The rotating part of the machine is called the Rotor. There are two types of rotor construction, namely the salient pole type and the cylindrical rotor type. In the following, we will deal with each of these two types of rotors and you can find their differences in their structure and operation.

2.1. Salient Pole Rotor

The term salient means projecting. Thus, a salient pole rotor consists of poles projecting out from the surface of the rotor core. The end view of a typical 6 pole salient pole rotor is shown below in the figure.

Since the rotor is subjected to changing magnetic fields, it is made of steel laminations to reduce eddy current losses. Poles of identical dimensions are assembled by stacking laminations to the required length. A salient pole synchronous machine has a non-uniform air gap. The air gap is minimized under the pole centers and it is maximum in between the poles.

They are constructed for medium and low speeds as they have a large number of poles. A salient pole generator has a large diameter. The salient pole rotor has the following important parts.

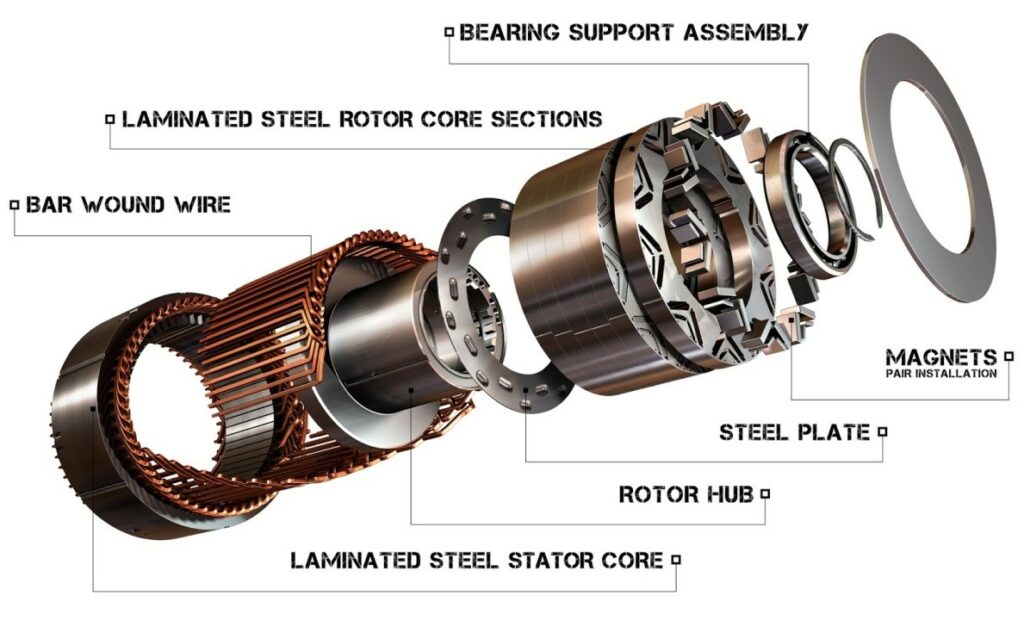

2.2. Non-Salient Pole Rotor or Cylindrical Rotor

In this type of rotor, unlike Salient Pole Rotor, there are no projected poles, but the poles are formed by the current flowing through the rotor exciting winding. Cylindrical rotors are usually made from solid forgings of high-grade nickel chrome-molybdenum steel. It has a comparatively small diameter and long axial length.

This type of Rotor is useful in high-speed machines. The cylindrical rotor has two or four poles on the rotor. Such a construction provides greater mechanical strength and allows more accurate dynamic balancing. The smooth rotor of the machine makes fewer windage losses and the operation is less noisy because of the uniform air gap. Cylindrical Rotors are driven by steam or gas turbines. The machines are built in many ratings from 10 MVA to over 1500 MVA. The biggest size used in India has a rating of 500 MVA installed in the super thermal power plant.

Cylindrical Rotors have the following seven parts and components. We have listed all these parts and components below and have prepared a brief and useful explanation for each of them for more familiarity.

1) Rotor Core

The rotor core is made of silicon steel stampings. The rotor core is placed on the shaft (we will explain what the shaft is). At the outer periphery, slots are cut in which exciting coils are placed.

2) Rotor Winding (Exciting Winding)

It is placed on the rotor slots, and the current is passed through the winding in such a way that the poles are formed according to the requirement.

3) Pole Core and Pole Shoe

It is made of laminated sheet steel material. The Pole core provides the least reluctance path for the magnetic field and the pole shoe distributes the field over the whole periphery uniformly to produce a sinusoidal wave.

4) Spider

It is made of cast iron to provide an easy path for the magnetic flux. It is keyed to the shaft and at the outer surface, pole core and pole shoe are keyed to it.

5) Field Winding (Exciting Winding)

It is wound on the former and then placed around the pole core. DC supply is given to it through slip rings. When direct current flow through the field winding, it produces the required magnetic field.

6) Damper Winding

At the outermost periphery, holes are provided in which copper bars are inserted and short-circuited at both sides by rings forming Damper winding.

7) Rings

Slip rings provide DC supply to the rotor windings.

3. Miscellaneous Parts and Components

We mentioned at the beginning of this section that in addition to the rotor and stator and their components, there are other components in a synchronous motor. In the following, you will become more familiar with these parts and their role. The miscellaneous parts are given below.

A) Brushes

Brushes are made of carbon, and they slip over the slip rings. A DC supply is given to the brushes. Current flows from the brushes to the slip rings and then to the exciting windings.

B) Bearings

Bearings are provided between the shaft and the outer stationary body to reduce friction. They are made of high carbon steel.

C) Shaft

The shaft is made of mild steel. Mechanical power is taken or given to the machine through the shaft.

Download Construction of Synchronous Motor PDF

If you would like to read this article whenever you like, you can download it as a PDF.

What are the Main Applications of Synchronous Motors?

In applications that require a constant and precise speed, synchronous motors are normally used. Such low-power motors are commonly used for positioning machines. Additionally, they are used in robot actuators. Additionally, synchronous motors are found in ball mills, watches, record players, and turntables.

Which Are the Advantages and Disadvantages of Synchronous Motors?

A synchronous motor has the advantage of being easy to control in terms of power factor and of maintaining a constant rotational speed that is independent of the applied load. The downside of synchronous motors is their cost and the need for a DC supply to excite the rotor.

Conclusion

The present article was an attempt to deliver all the essential information about the construction of synchronous motors. we brought the basic definition of what synchronous motor is firstly and then we moved to the construction and the introduction of the components. We tried to introduce all the main and secondary components of a synchronous motor in this article in a complete and useful way and to explain their function in the motor.

If you have any experience of using synchronous motors and know more about their components, we will be very glad to have your opinions in the comments on our website Linquip. Moreover, if you have any questions about this topic, you can sign up on our website and wait for our experts to answer your questions. Hope you enjoyed reading this article.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Types of Synchronous Motors: A Full Description

- The Beginner’s Guide To Permanent Magnet Synchronous Motors

- Why Is Synchronous Motor Not Self-starting?

- Types of Generators: Learn the Basics, Get the Most Out f it!

- The Good Guide to Types of Electric Motors

- Synchronous Motors: Definition, Working Principle, Types, and Applications

- Working Principle of Induction Motor: 2022 Full Guide

- The Construction of Synchronous Motor: All the Necessary Details You want to Read About

- Types of Synchronous Motors: A Full Description

- Why Synchronous Motor is Not Self Starting ?

- Synchronous Motors: Definition, Working Principle, Types, and Applications

- Types of Induction Motor: A Concise and Useful Guild

Excellent

Thanks for visiting our website and leaving your comment, Avijit! We hope to hear from you again in our other posts.

An Absolute nice blog written. You have defined Synchronous motors in deep with proper content and images.

Thank you for letting us benefit from your knowledge and insight. Thousands of different types of industrial equipment, tailored to your specific needs, may be found in our industrial directories.