Thermal insulation reduces heat transfer (for example, the transfer of thermal energy in the wall or floor of the building) between objects in a range of radiative influence or thermal contact. Thermal insulation can be designed with specially engineered processes or methods, same as shape optimization and material selection.

What Are The Heat Transfer Types

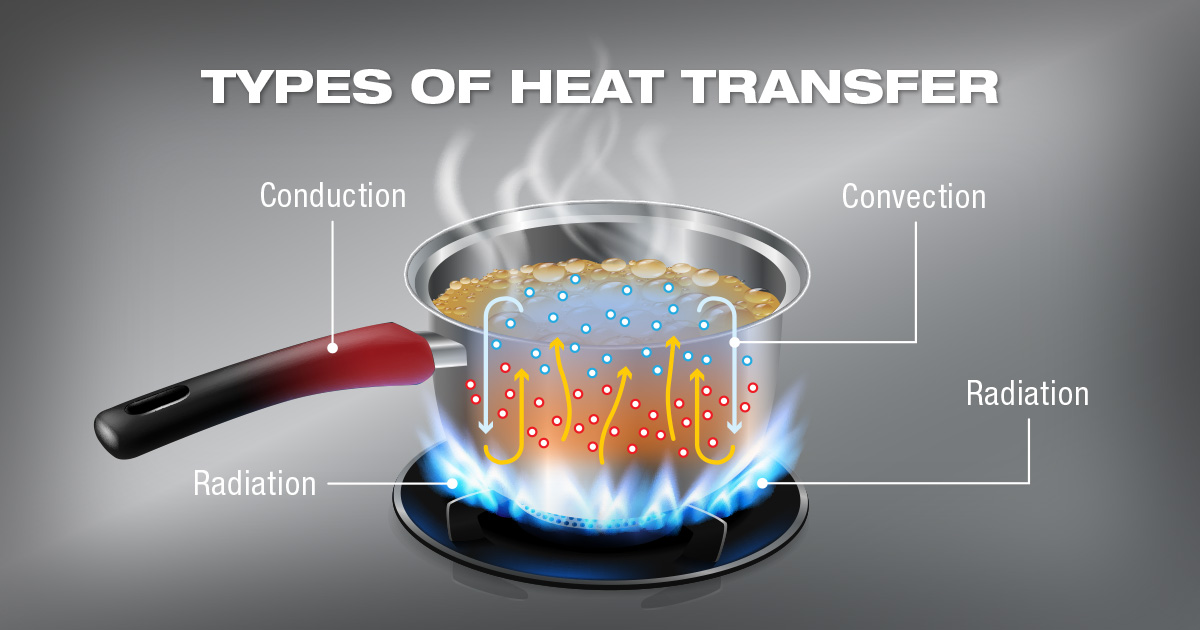

It is essential to know how heat is transferred in the environment and devices. Heat is transferred by convection, conduction, or radiation, or by a mixed process of all three. Heat continually moves from warmer to colder zones as it seeks a balance. Suppose an insulated

container’s interior is colder than the outside air. In that case, the box draws heat from the exterior space—the more significant the temperature difference, the faster the heat moves to the colder area. In practice, the heat transfer into the interest area results from a mixture of the three forms mentioned above, but usually, the most vital mode is by conduction through the walls and boundaries.

Convection

By this heat transfer method, heat is transferred when a heated liquid or air/gas moves from one place to another, carrying its heat with it. The heat flow rate will depend on the moving gas or liquid temperature and its flow rate,

Q=hA\Delta T

where:

Q = heat transfer rate h = convection heat-transfer coefficient A = exposed surface area \Delta T = temperature difference

Conduction

In this transfer mode, heat energy is passed through a solid, liquid, and gas from molecules to molecules in a material. For conduction of the heat, there must be physical contact among particles and some temperature difference between them. Consequently, thermal conductivity is the measure of the rate of heat flow passed between particles. The rate of heat flow through a specific material will be determined by the difference in temperature and by its thermal conductivity,

q=-k\Delta T

in which:

q= local heat flux density k = material’s conductivity \Delta T = temperature gradient

Radiation

Heat energy is also transmitted in the form of light, or in the form of electromagnetic waves like infrared radiation. This energy can emanate from a hot body and travel freely through completely transparent media. The atmosphere and translucent materials, the same as glass, pass a significant amount of radiant heat, and this radiant will be absorbed when it falls on a surface (for example, the ship’s deck surface absorbs radiant heat and becomes hot on a sunny day which has a bad effect in the fishing ships). We are aware of the well-known fact that shiny surfaces or light-colored reflect most of the radiant heat than dark or black surfaces; therefore, the area will be heated more slowly. By absorbing the radiant heat, conduction and convection can befall in continue. The well-known equation for the radiation heat transfer is:

Q=\sigma A(T_1^{4}- T_2^{4})

where:

Q = heat transfer \sigma = the Stefan-Boltzmann constant = 5.67\times 10^{-8}j/s.m^{2}.k^{4} A = surface area T_1 = absolute temperature in kelvin for the environment with uniform temperature T_2 = surface temperature

Definitions of the Parameters

The thermal properties of insulating materials and other common fishing vessel construction materials are known or can be accurately measured. We can calculate the amount of heat transmission (flow) within any combination of materials. However, it is necessary to understand some specific technical terms to calculate heat losses and know the factors involved.

The ending “-ity” indicates the property of a material that its thickness is not important, and the ending “-ance” relates to the property of a specific body with a given thickness.

Heat Energy

One kilocalorie (1000 calories or 1 kcal) is the amount of heat and energy required to raise one kg of water temperature by one degree Celsius (°C). In the SI standard, the unit for energy is Joule (J). One kcal is 4.18 kJ which varies slightly with temperature. Another energy unit is the Btu (British thermal unit), and one Btu is roughly one kJ.

Thermal Conductivity

In simple terms, this is a measure of a material’s capacity to conduct heat through its mass. All types of material and also different insulating materials have specific thermal conductivity values that can be employed to measure their insulating effectiveness. It can be described as the amount of heat/energy (in kcal, Btu, or J) that can conduct in unit time through the unit area with the unit thickness of material while we have a unit temperature difference. We can display thermal conductivity in Btu ft-1 °F-1, kcal m-1 °C-1, and in the SI system, it is W m-1 °C-1 (W refers to Watt). Thermal conductivity is also identified as the k-value.

Thermal Conductance Coefficient \Lambda (kcal m-2 h-1 °C-1)

This is named as \Lambda ( lambda the Greek letter ) and designated as the amount of heat (in kcal) conducted through one m2 of material in one hour, with a thickness of 1 m, while the temperature drop is 1 °C through the body in steady conditions of heat flow. The thermal conductance is verified by tests and is the primary rating for any material. lt can also be shown as Btu ft-2 h-1 °F-1 (per square foot, hour, and degree Fahrenheit in the British thermal unit ) or in SI units as W m-2 K-1.

Thermal Resistivity

The reciprocal of the k-value (1/k) is known as the thermal resistivity.

Thermal Resistance (R-value)

The reciprocal of l (1/l) is known as the thermal resistance (R-value) and is utilized for calculating the thermal resistance of all the materials or composite of them. The R-value can be represented in simple terms as the resistance that any particular material in the way of heat flow. Good insulation material has a high R-value. The R-value grows in direct proportion to the increase in the insulation material’s thickness. The relation is x/l since x stands for the thickness of the insulator in meters.

Heat Transmission Coefficient (U) (kcal m-2 h-1 °C-1)

The symbol U indicates the overall coefficient of heat transmission for any section or composite of a material. The unit for U is kcal per hour per square meter of section per degree Celsius, which is the difference between the section’s inside and outside temperature. We can also express it in other unit systems. The U coefficient involves the thermal resistances of both surfaces of flooring or walls, as well as the thermal resistance of particular layers and air spaces within the wall or flooring we prepared.

Permeance to Vapor Water (pv)

This is known as the quantity of water vapor that passes through the unit of area of a material of unit thickness, while the difference of water pressures is the unit between both faces of the material. It can be shown as g cm mmHg-1 m-2 day-1 or as g m MN-1 s-1 (MN means mega Newton per second) in the SI system.

Resistance to Water Vapor (rv)

The Resistance to water vapor is the reciprocal of permeance to water vapor and is defined as rv = 1/pv.

What Is Insulation and Why Is It Necessary?

Thermal insulation reduces heat transfer (i.e.` the transfer of thermal energy between objects of differing temperature) between objects in thermal contact or in the range of radiative influence. We can achieve thermal insulation with specially engineered methods or processes and suitable object configurations and materials.

Heat flow is an inevitable result of contact between materials with different temperatures. Thermal insulation presents a region of insulation in which thermal conduction is diminished, or thermal radiation is reflected instead of absorbed by the lower-temperature body.

An Example For Understanding Why We Need Heat Insulator

The main function of thermal insulation materials employed in small fishing vessels, including ice, is to reduce heat transmission through fish hold walls, stanchions, hatches, or pipes into the place where chilled fish or ice is stored. The amount of ice that melts can be reduced by reducing heat leaks, so the icing process’s efficiency can be increased. Another example of using an insulator is a building, which limits energy consumption for air ventilators by avoiding warmer or colder air reach inside the building.

In the fish containers, we use ice to remove heat energy from the fish and heat energy leaking through the walls of the storage. Insulation of the container walls can decrease the amount of heat that enters the container and the ice needed to keep the contents cooled.

For this application, the main advantages of insulating with sufficient materials are:

- Preventing heat transmission from invading warm air, the engine room, and heat leaks.

- Optimizing the maximum useful capacity of the fish container and fish-chilling running costs;

- to help decrease energy necessities for refrigeration systems if these are applied.

The costs of insulation may amount to a notable price proportional to the costs, including construction. As a result, choosing insulation materials is very important due to the space requirements and material costs.

Again, for the fishing container application, several thermal insulation materials are employed commercially for fishing vessels, but just a few are completely satisfactory for this goal. The main difficulties are lack of sufficient moisture absorption and mechanical strength, which is a particularly significant problem, where they use melting ice as a chilling medium. Thermal insulators act by trapping pockets of gas or bubbles inside a foam structure. By filling these cells of gas with moisture, we observe significant losses in insulating efficiency.

The thermal conductivity of ice (at 0 °C) is 2 kcal m-1 h-1 °C-1, while for water (at 10 °C) is 0.5 kcal m-1 h-1 °C-1 (for ice, it is four times the value of water). On the other hand, it is about 0.02 kcal m-1 h-1 °C-1 for dry stagnant air. You can find the thermal conductivities of materials in books, tables, or catalogs prepared by suppliers; also, you can see some of them here.

Moisture absorption in the insulating materials can occur by direct contact with water leaking and condensation of water vapor on the walls.

Therefore, water vapor barriers’ proper design is essential for protecting the insulation from absorbing moisture. In most climates, the moving of water vapor tends

to be from the exterior to the interior side of the hold walls because of the higher temperature of the external than the internal side. Insulation needs an impervious moisture-proof layer outside the box and a waterproof barrier on the lining to stop liquid meltwater from entering the insulation. We can achieve the vapor barriers either through waterproof covers or prefabricated insulation panels. For example, sandwich-type panel’s one face is a vapor barrier steel sheet of light-gauge galvanized and the other internal finish face with galvanized iron sheets or plastic-coated aluminum. Polythene sheets, plastic films of a minimum thickness of 0.2 mm, reinforced plastic materials, or aluminum foils with a minimum thickness of 0.02 mm, laminated with a bitumen membrane are other examples for fish holder insulation.

What Are The Most Common Thermal Insulation Materials

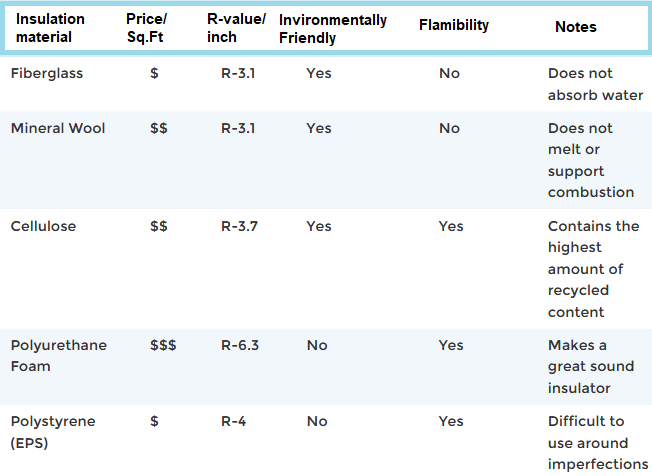

We have plenty of cheap and common insulation materials ready to buy on the market now. Many of them have been nearby for quite some time. All of these insulation elements have their ups and downs, and when deciding about the type of insulation material you need, it is better to be certain and aware of the material type that would work the best in your application. Consider differences like price, environmental impact, R-value, flammability, sound insulation, and other factors presented in the table. The five most common kinds of insulation materials are:

Fiberglass

In these modern times, the most common insulation material is fiberglass. Because of its structure, by efficiently weaving fine strands of glass in insulation material, fiberglass can minimize heat transfer. The main disadvantage of fiberglass is the risk of handling it. As fiberglass is consists of finely woven silicon, tiny shards of glass and glass powder, it can cause damages to the lungs, eye, and even skin if the conventional safety equipment isn’t utilized. Nevertheless, when the proper protective equipment is employed, fiberglass installation would be performed without incident.

Fiberglass is an excellent insulation material, which is non-flammable. Its R-values ranging from R-2.9 to R-3.8 per inch, and if you are looking for cheap insulation, this is clearly the way to go. However, installing it needs safety precautions, and be sure to use eye protection, gloves, and masks when handling this product.

Mineral Wool

Mineral wool refers to several different insulation types:

- It may refer to fiberglass manufactured from recycled glass named glass wool.

- It may refer to a type of insulation made from basalt named rock wool.

- It may refer to a type of insulation that is produced from the slag from steel mills called slag wool.

The major mineral wool in the United States is the type of slag wool. Mineral wool can be obtained in batts or as a loose material. Usually, mineral wool does not include additives to make it fire resistant and makes it poor for extreme heat situations. As it is not combustible, when used in conjunction, more fire-resistant forms of insulation, mineral wool can be an effective method for insulating large areas. Mineral wool’s R-value is ranging between R-2.8 to R-3.5.

Cellulose

Cellulose insulation is conceivably one of the most eco-friendly kinds of insulation. Cellulose is produced from recycled paper, cardboard, and other similar materials and appears in loose form. R-value between R-3.1 and R-3.7 is associated with cellulose. Some current studies on cellulose show that it may be an excellent product for minimizing fire damage. Due to the compactness of the materials, cellulose can have approximately no oxygen within it. Without oxygen inside the material, the amount of damage would minimize.

Cellulose is one of the most fire-resistant forms of insulation. However, this material has important disadvantages, such as the allergies some people may have to paper dust. Also, obtaining individuals skilled in handling this type of insulation is almost hard compared to the fiberglass mentioned above. Still, cellulose is a low-cost and effective method of insulating.

Polyurethane Foam

Polyurethane foams are an excellent kind of insulation. Nowadays, polyurethane foams utilize non-chlorofluorocarbon (CFC) gases to be employed as a blowing agent. It helps to decrease the harmful effects to the ozone layer. They are comparatively light and weighing roughly two pounds per cubic foot (2 lb/ft^3). They have an R-value of around R-6.3 per one inch of thickness. There can be sprayed into areas of not being insulated and are low-density foams. These types of polyurethane insulation have nearly an R-3.6 rating per one inch of thickness. Another advantage of this kind of insulation is fire-resistance properties.

Polystyrene

Polystyrene is a type of waterproof thermoplastic material in the form of foam and is an excellent temperature and sound insulation material. It appears in two varieties, expanded (EPS) and extruded (XEPS), also identified as Styrofoam. The two models differ in cost and performance ratings. The more expensive XEPS type has an R-value of R-5.5 while it is R-4 for EPS. Polystyrene insulation has a special smooth surface compared to other kinds of insulators.

The foam is typically created or cut into blocks and is an ideal choice for wall insulation. As the foam is flammable, it needs to be coated with a fireproofing chemical named Hexabromocyclododecane (HBCD). Recently, HBCD has been brought under fire for health and environmental dangers associated with its usage.

Other Common Insulation Materials

Although the matters noted above are the most typical insulation materials, they are not the only items used. Recently, materials same as aerogel have become affordable and available. NASA used aerogels for the construction of heat-resistant tiles, able to withstanding heat up to roughly 2000 degrees Fahrenheit with no or little heat transfer, and one particular item is Pyrogel XT. One of the most efficient technical insulations in the world is Pyrogel. This type’s required thicknesses are about 50% – 80% less compared to the other insulation materials. It is a little more expensive than other insulation materials, but Pyrogel is being used further in specific applications.

Other insulation materials not discussed are natural fibers like hemp, cotton, sheep’s wool, and straw. Polyisocyanurate, comparable to polyurethane, is a closed-cell thermoset plastic. It has a high R-value making it a favorite choice as an insulator. Some hazardous materials for health that were used before as insulation and are now banned, unavailable, or uncommonly used are perlite, vermiculite, and urea-formaldehyde. These materials are containing formaldehyde or asbestos, which has permanently removed them from the list of regularly used insulation materials.

There are many kinds of insulation available, each with its own set of properties. Only by investigating each kind thoroughly, you can discover which will be the appropriate one for your special needs. As a quick overview:

- Aerogel is more costly but definitely the most suitable type of insulation.

- Fiberglass is affordable but needs careful handling.

- Mineral wool is practical but not fire-resistant.

- Cellulose is fire-resistant, effective, and eco-friendly but hard to use.

- Polyurethane is an all-around good insulation material, though not exceptionally eco-friendly.

- Polystyrene is a diverse insulation product, but its safety is argued.

Application of The Insulators

Thermal insulators are used vastly in many various industries and are very popular products. Some of the main applications of insulators are:

Natural animal insulation and Clothing in birds and mammals_ Gases have poor thermal conduction properties than liquids and solids, making strong insulation materials if they can be trapped.

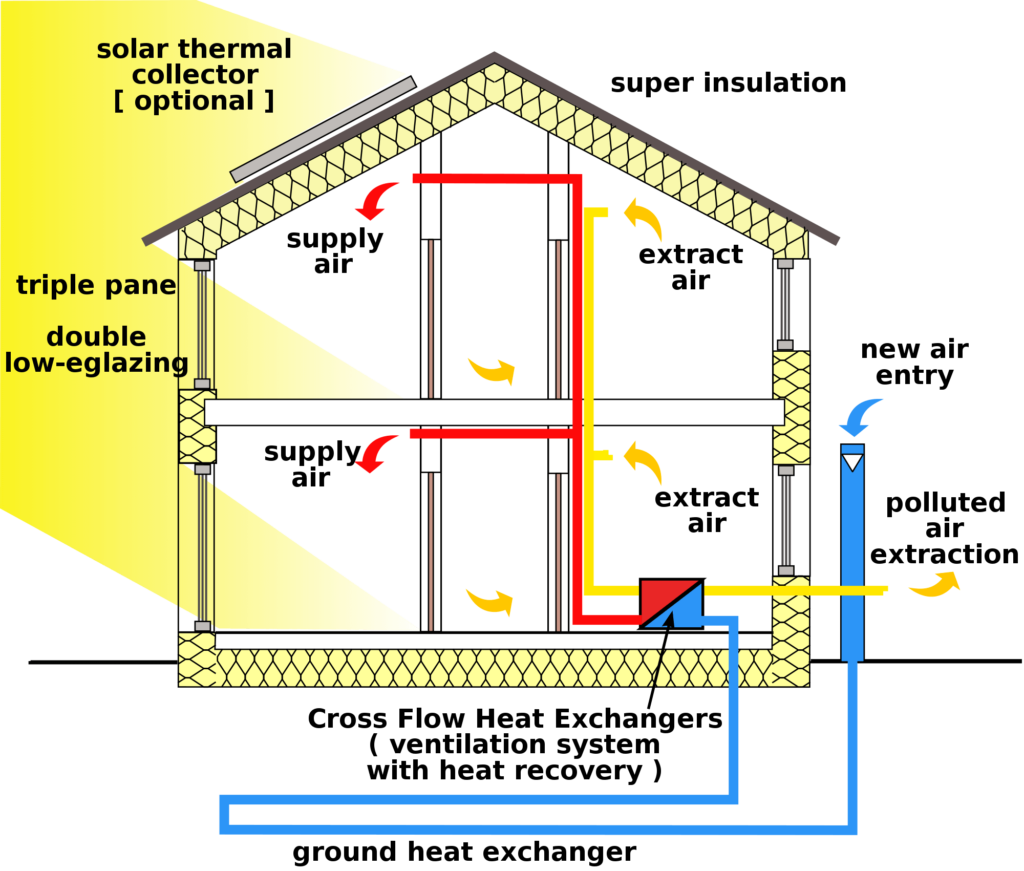

Buildings_ Maintaining satisfactory temperatures in buildings (by cooling and heating) uses a large amount of global energy consumption that needs to be reduced. Insulation will play an essential role in this way.

Mechanical systems_ Cooling and Space heating systems distribute heat throughout facilities employing pipes or ductwork that need to be insulated. Mechanical insulations are commonly installed in commercial and industrial facilities.

Refrigeration_ A refrigerator has a heat pump and a thermally insulated chamber.

Spacecraft_ Launching and re-entry place critical mechanical stresses on spacecraft.

Automative_ Internal combustion engines generate a lot of heat during their combustion sequences.

Which Type of Insulation Materials Are the Most Fireproof for Home Application?

When choosing the suitable insulation material, the several properties of that stuff and how well they match your application needs become very important. You naturally want to be sure of the type of insulation that will be effective enough to provide the overall energy efficiency of your facility, but other characteristics might not get equally important and as much care. As insulation’s whole purpose is to cover your house to provide a block against heat transfer, selecting fireproof insulation is vital. Take a look at some of the most popular options for fireproof insulation in homes, shows these results:

Fiberglass: Naturally, fiberglass insulation is fire-resistant. Although the fiberglass will not burn itself, we need to be careful of the batts that are backed with foil and paper, as these elements can burn quickly.

Mineral wool: This type has a high melting temperature and a good insulation material. That’s an excellent fit for thermal applications due to its superior fire-resistant properties. Whether the mineral wool is formed of steel byproducts and recycled iron or from the actual mineral rock, the insulation is naturally non-combustible.

Fibrous mats: Fibrous mats are one of the most popular types of insulation used in the home and are made up of various minerals as a unit referred to as asbestos. The possible health risks of asbestos are entirely understood. However, there are very few replacement items available at this time, and therefore, asbestos continues to be one of the frequently used materials not only in insulation production but in shingling and also car parts as well. Asbestos is a solid material with high chemical and heat resistance that doesn’t pass electricity, which also reduces the fire risk for the insulation.

Cellulose: While cellulose insulation isn’t fireproof, flame retardants can help the material resist combustion. By treating cellulose with these fire-resistant chemicals, cellulose can endure temperatures of up to 300 degrees before possibly catching on fire. Cellulose composed of foam materials is even less easily combustible, as it can resist temperatures up to 400 degrees.

When it comes to decide about fireproof insulation, there will be several alternatives available to you. However, you will need to be sure that whichever you choose is the best overall fit for your home, and in this way, you may need experts.