Welcome to Linquip Blog. Today and in this article, we are going to encounter the title of “What is a Plate Heat Exchanger?” A plate heat exchanger is a type of heat exchanger using metal plates to transfer heat between two fluids never encountering each other due to being separated by the heat exchanger. This article is about the design, working principle, and an introduction to different types of Plate Heat Exchanger.

Our team gathered all of the necessary information on this topic to eliminate the need for reading diverse content on other websites. Stay with us until the end to find the answer to your question on this topic. We have a long journey ahead of us, so take a deep breath, sit back, and keep reading this article until the end.

What is Plate Heat Exchanger?

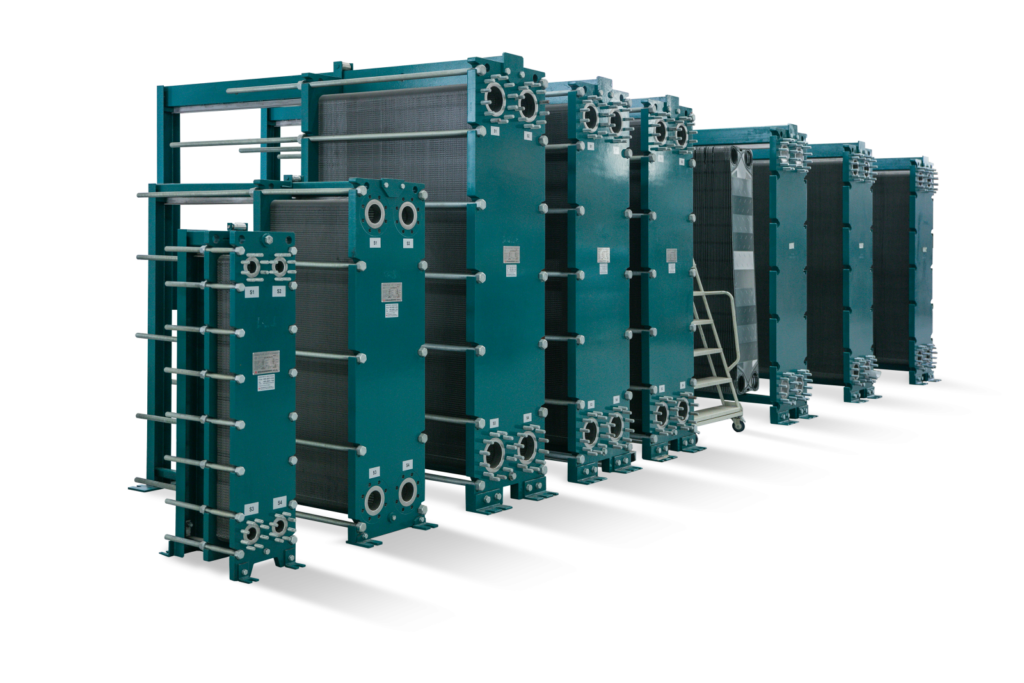

A plate heat exchanger is used to transfer heat energy from one fluid to another. These fluids never encounter each other due to being separated by the heat exchanger. Typically, a plate heat exchanger will consist of several parallel plates positioned above each other, thus creating a passage in which the fluid can flow between. The spacing between two opposite plates provides a channel for the fluid to flow through.

How is Plate Heat Exchanger Constructed?

A plate exchanger consists of a series of parallel plates that are placed one above the other so as to allow the formation of a series of channels for fluids to flow between them. The space between two adjacent plates forms the channel in which the fluid flows.

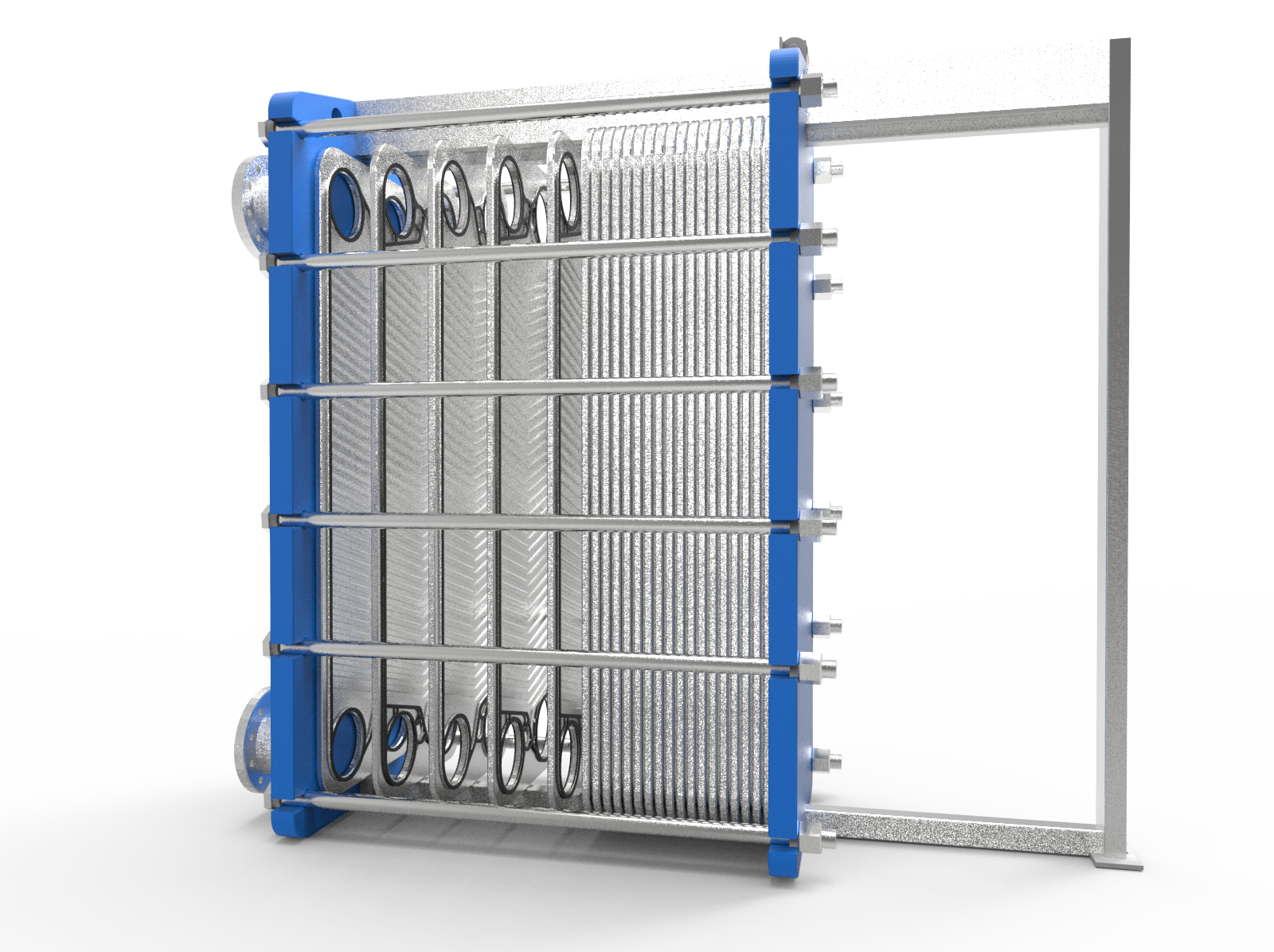

Inlet and outlet holes at the corners of the plates allow hot and cold fluids through alternating channels in the exchanger so that a plate is always in contact on one side with the hot fluid and the other with the cold.

The size of a plate varies from a few square centimeters (100 mm x 300 mm side) up to 2 or 3 square meters (1000 mm x 2500 mm side). The number of plates in a single exchanger ranges from just ten to several hundred, so reaching surface exchange areas up to thousands of square meters.

The plates are often spaced by rubber sealing gaskets which are cemented into a section around the edge of the plates. The plates are pressed to form troughs at right angles to the direction of flow of the liquid which runs through the channels in the heat exchanger. These are arranged so that they interlink with the other plates which forms the channel with gaps of 1.3–1.5 mm between the plates.

What is Plate Heat Exchanger Working Principle?

The purpose of a plate heat exchanger is to transfer thermal energy between two fluids, without the fluids mixing together. For example, in building services, you might want to transfer heat from a primary loop connected to a boiler over to a separate secondary loop, maybe in a district heating network. In manufacturing, you may want to cool down some oil using water, but obviously you don’t want to mix the oil and the water together.

The liquid to be heated or the liquid heats, are totally separated from each other with plates. In standard plate heat exchangers, there are 4 in-out ports and two of them are for heater liquid and two of them for heated liquid. With special production, it is possible to produce heat exchangers which have more than one heater or heated liquids.

In Plate Heat Exchangers, the flow is diagonal. When the hot liquid enters in the top portion and leaves from the bottom, the cold liquid enters in the bottom and leaves from top. So, efficiency reaches maximum level.

What are Different Types of Plate Heat Exchanger?

- Brazed Plate Heat Exchangers: These are used largely for refrigeration & industrial applications. The main benefit of brazed plate heat exchangers is that they are highly resistant to corrosion. This is due to them being made from a combination of stainless steel and a copper brazing.

- Gasketed Plate Heat Exchangers: These heat exchangers are suitable for a number of industries such as HVAC, Food, Brewing and Pharmaceutical. The heat exchangers make use of gaskets which seal the plates together in the process preventing leaks. Reduced maintenance costs are involved due to the plate easily being removed for replacement and cleaning purposes.

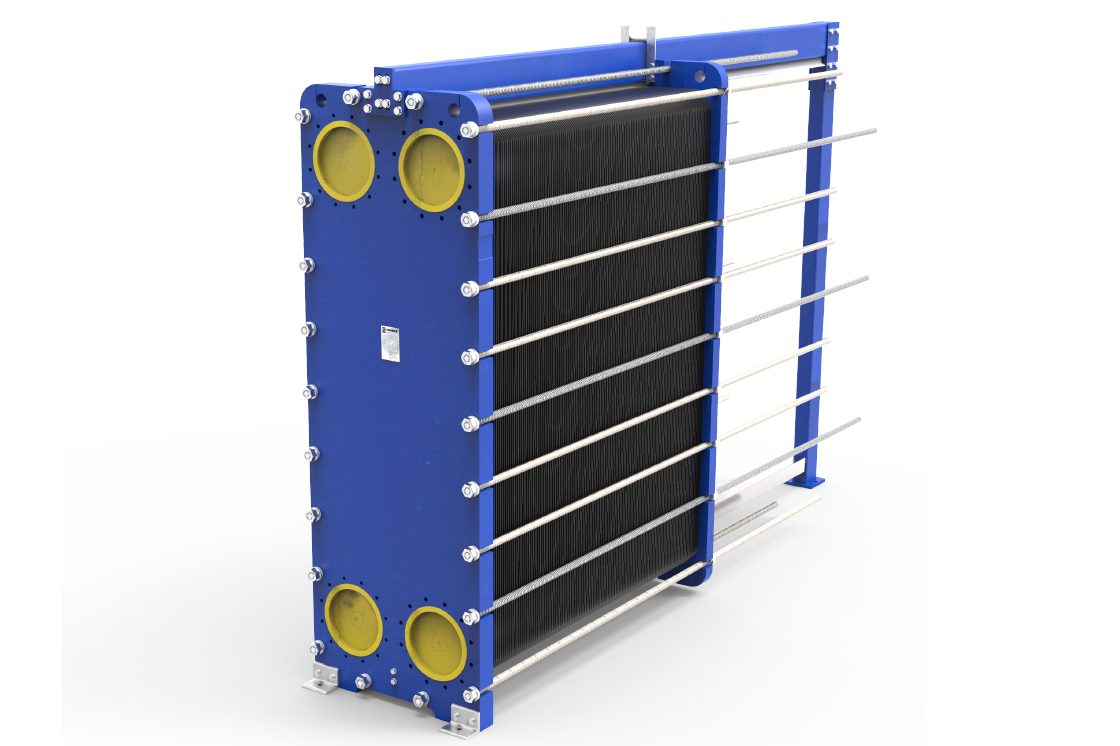

- Welded Plate Heat Exchangers: These heat exchangers are mainly used in the oil, gas and chemical industries. An advantage of these heat exchangers is that they are highly durable and ideal for transferring corrosive fluids or fluids which reach high temperatures. The only issue of these plate heat exchangers is their cost which is accentuated by the fact that the plates are welded together. This means that replacing the plates is difficult and that cleaning the plates is also an issue unlike the removable plates in a gasketed plate heat exchanger.

- Semi-Welded Plate Heat Exchangers: This variety of plate heat exchanger combines the use of welded and gasketed plates. The heat exchanger contains twin sets of plates which have been welded together. These have then been gasketed to other sets, thus making one of the fluid passages welded and another gasketed. The main benefit of a semi-welded plate heat exchanger is that high temperature, corrodible fluids can be transferred on one side while the other side allows for easy servicing.

Conclusion

The present article was an attempt to explain “What Is a Plate Heat Exchanger?” and deliver all the essential information about how it works, how it is constructed and what its different types are.

The purpose of a plate heat exchanger is to transfer thermal energy between two fluids, without the fluids mixing together. Typically, a plate heat exchanger will consist of several parallel plates positioned above each other, thus creating a passage in which the fluid can flow between.

If you have any experience of using any types of Plate Heat Exchanger, we will be very glad to have your opinions about their performance in the comments on our website Linquip. Moreover, if you have any questions about this topic, you can sign up on our website and wait for our experts to answer your questions. Hope you enjoyed reading this article.

Read More on Linquip

Hello

We are whriting from our head company nomads is one of the biggest food network company in Mongolia. I am Namuuna, product development specialist at central nomads office and i need some information of your product Fresh cliccer, Low temprature incubator, Plante heat exchanger

Kind regards

Namuunaa

The very helpful note and full know Heat Exchanger Working Principle and Construction

Thanks for visiting our website! We also encourage you to visit the Linquip website, where you can find numerous industrial equipment, along with companies and experts.