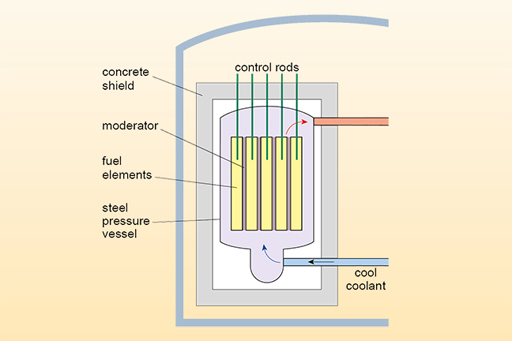

The short answer to “what are the components of nuclear reactor” is that nuclear reactors all contain several components in common such as fuel, control rods, moderator, and coolant.

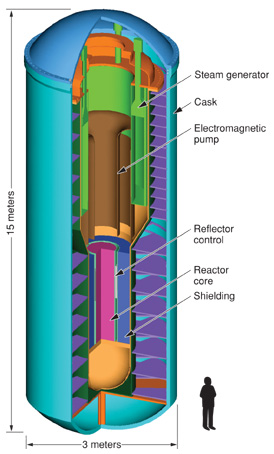

The main components specific to a reactor are located in the nuclear island. This is where the fission reactions are accomplished, including the nuclear boiler, systems for the fuel, and the equipment required to work and guarantee the safety of the entire facility. The other section of the nuclear power plant is called the conventional island and includes, among others, the turbine, the alternator, and the condenser.

There is a vast number of systems in which a nuclear reactor may be designed and constructed; many types have been experimentally realized.

Over the years, nuclear engineers have elaborated reactors with solid and liquid fuels, thick- and no-reflectors, forced cooling circuits and natural conduction or convection heat-removal systems, and so on. Most reactors, nevertheless, have specific basic components.

A nuclear reactor is any class of tools that can initiate and control a self-sustaining series of nuclear fissions. Nuclear reactors are used as research devices, systems for producing radioactive isotopes, and most prominently, energy sources for nuclear power plants.

Components of Nuclear Reactor

In this section, we list the various components of the nuclear reactor and explain them.

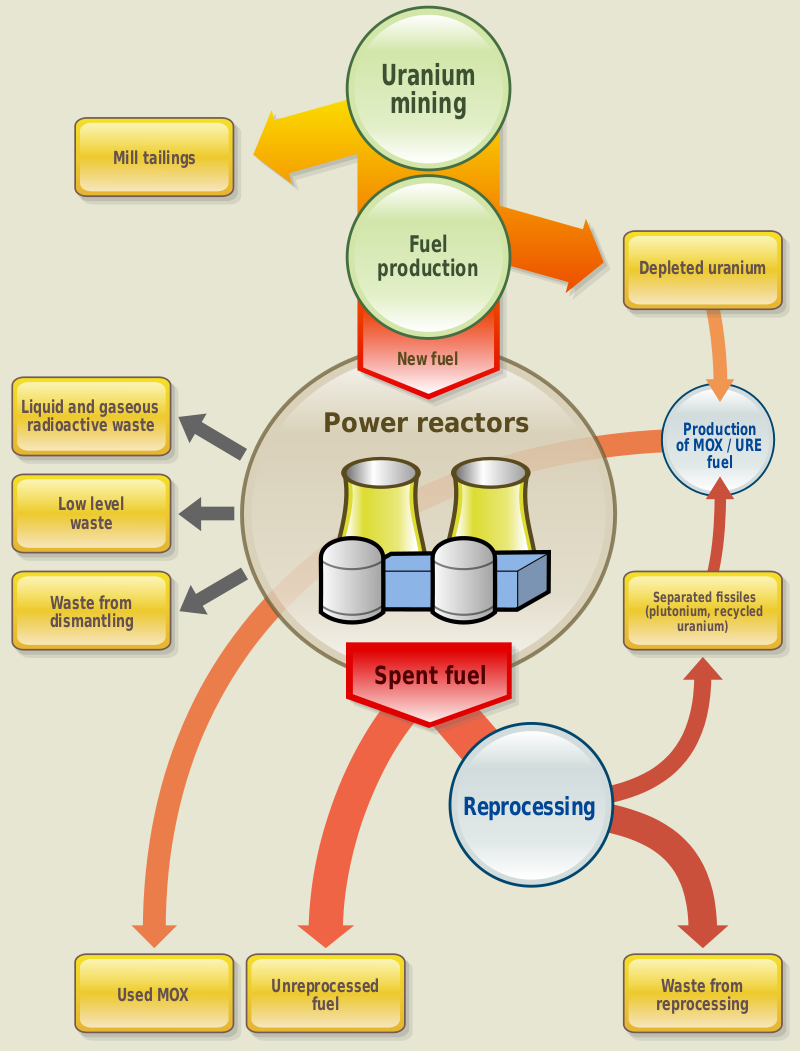

Fuel

Uranium is the basic fuel. Generally, pellets of uranium oxide (UO2) are arranged in tubes to shape fuel rods. The rods are arranged into fuel assemblies in the reactor core.

A reactor fuel must comply with the integral design of the reactor as well as the mechanisms that drive its activities. Brief explanations of the fuel materials and configurations employed in the different types of nuclear reactors are provided in the following.

Light-Water Reactor

The light-water reactor (LWR), which has the most widely used variety for commercial power generation globally, employs a fuel including pellets of sintered uranium dioxide loaded into cladding tubes of zirconium alloy or some other advanced cladding material.

The tubes, called pins or rods, size nearly 1 cm (less than half an inch) in diameter and roughly 3 to 4 meters (10 to 13 feet) in length. The tubes are packed together within an assembly, along with the pins configured in a square lattice.

The used uranium in the fuel is 3 to 5 percent enriched. Since light water, used in light-water reactors as both the coolant and the moderator, tends to absorb more neutrons than other moderators do, such enrichment is crucial.

Heavy-Water Reactor

The CANDU (Canada Deuterium Uranium) reactor, the principal type of heavy-water reactor, uses natural uranium compressed into pellets. These pellets are inserted in long tubes and arranged in a lattice.

A CANDU reactor fuel assembly is approximately 1 meter (almost 40 inches) long. Several assemblies are arranged end-to-end within a channel inside the reactor core. The utilization of heavy water rather than light water as the moderator enhances the scattering of neutrons. So, thereby the probability of fission with the fuel material increases.

High-Temperature Graphite Reactor

In a high-temperature graphite reactor, the fuel is made of small spherical particles or microspheres containing uranium dioxide at the center with concentric shells of carbon, silicon carbide, and carbon around them. These shells serve as localized cladding for each fuel sphere. The particles are then blended with graphite and encased in a macroscopic graphite cladding.

Research Reactor

The most common sort of fuel utilized in research reactors contains plates of a uranium-aluminum alloy with an aluminum cladding. The uranium is fortified to somewhat less than 20 percent.

Aluminum has a lower melting point compared to other cladding materials. However, the flat plate design keeps a low fuel temperature, as the plates have a thickness of just more than 1.25 mm. A common type of research reactor known as TRIGA employs a fuel of mixed uranium and zirconium hydride, with slight condensation of erbium and is coated with stainless steel.

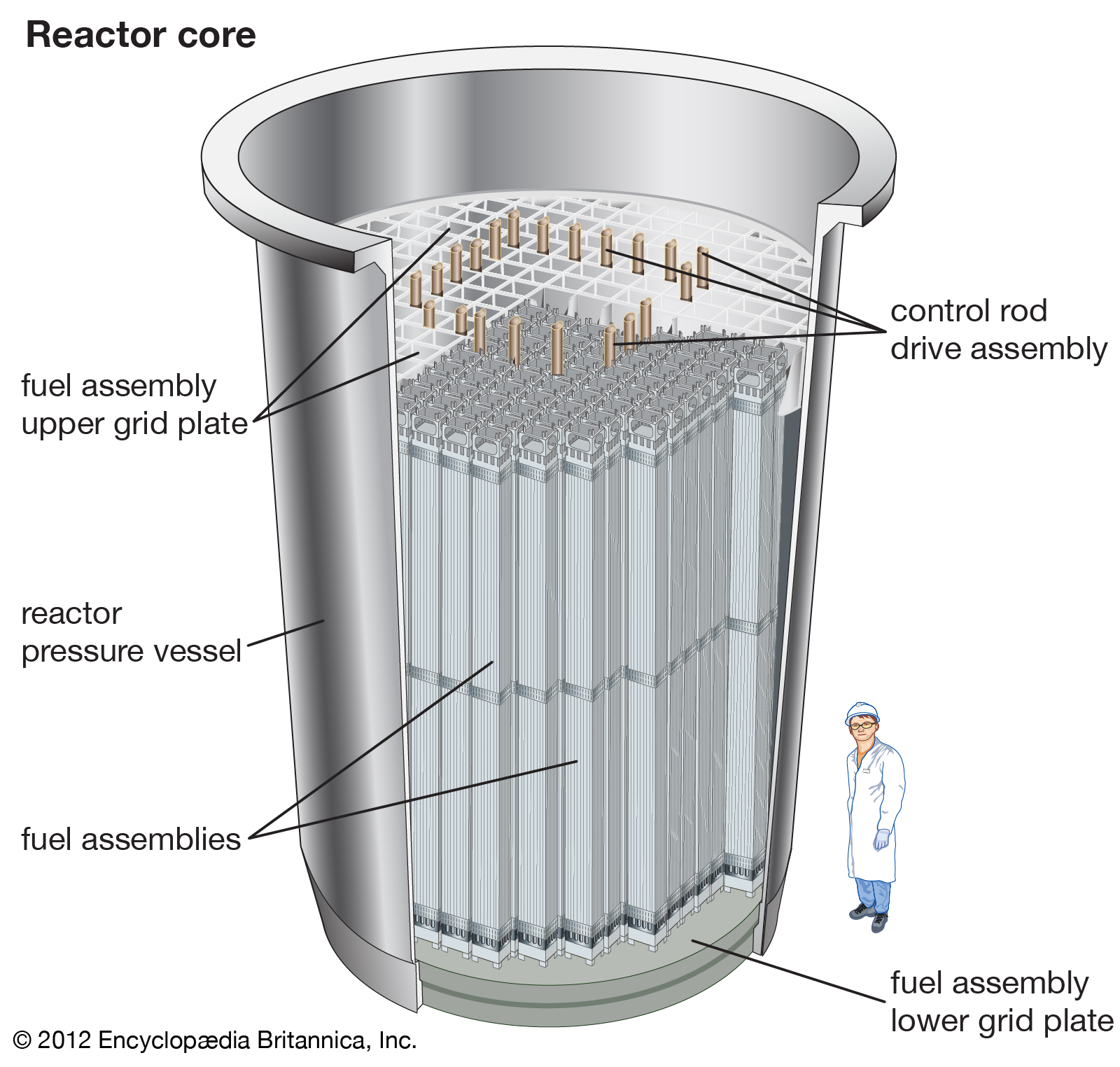

Core

A nuclear reactor core is the part of a nuclear reactor, including the nuclear fuel components where the nuclear reactions happen, and the heat is produced. In most cases, the fuel is low-enriched uranium included in thousands of fuel pins. In addition, the core comprises structural components to moderate the neutrons, control the reaction, and take the heat from the fuel to the required destination outside the core.

All reactors have a core, a central section containing the fuel, coolant, moderator, and fuel cladding. In a nuclear reactor, the fission energy is generated within the core.

In general, the fuel is heterogeneous. It is included in components holding fissile material and a diluent. The diluting factor can be fertile material or material that has suitable mechanical and chemical characteristics and does not immediately absorb neutrons. All diluents work as a matrix in which the fissile can be placed during its operational life.

In solid fuels, cladding surrounds the diluted fissile. The cladding is a material separating the fuel from the coolant and decreases the chance of releasing the radioactive fission products.

Water-moderated Reactors

There are fuel rods about 4 meters long, inside the core of a pressurized water reactor or a boiling water reactor. They are classed by the hundreds in bundles known as “fuel assemblies.”

In the fuel rods, pellets of uranium, or uranium oxide, are stacked from end to end. Additionally, there are control rods inside the core filled with pellets of materials such as boron, hafnium, or cadmium that easily capture neutrons.

When the control rods are drawn into the core, they absorb neutrons. It cannot participate in the nuclear chain reaction. In contrast, as the control rods are removed, more neutrons hit the fissile U-235 or Pu-239 nuclei close to fuel rods, intensifying the chain reaction.

The core shroud placed within the reactor provides the flow of water for cooling the nuclear reactions inside of the core. The water helps to remove the fission reaction heat and works to balance the neutron reactions.

Graphite-Moderated Reactors

A graphite-moderator reactor utilizes solid nuclear graphite as the neutron moderator and regular water as the coolant.

In the Advanced Gas-cooled Reactor (AGCR), a British design, the core includes a graphite neutron moderator, where the fuel assembly is placed. Carbon dioxide gas acts as a coolant. It circulates within the core to remove the heat.

There are also some experimental reactors using graphite as a neutron moderator.

Reflectors

The reflector is a layer of material immediately surrounding a reactor core that scatters or reflects back many neutrons that escape into the core. The reflected neutrons can then cause more fissions and enhance the neutron economy of the reactor. Typical reflector materials include graphite, water, beryllium, and natural uranium.

These design specifications allow for a smaller core size. Moreover, reflectors smooth out the power density using neutrons that leak out differently through the fission process within fuel material close to the exterior region of the core.

The reflector is especially important in research reactors because it is the place in which most of the experimental equipment is installed.

However, in most power reactors, the reflector is less important due to the large size of the reactor. This feature decreases the proportion of neutrons that may escape from the core.

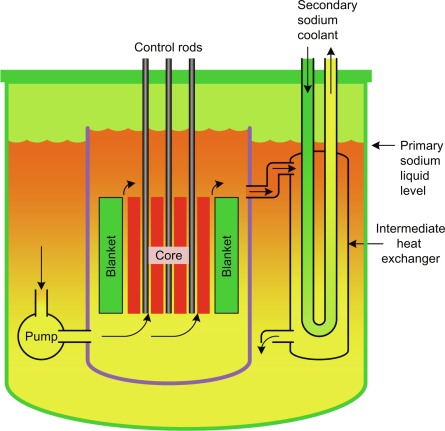

The liquid-metal reactor is a particular case. Most sodium-cooled reactors are built to allow those neutrons that are not needed to maintain the chain reaction to leak from the core. These neutrons can generate new fissile material when they are absorbed by fertile material. Therefore, fertile material, including depleted uranium or its dioxide, is ready around the core to take the leaking neutrons. This absorbing-type reflector is called a blanket or a breeding blanket.

Coolants and Moderators

The heat generated by nuclear fission in reactors must be captured and carried for the environment and electricity generation. For this purpose, reactors utilize coolants for removing heat from the core where the fuel is processed. Coolants also act to maintain manageable pressures inside the core.

For the coolant to act effectively, it must have several key specifications. Basically, it must have effective heat transfer features.

The coolant must also be a fluid that can fill the core gaps and be transferred to a steam generator or turbine. The coolant must have a chemically stable state at high temperatures and be a poor neutron absorber and non-corrosive. So, the coolant must have a low absorption cross-section.

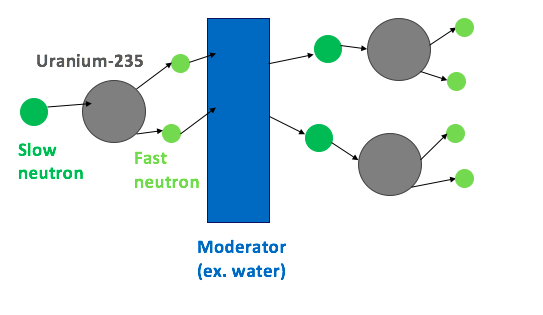

When a neutron is thrown from the uranium-235, the atoms with which it strikes scatter or absorb the neutron. The probability of each event is designated as a nuclear cross-section or effective area given by the nucleus. It has the unit of barns (shown in σ).

The optimal case is high scattering and low absorption cross-section. However, when coolant absorbs the neutrons, the resulting radioactivity must have a short lifespan. Finally, cost-effectiveness is an important consideration for reactors.

The coolant affects some aspects of the reactor operating conditions, including the operating pressure and temperature, the core size, and ways of fuel handling.

Two common coolants are used in the industry: water and liquid sodium.

Water

The two main water-cooled reactors are pressurized water reactors (PWR) and boiling water reactors (BWR). Both utilize light water but with somewhat different cooling methods. In a boiling water reactor, also, the water converts into steam in the core and is thus sent directly to the steam turbines to generate electrical power.

In a pressurized water reactor, the coolant flowing through the core reaches a very high pressure (2250 psi). Therefore, it remains a liquid. Then, it gives heat to a secondary loop of the flow of water that vaporizes and spins the turbines.

The latter process ensures that any radioactivity in the coolant remains in the reactor. Because the latent heat of vaporization needs for the phase change limits thermal efficiency, some developing research is in progress on a Generation IV supercritical reactor.

Also, pressurized water can moderate the neutrons because hydrogen, which comprises regular water, has a scattering cross-section of 82.03 barns (σ = 82.03 barns), much greater than any other atoms.

Pressurized water reactor experiences a significant loss when the reactor overheats to the thermal point where the primary loop water boils. Neutrons have less interaction with steam and, thus, do not heat up. Therefore, the excess of fast neutrons decreases the fission event rate. After a few minutes, a passive shutdown occurs for the reactor.

A more efficient coolant and the moderator is heavy water (liquid D2O) because its cross-section is three times less than hydrogen. But, it is also very expensive.

Molten metal: Sodium

Molten sodium is the coolant chosen for fast breeding reactors. It is one of the most inexpensive metals available. Also, liquid sodium has some compatibility features, including high strength density and non-corrosive treats to stainless steel.

Like pressurized water reactors, the sodium-cooled fast reactor (SFR) applies an initial cooling loop to transfer the heat to a steam generator through a separate water cycle.

In contact with fuel, sodium is highly radioactive but remains within the reactor. Its short half-life is approximately fifteen hours. Similar to light water, liquid sodium is naturally safe in the case of airflow loss. In addition, the high heat capacity and thermal conductivity of sodium prevent significant temperature rise.

However, liquid sodium has notable downsides. It ignites immediately upon contact with air and reacts with water. Moreover, exposed sodium generates extremely toxic aerosols that can harm devices to the deposited surfaces. Finally, the operational problem is that coolant turbidity results in complicated fuel control and monitoring.

Molten Salt

Molten salt is an alternative to liquid metal. This coolant may operate better at high temperatures, which decreases the impacts of mechanical stress and improves the inherent safety of the reactor. Heat transfer through molten salt is efficient.

Structurally, the main difference is that the fuel, including sodium, zirconium, and uranium fluoride, are dissolved in the coolant. This set eliminates the need for making fuel and the drawbacks of change in isotopic ratios within the fuel rods.

Other nuclear reactor currents include gases such as helium, carbon dioxide, and liquid lead, and organic compounds.

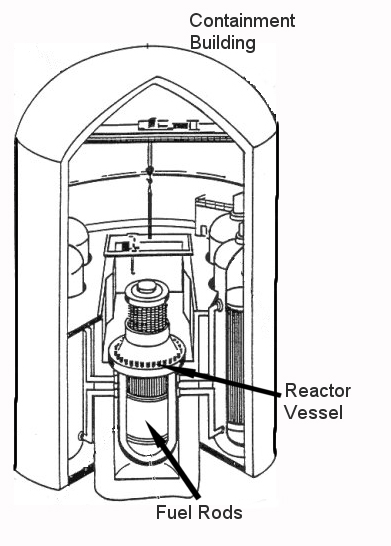

Containment system

Reactors are designed to operate safely without emitting radioactivity to their surroundings. However, it is considered that accidents may occur.

The idea of using multiple fission product barriers is adopted to deal with these accidents. The barriers include, successively, the fuel ceramic, the metal fuel cladding tubes, and reactor vessel and coolant system. As the last and fourth barrier, the reactor is placed in the containment.

In its most normal application, the containment structure is reinforced steel, concrete, or lead building surrounding the nuclear reactor, usually sealed off from the outside atmosphere. The steel is free-standing or connected to the concrete missile shield. In any emergency, it is designed to cover the release of radioactive steam or gas to a maximum pressure between 275 and 550 kPa (from 40 to 80 psi).

Each nuclear plant in the U.S. is constructed to withstand the special conditions described in the Final Safety Analysis Report (FSAR).

In the U.S., the design standards of the containment and missile shield are determined by federal regulations (10 CFR 50.55a). They must be sturdy enough to resist the influence of a fully-loaded passenger airliner without a break.

As containment performance plays an essential role in the most rigorous nuclear reactor accidents, it is only designed to hold or condense steam in short-term accidents. Long-term heat elimination still needs to be prepared by other mechanisms.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip