Thorium salt reactor in a thorium-based nuclear power generation mainly providing the energy of nuclear fission of the uranium-233 isotope produced from the fertile element thorium. A thorium fuel cycle has some potential benefits over a uranium fuel cycle such as a much greater abundance of thorium on the Earth, superior physical and nuclear fuel properties and reduced nuclear waste production.

One of the best advantages of thorium fuel is its low weaponization capability; it is challenging to weaponize the uranium-233/232 and plutonium-238 isotopes in thorium reactors.

From 1999 to 2021, the number of working thorium reactors has risen from zero to some of the research reactors to commercial plans for building full-scale thorium-based reactors for utilization as power plants on a nationwide scale.

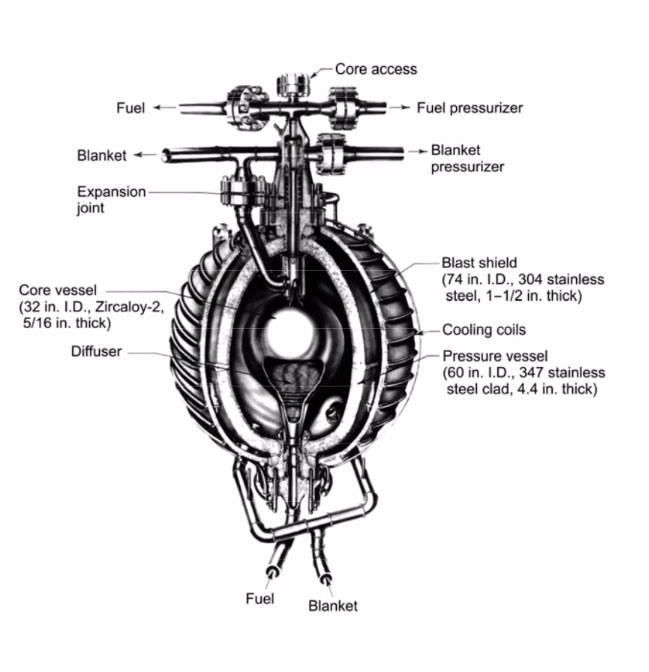

The liquid fluoride thorium reactor (LFTR) is considered a heterogeneous MSR (Molten Salt Reactor) design that produces its U-233 fuel from a rich blanket of lithium-beryllium fluoride (FLiBe) salts with thorium fluoride. The thorium-232 absorbs neutrons from the reactor core to turn into protactinium-233, decaying (27-day half-life) to U-233.

Molten salt reactors utilize molten fluoride salts as a primary coolant at low pressure. This item is not a radical derivation while the fuel is solid and fixed. However, extending the concept to dissolving the fissile and fertile fuel in the salt represents a leap in lateral thinking relative to almost all reactor operated so far. Nevertheless, the idea is not new, as described below.

MSRs may work with epithermal or fast neutron spectrums and with a mixture of fuels. Much of today’s interest in reviving the MSR theory relates to using thorium (to produce fissile uranium-233), where an original source of fissile material such as plutonium-239 needs to be provided. There are several different MSR design concepts and many interesting challenges in the commercialization of much notable thorium.

The salts are considered as primary coolants, often lithium fluoride and lithium-beryllium fluoride, remain liquid with no pressurization from about 500 °C up to about 1400 °C, in contrast to a PWR which works at a temperature of about 315 °C and a pressure of 150 atmospheres.

The principal MSR concept is to have the fuel dissolved in the coolant as fuel salt and finally to reprocess that online. Uranium, thorium, and plutonium form suitable fluoride that easily dissolves in the LiF-BeF2 (FLiBe) mixture and can easily separate thorium and uranium from one another in fluoride form. Batch reprocessing is likely short-term, and fuel life is reported at 4-7 years, with high burn-up. Standard designs and the AHTR have fuel particles in solid graphite and have less potential for thorium utilization.

Through the 1960s, the USA extended the molten salt breeder reactor concept at the Oak Ridge National Laboratory.

Types of thorium-based reactors

According to the WNA (World Nuclear Association), seven types of reactors can use thorium as a nuclear fuel. Six of these have all started their operation in some cases. The seventh is still conceptual, although currently in progress by many countries:

Heavy water reactors (PHWRs)

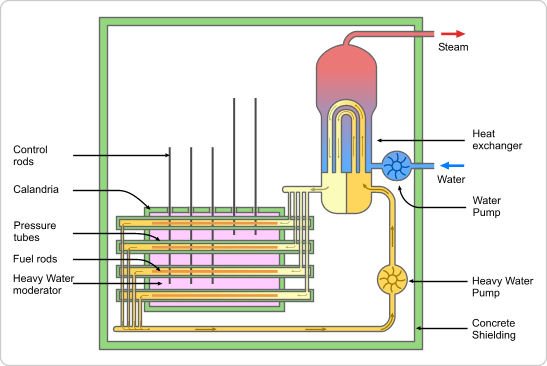

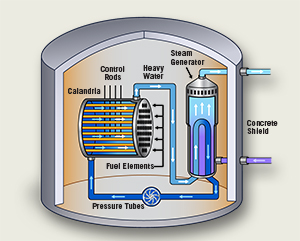

A pressurized heavy-water reactor (PHWR) implies a nuclear reactor that utilizes heavy water (deuterium oxide D2O) as its coolant and neutron moderator.

The heavy water coolant is held under pressure to avoid boiling, allowing it to reach a higher temperature without forming steam bubbles, precisely for a pressurized water reactor.

While heavy water is very costly to isolate from regular water, its low absorption of neutrons considerably raises the neutron economy of the reactor, avoiding the necessity for enriched fuel.

The high cost of heavy water is balanced by the reducing cost of utilizing natural uranium and alternative fuel cycles, as discussed in the previous sections. As of the commencement of 2001, 31 PHWRs were active, with a total capacity of 16.5 GWe, representing roughly 7.76% by number and 4.7% by generating capacity of all working reactors.

Advanced Heavy Water Reactor (AHWR)

The advanced heavy-water reactor (AHWR) is the most modern Indian design for a next-generation nuclear reactor that consumes thorium in its fuel core. It is determined to build the third stage in India’s three-stage fuel-cycle system. This phase of the fuel cycle plan is assumed to start with a 300MWe prototype in 2016. However, since 2018, construction has not started, and a firm date has not been set.

Bhabha Atomic Research Centre (BARC) established a vast foundation to promote the design and development of these Advanced Heavy Water reactors. Points to consider range from critical components, materials technologies, safety analysis, and reactor physics.

The new version of AHWR will be equipped with more general safety elements. India is the top country for these types of reactors due to its large Thorium reserves; therefore, it is more equipped for continual usage and development of the AHWR.

Aqueous Homogeneous Reactors (AHR)

AHRs is a fluid-fueled design using thorium and naturally occurring uranium suspended in a water solution. AHRs have been created, and as stated by the IAEA reactor database, seven are currently in process as research reactors.

Aqueous homogeneous reactors are considered nuclear reactors in which soluble nuclear salts (often uranium sulfate or uranium nitrate) are dissolved in heavy or light water. The fuel is combined with the coolant and the moderator. So, it is referred to as homogeneous. The water could be either heavy water or regular, both of which require to be very pure.

Their self-controlling characteristics and capability to handle make them unique among reactors and probably the safest.

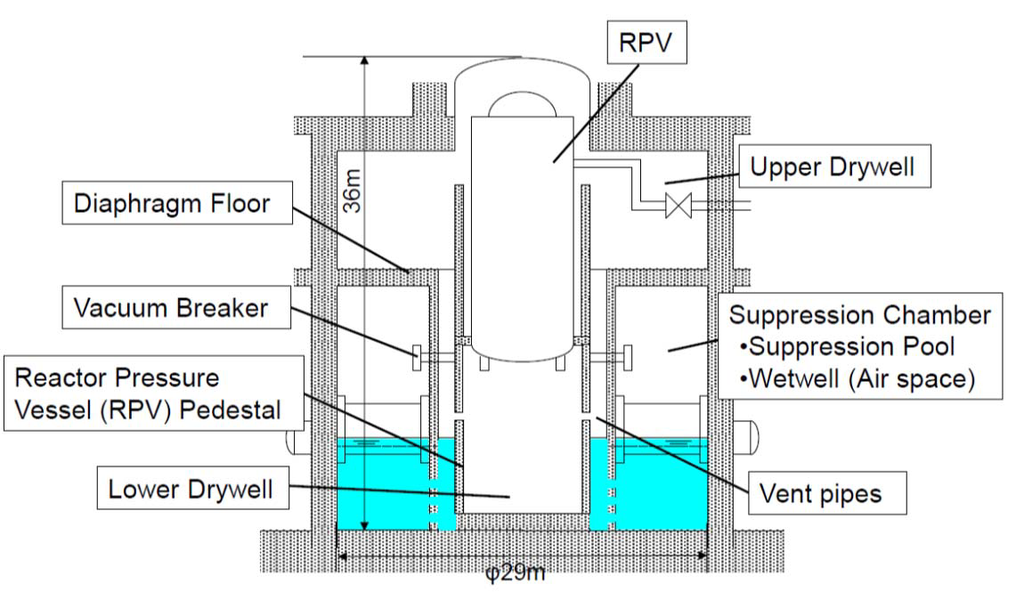

Boiling Water Reactors (BWRs)

A boiling water reactor (BWR) is a kind of light water nuclear reactor used to generate electrical power. It is the second most common type of electricity-generating nuclear reactor after the pressurized water reactor (PWR), a type of light water nuclear reactor.

The principal difference between a BWR and PWR is that in a BWR, the reactor core makes the water convert into steam and runs a steam turbine. In a Pressure Water Reactor (as will be described later), the reactor core heats water but does not boil. This hot water then transfers heat to a lower pressure water system, which turns to steam and runs the turbine. The BWR was generated by the Argonne National Laboratory and General Electric (G.E.) in the mid-1950s.

Pressurized Water Reactors (PWRs)

A pressurized water reactor (PWR) is a class of light-water nuclear reactors. PWRs compose the vast majority of the world’s nuclear power plants (with remarkable exceptions being Japan, Canada, and the U.K.).

A PWR pumps the primary coolant (water) under high pressure to the reactor core to be heated by the power released by the fission of atoms. The high-pressure heated water then moves to a steam generator, where it carries its thermal energy to lower pressure water of a secondary system that produces steam.

Thus, the steam turns the turbine to spin an electric generator. Unlike the boiling water reactor (BWR), pressure in the primary coolant loop prevents the water from boiling within the reactor. All light-water reactors utilize normal water as both coolant and neutron moderators.

PWRs were initially planned to serve as marine nuclear propulsion for nuclear submarines. They were utilized in the original design of the second commercial power plant at Shippingport Atomic Power Station.

(Reference: en.wikipedia.org)

Molten Salt Reactors (MSRs)

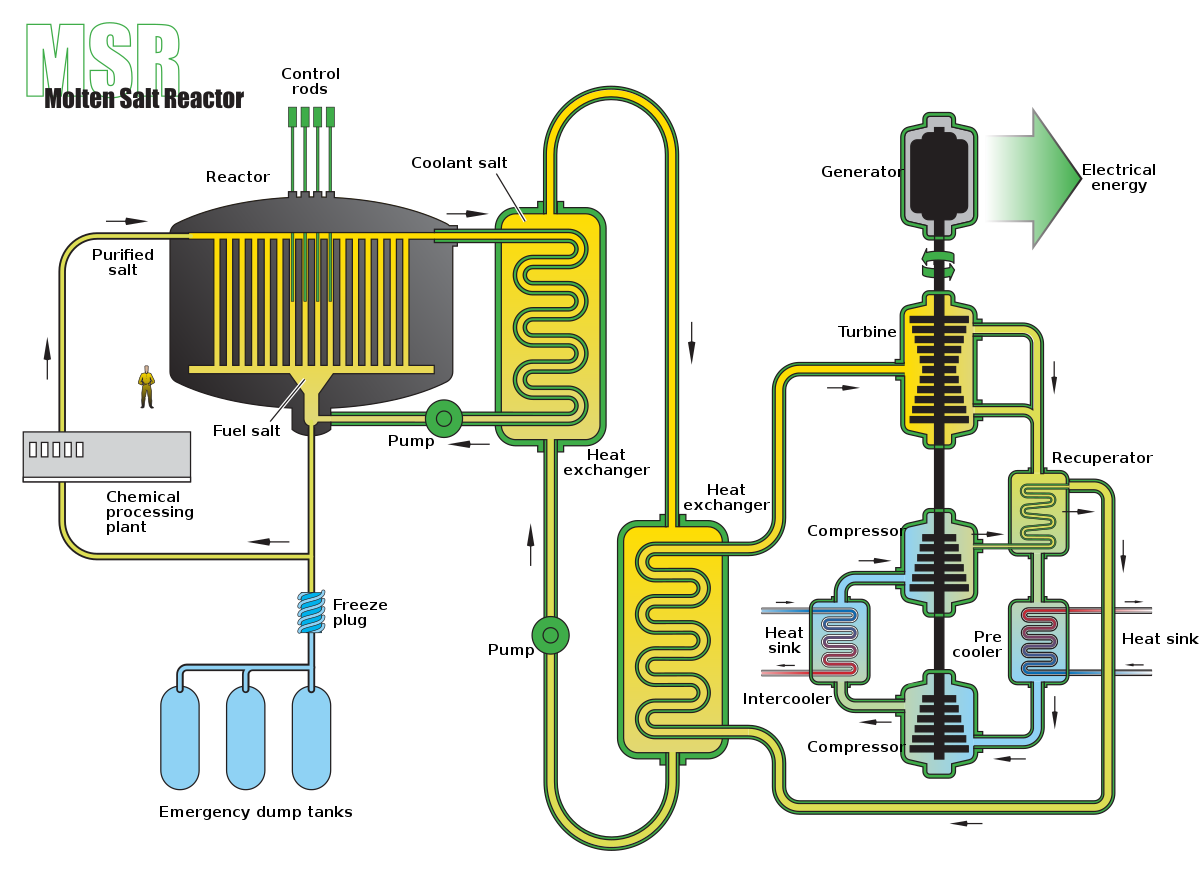

Molten salt reactors (MSRs), including LFTRs (Liquid fluoride thorium reactors), rather than fuel rods, apply fissile materials in the form of molten salts cycling through the core to undergo fission.

Then, the molten salt transfers the heat generated by the reactions away from the core to exchange with a secondary medium.

Molten salt breeder reactors, or MSBRs, are another class of molten salt reactors that employ thorium to breed more fissile material.

The Oak Ridge National Laboratory planned and built an MSR that worked from 1965 to 1969. It utilized U-233 (bred from Th-232) as fuel in its last year.

High-Temperature Gas-Cooled Reactors (HTRs)

The HTGR is a reactor that can reach high outlet temperatures up to 1000 °C.

There are two principal classes of HTGRs, including pebble bed reactors (PBR) and prismatic block reactors (PMR). The PMR has a prismatic block core structure, in which hexagonal graphite blocks are fitted in a cylindrical pressure vessel.

The pebble bed reactor (PBR) design includes fuel in the pebbles form, stacked together in a cylindrical pressure vessel.

Both mentioned reactors can have the fuel stacked in an annulus zone with a graphite core spire based on the design and desired power.

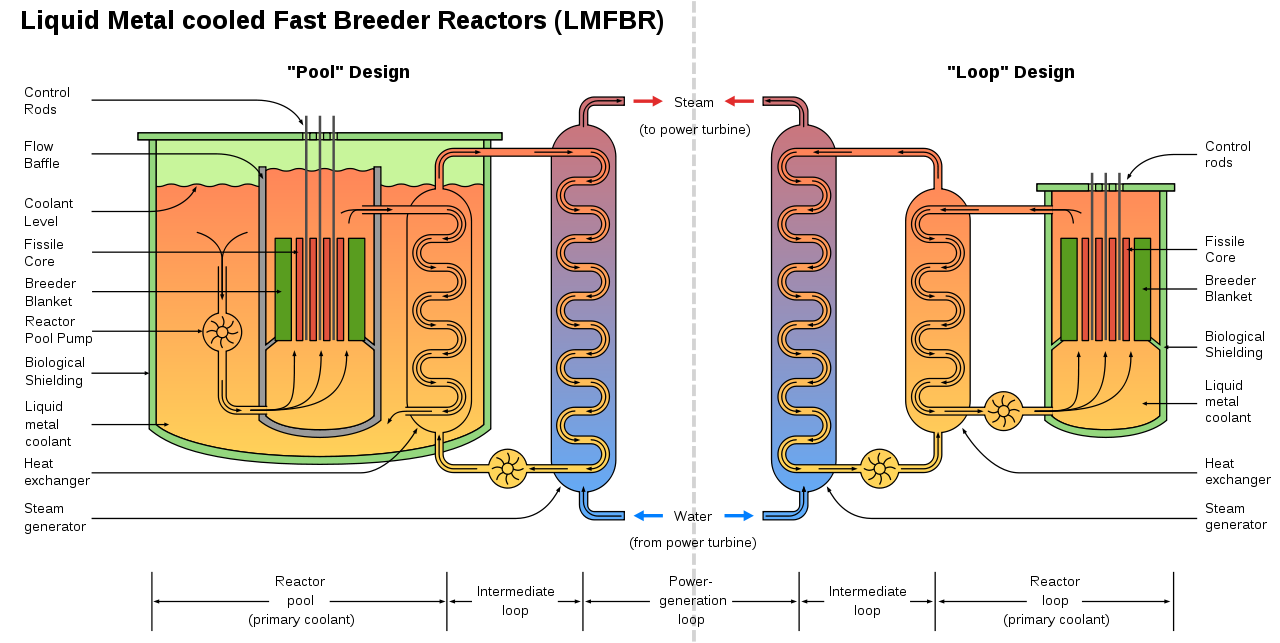

Fast-Neutron Reactors (FNRs)

A fast-neutron reactor (FNR) is a nuclear reactor type. In this reactor, the fission nuclear chain reaction is sustained by fast neutrons (transporting energies above 0.5 MeV or more) instead of thermal neutrons in thermal-neutron reactors. This type of reactor requires no neutron moderator but fuel that is almost enriched in fissile material compared to a thermal-neutron reactor.

Accelerator-Driven Subcritical Reactor

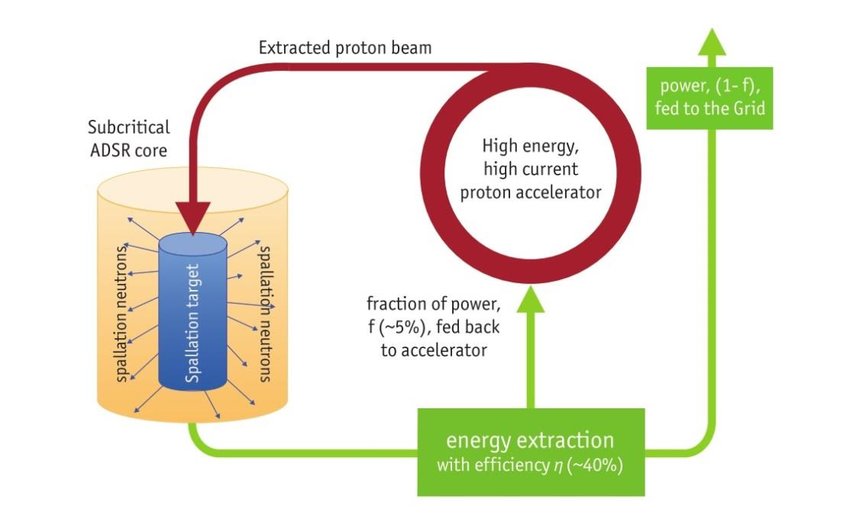

An accelerator-driven subcritical reactor signifies a nuclear reactor configuration that is made by coupling a subcritical nuclear reactor core, including a high-energy proton or electron accelerator. It can apply the thorium as its fuel.

The neutrons required for providing the fission process can be produced by a particle accelerator. These neutrons activate the thorium to complement fission without making the reactor critical.

An advantage of these reactors is their waste products short half-lives.

Thorium reactors can produce power from the plutonium residue from uranium reactors. Unlike uranium, thorium does not need significant refining. Additionally, it has a higher neutron yield per neutron absorbed.

Thorium Salt Reactor Function

The fuel is a combination of molten lithium and beryllium fluoride (FLiBe) salts in the standard or fundamental MSR concept; in addition, these must be dissolved with low-enriched uranium (U-235 or U-233) fluorides (UF4). Also, the core includes an unclad graphite moderator designed to allow the flow of salt at approximately 700°C and low pressure.

Much higher temperatures are feasible but not yet examined. Heat is transported to a secondary salt circuit and therefore to steam or process heat. Notice that the basic design is not a fast neutron reactor, while with some moderation which works by the epithermal graphite (intermediate neutron speed). The breeding ratio is less than 1. However, with fuel dissolved in the salt, this concept is further from commercialization than solid fuel designs, setting the ceramic fuel in pebbles, plates, prisms, or one design with liquid fuel in static tubes. According to the reports, reprocessing that fuel salt online is still further from commercialization.

MSR Designs

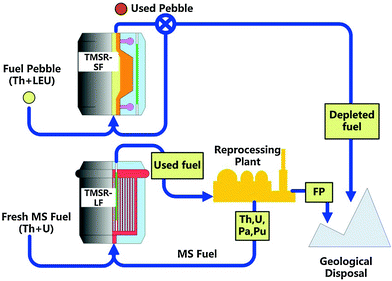

With a liquid-fuel MSR design, thorium could be dissolved with the uranium in a single-fluid MSR as a homogeneous design. Two-fluid, or heterogeneous MSRs, would possess fertile salt including thorium in a second ring separate from the fuel salt, including fissile uranium or plutonium, operating as a breeder reactor (MSBR).

Here, the U-233 is gradually separated and carried to the primary circuit. Experts estimated that the entire reactor vessel should be replaced after about eight years due to graphite degradation from neutron flux in the two-fluid design.

In liquid-fuel MSRs, the fission products dissolve in the fuel salt and are ideally eliminated to be replaced with fissile uranium, plutonium, and other actinides.

The MSR operates at near atmospheric pressure, which eliminates the risk of explosive release of radioactive materials.

Thorium Salt Reactor Advantages

Thorium can provide a clean and efficiently limitless power source while eliminating some serious public concerns such as weapons proliferation, toxic waste, radioactive pollution, and costly and complicated-to-process fuel.

- Thorium is three times more available than uranium and almost as plentiful as lead and gallium in the crust of the Earth.

- Making a practical nuclear bomb from the byproducts of a thorium reactor is difficult.

- A plutonium production rate in a thorium reactor is less than 2 percent of a standard reactor, and the isotopic content of plutonium makes it unsuitable for a nuclear detonation.

- When thorium is employed as a fuel in a liquid fluoride thorium reactor, there is much less nuclear waste up to twice that eliminates large-scale or long-term storage.

- The thorium fuel cycle provides great energy security advantages in the long term because it can be a self-sustained fuel without requiring fast neutron reactors.

- The thorium fuel cycle is a possible method to generate long-term nuclear energy, including low radio-toxicity waste.

- There is no need for expensive fuel enrichment because all-natural thorium can be utilized as fuel.

- Thorium mining is safer and more efficient than uranium mining.

Thorium Salt Reactor Disadvantages

- In a thermal neutron spectrum, breeding is slow and needs vast reprocessing.

- Complicated and expensive testing and licensing work is needed, which requires business and government support.

- The cost of fuel fabrication and reprocessing is higher than in plants that use traditional solid fuel rods.

- When irradiated for performance in reactors, thorium produces uranium-232, which emits gamma rays. The irradiation may then produce uranium-233, which is suitable for use in nuclear weapons.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip