Ball valve vs Plug valve-A plug valve with a one-piece top-entry construction resembles a one-piece top-entry ball valve in many ways. Ball valves and plug valves are technically the same valves because they perform the same functions and have similar features, and they both have a wide range of uses. Today, we’ll look at the differences between a plug valve and a ball valve.

Ball Valve vs Plug Valve: Clear Definition

Control valves are an important component of every piping system. The primary purpose of these valves is to control the flow of the medium through various piping sections of a system. Ball and plug valves are two types of control valves that perform similar tasks and are frequently interchanged. However, in terms of structure and overall function, they are still distinct.

There are so many different types of control valves to choose from that it might be overwhelming. If you’re working with important applications, installing the wrong valve in your system can make it less efficient and even deadly. This post will explain the differences between plug and ball valves so that you can make an informed decision about which is best for your application. Continue reading to learn more.

What Are the Ball and Plug Valves?

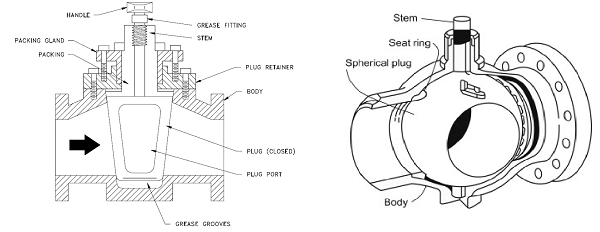

Let’s start with a fundamental understanding of what ball and plug valves are. Control valves with a spherical disc inside are known as ball valves. This disc has a port, which is a hole in it. The valve is open when the port is aligned with both ends of the valve, allowing the medium to flow freely through it. The valve is closed and the medium flow stops when the port is perpendicular to the ends of the valve.

The ball valve evolved from a plug valve with a ball as its closing part; it revolves around the valve’s center to open and close and is primarily used to cut off, distribute, and change the flow direction of the medium. With merely 90 degrees of rotation or a small torque, ball valves can close firmly. Through the flow path for the medium, the whole horizontal of the valve body cavity provides no resistance.

The ball valve’s key characteristics are its compact structure, ease of operation and maintenance, and suitability for water, acids, solvents, natural gas, and other general media. It’s also suited for harsh media such as oxygen, hydrogen peroxide, methane, and ethylene. The ball valve body can be one piece or a combination of pieces. Ball valves are commonly thought to be best for opening and closing immediately, but new improvements have made them suitable for throttling and flow control.

A plug valve gets its name from the conically tapered or cylindrical disc that looks like a plug. The plug has one or more sideways openings that allow the fluid to pass through. When the bore passage aligns with the flow, the valve opens, allowing fluid to flow through it freely. The solid section of the stopper restricts the flow and so closes the valve when it is turned.

A plug valve is a type of old-line valve that is also known as a cock valve or a spinning plug valve. The valve “plug” (usually conical or cylinder) is connected with the body of the conical hole surface of the sealing, which moves around the centerline of the valve depending on the plug body to achieve open and close. It is mostly used for media cutting, distribution, and changing of flow.

The plug valve has a simple design and is tiny in size. It can only be rotated 90 degrees to open and close. It’s commonly utilized in low-pressure, small-diameter, medium- to low-temperature situations. The sealing surface of the plug valve is easily worn, and it is also easy to become stuck in high temperature or high-pressure situations, making it unsuitable for flow regulation.

Both ball and plug valves are quarter-turn valves, which means they can be opened or closed with a rapid 90-degree rotation of the actuator. They are quick-acting valves that are used for sealing and shutting down processes. Both ball and plug valves are ineffective for throttling. It is possible to modify the design and construction of either valve to make it suitable for throttling, but this would be quite expensive.

What Are the Differences Between Ball Valves and Plug Valves?

In terms of basic function and use, ball and plug valves are extremely similar. Both are control valves that are utilized in various piping units to produce tight shut-offs. They all operate on the same basic premise, with a perforated disc controlling the flow of the medium. They do, however, differ in a number of ways. Here are some of the key distinctions between ball valves and plug valves:

Construction

Bored discs are found at the center of both ball and plug valves. A ball valve has a hollow center and a spherical disc. A conical or cylindrical disc with drilled openings runs through a plug valve. In a ball valve, the disc or ball is smaller than the disc or plug in a plug valve. A plug valve can give a tighter shut-off than a ball valve because of this. In comparison to a ball valve, plug valves are also smaller. Plug valves can be easily placed in smaller units due to their lower footprint.

Different Principle

The plug valve gave way to the ball valve. They both rotate at 90 degrees, but the “plug” is either a plug or a ball with a circular through hole or channel going through its axis. The ball and ports should look like this: the sphere will appear as a sphere at the intake and outlet when rotated by 90 degrees, cutting off the flow. The upper sections of the plug valve, the conical plug, and the conical pressure-formed body surface, are sealed with packing between the plug and the space between the body. Because it normally does not have bonnets and instead has the handle exposed outdoors at the end, plug valves are simple and often cost-effective.

Different Application

In terms of cutting performance, plug valves outperform ball valves, however, this isn’t readily apparent. The plug valve’s sealing surface is substantially larger than the ball valve’s and provides a superior sealing effect but at the cost of greater torque and a smaller diameter. To reduce medium erosion and valve tightening over time, the ball valve should be used for switching pipeline medium rather than as a throttle valve.

With the advancement of sealing technology, the sealing effect of the ball valve has greatly improved, so we can say that the plug valve is used when the sealing requirements are stringent but the diameter is small, and the ball valve is used when the sealing effect is not stringent but the diameter is large.

Plug Valve Is Lower Cost

The bushing entirely covers the “plug” on the plug valve, preventing wear on the valve body and plug. The valve may be repaired and updated by replacing the bushing and top seal, which can meet the long-term service requirements of 300°C. This temperature range provides significant advantages over alternative hard-sealed metal ball valves.

Furthermore, the top face and flange of the plug valve are the only elements that require processing; all other sections are cast in one stage, and the interior body does not require processing. When manufacturing MONEL, INCONEL, HAST alloy, and other exotic materials as materials, the plug valve has an evident economic advantage over the ball valve.

Function

Control valves such as ball and plug valves are used to start and halt the flow of a medium. The plug valve’s sealing surface is substantially bigger than that of a ball valve. Because the valve’s cylindrical or conical stopper has a bigger surface area, it can offer a better seal. A larger surface area, on the other hand, equates to more torque. Because of the tremendous torque, the valve is rigid and difficult to operate.

Ball valves, on the other hand, operate without requiring any torque. Ball valves can suffer from poor sealing performance due to their reduced surface area, however current advances in chemical sealants and seal injections imply that this is no longer an issue. Plug valves are heavier than ball valves. Plug valves are heavier because they have a solid disc or plug in the center that is greater in size. Because large-sized plug valves are expensive to manufacture and can become quite heavy, plug valves are typically employed in smaller applications. Visit here to explore more about the Ball valve vs Plug valve functionally.

Maintenance

Control valves must be maintained regularly in order to function properly. Because the ball or disc is positioned deep inside the valve and cannot be easily accessible, ball valves are difficult to maintain. Indeed, one of the most common critiques of ball valves is that the valve’s body cavity acquires particles from the medium over time, making them difficult to remove.

Because the plug can be quickly removed and cleaned, plug valves are easier to maintain. This also allows for easy access to the rest of the valve body, making maintenance a breeze. Plug valves feature a simpler design and fewer moving parts than other valves. They’re also a lot smaller than ordinary valves. This makes repairs and maintenance much easier.

Types

Ball valves are a type of control valve that can be used in a variety of applications. They come in a variety of shapes and sizes, depending on their structure and function. This is why they are currently one of the most widely utilized valves in the pipe sector. Ball valves with full and reduced bores are available. Full bore ball valves allow for unhindered medium flow through the valve. Reduced bore or reduced port valves limit the flow of medium since the bore is smaller than the pipeline diameter.

Ball valves can be installed on a trunnion or float. In applications where a bi-directional shut-off is required, floating ball valves are used. Ball valves with trunnion mounting are utilized in high-pressure, high-temperature applications.

There aren’t as many types of plug valves as there are for ball valves. The majority of plug valves, particularly rectangular port valves, are full bore. Reduced bores are also possible with round port and diamond port valves, although they can only be utilized in low-pressure situations.

Plug valves are divided into two categories: lubricated plug valves and non-lubricated plug valves. Lubricated plug valves are normally composed of metal and have a lubricant chamber that keeps the valve’s plug lubricated at all times. The lubricated plug is easier to move, has less friction, and resists corrosion. Larger applications and high-temperature services can be handled by lubricated plug valves.

A non-metallic elastomeric sleeve is inserted between the plug and the valve body in non-lubricated plug valves. The friction between the plug and the body is reduced by this sleeve. However, because of the non-metallic seat, this valve cannot be used in high-temperature applications.

Longevity

Ball valves, on average, have a longer lifespan than plug valves. A plug valve must handle more torque and has a larger surface area in contact with the medium. This indicates that the valve has experienced more wear and tear and is more susceptible to corrosion. Special features in ball valves prevent the medium from coming into continual contact with the disc. The low torque means less wear and tear, despite the fact that it contains more moving components.

Control Capability

Ball valves can be operated by a variety of actuators, including manual, electric, pneumatic, hydraulic, and other types. Even when operating under high-pressure situations, they are simple to open and close and require very little force. Manual and electric actuators can be used to operate plug valves. They can also be controlled by pneumatic actuators, although they are quite costly to install. Due to the significant amount of torque, plug valves can be difficult to open and close in high-pressure applications. This is why plug valves aren’t typically employed in larger applications.

Customization

Ball and plug valves can both be adjusted to meet individual needs. Ball valves, on the other hand, allow considerably more adjustability than plug valves. Because there are so many different types of ball valves on the market, you have a lot of options. Unidirectional, bidirectional, and multidirectional ball valves are available. They can have several ports and a one, two, or three-piece body. Top-entry, end-entry, side-entry, and split-body ball valves are available. Double block and bleed capabilities can also be added to ball valves.

Customization of plug valves is also possible, although only to a limited extent. This is due to their simplistic structure, which leaves limited room for advancement. Multi-port plug valves are available in a variety of sizes, ranging from two to five ports. Multiport valves must be used with caution since they may not produce a particularly tight shut-off. All other types of plug valve adaptations, such as inserting electric or pneumatic actuators or adding anti-friction components, are quite costly.

What Are the Applications of Ball Valve vs Plug Valve?

Ball and plug valves are widely employed in a variety of pipeline applications. Plug valves are utilized in fluid services such as air, gas, vapor, hydrocarbon, and others to enable bubble-tight shut-off. Plug valves are commonly used in slurries, mud, and sewage applications because they offer a higher surface area and allow for unrestricted medium flow. When dealing with corrosive or hard materials, fortified plug valves are employed to provide tight sealing. They are the most reliable shutdown choice in critical applications due to their basic operational structure and anti-corrosion properties.

Ball valves are utilized in a variety of applications. Turbine skids, compressor skids, gas feed lines, generator skids, crude oil plants, polymer plants, separator skids, field gas plants, LNG plants, industrial gas processing plants, tank farms, hydrocarbon processing, oil refinery feedstock lines, and automated process applications are just a few of the applications where they’re used. Subsea, underground, and cryogenic services all require high-pressure ball valves. Cooling water, petroleum refining, feedwater, desalination, and brewing all require stainless steel ball valves.

Conclusion

Control valves such as ball and plug valves are utilized to provide bubble-tight seals in a variety of applications. Plug valves seal better, but they’re difficult to use and too expensive and heavy for large-scale applications. Ball valves may not have the best sealing capabilities, but they are simple to operate and scale up for bigger applications. Furthermore, with the addition of technology and systems, their sealing capacities can be improved. Our catalogs provide a wide range of ball and plug valves. If you need help with your valve needs, contact us to get experienced guidance on your applications.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Gate Valve vs Ball Valve

- Ball Valve Types and Their Uses

- Ball Valve Manufacturers

- Plug Valve Manufacturers

- Gate Valve Manufacturers

- Pinch Valve Manufacturers

- Valve Manufacturers

- Gate Valve Installation Costs and Maintenance in 2022 (Clear Guide)

- Globe Valve Installation Costs in 2022 (Clear Guide) + PDF

- Air Release Valve Installation Costs in 2022 (Ultimate Guide) + PDF

- Angle Valve Installation Costs: Practical Factors in 2022

- Solenoid Valve Installation Costs: Main Factors in 2022 + PDF

- Ball Valve Parts: An Easy-to-Understand Guide (2022 Updated)

- globe valve vs ball valve; Which One Is the Best for You?

- Backwater Valves Installation, Costs and Maintenance in 2022

- How to Repair a Gate Valve? (Clear Guide)

- Backflow Valve Installation, Costs and Maintenance in 2022

- How to Install a Thermostatic Mixing Valve? (Costs and Maintenance in 2022)

- How to Install a Water Pressure Reducing Valve? (Costs and Maintenance in 2022)

- Check Valve Installation Costs and Maintenance in 2022

- The 10 Best Water Shut off Valves of 2022

- What is Drain Valve? Working Principle, Types & Applications

- What are Coaxial Valves? Working Principles and Type

- What is Isolation Valve? Working Principle & Types