The 10 Best Warehouse Pallet Shelving of 2023 – A Pallet Shelving system is a storage solution that allows products to be stacked horizontally on many levels. Here we are going to introduce some of the best Pallet Shelving systems of 2023.

To find out more about Warehouse Racking, please visit our Warehouse Racking for Sale pages, where you can also request a quote. You can find vast verities of big companies such as Prologis Essentials, which is the only integrated solutions provider with the expertise to optimize your warehouse today and the vision to futureproof it for tomorrow.

How We Selected The Best Warehouse Pallet Shelving of 2023

We analyzed more than 10 webpages and hundreds of products and reviewers to find the best warehouse pallet shelving for 2023. We consulted with our experts and looked at our previous experiences to make sure we were recommending the best products.

Here are the factors we considered when making our picks:

- Quality: We only considered products that were made from high-quality materials and that were built to last.

- Versatility: We wanted to find products that could be used to store a variety of items, from small to large, heavy to light.

- Ease of use: We wanted to find products that were easy to assemble and use, so that businesses could get up and running quickly.

- Affordability: We wanted to find products that were affordable for businesses of all sizes.

Based on these factors, we narrowed down our list to the 10 best warehouse pallet shelving products of 2023. These products are all made from high-quality materials, are versatile, easy to use, and affordable.

We hope this information helps you choose the best warehouse pallet shelving for your business.

Here are some additional details about our process:

- We analyzed more than 10 webpages, including product reviews, industry publications, and manufacturer websites.

- We read hundreds of product reviews from customers who have used the products.

- We consulted with our experts, who have years of experience in the warehouse industry.

- We looked at our previous experiences with warehouse pallet shelving to see which products worked well and which did not.

We believe that the products we have chosen are the best of the best. They are made from high-quality materials, are versatile, easy to use, and affordable. We hope that you will find one of these products to be the perfect solution for your warehouse storage needs.

Basics of Led Fixtures for Warehouse & Garage

A warehouse Shelving system is a storage solution that allows items to be stacked horizontally on many levels. These technologies may help you manage and make better use of your warehouse space, as well as organize your freight to expedite operations.

Every warehouse has its unique set of requirements. The perfect Shelving system will maximize space usage while causing the least amount of interruption to your operations, particularly the picking process. To evaluate which Shelving system is ideal for your warehouse, consider the following factors:

- Floor Utilization: The capacity of a Shelving system to make utilization of warehouse floor space.

- Budget: A rough estimate of the cost per pallet. When verifying that the Shelving system fits all of your criteria, keep this in mind.

- Accessibility for Forklifts – The ability to accommodate forklifts that move heavy items. This takes into account the amount of aisle width required by forklifts.

- Storage Utilization: The amount of space available in the Shelving system. The volume, size, and weight of your package will determine the quantity you’ll need.

- Inventory Management: Items management refers to the warehouse’s preferred sequence for retrieving inventory.

- Versatility: Versatility refers to a Shelving system’s ability to hold a wider range of objects.

In today’s fast-paced and highly competitive marketplaces, inventory management is vital to streamlining warehouse operations. It’s one of the many challenges that warehouse managers face, but it may be alleviated by selecting the appropriate warehouse Shelving system. As a consequence, we’ll discuss the best Shelving warehouse systems in this piece, as well as the factors to consider when selecting a suitable Shelving system and the many types.

Please visit our Warehouse Shelving for Sale website to learn more about Warehouse Shelving and to obtain a quote.

Best Warehouse Pallet Shelving Reviews

1. Selective Shelving System

Specifications

| Budget | $45 – $65 per pallet |

| Floor Utilization | 40% |

| Storage Utilization | 90 – 95% |

| Inventory Management | First in, First Out (FIFO) |

General Descriptions

The selected Shelving system is the most popular because of its inexpensive cost and a wide choice of sizes and attachments. This Shelving system is perfect for traditional storage in any application where items must be accessed quickly.

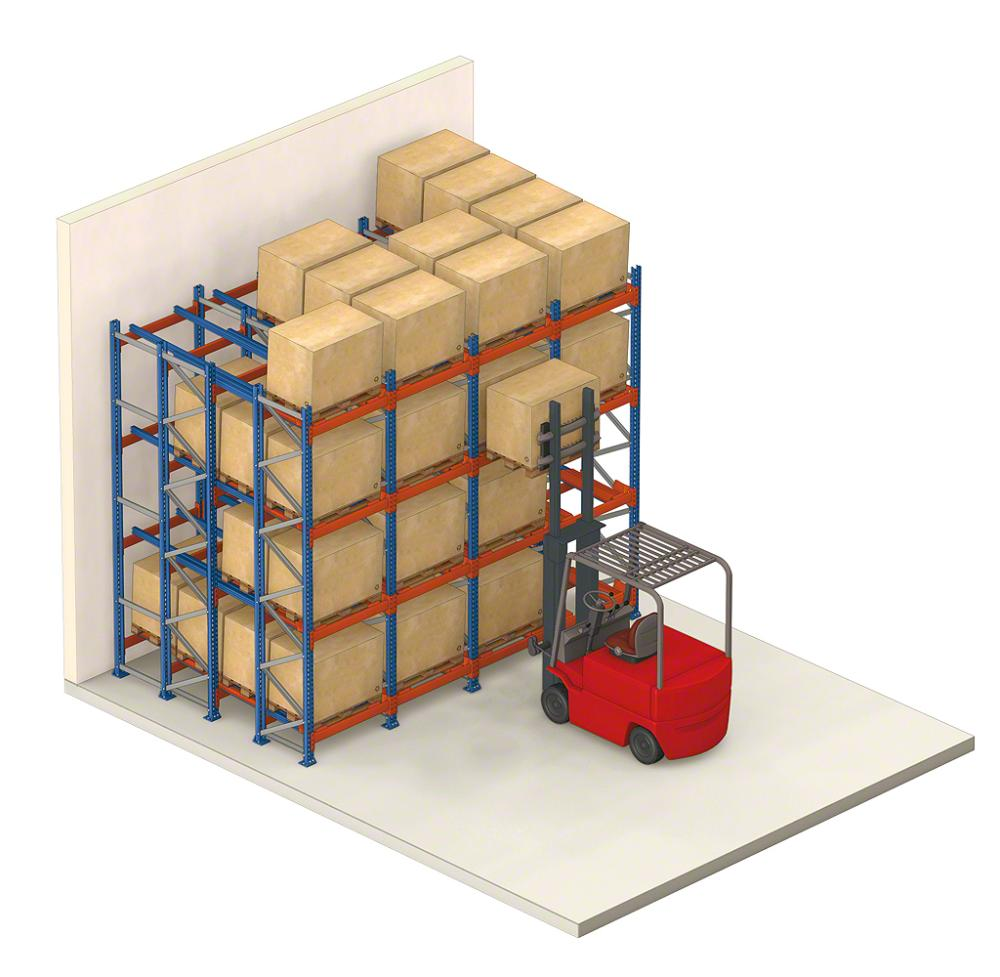

2. Double-Deep Shelving System

Specifications

| Budget | $50 – $70 per pallet |

| Floor Utilization | 60% |

| Storage Utilization | 85 – 90% |

| Inventory Management | First In, Last Out (FILO) |

General Descriptions

The double deep Shelving system is a version that delivers a great density gain but requires special equipment (extendable forks) and takes longer to set up. It combines the advantages of selective and high-density Shelving.

3. Pallet Flow/Live Shelving System

Specifications

| Budget | $170 – $185 per pallet |

| Floor Utilization | 70 – 75% |

| Storage Utilization | 85 – 90% |

| Inventory Management | First In, First Out (FIFO) |

General Descriptions

Pallet flow racks combine elevated rails with dynamic components such as gravity rollers and conveyors to create a high-density storage solution. These warehouse storage racks are propelled by gravity. This Shelving system has the potential to double, triple, or even quadruple the storage capacity of your warehouse, and it’s great for expiration-date-sensitive items.

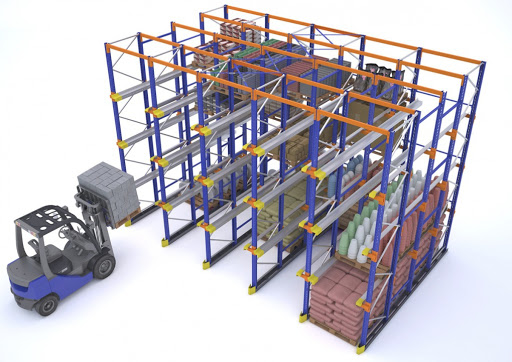

4. Drive-In Shelving System

Specifications

| Budget | $160 – $185 per pallet |

| Floor Utilization | 65% |

| Storage Utilization | 60 – 65% |

| Inventory Management | Last In, First Out (LIFO) |

General Descriptions

The drive-in Shelving system allows you to store items at maximum density in your warehouse. In a warehouse, it reduces aisles and is perfect for storing large amounts of similar items in a small amount of area.

5. Push Back Shelving System

Specifications

| Budget | $275 – $295 per pallet |

| Floor Utilization | 75% |

| Storage Utilization | 75% |

| Inventory Management | Last In, First Out (LIFO) |

General Descriptions

By employing distinct lanes for each SKU, the push-back pallet Shelving system enables more pallet storage while also enhancing selectivity, making them easier to identify, pick, and put away. By allowing for front-loading and unloading, push back warehouse storage racks eliminate the need for several aisles.

6. Narrow Aisle Shelving System

Specifications

| Budget | $50 – $60 per pallet |

| Floor Utilization | 90% |

| Storage Utilization | 95% |

| Inventory Management | First In, First Out (FIFO) |

General Descriptions

Narrow aisle Shelving, like selective Shelving, allows for simpler access to individual pallets. To provide high-density storage, warehouse storage racks make use of floor area and roof height.

7. Midwest Pallet Racking

Specifications

| Material | Midwest Pallet Racking uses a variety of materials in their products, including steel, aluminum, and wood. |

| Size | Their products are available in a variety of sizes and styles to meet the needs of businesses of all sizes. |

| Accessories | They offer a variety of accessories to make their products more functional and safe. |

General Descriptions

Midwest Pallet Racking is a good option for businesses that are looking for a high-quality pallet racking system from a reputable company. They offer a wide range of products and services to meet the needs of businesses of all sizes. Their prices are competitive, and they offer a variety of customization options. However, they are not the most affordable option on the market, and their products may not be as customizable as some other options.

If you are looking for a high-quality pallet racking system from a reputable company, Midwest Pallet Racking is a good option to consider. However, if you are on a tight budget or need a highly customizable system, you may want to consider other options.

8. Uline Pallet Racking

Specifications

| Material | Uline Pallet Racking is made from high-quality steel. |

| Size | Uline Pallet Racking is available in a variety of heights, widths, and depths. |

| Load Capacity | Uline Pallet Racking can support a variety of loads, up to 5,000 pounds per pallet. |

General Descriptions

Uline Pallet Racking is a good option for businesses that are looking for a durable, affordable, and easy-to-use pallet racking system. Uline Pallet Racking is available in a variety of styles and configurations, making it a good option for businesses of all sizes.

If you are looking for a pallet racking system that is durable, affordable, and easy to use, Uline Pallet Racking is a good option to consider. However, if you are looking for a pallet racking system that is highly customizable or aesthetically pleasing, you may want to consider other options.

9. Steel King Pallet Racking

Specifications

| Material | Steel King Pallet Racking uses a variety of materials in their products, including steel, aluminum, and wood. |

| Size | Their products are available in a variety of sizes and styles to meet the needs of businesses of all sizes. |

| Accessories | They offer a variety of accessories to make their products more functional and safe. |

General Descriptions

Steel King Pallet Racking is a good option for businesses that are looking for a high-quality pallet racking system from a reputable company. They offer a wide range of products and services to meet the needs of businesses of all sizes. Their prices are competitive, and they offer a variety of customization options. However, they are not the most affordable option on the market, and their products may not be as customizable as some other options.

If you are looking for a high-quality pallet racking system from a reputable company, Steel King Pallet Racking is a good option to consider. However, if you are on a tight budget or need a highly customizable system, you may want to consider other options.

10. Jungheinrich Pallet Racking

Specifications

| Material | Jungheinrich Pallet Racking is made from high-quality steel. |

| Size | Jungheinrich Pallet Racking is available in a variety of heights, widths, and depths. |

| Load Capacity | Jungheinrich Pallet Racking can support a variety of loads, up to 5,000 pounds per pallet. |

General Descriptions

Jungheinrich Pallet Racking is a good option for businesses that are looking for a high-quality, durable, and easy-to-use pallet racking system. Jungheinrich Pallet Racking is available in a variety of styles and configurations, making it a good option for businesses of all sizes.

If you are looking for a pallet racking system that is high-quality, durable, and easy to use, Jungheinrich Pallet Racking is a good option to consider. However, if you are looking for a pallet racking system that is highly customizable or affordable, you may want to consider other options.

Considerations When Selecting Led Fixtures for Warehouse & Garage

There is a warehouse racking provider for you, no matter your circumstance. If you’re searching for pallet storage, drive-in racking, or even second hand equipment, you’ll find it with one of these racking companies.

It’s probably a good idea to have a scalable staff to accommodate the extra demand once you have the enhanced warehouse capacity you require.

Look no farther than Linquip if you’re searching for a simple solution to boost your warehouse labor to meet demand. We have a user-friendly platform that allows you to swiftly staff people without the headache of hiring.

Frequently Asked Questions regarding Warehouse Shelving Systems

1. What Are the Benefits of Using a Warehouse Shelving System?

For starters, Shelving is significantly less expensive than expanding the size of an existing warehouse. The addition of a Shelving system to your warehouse may double or even treble the number of items you can handle, and the addition of forklifts to a simple warehousing operation generally results in a considerable gain in efficiency.

Businesses are more concerned than ever before with the bottom line, and a warehouse without even the most basic Shelving system is almost always inefficient. In warehouses that deal with large goods, forklifts are common, making the transition to a Shelving system much easier.

2. What Safety Concerns Do We Have In Mind?

Because your raw materials will be kept dozens of feet above the warehouse floor, you’ll need to take extra special care to avoid damage. Pay close attention to any loose Shelving system components, especially after they’ve been installed, because even the tiniest error might result in materials dropping.

Also, make sure to follow each manufacturer’s strict load restrictions. While your Shelving system may appear to be capable of taking more, it is not safe and might cause damage to goods or injury to personnel. Rack audits should be performed on a regular basis to ensure product integrity.

3. What Is a Concentrated Point Load, and How Does It Work?

A concentrated static load’s weight is not evenly distributed throughout the deck’s surface. A point load is a static force localized at one or more points on the deck. A container with feet or bars, for example, might be used to carry the weight that is concentrated in a few distinct areas of the container.

4. How Frequently Should My Racks Be Inspected?

Your racks should be reviewed at least once a year, according to the MHI (Material Handling Institute). In addition, if your Shelving system is damaged by a forklift or other warehouse equipment, we recommend having your racks examined and replacing the damaged item. Safety should be a primary issue in your warehouse.

5. Why Do I Need to Anchor My Racks?

According to the Rack Manufacturers’ Institute, Shelving must be secured to the floor. This is true at all times for all Shelving frames. If you’re not sure what size anchor bolts to use, contact the manufacturer. If you’re in an earthquake zone, you could need more than a standard 12″ anchor bolt to fulfill the criteria.

Depending on the racks and your position, you may just need one anchor bolt per column or you may need to use all four holes in the base. Your manufacturer should be familiar with the rules and can verify that your racks are correctly grounded in accordance with local laws. Anchors keep the racks in place, ensuring pallet Shelving’s dependability and longevity as well as warehouse security.

Conclusion

Choosing the finest racking warehouse systems might be tough due to a large number of racking systems available on the market. The easiest way to avoid being overwhelmed with this task is to consider the aspects listed above. The best warehouse racking system can help you maximize your space while also simplifying your operations.

If you are interested in automating inventory management, looking for a solution to increase efficiency, or if you have any questions regarding pallet racking or any other warehouse equipment or services, call now to talk with one of our Material Handling Service Providers on Linquip.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Warehouse Management In Manufacturing: A Clear Guide

- 11 Essential Warehousing Services Offered by Warehousing Companies

- Top Warehouse Suppliers: The Best All over the World

- Top Manufacturing Warehouses: A Clear Guide

- High Bay Lighting Buying Guide: An Ultimate Guide

- Best Pallet Jacks : A Clear Guide

- Prologis Essential Company Page on Linquip

- List of All Prologis Essential Service

- Prologis Essentials General Services

- Prologis Essentials Installation

- Prologis Essentials HVAC Maintenance

- Structural Pallet Racking for Sale by Prologis Essentials

- Warehouse Lighting Products by Prologis Essentials

- High bay LED lighting Products by Prologis Essentials

- Warehouse Solar Products by Prologis Essentials

Thank you for sharing this blog. In this blog complete information about Shelving racks.

Thanks for visiting our website and leaving your comment! We hope to hear from you again in our other posts.