Do you want to know what the best welding machines will be in ? You can identify the best models on the market and learn about the most crucial factors to consider when purchasing a welding machine with Linquip’s step-by-step guide.

When it comes to welding machines, Linquip has a lot of information that may help you make an informed choice. In order to assist you in performing your duties more effectively, Linquip brings to you the best welding machines presently available on the market. Do you intend to purchase a welding machine in the near future? When you search through Linquip’s vast range of Welding Machine Products for free, it’s simple to find the right product for your needs. Please contact Welding Machine Experts, if you want to learn more about what Linquip can provide you depending on the purpose of your welding machine.

Linquip platform might be very helpful to you if you’re looking for a price for a welding machine and other associated equipment. You can quickly obtain free quotes from a range of Welding Machine Suppliers and Companies using our user-friendly web form. Within a short time, you will be able to obtain them.

Welding is one of the most important processes in the construction of sturdy metal structures. The metal bond is solid and enduring thanks to proper welding. On the other hand, improper welding might damage the building materials and waste your hard-earned money. Therefore, obtaining a reliable welding machine is crucial. However, given the wide range of products on the market, you could become confused. We’ve compiled a list of the best welding machines for to simplify the process for you to get your hands on an elevated product. These welding machines offer high-security features that protect materials while keeping you safe. Additionally, these devices will make welding quick and simple for you. So instead of wasting time looking at several options, focus on these top welding machines.

List of 10 Best Welding Machines in 2024

According to the factors that we will mention in this article, Here is the List of 10 Best Welding Machines in 2024:

- Lincoln Electric K2278-1 Handy Core Buy Now

- Millermatic 252 Buy Now

- Hobart 500559 Handler 140 MIG Welder 115V Buy Now

- Forney Easy Weld 261, 140 FC-i MIG Welder Buy Now

- Weldpro 200 Amp LCD Inverter 5 in 1 Multi Process Welder Buy Now

- DEKOPRO 110/220V MMA Welder,160A ARC Welder Machine IGBT Digital Display LCD Buy Now

- MagicWave 230i Welder Buy Now

- HITBOX MMA Welder ARC-200 Buy Now

- Forney Easy Weld 261 Buy Now

- SUNCOO 130 MIG Welder Buy Now

Basics of Welding

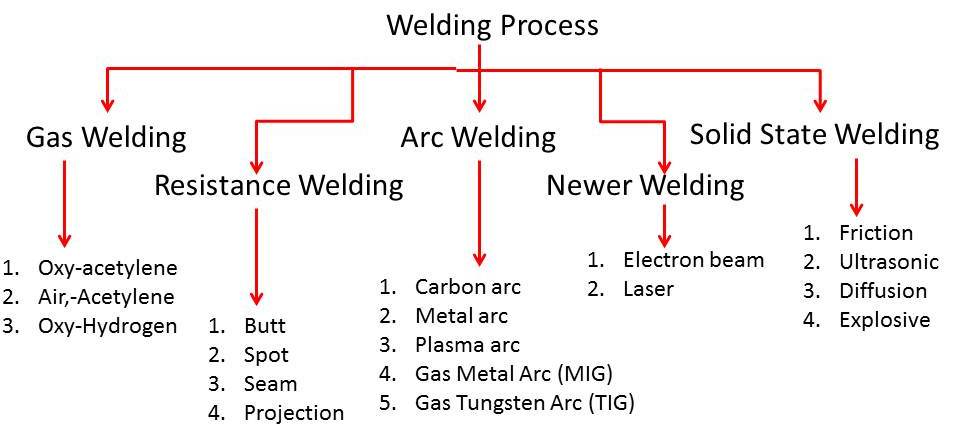

Since the early 19th century, welding has been a critical part of the automobile, aircraft, fabrication, structural formation, architecture, and shipbuilding industries. Welding is the technique of uniting two metal segments with the correct quantum of voltage. The most popular kind of welding is arc welding.

Arc welding technology uses a high-powered electrical “arc” to melt a metal workpiece attached to the welding machine and an electrode similarly grounded to the welding machine. Electric current “jumps” and passes through the air between two conductors, causing electrical arcing to happen. In this situation, it’s the metal workpiece and the electrode, both of which are subjected to a high electrical current via the welding machine. This arc warms the metal to extremely high temperatures, melting both the electrode and the metal it comes in contact with, forming a weld pool that allows the two metals to be united.

Arc welding works on a similar concept to conventional and inverter types of machines. Inverter technology has improved the ability to provide a more constant, stable, and desirable quantity of output current. They also include a mechanism for switching the power source from AC to DC, and the DC power changes the smooth welding output for a stable arc formation.

A few advantages of inverter welding machines over conventional types of equipment:

- The arc’s quality is higher and more stable than with conventional machinery.

- The inverter welder produces higher-quality welding results.

- The inverter technology boosts productivity.

- Compared to conventional, inverter welders use less energy.

- Inverter welders are known for their mobility.

- The cooling feature of the fan is designed.

Welding Machine Buying Guide

Just check out the free tips and tricks listed below to get the best welding equipment for your needs.

1) Evaluate the Nature of the Metal

Welding is often limited to carbon steel. The excessive heat that an inexperienced welder can accidentally deliver to the metal can be handled by carbon steel. As a result, it is compatible with the vast majority of welding machines in use.

Because of its corrosion resistance, stainless steel is ideal for storing beverages or edibles. It is completely compatible with TIG or MIG welding equipment and uses less amperage when being welded than carbon steel does.

Due to its excellent heat conductivity, aluminum requires an almost constant heating source to prevent the weld pool from drying out. However, the workpiece frequently deforms as a result of the excessive heat input. To be connected optimally, aluminum requires more advanced welding machines, such as MIG machines equipped with the capacity to do pulse welding. A high-end TIG welding equipment would be a superior option for welding aluminum. Therefore, it would be better if you evaluated the metal that you wanted to combine before choosing a welding machine.

2) Choose the Ideal Ampere Range

The cost of a welding machine depends on how much current it can produce; thicker metals often need more current to be effectively welded. Therefore, it is recommended to pay close attention to both the thickness of the fixtures and the base metals that you would need to deal with for a project.

To successfully weld materials like heavy structural steel and pipes with a thickness higher than half an inch, you would need either a stick welding equipment or a high-end MIG welding machine.

Contrarily, thinner metals would require more sensitive welding equipment that would deliver precisely the proper amount of heat to make the weld. In this regard, welding aluminum becomes nearly identical to welding a relatively thinner metal.

3) Select an Ideal Site for Welding

Finding the right welding machine also depends on the location of the welding operation. You might connect your machine to a 115 volt AC machine or a 220-240 volt AC source while welding inside. The standard supply for every household or business facility is 115 volts. At this voltage, the majority of basic welding equipment is operational. The machine may operate as a single-phase or three-phase device.

4) Refer to the Specs Sheet

You may learn various things that are essential for separating a good welding equipment from another by consulting the specs sheet. A specifications sheet, for example, can assist you in determining how much continuous welding a machine can complete in ten minutes. Duty cycle is a measure of how many minutes you can weld in a typical ten-minute interval. Overworking a machine might cause it to heat up and damage its internal circuitry.

5) Examine Any Compressed-Gas Requirements

Different compressed gasses must be used for various welding procedures. The three compressed gasses that are most frequently utilized in welding processes are oxygen, argon, and carbon dioxide.

Best Welding Machine Reviews

We’ll assess the best welding machines in this article based on their use, efficacy, and safety features. Each is also described, along with its features, advantages, and disadvantages.

1. Lincoln Electric K2278-1 Handy Core

Specifications

| Item Weight | 45 pounds |

| Item Dimensions | 8.82 x 17.99 x 12.8 inches |

| Country of Origin | Poland |

| Input Voltage | 110/115/120 V |

| Rated Output | 70 amps, 17 volts, at 20% duty cycle |

Lincoln Electric, a company that has been operating out of Ohio since that time, was founded in the year 1895. Since more than 120 years ago, Lincoln has produced welders of exceptional quality, and this machine is undoubtedly one of them.

With the purchase of this welder, which is a deal and yields top-notch results, the user may anticipate an improvement in both overall power and performance. Welders who don’t need a lot of power from their machine will appreciate this Lincoln welder‘s reputation for reliability and durability. It is also quite portable because it only weighs 45 pounds. Customers who have used this welding equipment have praised it for being convenient, efficient, and affordable.

The Handy Lincoln welder is capable of welding mild steel with thicknesses ranging from 18 gauge to 1/8 inch. The associated slider allows the user to choose one of four output power levels. The fan cooling technique considerably reduces the chance of overheating. The Lincoln welder should have a duty cycle of 20% while running at 35-88 amps (optimally at 70 amps). This welding equipment may be powered by a typical household socket because it accepts 115V (20 amps) power.

2. Millermatic 252

Specifications

| Item Weight | 205 lb |

| Item Dimensions | 40 X 19 X 30 inches |

| Country of Origin | USA |

| Input Voltage | 208 V

220/230/240 V |

| Rated Output | 300A maximum of 200 Amps at 28 VDC on a 60% duty cycle OR 250 Amps at 28 VDC on a 40% duty cycle |

The Millermatic 252 has the highest output of any Millermatic welder, making it an excellent choice for individuals who weld for a livelihood. It’s an exceptionally adaptable system that can handle even the busiest of situations and workloads. Whether you’re welding stainless steel or carbon steel, the Millermatic 252 is capable of the task.

The Millermatic 252 has a maximum output amperage of 300A. This allows you to weld at a higher output for a longer amount of time, which is ideal for longer operations. The 252 is ideal for a wide range of industrial applications since it can run from 22 gauge to 1/2 inch steel in a single pass. A durable and reliable setup is essential for welders who need to inject a ton of wire into their welds. It is critical in this day and age to be able to weld successfully without risking delays. Financial losses caused by machine breakdowns or jams can have a detrimental impact on a company. Remember that choosing the correct welding wire for the job is critical.

Fortunately, the Millermatic 252 has a high-quality design that has been particularly built to avoid events like these from happening. It has an aluminum dual-gear drive system that allows the machine to feed wire without stopping. There are areas on the machine for you to store drive rollers, minimizing disturbance to your work.

3. Hobart 500559 Handler 140 MIG Welder 115V

Specifications

| Item Weight | 57 pounds |

| Item Dimensions | 19 x 11 x 13 inches |

| Country of Origin | USA |

| Input Voltage | 110/115/120 V |

| Rated Output | 90 A @ 20% duty cycle |

Hobart, an American welding equipment manufacturer, has been creating high-quality products since its foundation in 1917. One of the most powerful equipment that can be connected into a standard electrical socket is the Hobart 500559 welding machine. It is simple to operate and has a 140 amp current output. This welding equipment is ideal for home usage; but, if you are a professional looking to undertake complicated welding, you should consider other options.

With five separate levels of voltage and a wire feed speed range of 40-700 IPM, the Hobart 500559 provides all of the versatility you need to dial in the ideal weld. Because the amperage range is 25 to 140, you have a lot of control over the depth of the weld. This equipment is capable of MIG and Flux-Cored welding, and it comes with a 5-year warranty. This is a welding equipment that will not let you down.

It has a Duty Cycle of 20%, which means it can run for 20% of the time without overheating (for every 10 minutes of work, the machine can run for 2 minutes continuously without overheating).

The Hobart 500559 weighs 57 pounds, which is considered heavy and may restrict its portability. However, the heavyweight is due to the exterior shell’s strong and thick steel, which exhibits good quality and robustness.

4. Forney Easy Weld 261, 140 FC-i MIG Welder

Specifications

| Item Weight | 19 pounds |

| Item Dimensions | 16.7 x 12 x 8.1 inches |

| Country of Origin | USA |

| Input Voltage | 120 V |

| Rated Output | 90 Amps @ 20% duty cycle |

Cost is typically one of the most crucial issues for do-it-yourself welders when deciding which tools to acquire. If you are concerned about having enough money left over after purchasing the welder for your project, then the Forney Easy Weld 261 is your best friend. This welding equipment is reasonably priced and simple to set up. Because of the infinite voltage control and wire feed speed adjustment, you can dial in the optimal parameters for each and every weld.

A standard 110-volt outlet can power the Forney Easy Weld 261 Machine. Amperages range from 32 to 140. It weighs only 19 pounds, making it extremely portable; you’ll have no problem using it even while traveling. It is ideal for minor garage maintenance and modest welding projects.

The Forney Easy Weld 261 Machine has a very tiny footprint, which means it won’t take up any of the important space you have available while not in use. All of this is offered at a reasonable price and is backed by a one-year warranty.

5. Weldpro 200 Amp LCD Inverter 5 in 1 Multi Process Welder

Specifications

| Item Weight | 53.9 pounds |

| Item Dimensions | 25.2 x 23.6 x 12.9 inches |

| Input Voltage | 115 V / 240 V |

| Rated Output | 115V: 30% @ 120A, 100% @66A

240V: 30% @200A, 100% @110A |

This fantastic Weldpro 200-amp welding machine is extremely versatile because it can do MIG welding (also known as flux core), stick welding, and TIG welding all in one machine. It allows those with no prior experience to learn nearly any type of welding using this multipurpose beast. Furthermore, it enables contractors or freelancers to provide solutions that meet a wide range of customer requirements. It is a good deal, especially considering the low level of investment required.

With a maximum output of 200 amps, the Weldpro has plenty of power and can weld mild steel with thicknesses ranging from 24 gauge to 1/4-inch. It works with either a 110V or a 220V power supply. This kit includes MIG and TIG torches as well as a MIG gas regulator.

The dependable device also includes a digital screen for easy viewing. It weighs 54 pounds but is relatively quiet.

6. DEKOPRO 110/220V MMA Welder,160A ARC Welder Machine IGBT Digital Display LCD

Specifications

| Item Weight | 12.1 pounds |

| Item Dimensions | 15.98 x 11.85 x 6.61 inches |

| Input Voltage | AC 110/220 V |

| Rated Output | Rated Duty Cycle(%): 40/60 |

Due to its low price and light weight of only 12 pounds, the DEKOPRO 110/120V MMA Welder may not appear to offer much to the serious welder at first look. Nonetheless, with an output range of 10-160A, this welding machine can handle mild steel up to one-fourth inch thick.

Work can also be done on aluminum and cast iron if the proper welding rod is used. This stick welder, like all stick welding devices, can be used indoors or outdoors and is powered by either 110V or 220V.

A fan that can cool the welder and assist in cleaning it is a useful feature to have whether you’re moving the machine around or doing some welding outside. Because of its simple operation, there is no gas to adjust; instead, the amount of current is controlled by a single dial. Although the welder is not ideal for delicate or precise work, it is difficult to beat in terms of portability and functionality, whether at home or elsewhere.

7. MagicWave 230i Welder

Specifications

| Item Weight | 36.4 pounds |

| Item Dimensions | 14.5 x 8.3 x 22 in |

| Input Voltage | 230 Volt |

| Rated Output | 100% Duty Cycle at 165 amps, 35% at 230 amps |

The Fronius Magicwave 230i digital welding system is one of the most advanced on the market. With a feature set that rivals that of a Tesla, the Fronius Magicwave 230i can handle practically everything you throw at it, and it will always be at the top thanks to free firmware updates.

With advanced welding parameters like AC Current offset, independently controlled waveforms for AC TIG and DC Pulse TIG, TAC function, and cap shaping standard on every machine, there’s always something that improves productivity and user experience.

8. HITBOX MMA Welder ARC-200

Specifications

| Item Weight | 6.3 pounds |

| Item Dimensions | 9.06 x 4.33 x 6.69 inches |

| Input Voltage | 110/220 V |

| Country of Origin | China |

| Rated Output | 10-190A with 40% duty cycle |

The HITBOX MMA Welder is a compact, all-rounder portable welding machine that is ideal for both professionals and casual users, as it weighs only 6 pounds and is easy to transport. It has a rated cycle duty of 60% and can weld 7018 1/8 inches of steel, as well as 6013 and 7018 3/32 inches. It also includes a one-year warranty and, if a problem arises while using it, HITBOX’s agents will repair it for free. It also includes an electrode holder and an earth clamp.

9. Forney Easy Weld 261

Specifications

| Item Weight | 19 pounds |

| Item Dimensions | 16.7 x 12 x 8.1 inches |

| Input Voltage | 120 V |

| Country of Origin | USA |

| Rated Output | Duty Cycle 30% @ 90A |

Due to its wonderful qualities and singularity, the Forney MIG Welders very name is a declaration in and of itself. This welder can weld 24-gauge steel up to 1/4″ thick. FC-i is an abbreviation for flux core inverter. Forney’s goal is to instill a mental image of the product in the customer’s mind through the distinguishing features and benefits it provides, ensuring little to no competition. The use of an inverter allows for the installation of a flux core welder that is lighter than the alternatives on the market.

Whereas most welders use transformer-based welders, this inverter-based welder is here to steal the spotlight from its competitors. It is more portable, lighter, produces more output, and is simpler to use and install.

The Forney Easy Weld 261, 140 FC-i MIG Welder is an excellent choice if you are a professional welder, a welding enthusiast, or an amateur welder. It weighs 19 pounds, making it lighter than competing welders on the market. With dimensions of 16.75″ x8.125″ x12″, the Forney 140 FC-i MIG Welder allows for gas-free welding, has infinite voltage, and performs welding to perfection. The best part about the product is that it is also suitable for beginners. Its uses range from do-it-yourself to maintenance and repair, metal fabrication, and hobbyist. The welder comes with an 8′ MIG gun, an 8′ ground clamp, and a 20 A-15 A adapter that operates at a duty cycle of 30% at 90 A.

10. SUNCOO 130 MIG Welder

Specifications

| Item Weight | 36.4 pounds |

| Item Dimensions | 13.4 x 7.2 x 11.4 inches |

| Input Voltage | 110 V |

| Country of Origin | Import from US |

| Rated Output | Duty Cycle 105 @15% |

The gasless flux welders are defined by the Suncoo Mig 130. It does not require any gas to operate, and with the features it includes, we can say that it is one of the best under $300. The welder has an automatic feeding system and a very compact design with MIG welding capability, making it a good choice for various types of welding and a unique option with versatile features.

Its stainless steel body makes it highly durable and sturdy in design. It is suitable for heavy-duty DIY projects as well as many industrial applications. Because it is a pure flux core welding, no gas is required. It instead employs self-produced inert gasses to secure your weld and prevent contamination.

Because shielding gasses prevent oxidation, the welded surface remains smooth and free of impurities. It is also a very portable machine with numerous applications. You can weld almost any metal, including iron, steel, and aluminum. It includes a protective mask to ensure your safety. To suit your welding needs, you can also adjust the power up to ten stages.

Download the Best Welding Machines PDF

There is an option to download the article in PDF format if you find that to be more convenient for you. You can download the file by clicking on the following link.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More On Linquip

- The 10 Best Snow Blowers + Buying Guide & PDF

- The 10 Best Glues for Metal + Tips for Choosing

- The 10 Best Electric Pressure/Power Washers

- The 10 Best Torque Wrenches + PDF & Buying Guide

- The 8 Best Attic Ladders + Buying Guide & PDF

- The 10 Best Electric Space Heater + Buying Guide

- The 9 Best Cordless Impact Wrenches

- The 7 Best Portable Band Saws + Tips for Choosing

- The 10 Best Hammers

- The 10 Best Circular Saws in the USA

- The 10 Best Mini/Benchtop Milling Machine

- The 8 Best Pressure Washers

- 18 Types of Machining Vises (Clear Guide)

- 8 Types of O-Ring + Applications (Clear Guide)

- The 8 Best Engine Hoists & Accessories + Buying Guide

- Top 10 Irrigation Equipment Suppliers

- Top 10 Railroad Equipment Suppliers in USA & Worldwide

- 8 Best Soldering Iron for Electronics & The Like

- The 10 Best Fertilizer Spreader

- The 10 Best Steel Toe Boots for Women

- The 10 Best Electric Lawnmowers

- The 9 Best Commercial Patio Heaters + Buying Guide

- The 8 Best Soldering Irons + Buying Guide

- The 10 Best Drywall Anchors + Buying Guide

- The 10 Best Box Cutter/Utility Knife Options

- 11 Types of Drilling Machines and Their Usages

- 5 Types of Grinding Machines + Applications & Characteristic