Boiler Efficiency – The initial cost of a boiler is a minor part of the total costs connected with the boiler over its lifetime, as is widely known. Major costs emerge from fuel costs during a boiler’s operational life. It is vital to ensure that the boiler operates efficiently to reduce fuel expenses.

It’s not always the case that a boiler will operate at its maximum efficiency. If sufficient efficiency monitoring is not done, the boilers almost always operate at substantially lower efficiencies than the rated efficiencies.

What is Boiler Efficiency?

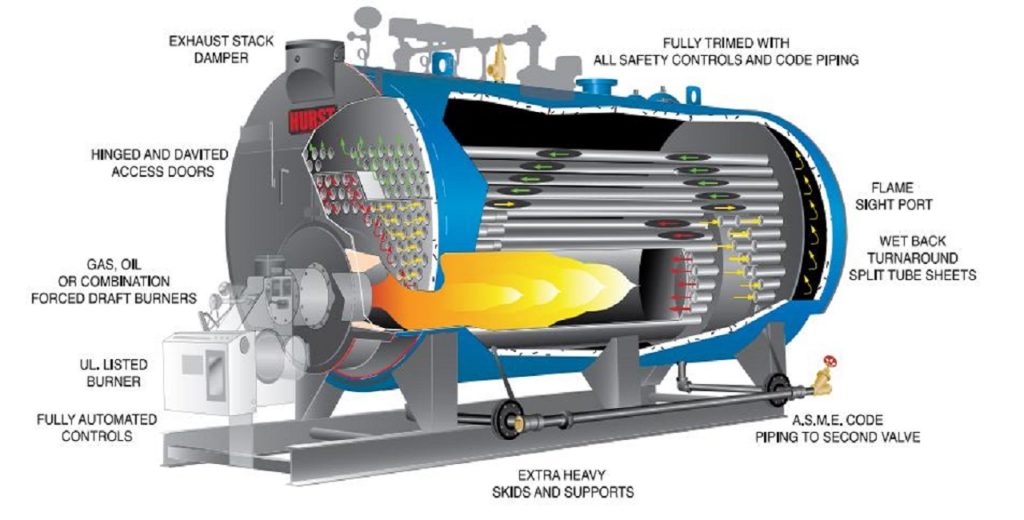

The efficiency of a boiler is the sum of the efficiencies of its many components. A boiler contains several subsystems, each of which has an impact on the overall efficiency of the boiler. The following are a few efficiencies that ultimately determine boiler efficiency:

- Combustion efficiency

- Thermal efficiency

Aside from these efficiencies, there are a few other losses that play a role in determining boiler efficiency and must be taken into account when evaluating boiler efficiency.

Combustion Efficiency

The ability of a boiler’s burner to burn fuel is measured by its combustion efficiency. Unburned fuel amounts in the exhaust and excess oxygen levels in the exhaust are the two criteria that affect burner efficiency. The amount of unburned fuel in the exhaust reduces as the amount of extra air is increased. As a result, unburned fuel losses are reduced while enthalpy losses are increased. As a result, maintaining a balance between enthalpy losses and unburned losses is critical. The efficiency of combustion varies depending on the fuel being burned. Solid fuels have a lower combustion efficiency than liquid and gaseous fuels.

Thermal Efficiency

The thermal efficiency of a boiler refers to the efficiency of the boiler’s heat exchanger, which is responsible for conveying heat energy from the fireside to the waterside. The buildup of scale/soot on the boiler tubes has a significant impact on thermal efficiency.

Direct and Indirect Boiler Efficiency

Apart from combustion and thermal efficiencies, several other factors influence overall boiler efficiency. ON-OFF losses, radiation losses, blow-down losses, convection losses, and so on are some of the other characteristics. In practice, two ways of calculating boiler efficiency are typically utilized, namely the direct approach and the indirect method.

Direct Efficiency

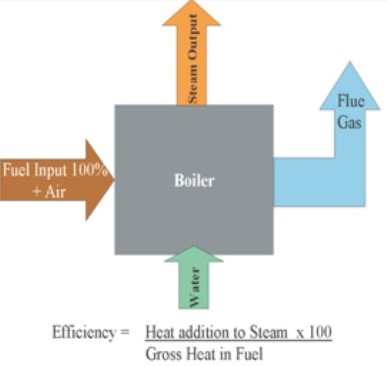

The basic efficiency formula is used to calculate boiler efficiency in this method:

\eta=(Energy output)/(Energy input)\times100

To calculate boiler efficiency using this method, divide a boiler’s total energy output by the boiler’s total energy input, multiplied by a hundred.

E= [Q \frac{(H-h)}{q}\times GCV]\times 100

where,

Q= Quantity of generated steam (kg/hr)

H= Enthalpy of the steam phase (Kcal/kg)

h= Enthalpy of the water phase (kcal/kg)

GCV= Gross Calorific Value of the fuel.

Indirect Efficiency

The indirect efficiency of a boiler is measured by adding up all of the losses that occur in the boiler and subtracting the total from 100%. This method entails doing separate measurements to determine the magnitudes of all measurable losses in a boiler. To calculate the ultimate efficiency, all of these losses are put together and deducted from 100 percent. During the procedure, the blow-down valve is kept closed. This approach should be implemented by the BS845 standards. Stack losses, radiation losses, and blowdown losses are among the losses calculated.

Comparison of Direct and Indirect Efficiency

Both approaches for determining boiler efficiency listed above have their own set of benefits and drawbacks. The most significant benefit of the indirect method is that it also addresses the sources of losses. By determining indirect efficiency, one can determine where losses are occurring and how they can be mitigated. Direct efficiency values, on the other hand, are closer to reality than indirect efficiency values due to uncovered losses such as radiation losses, ON-OFF losses, and so on. Direct efficiency, on the other hand, can only tell us about the size of the overall loss. Direct efficiency calculations provide no information about specific losses or their magnitudes.

There is always a gap between the direct and indirect efficiencies. Direct efficiency is calculated over some time, whereas indirect efficiency is measured at a certain time. As a result, losses due to variable loads, boiler on-off, and other factors are taken into account.

Real-Time Efficiency Monitoring

Boiler efficiency does not stay constant, and considerable deviations from optimum values occur during operation. Depending on the boiler type and on-site conditions, switching to real-time efficiency monitoring can dramatically improve boiler efficiency. In a word, monitoring and maintaining boiler efficiency throughout the boiler’s operational life is necessary if you want to save money on fuel and lower your carbon footprint.

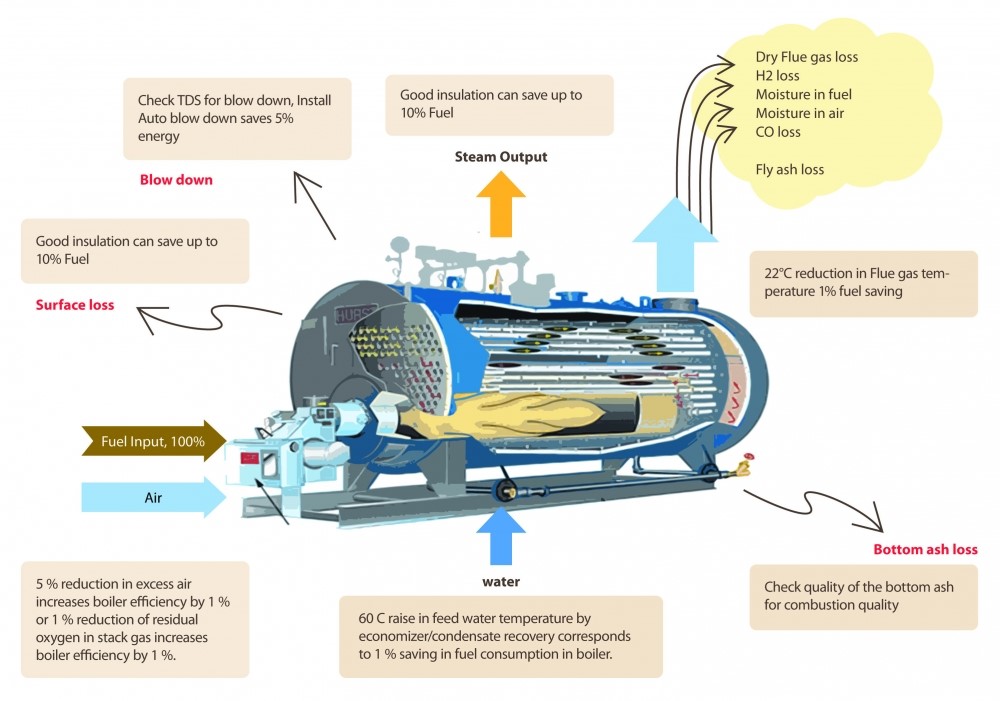

Ways to Increase Boiler Efficiency

Here we present some descriptions of how to minimize heat loss in a boiler and thus increase efficiency.

Lower The Temperature of The Stack

A simple day/night setback could help lower stack temperatures. When idling on mild days or at night, this decreases the operating pressure for steam boilers and the operating temperature for hydronic boilers.

Install An Economizer

The discarded hot flue gas is used to heat feed water on its route to the boiler in an economizer. This should be your priority if your steam boiler doesn’t have an economizer or if your economizer isn’t operating. Economizers conserve fuel and protect the boiler from the harmful effects of cold water supply.

Install A Variable Frequency Drive

There aren’t many burner fans or pumps on the market now that don’t have VFDs. Take note if you’ve never heard of VFDs or if you have a system that doesn’t use them. The affinity laws for pumps and fans are responsible for the tremendous power savings. Your system is squandering electricity at partial loads if it contains a fan or circulation pump controlled by a damper or valve. The magic happens when your system uses a VFD to control flow instead of fan or pump speed.

Tune The Burner Regularly

When it comes to boiler efficiency, another common issue is not getting the proper amount of air. A particular amount of oxygen is required for proper fuel combustion inside the boiler. If there isn’t enough air, the carbon in the fuel will be oxidized, resulting in carbon monoxide. Because the fuel isn’t entirely burned, less heat is released, lowering fuel use efficiency. Soot, smoke, and carbon monoxide are all harmful byproducts of low air. In addition, too much air affects efficiency. The excess air enters the stack cold and exits hot, losing heat.

The ideal procedure allows the fuel to burn safely with just enough air. An O2 probe is used to determine the amount of air required. While tuning the burner for maximum boiler efficiency, we insert the probe into the stack. The temperature of the air brought into the burner, however, fluctuates with the seasons in some facilities. For best savings, this necessitates more frequent burner tuning.

Clean The Fireside

Soot may accumulate on the fireside of the boiler tubes over time, especially with older equipment. This soot coating works as an insulator, slowing heat transfer and increasing fuel consumption. The hot gases pass through without transferring heat to the water due to the lower heat transfer rate, raising the temperature of your stack. As part of your routine boiler maintenance, clean and inspect your boiler tubes to ensure that soot is kept to a minimum. This improves the boiler’s overall efficiency.

Clean The Water Side

Water treatment is necessary to keep the waterside of your boiler clean and free of leaks. Regularly inspect the waterside of your boiler. To ensure good heat conduction from the metal to the water, clean out any mud legs or mud drums. Because of high water hardness, incorrect chemicals, and not blowing out the boiler regularly, the scale will build up on heat transmission surfaces. This scale will obstruct heat transfer, lowering the efficiency of your boiler. Water will not be able to cool these heat transfer surfaces because of the scale. If the scale isn’t removed, it might cause the boiler to overheat, resulting in expensive boiler repairs and leaks.

Insulate Your Valves

Many facilities remove the insulation on boiler room valves for maintenance and never replace it because it is inconvenient. Exposing these huge valves to the air, on the other hand, results in significant heat loss and can make the boiler room extremely hot. The use of a Removable Blanket to insulate these valves can save money and improve boiler room comfort. The blankets also limit the risk of burns while providing easy maintenance access.

Preheat Combustion Air

With the flame, the burner must heat the incoming combustion air. It takes less fuel to produce the same amount of steam in the boiler if the air delivered to the burner is warmer. A simple increase in fresh air temperature of 40 degrees Fahrenheit can save 1% of the fuel expense. Even with our historically low gas rates, this can quickly mount up if you run huge boilers around the clock. An air preheater can pay for itself in as short as a year in some situations.

Return Condensate to The Boiler

As steam transfers its heat and condenses, condensate forms. It is irresponsible to squander this valuable resource. The clean water contains no dissolved solids or gases and is ready to be used in your boiler again. Because the water is already heated, it takes a lot less fuel to turn it back into steam. Reusing the condensate also cuts down on the amount of cold makeup water, chemicals, and treatment your boiler needs. Finally, returning condensate to the feedwater system can save money on wastewater treatment and sewage expenditures.

Return Condensate to The Boiler

Consider installing a high-pressure condensate return system on your largest steam consumers to boost boiler efficiency even more. This raises the pressure of your condensate. Because the condensate does not flash, you may return more water to your boiler at a much higher temperature.

Control Blowdown Rate

Blowdown removes pollutants from the boiler, such as water hardness, and is necessary to maintain the boiler surfaces clean. Blowdown, on the other hand, removes heat from the system. Water enters the system at room temperature, is heated to boiler temperature, and then exits through the blowdown. Continuous blowdown is a feature of some boiler systems that do not alter with boiler load. To keep the quantity of heat going down the drain under control, the blowdown should be limited to the amount required to keep the dissolved solids under control. Control dissolved solids with an automated blowdown valve for significant cost savings. You may save a lot of electricity by blowing down the boiler regularly. This also decreases the danger of scale causing harm to your boiler.

Recover Heat from Boiler Blowdown

Recovery of heat from boiler blowdown, such as returning condensate to the boiler, can improve boiler efficiency. The blowdown valve is used to remove soluble and insoluble materials from boiler water. It helps avoid boiler scale by lowering the level of dissolved particles in the boiler water. Unfortunately, removing hot water wastes energy as well. A blowdown heat exchanger, flash tank, or a combination of the two can assist your boiler system in recovering some of this energy. Improve energy efficiency by using heat recovery to cool down the blowdown and heat your make-up water.

This post also includes a PDF of the description of Boiler efficiency which you can download from here. You can also this amazing video to understand more about boiler and combustion efficiency.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip