Breeder reactors are one of the nuclear reactor models which provide more fissile materials compared to their consumption. Engineers have designed them to extend the nuclear fuel supply for electricity generation. They have been named a potential renewable energy source by mistake, but they use fossil fuels which are available forever. Concerns about nuclear weapons propagation have been one significant impediment to building commercial breeder reactors.

Unlike regular reactors, which barely use uranium-235 as their nuclear fuel, breeder reactors use natural uranium-238. Uranium-235 is only available in low concentrations of about 0.7% of natural uranium with no enrichment, while uranium-238 is much more common. Breeder reactors can use approximately 70% of the uranium-238 for power generation, whereas typical reactors can only use about 1% of it. They can also utilize thorium-232 to breed uranium-233, which is another fissionable material. The most well-known breeding is plutonium-239, which is bred in a process shown below.

The earliest experimental breeder reactor (EBR-1) occurred in 1951, in Idaho, U.S.A. Subsequently, Russia, Great Britain, Japan, and France began their experimental breeder reactors; however, we do not have a nation that has developed a suitable one for high-capacity commercial use. So far, the largest implementation of breeder reactors was made in France with their Super-Phenix fast breeder reactor.

Types of Breeder Reactor

Based on the speed of the neutrons, breeder reactors come in two categories. Fast breeder and thermal breeder reactors are the two types of this reactor, which use uranium-238 and thorium-232 as fuel, respectively. Fast breeders do not need moderation as neutrons need to move fast. In contrast, thermal breeders make use of moderation to reach slower-moving neutrons.

Fast Breeder Reactor

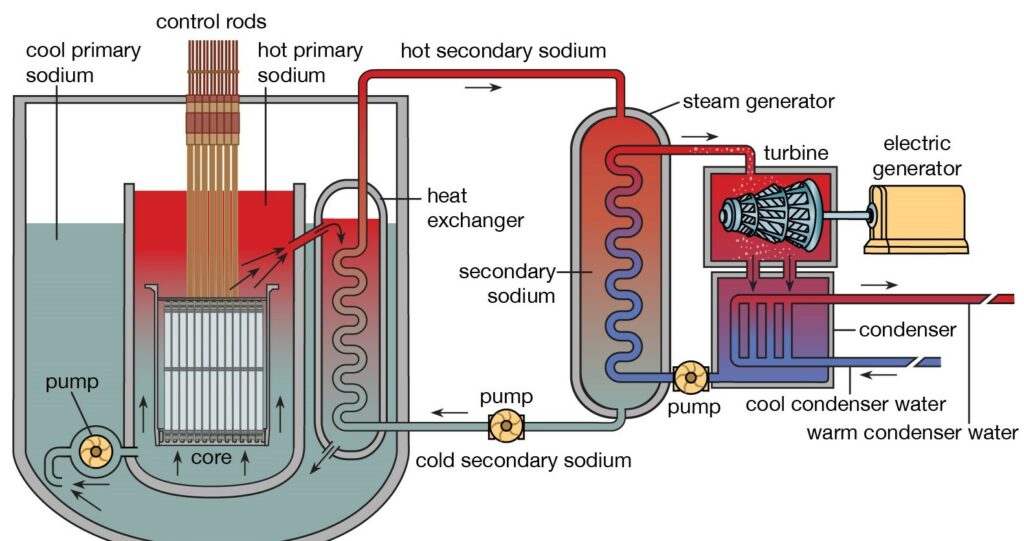

The most promising breeder reactor is the Liquid Metal Fast Breeder Reactor (LMFBR), which uses liquid sodium coolant and breeds plutonium uranium-238. It operates by using highly concentrated uranium, about 15-20% uranium-235 content, covered or “blanketed” by natural uranium-238 in the core of the reactor. We do not have a moderator for slowing down the neutrons as high-speed neutrons transmute uranium-238 more efficiently compared to slow neutrons.

Using water coolant would decrease the neutron abundance because neutrons are absorbed by water, so liquid sodium is employed instead. Using sodium rapidly raised concerns about safety at the first steps of designing as sodium is a highly reactive substance.

It is essential to keep away the liquid sodium to have contact with air or oxygen to evade explosions. However, using liquid sodium coolant is not any riskier than pressurized water reactors. It is all because we do not need to pressurize the sodium to continue in a liquid phase similar to water, as it boils at 892oC. It causes the bursting of pipes far less possible than in water reactors. Also, liquid sodium has a high specific heat capacity and is a perfect choice for heat transfer applications and removing heat from the reactor.

Types of Fast Breeder Reactors

Other fast breeder types are molten salt reactors, supercritical water-cooled reactors, gas-cooled reactors, and lead-cooled reactors.

Thermal Breeder Reactor

Same as the fast breeder reactors, these types of reactors would need fissile fuel to start the breeding; however, the neutrons generated from this fissile substance need to be slowed down by using a moderator.

Light water is utilized as the coolant to dissipate the produced heat by the continuous series of fission reactions instead of a liquid metal system. The technology for this type is much simpler than the science behind the liquid metal fast breeder.

Thorium hasn’t been employed in large-scale reactors despite using it successfully in the past. A light water coolant breeder reactor operated for five years in Shippingport, Pa, U.S.A. By the end of its service, it had 1.4% extra fissile fuel than it began.

What is Lead Cooled Fast Breeder Reactor?

The lead-cooled fast reactor is a kind of nuclear reactor that emphasizes a fast neutron spectrum and molten lead-bismuth eutectic coolant or lead. Molten lead-bismuth eutectic or lead can be employed as the primary coolant as lead and bismuth have weak neutron absorption and low melting points relatively.

Neutrons become slower by interaction with their heavy nuclei (not neutron moderators). Therefore, they make this kind of reactor a fast-neutron reactor. However, the coolant serves as a neutron reflector, reflecting some escaping neutrons to the core. Fuel for this reactor scheme includes fertile uranium as a metal, metal nitride, or metal oxide. Smaller lead-cooled fast reactors (same as SSTAR) can use natural convection for cooling, while larger designs (same as ELSY) have forced circulation in regular power running and also a natural circulation emergency cooling.

The concept is commonly very similar to the sodium-cooled fast breeder reactor. Most of the liquid-metal reactors have used sodium rather than lead. Just a few lead-cooled reactors have been built without considering some Soviet nuclear submarine reactors in the 1970s. However, several proposed latest atomic reactor designs are lead-cooled types. This type is one of the IV generation reactors.

What Is Molten Salt Fast Breeder Reactor?

Molten salt Fast reactors (M.S.R.s) are one of the Generation IV nuclear reactors that use high-temperature liquid molten salts as their nuclear fuel instead of conventional solid fuels. Using fluids enables it to work as a coolant (removing heat) and fuel (generating heat) simultaneously.

These types have various designs for using different fuels. Initially, fuel bonded to fluoride chemically to be able to dissolve in a molten carrier salt. The most regularly suggested carrier salt is a mixture of BeF2 (Beryllium Fluoride) and LiF (Lithium Fluoride), named FLiBe. Due to scientific issues related to the salts’ high temperature and corrosive nature, it has not been used widely.

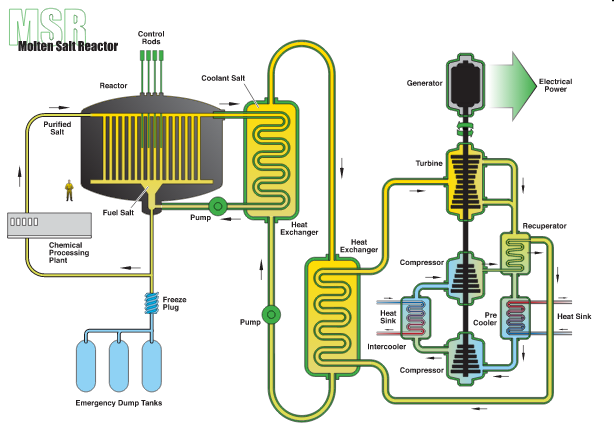

How Does Molten Salt Reactor Work?

Any reactor intends to produce thermal energy by using nuclear chain reactions. This occurs variously and drastically between reactors, and among these reactors, molten salt reactors are reasonably one of the unique ones. Currently, modern reactors use solid fuels in their operation, and uranium is the dominant fuel for them. M.S.R. types dissolve these fuels in a molten salt mixture.

In a primary molten salt reactor, enriched uranium (Uranium-233 or -235) is dissolved in a particular molten salt solution. The core has a neutron moderator that enables the salt solution to flow at great temperatures – 700°C or higher – while continuing at fairly low pressures. Low-pressure flow is an important safety feature for a reactor since the risk of a malfunction is greatly reduced. The generated heat by the reactions in the salt solution would heat water to steam to produce electricity in the secondary circuit.

Molten Salt as a Fast Breeder Reactor

The molten salt breeder reactor (MSBR) grows on the basic M.S.R. operating system. Rather than a single fluid system, a secondary molten salt solution is introduced to breed fissile isotopes. The first fluid contains a fissile fuel, the same as Uranium-235 or others. The fission process provides neutrons to the other loop, moderated to intermediate low speeds, and normal chain reaction, which provides valuable energy. The next fuel loop contains a fertile fuel, able to absorb these neutrons and finally transmuted itself into a fissile fuel. It may breed much more new fissile fuel than what it used to do first, so the name “breeding”.

The performance of the MSBR is encouraging by using thorium as a nuclear fuel as it has good potential, but it is not in use currently. A type of MSBR that can use thorium is named the Liquid Fluoride Thorium Reactor (LFTR). In the LFTR reactor, thorium absorbs neutrons in the fissile loop and provides uranium-233 by beta decay series. The uranium-233 was extracted from this loop chemically and inserted into the other fissile loop. Using a breeder reactor extends the fuel life of the reactor and diminishes nuclear waste.

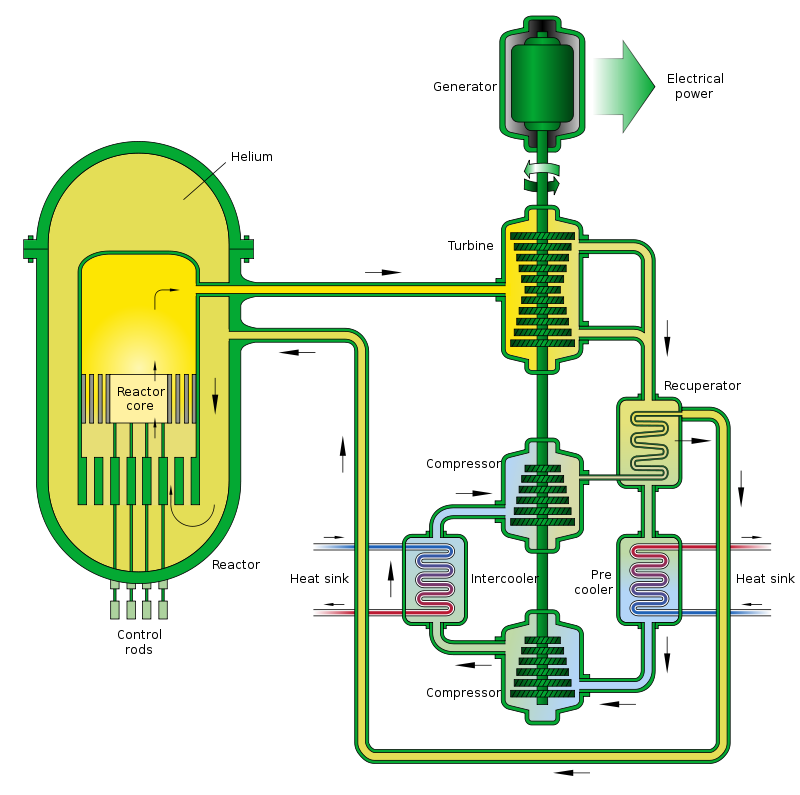

What is Gas Coolant Fast Breeder Reactor?

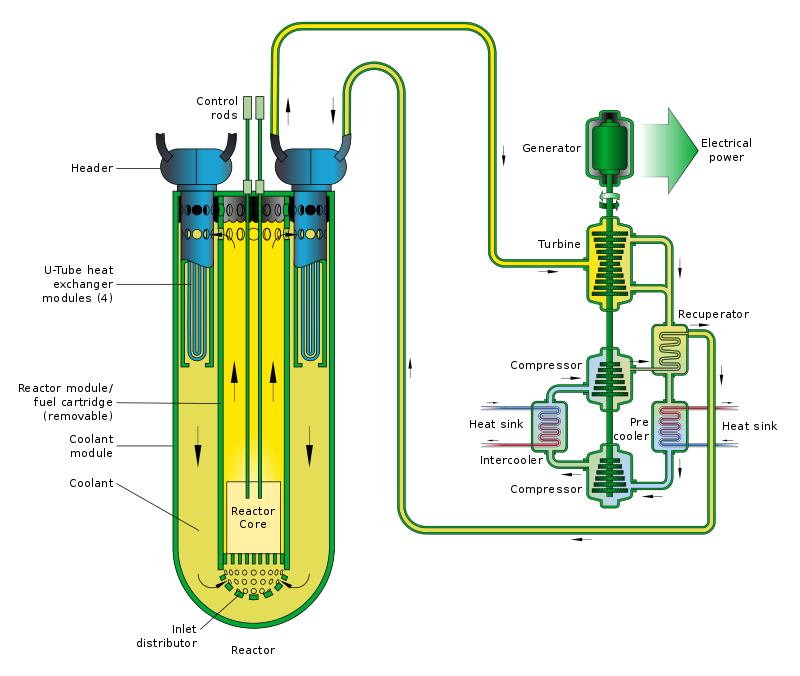

The gas-cooled fast reactor (G.F.R.) is a nuclear reactor design that is currently in development and is Classified as a Generation IV reactor. It features a closed fuel cycle and fast-neutron spectrum to convert fertile uranium and control actinides effectively. The source reactor design is a helium–cooled system working with an exit temperature of 850°C employing a direct Brayton closed-cycle gas turbine for significant thermal efficiency.

Several fuels are being regarded for their potential to run at very high temperatures and to guarantee excellent retention of fission products. Some of them are advanced fuel particles, composite ceramic fuel, and ceramic-clad components of actinide compounds. Same as other breeder reactors, this reactor generates electricity while producing (breeding) another new nuclear fuel at the same time.

What is Light Water Coolant Breeder Reactor

Reactors use uranium for nuclear fuel. The uranium is prepared in small ceramic pellets and piled together inside sealed metal tubes named fuel rods. Usually, more than 200 rods are bundled together to build a fuel assembly. The reactor core is typically constructed by a couple of hundred assemblies based on the power level.

The fuel rods are immersed in water which works as a coolant and moderator in the reactor vessel. The moderator slows down the neutrons generated by fission to maintain the chain reaction. Control rods are inserted into the reactor core to decrease the reaction rate or removed to increase it. The heat produced by fission converts the water into steam, spinning a turbine to provide carbon-free electricity.

Design of Light Water Coolant Breeder Reactor

The light-water reactor generates heat and electricity by controlled nuclear fission. The nuclear reactor core is part of a nuclear reactor where nuclear reactions occur. It principally consists of control elements and nuclear fuel. Each roughly 12 feet (3.7 m) long pencil-thin fuel rod are arranged hundreds in bundles named fuel assemblies. Pellets of uranium, more regularly uranium oxide, are accumulated end to end Inside fuel rods.

On the other hand, we have control elements named control rods, which are filled with pellets of materials like cadmium or hafnium to capture neutrons. The control rods absorb neutrons when they are lowered into the core for preventing neutrons from taking part in the chain reaction. By lifting control rods out of the way, more neutrons hit the nuclei of the fissile atoms in nearby fuel rods, and the chain reaction increases. All of this process happens in a water-filled steel pressure vessel, named the reactor vessel.

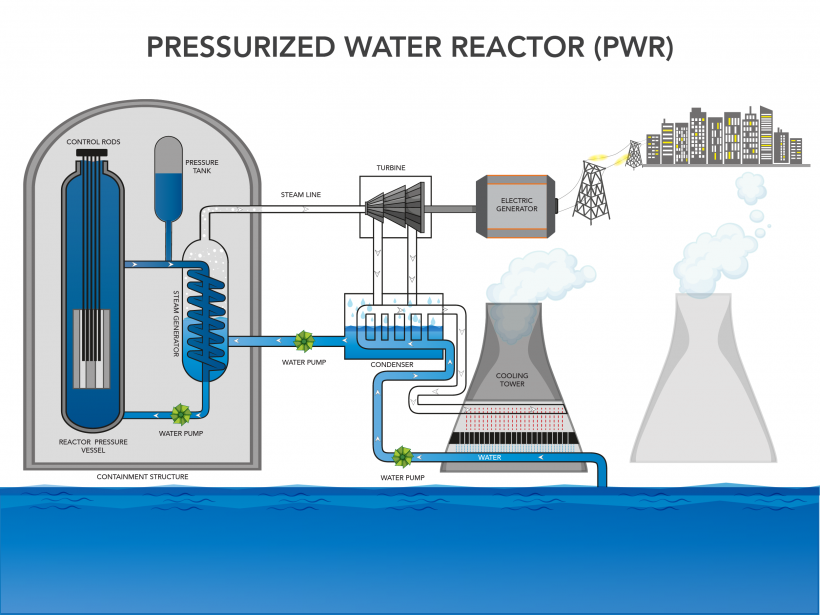

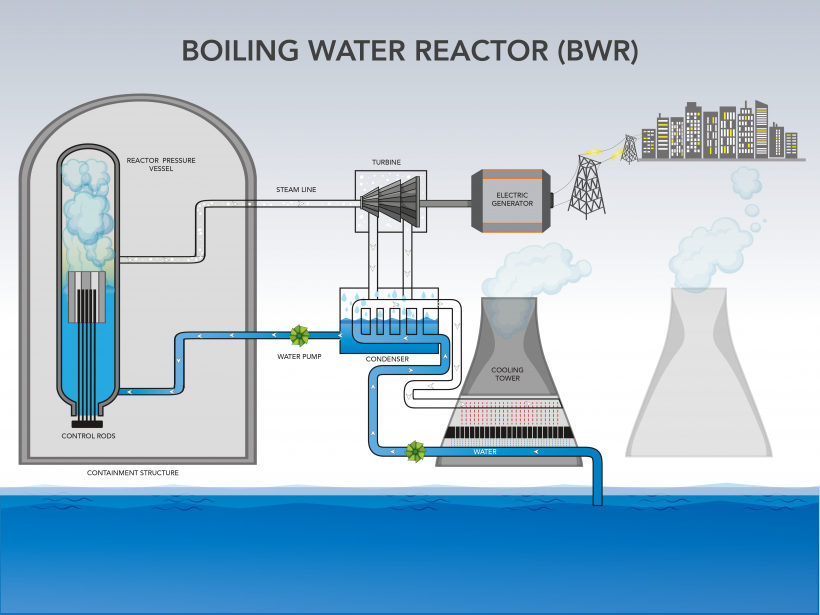

In the boiling water reactors, the generated heat by fission converts the water into steam, directly driving the turbines. In the pressurized water reactor, the generated heat by fission is given to a secondary loop through a heat exchanger. Steam is provided in the secondary loop, and it drives the turbines. In both cases, after passing through the turbines, the steam changes to water in the condenser.

The required water for cooling the condenser is from a nearby ocean or river. The outlet-warmed water in the condenser is pumped back into the ocean or river. Also, we can use a cooling tower to dissipate heat into the atmosphere.

Types of Light-Water Reactors

There are three types of light-water reactors available now, pressurized water reactors, boiling water reactors, and supercritical water-cooled reactors. All nuclear reactors in the U.S. are light-water-type reactors. It means they use normal water for coolant and neutron moderators.

Pressurized Water Reactors

In these reactors, water is pumped into the reactor core under high pressure to stop the water from boiling. The water inside the core is heated with the energy from nuclear fission and then pumped into a heat exchanger—those tubes inside the exchanger boil separate water sources to produce steam. The steam then drives an electric generator to generate electricity. The core water turns back to the reactor to be boiled again, and the process is renewed.

Boiling Water Reactors

Boiling Water Reactors (BWR) use light water (usual water) for their coolant and neutron moderator. BWR heats water and provides steam directly in a reactor vessel. Water is pumped up into the reactor core and boiled by fission. Pipes then supply the steam to a turbine to generate electricity. The output stream is then condensed and resend to the heating process. These types are the second most constructed reactor for nuclear power generation globally, after the Pressurized Water Reactor (PWR)—which had 75 operations until 2018.

Their maximum working temperatures are around 285oC. Their Carnot efficiency of boiling water reactors in power generation is 46% (maximum efficiency). However, the practical efficiency of these reactors in power generation is around 33-34%.

What is Supercritical Water-Cooled Breeder Reactor?

A supercritical water-cooled reactor (SCWR) is one of the proposed Generation IV reactors which operates above the thermodynamic water’s critical point. The critical point of water happens when it reaches a temperature of 374°C and a pressure of 22.1 MPa. Water becomes neither a gas nor a liquid at this point but rather a different state with unique properties. The SCWR is one of the three types of light-water nuclear reactors. The other types are boiling water reactors and pressurized water reactors, which will be discussed in the different sections. The most used type of reactor in the world for nuclear power production is SCWR.

The design of the SCWR is a combination of the fundamental principles of supercritical coal plants and boiling water reactors. Both mentioned plants have been used extensively and reduce experimental difficulties encountered with new projects. Using supercritical water would increase the reactor’s efficiency up to 44%, compared to the current reactor’s efficiency, which is around 34%. However, it is potentially reducing the capital cost by up to 30% because of the smaller essential containment and safety systems. The efficiency increment would minimize the waste heat produced by 35% and make better use of the fuel in the reactor.

The reactor core may have a fast neutron or a thermal spectrum based on the core design. The concept may be found in pressure vessels or pressure tube reactors, using heavy water or light water as a moderator. Unlike conventional water-cooled reactors, the coolant experience a more expensive enthalpy growth in the core, which decreases the core mass flow for a given thermal power and enhances the core outlet enthalpy superheated states. We know that in boiling water reactors, the superheated steam is supplied to the high-pressure steam turbine, while the feed water is supplied back to the core from the steam cycle.

The important advantage of the SCWR is its potential for plant simplification and improved economics because of its higher thermal efficiency. We can use thorium as fuel in an SCWR.

Read More In Linquip

- What are the Disadvantages of Nuclear Fusion?

- Heavy Water Reactor

- Differences Between Nuclear Fusion and Fission

- Thorium Salt Reactor

- What Is Nuclear Fission?

- Boiling Water Reactor

- What is Shunt Reactor

- Components of Nuclear Reactor

- How Does a Nuclear Reactor Work? A Closer Look at the Working Principle of Nuclear Reactors

- What is a Continuous Stirred-Tank Reactor? Application and Working Principles

- Gas Cooled Reactor

- What Is Nuclear Fission?