Today you are going to get some data about one of the most popular boilers. The boiler that we want to talk about is the Cochran boiler. Therefore firstly, we need to have a definition of what this boiler is. In the next step, we will delve into the different components it has and elaborate on each parts’ role in the boiler. Then, we reach the working principle and in the last four sections, respectively, information such as the characteristics, advantages, disadvantages, and applications of Cochran boilers will be delivered.

Our team gathered all the necessary information about this device to eliminate the need for reading diverse content on other websites. Stay with us until the end to find the answer to your question on this topic. Let us start with some basic definitions at the beginning.

What Is Cochran Boiler?

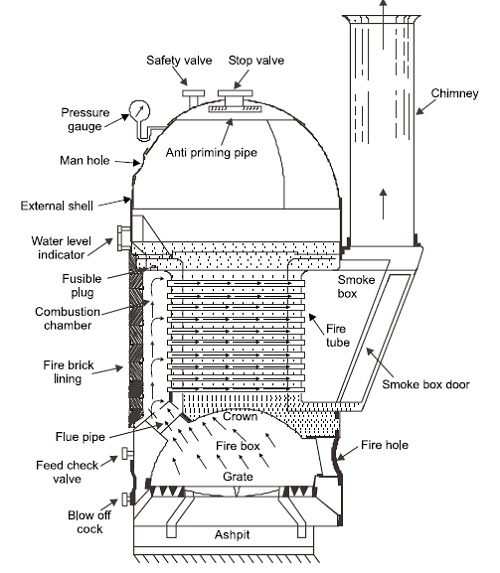

A Cochran Boiler is one of the multi-tubular vertical fire tube boilers that has several horizontal fire tubes. Cochrans are the modification of a simple vertical boiler where the heating surface has been increased employing some fire tubes. So, in comparison to the simple vertical boilers, the efficiency of this boiler is much better.

The Cochran boiler has an external cylindrical shell and a firebox. The shape of the shell and firebox is hemispherical and the hemispherical head of the boiler provides maximum space and strength for withstanding the pressure built up in the Boiler. Also, the hemispherical crown of the firebox is helpful to resist intense heat.

What Parts Does a Cochran Boiler Consist of?

There are more than twenty parts and components involved in a single Cochran boiler. We decided to focus only on the most important of these parts and give a brief description of what they do and what role they carry in the boiler. Below we listed nine of them.

-

Boiler Shell

The boiler shell is made of steel plates into a cylindrical form and it is riveted or welded together. The ends of the shell are closed by endplates. The boiler shell should have enough capacity to store water and steam.

-

Combustion Chamber

The combustion chamber is below the boiler shell for burning the fuel to generate steam from the water in the shell.

-

Grate

The grate is a platform in the combustion chamber where fuel is burnt. The grate is generally a cast-iron bar and there is space between them so the air can pass through it. The surface area of the grate where fire takes place is called a grate surface.

-

Furnace

The furnace is above the grate and below the boiler shell and in the furnace, the fuel is burned.

-

Fire Tubes

The fire tubes are the horizontal tube between the combustion chamber. The flue gases from the combustion chamber flow to the smokebox via some fire tubes. These fire pipes are used to exchange heat from hot flue gases to water.

-

Fire Hole

It is at the bottom of the combustion chamber for firing fuel inside the furnace.

-

Chimney

The chimney is provided at the top of the boiler and it is connected to the smokebox. These exhaust gases are coming out from fire tubes and pass through smokebox and exhaust through a chimney.

-

ManHole

The manhole is for cleaning, repairing, and inspecting the boiler shell.

-

Flue Pipe

The firebox and combustion chamber are connected through a short pipe and these pipes are called flue pipes. The hot flue gases from the grate flow into the combustion chamber via flue pipe.

Below you can see the diagram of a Cochran boiler and all the parts.

How Does a Cochran Boiler Work?

The first step that a Cochran boiler takes to work is the fuel inserted into the firebox and placed on the grate. The fuel is ignited through the fire hole installed at the right bottom of the boiler. So, the fuel is burnt in the firebox, and due to the burning of the fuel, smoke and hot flue gases come out. The flue pipes direct the hot flue gases into the combustion chamber.

From the combustion chamber, hot gases enter into the fire tubes. The fire tubes are surrounded by water. The hot gases inside the tubes transfer the heat from the hot gases to the water. Due to the exchange of heat, the temperature of the water starts increasing and it gets converted into steam. The steam produced rises upward and collected at top of the boiler in the hemispherical dome. An anti-priming pipe is installed at top of the boiler which separates the water from the steam and makes it dry steam. This dry steam is then transferred to the turbines through the steam stop valve.

The hot flue gases and smoke after rejecting heat, are directed to the smokebox. From the smokebox, the burnt gases and smoke is discharged into the atmosphere through the chimney.

A fusible plug is also provided at the top of the combustion chamber. When the temperature of the combustion chamber crosses the permissible level, the fusible plug melts, and the water through the combustion chamber enters into the furnace of the boiler and stops the fire. In this way, a big fire accident can be prevented to take place and also protects the boiler from damage.

What Are the Main Features of a Cochran Boiler?

Below we have prepared a list of features and characteristics of this boiler for you to read.

- It is portable

- It has a natural circulation

- It is a low-pressure boiler

- you can use any type of fuel for running a Cochran Boiler

- This is suitable for small capacity requirements

- It has about 70% thermal efficiency with coal firing and about 75% thermal efficiency with oil firing

- The ratio of grate area to heating surface area varies from 10:1 to 25:1

The Advantages and Disadvantages of Cochran Boilers?

Below we have prepared a list of strengths and weaknesses of this boiler for you to read.

-

Advantages

- It has a low initial installation cost

- It requires less floor area

- It has an easy operation and handles

- Its transportation is easy

- It can work on all types of fuels

-

Disadvantages

- It has a Low steam generation rate.

- Limited pressure handles capacity.

- It is difficult to inspect and maintain.

What Are the Applications of Cochran Boilers?

Cochran boilers are used in power generation plants where large quantities of steam from 500 kg/s with high pressures approx. 160 bar and high temperatures reach up to 550o C. In the following, we listed some other applications of Cochran Boilers:

- It is used in Refining units.

- It is used in Paper manufacturing plants.

- You can find Cochran boilers in Chemical processing divisions.

- And it is used in a variety of process applications in various industries

Conclusion

in this article, we tried to provide you with all the essential information about Cochran Boilers. we brought the basic definitions and then we moved to the parts and components. In the 3rd section, we delved into the working principle that cochrans are based upon. The remaining sections were related to the characteristics, advantages, disadvantages, and also applications of Cochran boilers. All we did in this article was an attempt to make it easier for you to understand how a brushless DC motor works.

If you have any experience of using this type of boiler and know more about it, we will be very glad to have your opinions in the comments on our website Linquip. Moreover, if you have any questions about this topic, you can sign up on our website and wait for our experts to answer your questions. Hope you enjoyed reading this article.

Read More In Linquip

- 5 Best Electric Boilers of 2022: A Practical Guide

- Boiler Efficiency: Definition, Formula Caculation

- The 5 Best Regular Boilers of 2022

- The 9 Best Combi Boilers of 2022

- Water Tube Boiler: What You Need to Know

- Benson Boiler: A Full Discussion on Structure, Working Principle, Pros and Cons and Applications

- Package Boiler: Your go-to guide to learn everything about them

- Locomotive Boiler 101: Your Go-To Guide for Locomotive Boilers

- Lancashire Boiler 101: A go-to guide to know Lancashire Boiler

- Cornish boiler 101: All you need to know about this boiler type

- Types of boilers: Which one is the best?

- How Steam Boiler System Works?

- Parts of Boiler and Their Function in the Boilers

- 5 Best Steam Boilers Worth Buying

Need Catalogue & price to work with you

Please contact our expert partners. They will give you the necessary explanations.

https://www.linquip.com/sign-up?client_redirect=/