We have already talked about the different types of electrical motors. You can find different articles on Linquip website dealing with topics such as DC and AC motors with their different types and functions. Today and in this article, we are going to explain one of the most important revolutionary components used in electric motors that brought new features. A commutator is the device we are going to elaborate on.

The process of commutation involves switching the field in the armature windings to generate consistent torque in one direction. The commutator is a component linked to the armature that makes it possible to switch the current. Commutator Motors are available from a variety of Suppliers and Companies, as well as other manufacturers and distributors, and there are various Commutator Motors for Sale on Linquip.

The Linquip platform offers a comprehensive range of commutator motor services for all OEM fleets. Vendors for Linquip can help you with this. For more information on how to get in touch with a wide range of service providers who continuously provide high-quality goods, please get in touch with Commutator Motor Experts.

In the following sections, we show you how commutator motors work and what features they bring to our lives.

An introduction to Electric Motors

As you may know, Electric motors are devices that convert electrical energy to mechanical energy. They usually do this by employing electromagnetic phenomena. The interaction of conductors carrying current in a direction at right angles to a magnetic field is what brings mechanical torque in electric motors. The different kinds of electric motors are distinguished by the ways in which the conductors and the field are arranged and also in the control that can be exercised over mechanical output torque, speed, and position.

Most of the types were explained before on the website and you can reach them with a simple search. As we mentioned before, we intend to talk about the commutator motors in this article. But what we need to reach this point is to see what a commutator is and how it works.

What Is the Commutation Process?

So far, we know that how generally and based on what main rule electric motors work. In this section and in order to better understand the performance and features of commutator motors, we intend to get acquainted with its main component i.e. the commutator.

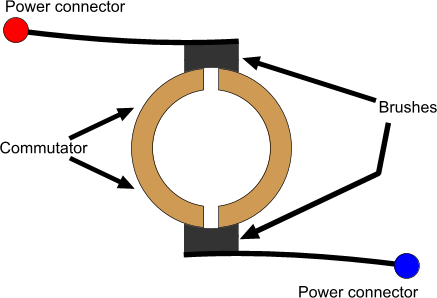

As you may know, The operating principle of DC motors is on the basis of the mutual interaction between the magnetic field of an armature rotating and the magnetic field of a fixed stator. when the armature’s north pole is attracted to the stator’s south pole or vice-versa, a force is produced on the armature causing it to rotate. Commutation is indeed the process of switching the field in the armature windings to make constant torque in one direction with the purpose of ensuring that the torque acting on the armature is always in the same direction and the device connected to the armature enabling this current switch is the commutator.

What Is Meant by A Commutator?

A collection of bars or segments linked to the generator’s or motor’s armature coils in order to convert alternating electricity into the direct current while the generator or motor rotates.

Where Is Commutator in Motor?

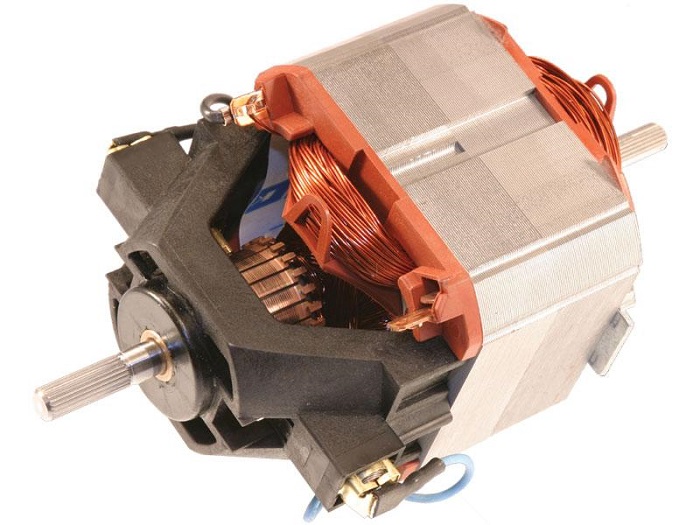

Commutator motors are a general term for any DC motors with the ends of the rotor coil linked to the bars of a commutator switch installed on the rotor shaft.

How Does a Commutator Work?

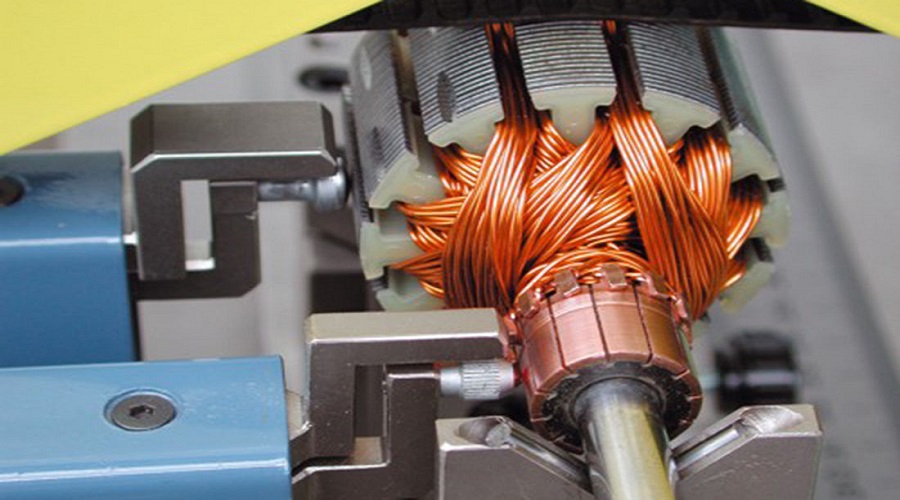

A commutator itself is a split rotary ring, typically made of copper, with each segment of the ring attached to each end of the armature coil that is used in some types of electric motors and electrical generators whose job is to periodically reverse the current direction between the rotor and the external circuit. The armature having multiple coils need a commutator with similarly multiple segments supporting each end of each coil. Spring-loaded brushes are put on each side of the commutator and make contact with it as the commutator turns and supplying the commutator segments and the corresponding armature coils with voltage.

Commutators are mostly applied in direct current machines such as dynamos or as they are called DC generators and many DC motors as well as universal motors. By reversing the current direction in the rotating windings each half turn, a steady rotating force which is called torque is produced. In a generator the commutator picks off the current generated in the windings, reversing the direction of the current with each half turn, serving as a mechanical rectifier to convert the alternating current from the windings to unidirectional direct current in the external load circuit. The first DC commutator machine, the dynamo, was built by Hippolyte Pixii in 1832.

We have to note that what we discussed above relates to traditional brushed DC motors with a traditional commutation process that uses mechanical means. Brushless DC motors also need a commutation process, but the difference is that for brushless designs the commutation process is carried out electronically, via an encoder or hall effect sensors monitoring the position of the rotor to determine when and how to energize the coils in the armature.

What Is a Commutator Motor?

The basic form of almost all the direct-current motor is the same. A stationary magnetic field is made across the rotor by set poles on the stator. The coils carrying direct current encircle these poles or they may contain permanent magnets. The armature or as it is called the rotor consists of an iron core with a coil accommodated in slots. Almost all the DC motors whose ends of the rotor coil are connected to the bars of a commutator switch mounted on the rotor shaft are called commutator motors.

Suppose the armature terminals connected to a direct-current supply in a wat that a current enters at the positive terminal. The interaction between this current and the magnetic flux produces a counterclockwise torque accelerating the rotor. The commutator enters when the rotor has turned about 120°, and reverse the connection from the supply to the armature.

The new direction of the current in the armature coil is such as to continue to make counterclockwise torque while the coil is under the pole. Proportional to the speed, a voltage is generated in the armature coil. As this coil voltage is alternating, the commutation process makes a unidirectional voltage at the motor terminals. The electrical input will be the product of this terminal voltage and the input current. The mechanical output power will be the product of the rotor torque and speed.

Features and Disadvantages of Commutator Motors

in the previous sections, we get acquainted with the commutation process and how a commutator works. Here and in this section, we list some of the features and disadvantages of the commutator motors.

The following are some of the features that Commutator motors offer to us:

- They can be used with 100 VAC for home appliances

- They can Rotate faster than induction motors

- under increased load, the rotating speed goes down, and torque increases

- Startup torque is large

- They provide high output

- They are lightweight motors

Because of these characteristics, the commutator motors are used for home appliances such as electric vacuum cleaners and some other tools such as electric drills that require high-output, lightweight motors. some other devices such as mixers and coffee mills requiring rotations faster than induction motors, use commutator motors as the driving force.

On the other hand, the commutator motors have some disadvantages that we listed some of them below:

- They Generate loud noises

- Due to the service life of their brushes, these motors are not suited for constant or continuous operation.

Conclusion

in this article, we tried to give you essential and comprehensive information about the commutation process, commutator, and most importantly, the commutator motors. we talked about the design and construction of commutators and the vital role in most of the DC motors. Besides, for better understanding, we brought some basic pieces of information about the working principle of electric motors. In the end, we listed some of the features and disadvantages of this type of motor for you and mentioned where this type of motor is commonly used.

If you have any experience of using different types of commutator motors, we will be very glad to have your opinion in the comments. By the way, if you have any questions about this topic and if you still have ambiguities about this device in your mind, you can sign up on our website and wait for our experts in Linquip to answer your questions. Hope you enjoyed reading this article.

Download Commutator Motors PDF

Read More In Linquip

- All About DC Motor Types and Their Applications

- A complete Guide to The Difference Between Stepper Motor and DC Motor

- Shunt DC Motors: An Easy-to-Understand Explanation of Working Principle and Components

- A Simple Guide to the Difference Between Motor and Generator

- Series DC Motors: A Comprehensive Guide

- Synchronous Motors: Definition, Working Principle, Types, and Applications

- Brushed DC Motor: A Comprehensive Explanation of Working Principle, Parts, and Types

- 10 Types of CNC Machine + Applications & PDF

- 13 Parts of CNC Machine + Function & PDF: A Clear Guide

- What Is CNC Machining & How Does It Work? (A Comprehensive Guide)

- Working Principle Of DC Motor: Complete Guide

- Working Principle of Stepper Motor: Ultimate Guide

- Working Principle of AC Motor: Ultimate Guide

- Working Principle of Induction Motor: Full Guide

- DC Motor Efficiency: Calculation: Formula & Equation

- Efficiency of Induction Motor: Calculation & Equation

- What is Gear Shaft? Clear Principle & Advantages