We have already prepared some unique information on different types of electric motors which are AC and DC motors. In separate articles, we discussed different types of AC and DC motors. And now we want to introduce you to one of the most common-in-use types of DC motors. An engine that is made by combining two other types of engines. Compound DC motors are the subject of this article of Linquip.

As far as we can tell, a compound wound DC motor is made up of a shunt wound DC motor and a series wound DC motor that has been combined to offer the best of both worlds. The DC series motor, like a shunt wound DC motor, has an exceptionally efficient speed control feature, however, the shunt wound DC motor has a high beginning torque. Compound DC motors are available from a variety of suppliers and companies, as well as various Manufacturers and distributors, and there are several Compound DC Motors For Sale on Linquip.

A full list of compound DC motor services is available on the Linquip website, which covers all OEM fleets. Linquip vendors can assist you with this. Please contact DC Motor Experts in Linquip to learn more about how to connect with a diverse group of service providers who consistently deliver high-quality products.

In the following sections, we intend to define what a compound DC motor is. Then, we will talk about its different types defined by different ways of division. Next, we are going to elaborate on its characteristics, features, and capabilities. And at last, we mention some of the advantages and disadvantages of DC compound motors. stay with us till the end.

⇒ View a List of DC Motors for Sale and Their Suppliers ⇐

What Is a Compound DC Motor?

As we mentioned before, compound DC motors are basically made up of a combination of series and shunt motors. they are also called DC compound motors. this type of motor has both series and shunt field coils that are connected to the winding of an armature. These field coils which are linked to the armature windings, afford the essential amount of magnetic flux, and lead to generate the torque necessary to aid the rotation at the desired speed level in the armature. The majority of the field is wound for a shunt field with a few turns of series winding in the top.

The reason behind such a structure amalgamation is to win the better properties of both of these types. A shunt motor brings an extremely efficient regulation for speed, while a series motor has a great and high starting torque. Consequently, a compound DC motor has a great compromise on these features.

Note that their starting torque is not as high as the case of a series motor nor is their speed regulation as efficient as a shunt motor.

Different Types of Compound DC Motors

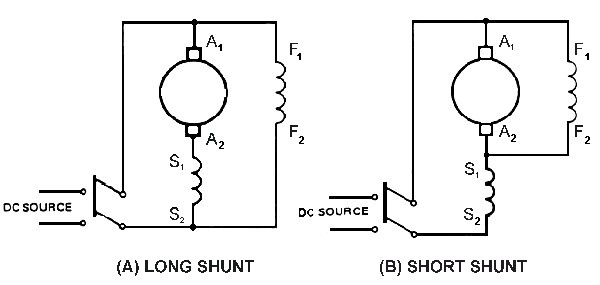

Compound motors can be divided into two major categories based on the way their field winding is connected to the armature winding and which are Long Shunt and Short Shunt. In the following section, we delve deeper into both of these categories.

Short Shunt Compound Motors

In terms of short shunt compound motors, the shunt resistor is just connected in parallel with the armature field coil, and the series field coil is exposed to the supply current.

Long Shunt Compound Motors

The shunt field coils of a long shunt motor are connected in parallel with the series amalgamation of both series field coil and the armature.

Apart from the previous categories that we mentioned before, there is another classification for compound DC motors which is based on excitation or the nature of compounding. Based on this classification, compound motors are subdivided into another two categories.

Cumulative Compounding

When the shunt field flux made by the shunt winding aids the effect of the main field flux made by the series winding, we can say that the motor is cumulatively compounded. Cumulative motors give high starting torque like a series motor and reasonable good speed regulation at high speeds like a shunt DC motor. It can work with huge loads and run smoothly after that. This type is practically suitable for most common applications and it is indeed widely used.

Differential Compounding

If the shunt field flux diminishes the effect of the main series winding we can say that the motor is differentially compounded. In fact, the polarities of the magnetic field of shunt winding and armature magnetic fields oppose each other. Note that This trait is not really desirable because the net flux produced is lesser than the main flux so, it does not find much of a practical application.

Characteristics of Compound DC Motors

One of the most important parts of any machine is its characteristics. The characteristics of a machine define its capabilities and applications.

The shunt field winding of cumulative motors and their additional flux from series winding produces a large amount of flux which causes a large amount of torque at low speed. It means that motors such as cumulative run at a reasonable speed on light or even no-load conditions.

On the contrary and in the differential motors, both series and shut fluxes oppose each other. It means that the flux decreases while the load increases. Actually, in this condition, the motor with an increase in load produces high speed and it can be horribly hazardous especially on full load.

Advantages and Disadvantages of Compound Motors

In previous sections, we tracked for the definition, construction, working principle, and different types of compound DC motors. the present section is dedicated to the advantages and disadvantages of compound motors. In the following, we deliver some of the pros and cons of this type of motor in two separate sections.

-

Advantages

The compound motors are made up of the specifications of series and shunt motor which means we face a motor that is capable of taking positives out of both of these motors. A shunt motor works at a constant speed. Thus, this kind of motor is not proper for applications that need variable speed requirements. nonetheless, the compound DC motors possess a very good speed control because of the presence of a series magnetic field.

On the other hand, a series motor creates a good speed control but it cannot be utilized for the requirements where the load is varied and initially set to zero because a series motor can eradicate itself with high speed at no load.

Thanks to the presence of the features of these two motors in compound DC motors, they can operate even at no load. they can run at some speed within the limits. As a result, a compound motor can be used for approximately all the applications where both series and shunt motor combined can be used. In some applications, the series motor will fail but the shunt will be useful and in some cases, the shunt will fail but series will be able to perform the task.

-

Disadvantages

Compound motors indeed have many advantages over other motors nevertheless, just like all other types of motors, the compound motor has few disadvantages too, which are been discussed and delivered briefly below.

- a compound motor also needs frequent maintenance due to the aging of parts, and its maintenance costs are relatively high.

- Due to the spark happening at carbon brushes, this type of motor is not suitable for the hazardous environment.

- In comparison to the AC motors and because of the presence of components expiring with age like brushes, the lifetime of compound DC motor is less.

- In differential motor which is one the types of compound motors, the flux of series field and shunt field oppose each other which causes lower flux and consequently low torque. This characteristic makes the motor unstable even with a negligible change in load.

- The differential compound motor cannot be used for any practical application due to its unstable behavior with even a slight variation of the load.

Applications of DC compound motor

Because of the capabilities of the compound motors to provide high starting torque and also speed regulation and control it has many applications in different areas. Below we listed some of the applications of a compound DC motor:

- Compound motors due to their ability to perform better on heavy load changes are used in elevators.

- Due to their high starting torque and better speed control for pressure variations, they are used in shears and punches.

- This kind of motors because of the high starting torque and heavy-duty load is used in steel rolling mills.

- Again due to the capacity of driving heavy loads, they are used in the printing press and cutting machines.

- They are also used in stamping presses to provide high starting torque.

- Their good speed control and high starting torque make them a great choice to be used in mixers.

As you can see, compound DC motors have many applications in industry and business machines due to their capabilities to handle high load variations and their abilities to provide control over the speed.

Conclusion

In this article, we tried to show you what exactly a compound DC motor does. To make it clear for you, we analyzed the working principle of a compound motor and how it works. We explained the parts a compound motor has to do its job. After that, we considered different and main types of it. then, we reached the different characteristics of compound motors and talked about the main advantages and disadvantages.

If you have any experience of using different types of compound motors, we will be very glad to have your opinions in the comments. By the way, if you have any questions about this topic and if you still have ambiguities about this device in your mind, you can sign up on our website and wait for our experts in Linquip to answer your questions. Hope you enjoyed reading this article.

Download Compound DC Motors PDF

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- A Simple Guide to the Difference Between Motor and Generator

- Differences Between Motor and Engine

- All About DC Motor Types and Their Applications

- What is a Hysteresis Motor: Ultimate Guide

- Shunt DC Motors: An Easy-to-Understand Explanation of Working Principle and Components

- Series DC Motors: A Comprehensive Guide

- A Complete Guide to Repulsion Motor

- Series Wound DC Motor

- Brushed DC Motor: A Comprehensive Explanation of Working Principle, Parts, and Types

- Commutator Motors: A Short Introduction to the Structure and Working Principle

- A complete Guide to The Difference Between Stepper Motor and DC Motor

- Working Principle of Stepper Motor: Ultimate Guide

- Working Principle Of DC Motor: Complete Guide

- DC Motor Efficiency: Calculation: Formula & Equation

- What is a Series Wound DC Motor?

- DC Motors vs Servo Motors: A Complete Comparison

- Universal Motor: a Simple Guide to Construction, Types and Working