There are many things to consider while running a condenser water system. Learning about the system’s components and the way they work together within a system will lead to a deep understanding of the overall system which results in an efficient and optimized system.

Condenser water systems elevate water from the basin to the top of the cooling tower by supplying the necessary condenser water flow rate and overcoming the pressure drop through the condenser of the chiller, the condenser water pipelines, elbows, and valves. Condenser water systems are available from a variety of suppliers and companies, as well as various Manufacturers and Distributors, and there are many Condenser Water Systems For Sale on Linquip.

There is a comprehensive list of condenser services on the Linquip website that covers all of your electrical needs. Linquip vendors can assist you with this. Please contact Condenser Experts to learn more about how to connect with a diverse group of Service Providers who consistently deliver high-quality items.

Linquip has provided all the essential information on these systems. Read on and enjoy effortless learning!

What is a condenser water system?

They are used to remove heat from a building or a process and reject it to the atmosphere.

How does a condenser water system work?

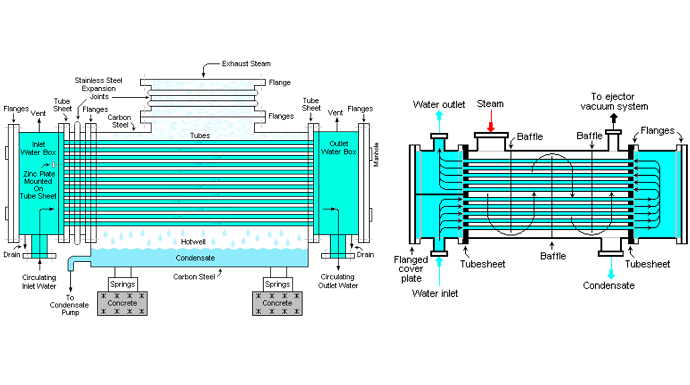

To learn the process in which the system works, first you must understand the refrigeration cycle. The most common method of rejecting heat is through a cooling tower located outside of the building. In these systems, water which is heated by the chiller is pumped to the top of the tower and then descends to the sump basin at the bottom of the tower.

Air is drawn through the porous media by a fan which causes the water to cool. The cool water is returned to the chiller to absorb the heat and replicate the cycle. In fact, the condenser water system connects the chiller to the cooling tower through supply and return piping. Water cooled in the tower is supplied to the chiller which adds heat to the water and returns it to the tower.

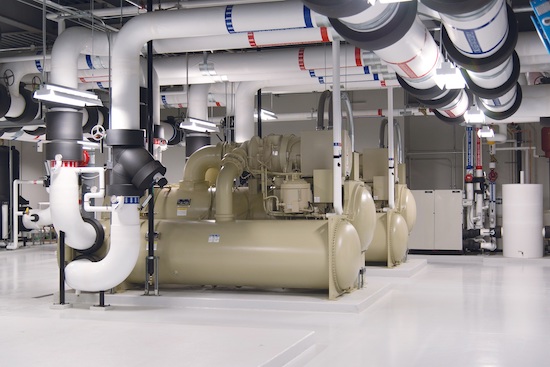

Components of the system

- Cooling towers: Cooling towers reject energy from water-cooled chilled-water systems.

- Condenser water pumps: they supply the required condenser water flow rate and overcome the pressure drop through the chiller’s condenser, the condenser water pipes, elbows and valves, and lift the water from the basin to the top of the cooling tower.

- Chillers: chillers use recirculating condenser water from a cooling tower to condense the refrigerant. They include compressor, condenser, expansion valve, and evaporator.

Differences between chilled water systems and condenser water systems

Chilled water systems are used to absorb heat energy from within a building or process while condenser water systems are used to remove that heat energy from the building and reject it to the atmosphere.

Common Pitfalls of the condenser water system

- Low flow through towers: Every cooling tower has a minimum flow requirement, which is defined by the allowable turndown. Low flow leads to dry air disease and the eventual build-up of mineral deposits on the cooling tower heat exchange surfaces. The purpose of maintaining the minimum flow is to keep all the interior surfaces of the cooling tower wet enough, which leads to consistent heat transfer by preventing dry passages in the fill. Otherwise the cooling tower fans will work extra hard to overcome a problem that they can only make worse.

- Towers flooding at Shut-off: Cooling towers are designed not to flood after being installed according to manufacturer. The sump basin in the bottom of the tower is designed to hold pull down volume of the tower, which includes full volume of water in the fill, the hot deck, and the overhead supply pumping to the tower. However, if the condenser and its associated piping are located at an elevation higher than the cooling tower, then the water in the equipment will certainly drain by gravity into the tower causing it to flood when the pump is turned off.

- Pumping Dry at Start-up: Pumping dry at start-up is an inevitable consequence of the previous pitfall of flooding the tower at shut-off. If you don’t install a water trap to catch the water from the condenser and piping located above your tower, the tower will flood and most of the water will spill out over the sides of the sump as soon as the pump is turned off. Then, when you turn your pump back on, you don’t have enough water in the system and you begin to pump dry.

So this is all you need to know about condenser water system and its components. If you enjoyed your time at linquip and want to share your experience with others, feel free to leave it in the comment section. Please let us know if you have any technical question or need an expert to help you out by signing up on our website.

Download Condenser Water System PDF

Read More In Linquip

- Difference Between Condenser and Evaporator: discovering new worlds of equipment

- Difference Between Condenser and Capacitor in a nutshell

- Difference Between Heat Exchanger and Condenser: A thorough guide

- Steam Condenser: Basics, Parts, Advantages and Disadvantages

- Water cooled condenser types : A go-to guide to choosing the right one

- Why vacuum is maintained in condenser: an easy-to-understand guide

- Evaporative condenser: An easy to understand guide

- What Is a Condenser; Parts, Functions and types

- An Applicable Introduction to different types of Condensers

- Water-cooled condensers: facts that will blow your mind!

It’s a great thanks for a valuable content:-)

Thanks for visiting our website and leaving your comment, Elvin! We hope to hear from you again in our other posts.