Each and every different control valve type has been designed with a specific purpose in mind. In this article, you’ll read about different types and categories of Valves to get a better understanding of its internal parts and units. Read on and see how Linquip eliminates the need for you to search more on this subject.

⇒ View a List of Control Valves for Sale and Their Suppliers ⇐

The Final Goal of Different Control Valve Types

The final control element or the control valve can convert the control signal of the controller with the help of a pneumatic device and regulate the fluid flow in the system. They can be used for different liquids, gasses, steam, air, etc.

Classification of Control Valve Types

Control valves can be categorized based on different features and control valve traits. Some prefer to categorize them based on control valve parts as well. The main categorizations are according to the movement profile of the controlling element, functionality, actuating medium, and pressure drop profile.

-

Pressure Drop Profile

- High-Recovery Valve (e.g. Butterfly valve, Plug valve, Gate valve, Ball valve, etc.)

- Low-Recovery Valve (e.g. Angle valve, Globe valve, etc.)

-

Functionality

- Check Valve (e.g. Turbine bypass valve, etc.)

- Shut-off and on-off Valve (e.g. Gate valve, Pinch valve, etc.)

- Spring-Loaded Safety Valve

-

Actuating Medium

- Manual Valve

- Pneumatic Valve

- Hydraulic Valve

-

Movement Profile of the Controlling Element

- Linear Motion (e.g. Gate, Globe, Diaphragm, etc.)

- Rotary Motion (e.g. Ball, Butterfly, Plug, etc.)

The most common classification is based on motion and we’ll briefly talk about its subcategories.

Read More on Linquip

- Flow control valve types and functions

- Control Valves 101: The ultimate guide to understand control valves and how they operate

- Industrial Valves A Comprehensive Review on Parts, Types and its Usability

- Control Valve Parts: The Go-To Guide for beginners and experts

- Control valve positioner: an easy-to-understand guide to know them better

- Types of Pneumatic Valves: Specifications and Working Principles

- Types of Hydraulic Valves and Their Working Principles

- Working Principle of Control Valve

- Types of shut off valve: Your ultimate guide

- Types of plumbing valves: A complete guide

- Types of isolation valve: All you need to know!

- Types of Water Valves: The Ultimate Guide

A. Linear Motion

Linear Motion Valves are named because of their closure member’s shape. A closure member in these control valve types moves with a linear motion resulting in the modifying the rate of flow through the valve.

-

Gate Valves

These valves are suitable for conditions with high temperature and are used for on/off applications and non-throttling services. This is because of their design which can be either fully open or fully closed. Gate valves have a sliding gate which moves by the stem to handle the flow. Gate valves best work when a straight-line flow of liquid is required with minimum restriction.

They are further divided into two subcategories: Parallel and Wedge-Shaped. The closure member in this type of valve is a flat face, a vertical disc, or a sliding gate. When you rotate the stem in a CTC (clockwise to close) motion or a CTO (clockwise to open) motion, gate valves begin to operate. With the movement of the stem, the gate moves up / down on the threaded step. With several turns of the valve, it goes from fully open to fully close. These valves are popular because of their tight sealing. And they also have a low pressure drop when they fully open. One of the disadvantages of Gate Valves is that they require large actuating force. Not to mention their slow response characteristics.

-

Globe Valve

Disc or plug in Globe valves moves on or off the seat. The opening of the seat is proportional to the plug’s travel. This control valve type is used for throttling purposes. They are among linear motion valves and can start, stop, and regulate the flow. The closure in globe valves is initiated with the help of a plug that has a flat or convex bottom, lowered onto a horizontal seat. This seat is in the center of the globe valve.

Globe valves are faster to open or close and have a reliable form of seating. The down point is that the seat disc in such valves wears in partial open conditions.

-

Diaphragm Valve

The closure member in the diaphragm valve is a compressor connected to the flex diaphragm. When the valve is open, the diaphragm is lifted and the fluid flows and when it is closed, the diaphragm closes the flow path tightly.

Diaphragm valves are suitable for corrosive liquids at low temperature and pressure. The simplicity of the construction and easy maintenance are among the advantages of using diaphragm valves. But keep in mind that you can’t use them in environments with high temperature and high pressure.

Read More on Linquip

- Diaphragm Valve Suppliers and Companies

- Plug Valve Suppliers and Companies

- Valve Parts Suppliers and Companies

- Downstream Valve Suppliers and Companies

- Midstream Valve Suppliers and Companies

B. Rotary Motion:

The closure member in Rotary valves modifies the rate of the flow through the valve with a rotary motion. Plug valves, Ball valves, and Butterfly valves are among the popular rotary valves.

Read More on Linquip

- What is Float Valve

- What is Foot Valve

- What is Gate Valve

- What is Globe Valve

- What is High pressure valves

- Flanged Control Valve V150 for Sale

- Fisher EZ Control Valve EZ for Sale

- Control Valve ET for Sale

- Top Control Valve Suppliers in the USA

- Plug Valve

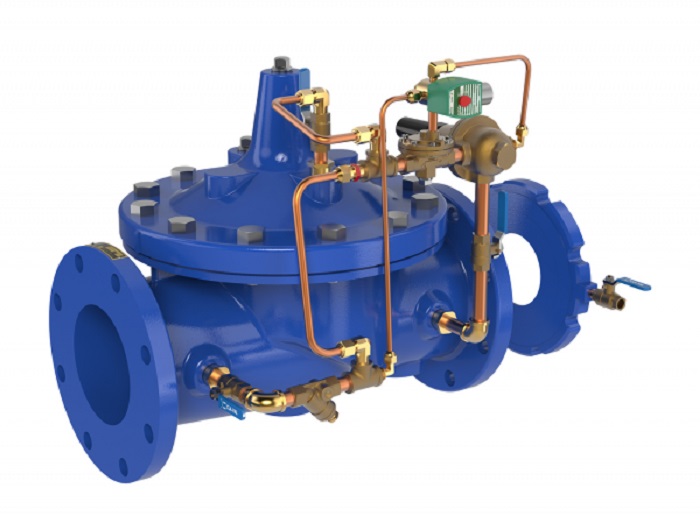

The plug in the Plug Valves is cylindrical or tapered, depending on the design. While open, the inlet and outlet ends of the plug valve are connected to each other via the bore in the plug to provide the flow line. Plug valves are suitable for chemical or petrochemical industries providing on/off services. They are also capable of handling fluid containing solids.

Plug valves are usually small and need less maintenance compared to other control valve types. Plus, they require less headroom due to their small size. Low pressure drop, quick opening and providing tight shut off are among the features you can expect from Plug valves. The disadvantage of these valves is that they’re relatively more expensive and are not recommended for throttling action. - Ball Valve

The name of this valve suggests the shape of its closure member that looks like a ball, containing a port for fluid flow. In the opening position, the ball valve enables a straight-through flow. And with a 90-degree rotation of the ball, the flow stops. Low pressure drop and quarter-turn actuation enable ball valves to be used in shut-off applications. They endure high-temperature as well as high pressure of the environment. This control valve type is also used for pressure and flow control and also for corrosive fluids, slurry, normal liquids and gasses as well. Easy maintenance and low torque are also two other plus points of ball valves. One of the disadvantages of this control valve type is that when the fluid traps in the ball in the closed position, sometimes the vapor pressure builds up and results in corrosion. - Butterfly Valve

Having a circular disc or vane rotating at right angles as the closure member, Butterfly valves enable straight-through fluid flow when in open position. And similar to the ball valves, they stop the flow with a 90-degree rotation. This control valve type in the rotary section is capable of large flow control as well as low-pressure applications. But they should be used where leakage is not important.

Quick opening, low pressure drop, affordability, compact form, and quick opening are among the advantages of butterfly valves. The only disadvantage of this control valve type is that the shut off is not tight.

See All Butterfly Valve for Sale

So, now you know everything you needed to know about different control valve types! Do you think these differences have more effects other than what we mentioned above? Share your thoughts with Linquip in the comment section. And feel free to sign up on our website if you want our experts to answer your most complicated questions regarding this field.

Read More on Linquip

- Control Valve Manufacturers in United States

- Gate Valve Manufacturers

- Plug Valve Manufacturers

- Globe Valve Manufacturers

- Angle Valve Manufacturers

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers