When it comes to the elements of cooling tower efficiency, talking about cooling tower approach is a must. However, let us walk down this path slowly and begin by saying that among all industrial equipment, the cooling tower is a simple HVAC device. It utilizes two widely available resources (water and air) to reject the heat from the manufacturing process in a wide range of industries, including oil refineries, chemical plants, power plants, and many others.

However, this device’s efficiency is dependent on a number of factors, including temperature, range, and more importantly cooling tower approach. In order to get the best out of a cooling tower, you need to understand:

- How the temperature in the cooling tower is influenced by humidity

- How to control the range of a cooling tower and efficiently set pumps and fans to have the lowest temperature of the water exiting the tower

- How to calculate the maximum amount of heat loss in a cooling tower

In this article, we provide detailed explanations to these three subjects.

Cooling Tower Temperature

For a cooling tower to be fully capable of reducing the water temperature, three important factors play key roles. With having the ambient temperature and humidity, range, and the cooling tower approach under control, the operators of a cooling tower can make sure that the hot water will become as cool as possible, without wasting energy.

To get a clearer view of the temperature’s effect on the performance of a cooling tower, you have to consider this device’s operation. Basically, a cooling tower uses the natural process of evaporation for reducing the temperature of water in a manufacturing plant. It passes the hot water through a number of fills to increase its contact with air. The result would be an improvement in the speed and quality of water’s evaporation.

In normal temperatures, 1.2% of the water that enters the tower evaporates for each 10° F cooling range. But not every cooling tower can guarantee this number. As the rate of evaporation is dependent not only on the temperature but also on the relative humidity, we need to consider two different kinds of temperatures.

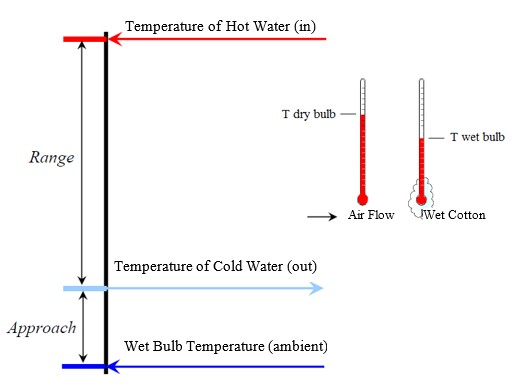

The more usual type of temperature is called dry bulb which is the temperature of a typical thermometer. In this kind of temperature, humidity is not considered. In order to take humidity into account and calculate the performance of a cooling tower, we need the wet bulb temperature as well. If we cover the bulb of a thermometer with a wet cloth and calculate the temperature with having the humidity level in mind.

These two temperatures help us measure the extent to which water can evaporate in a certain location. If the relative humidity is 100%, there will be no difference between the dry bulb and wet bulb temperature. This means evaporation and cooling of water is not possible.

With the help of dry and wet bulb temperatures, we can estimate how a cooling tower will operate in two different locations with various rates of humidity. Calculating the temperature correctly is required for measuring the cooling tower approach, which is a key indicator of performance in cooling towers.

What is the Cooling Tower Approach and how can We Find it?

As we mentioned before the wet bulb temperature shows us the extent to which evaporation and heat transfer can occur. On the basis of this factor, we measure the cooling tower approach.

As an essential factor in the water cooling process, the cooling tower approach would be the difference between the cold water temperature and wet bulb temperature. The smaller the number, the more efficient the cooling tower. A normal cooling tower offers a range of 5° to 9° F for its cooling tower approach. However, the design numbers are not going to work in actual conditions which is why the functionality of your cooling tower is 75% of what these numbers say.

You may now wonder what reasons are behind variations in the cooling tower approach approach. There are a number of factors that affect the cooling tower approach in a real situation. These three variables are heat load (the amount of heat removed by the tower), tower size, and airflow. To achieve better performance, operators can also increase the fan speed in mechanical draft towers.

What is the Range of Cooling Tower?

The cooling tower’s main feature is the ability to reduce the temperature of hot water and produce cool water. The difference between the temperature of the water that enters the cooling tower and the one that exits is called the range of the cooling tower.

Along with the cooling tower approach, the range is another key factor in optimizing the efficiency of the cooling tower. In fact, a higher range means that all parts of the tower are working effectively to reduce the temperature of the water. Be mindful of the fact that without knowing the cooling tower approach, range is proven to be insufficient in measuring the effectiveness of a cooling tower.

But what factors affect the cooling tower’s range? This parameter is associated with the heat load (total heat that can be removed from a unit of water) and the amount of water flow in the tower. A cooling tower that pumps higher water flow can bring a lower range to the operator, mainly because it increases the static pressure against the flow of air.

Those operators that are eager to use the cooling tower efficiently, need to fix pumps and control the heat load before application.

What is the Lowest Temperature a Cooling Tower Can Produce?

Idealistically, a cooling tower will provide water that is as cool as the temperature of the wet bulb, however, this rate of reduction in the temperature of the hot water that enters a cooling tower is not possible. For hot water experiencing 100% evaporation, a larger cooling tower is needed which is not a logical choice all the time. Increasing the air fans’ speed is not always recommended since the energy consumption and operation cots will rise.

As we mentioned before, the evaporation of water can have 75% of its potentials. This means that the difference between the temperature of the water that exits the tower and the wet bulb temperature cannot be lower than 5° F.

It is also worthwhile to know that the temperature of the water that is sent back to the process is always higher than the wet bulb temperature. Which is why we call the difference between the cold water temperature and wet bulb temperature “Approach”. This expression reminds us that the final temperature will approach (not reach) the wet bulb temperature.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

Sir,

Very good

Thanks

Very beneficial content