Learning the cooling tower diagram can help you to a great extent if you are eager to know about these systems or want to buy one for your industrial or commercial use. These systems have been designed to help remove the excess heat and transfer it to the outside environment. So understanding the diagram will help you know them better and choose the right one for your specific application.

In this article from Linquip, we will go through some of the most popular types of cooling tower and explain their diagram to help you get a deeper insight into cooling tower working principles. And before we get into the diagrams, we also explain some of the basics you need to know about cooling towers to make sure you understand the whole article without any problems.

Cooling tower definition

Cooling towers are systems used to exchange the heat from the ambient air to the outside environment. These systems have different designs based on their specific application, but all of them achieve the same purpose: removing the excess heat!

Each and every one of cooling tower parts is trying to do their part in the process of chilling down the water that has been heated by manufacturing methods and equipment.

Cooling tower basics

There are some cooling tower basics you need to know to understand the cooling tower diagram better such as different parts and types of towers.

Cooling towers feature a system for distributing the air, a basin or liquid holding system, an outer structure or casing, a medium to help transfer the heat, and a fan for moving the air.

There are also different types such as counter-flow, cross-flow, Induced draft, etc. which we will cover in this article to learn their diagram.

The most famous cooling tower types diagram explanation

So now I will go through famous tower types such as cross-flow, counter-flow, etc. and we will understand the diagram bit by bit.

-

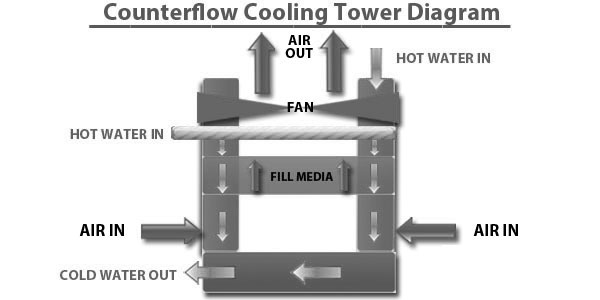

Counter-flow cooling tower diagram

As you can see in this cooling tower diagram, the vertical movement of the air is one of the main steps toward cooling down the water and decreasing its temperature. In this design, unlike the cross-flow, we don’t depend on the force of gravity to move the water; instead, it uses a pressurized spray technique for diffusing the water to the peak of the fill media at the top of the tower. And as you can see, the air comes from the bottom and when it receives the heat from the water, it leaves from the top to release the heat.

-

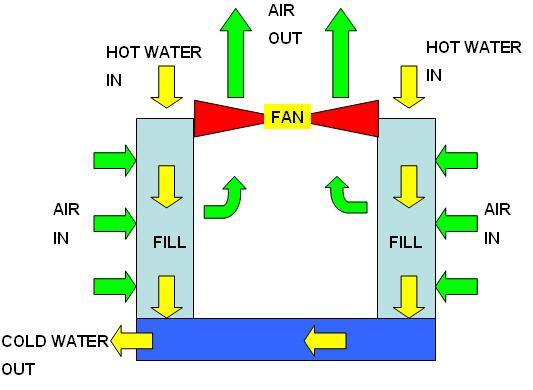

Cross-flow cooling tower diagram

As you can see in this diagram, the hot water in this tower type moves vertically from the top to the bottom through the fill media. The horizontal movement of the air across the dropping water, helps cool down the water and hence, the name. The force of gravity pulls down the water in this design, so there’s no need for the air to move through the transmission system.

-

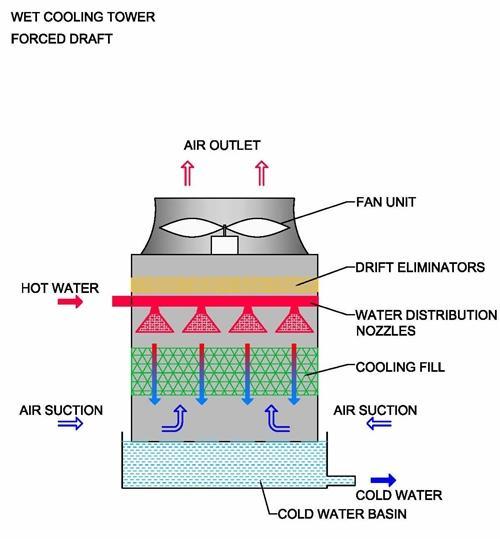

Forced-draft cooling tower diagram

The input of this tower contains a fan unit that works as air outlets. The fan also creates an air suction process to force the air into the tower by creating a low level of exiting air and a high level of entering air swiftness. This results in the circulation of the air throughout the tower, and therefore, decreasing the temperature of the water inside. This tower type has the capacity to operate with huge latent pressure and enables it to be used in some indoor locations as well as places with more restricted spaces.

-

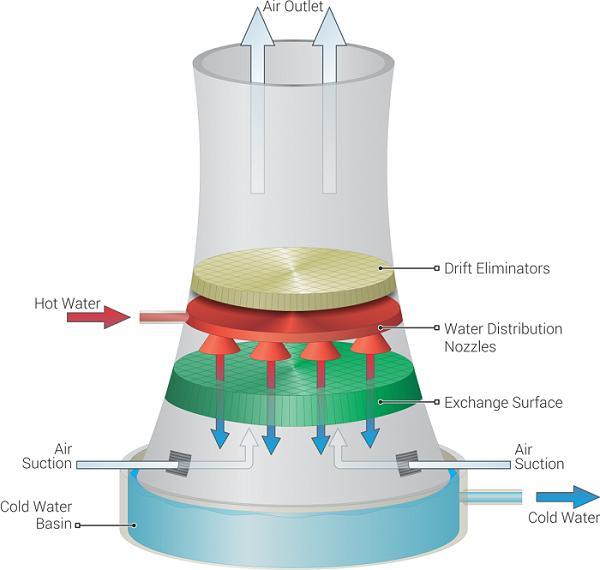

Natural draft cooling tower diagram

In this type, the hot water is distributed with the water distribution nozzles inside the tower. A heat exchange surface that has contact with the air that’s sucked into the tower, cools down the water that has been poured on it by the nozzles. The air then leaves from the top of the tower. The movement of the air to the top is because of the difference in the density with the dry air outside.

The thickness of the ambient air which is warm and humid after receiving the heat from the water, is lower than the drier outside air. This results in moving the air upward in the tower to leave from the top. Then the cold water poured down in the cold water basin will leave the tower to be used for different purposes.

-

Induced-draft cooling tower

In this tower, the air, too, comes in from the bottom and the cold water basin is there as well. The hot water is distributed with nozzles onto the heat exchange surface that’s in contact with the incoming air. When the water drops from this surface, its temperature decreases, producing cold air that will be poured on the basin at the bottom. The moist, hot air then leaves from the top with the help of the fan that creates a high level of exiting air and a low level of entering air rapidity.

So these were the most popular cooling tower diagrams you needed to learn to get a better understanding of different cooling tower designs. As you already understood, they all follow the same purpose with different approaches. These differences in the design make the using of towers for a wide variety of purposes possible. There are many other types of cooling towers that can be studied to further expand your knowledge on the subject and to know other choices if you think about buying one.

In the end, it depends on you, the application, and space you have in your facility to decide which one works best for you and provides your desired outcome. But keep in mind that there are other things to consider when choosing one, for example, you need to check with the regulation of your hometown as well, since some regulations forbid to use specific types of cooling towers indoor or outdoor.

Do you want to know about other types of cooling tower diagram too? Or have anything to add to this article? Then drop a comment below and let us know what you think. And if you have any questions about cooling towers and their working principles, feel free to sign up on Linquip to find the answers you were looking for with the help of our experts.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip