Cornish boilers are among boilers with a slightly different design. They are horizontal and large! In this article from Linquip, we will talk about Cornish boilers and help you understand their definition, parts, working principles, types, application, and advantages and disadvantages. By the end of this article, you’ll have a deeper knowledge about Cornish boilers and can easily figure out if they are suitable for the application you have in mind or not. Read on to learn and expand your knowledge.

What is a Cornish Boiler?

The Cornish boiler Wikipedia page defines it as below:

“The simplest form of the flued boiler was Richard Trevithick’s “high-pressure” Cornish boiler, first installed at Dolcoath mine in 1812. This is a long horizontal cylinder with a single large flue containing the fire. As the furnace relied on natural draught, a tall chimney was required at the far end of the flue to encourage a good supply of air (oxygen) to the fire.”

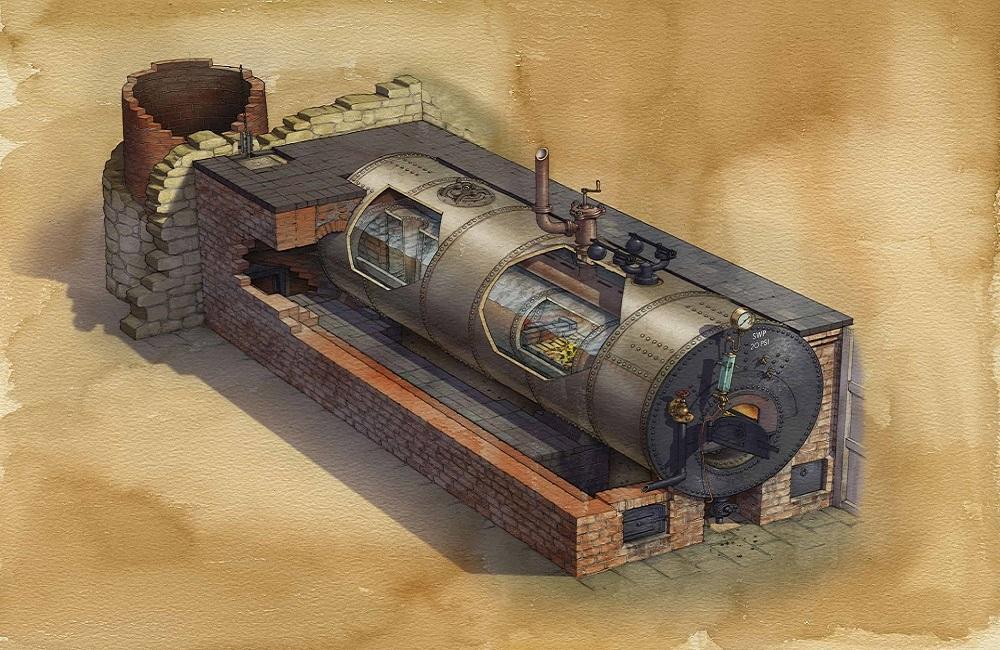

The Cornish boiler is a subcategory of Fire-tube boiler type. This type is among the popular types of boilers. The long horizontal cylinder used in this boiler type also contains a flue which is similar to the Lancashire boiler design. The cylindrical shell of Cornish boilers is about 1.25 meter to 1.75 meters in diameter and the length varies from 4 to 7 meters. The diameter of the flue tube that’s inside the Cornish boiler is 0.6 times the cylindrical shell’s diameter.

Cornish Boiler Parts

Cornish boiler has different parts and we’ll briefly go through:

- Shell: The shell in the Cornish boiler contains water and tubes . The heat transfer that cools down the water by the help of gasses, happens inside the shell.

- Tubes: They are located inside the shell and contain hot gasses that flow through them.

- Flue: There are two flues in the Cornish boiler: Side Flue and Bottom Flue. The side flue is the tube that receives hot gasses from the fire tubes. This flue is called side flue because it is located at the side of the horizontal shell. The bottom flue is located at the bottom of the horizontal shell and directs the smoke to the chimney at the bottom of the flue.

- Grate: The fuel is added in the grate for the combustion purposes.

- Combustion Chamber: This chamber supplies the generated heat in the grate to the fire tube.

- Fire tube: This unit is at the center of the water area in the boiler and contains the hot gasses from the grate.

- Brick arc: This unit prevents the ash from getting into the tubes and internal parts.

- Chimney: Chimney is located at the bottom of the flue and takes the smoke from there to release it to the outside atmosphere.

- Ash pit: When the fuel burns out completely, the ash pit keeps its ashes.

- Valves: Two valves have been designed in this boiler type: Stop Valve and Safety Valve. The safety valve is responsible for the safety of the process by making sure the steam pressure doesn’t exceed from the maximum limit and stop it before it does. Stop valve should regulate the flow of steam.

- Blower: The blower is used to clean the boiler. It discharges the sediments and the water from the bottom of the Cornish boiler.

- Water Feed Pump: This pump supplies the water to the Cornish boiler.

- Water Level Indicator: This unit identifies the level of the water in the boiler and also sends signals when the level is too low or too high than the desired amount.

Benson Boiler: A Full Discussion on Structure, Working Principle, Pros and Cons and Applications

Construction and working principle

A Cornish boiler has a long horizontal cylindrical external shell. The material used in this shell is steel plates. There’s one internal flue tube and a fire grate (furnace) designed in this boiler. The fire grate is at the front side of the tube and the coal goes through the fire hole into this grate. The brick art in this boiler prevents the ashes and burning coal from entering the internal parts and it also deflects the flue gasses upwards. The excess steam is responsible for releasing the extra steam pressure when the pressure is really high inside the boiler. There’s a feed pipe inside this boiler too, which is used for feeding water inside the boiler uniformly.

The coal in the Cornish boiler, is located inside the furnace and by burning of the coal, flue gas is generated. This gas will flow through the internal flue tube, the main flue tube, the side flue tube and bottom flue tube. This process circulates the water around and heats it up to generate steam. Then, by the priming pipe, it goes through the engine. The final step is that the flue gasses flow through the chimney. This was the whole working principle of a Cornish boiler.

Lancashire Boiler 101: A go-to guide to know Lancashire Boiler

Cornish Boiler Application

You can use this boiler type in different industries such as textile, chemical, paper, etc. You can even use the produced steam for running a steam turbine.

Cornish Boiler Advantages and Disadvantages

The simplistic design of this boiler type and its compactness makes it a perfect choice for many applications. A low maintenance cost is among the huge benefits of this boiler. But the down point is that the steam production rate in the Cornish boiler is low and needs more ground since it has a horizontal structure. This boiler has the ability to overcome load fluctuation as well. But again it has another disadvantage which is low maximum pressure range of 12 bar.

Now that you have reached the end of this article, you know all there’s to know about Cornish boilers and you can easily explain their function and application. You can also decide whether they are useful for you or not. Do you have anything to add to this article about Cornish boilers? Comment below and let us know what you think about them. And if you have faced any difficulties about these boilers, sign up on Linquip and our experts help you solve your problems.