Cross flow heat exchangers are called the type of heat exchangers which have 90 degree angles for the direction of the fluids. Totally, it is hard to find a specific exchanger using cross flow configuration, but generally, Plate, shell and tube, one-phase, and multi-phase exchangers can be categorized as cross flow heat exchangers.

Linquip’s website contains all the necessary information about Cross Flow Heat Exchangers. Linquip’s experts are ready to answer any of your questions regarding the Cross Flow Heat Exchanger. Linquip’s article entitled “What Is Cross Flow Heat Exchanger?” is a good place to begin. You may need to register as a Linquip Expert in order to take advantage of all the features available.

How about Guest Posting on Linquip? Guests are welcome to write their posts on Linquip.

Types of Heat Exchanger

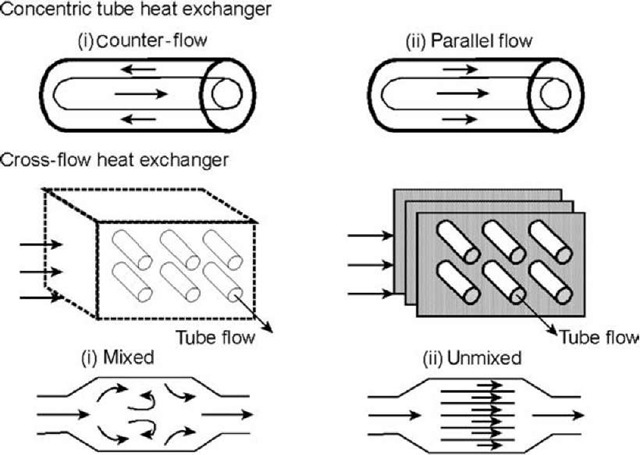

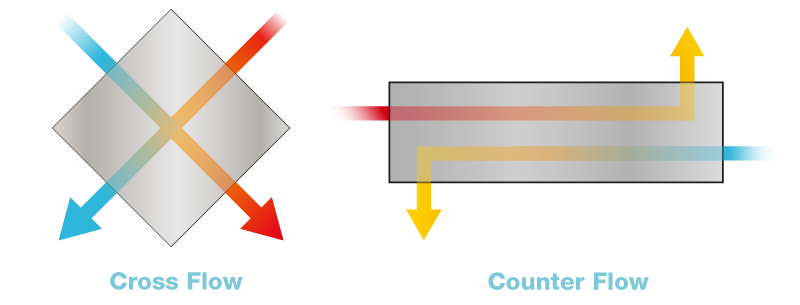

Totally, heat exchangers can be classified into three types: parallel, counter flow, and cross flow. The main differences between these heat exchangers are based on the fluid flow direction and the temperature diagram. Due to the design and configuration of exchangers, it is hard to find only one flow type, and there is a combination of several flow directions.

Parallel Flow Heat Exchanger

This type of heat exchanger has the same direction of the flow for the fluids. As can be seen in the figure below, the inlets are in one head, and the outlets are on the other side. Fluids have the heat transfer along the surface from inlets to the outlets, and temperatures get close to each other.

Counter Flow Heat Exchanger

In this type of exchanger, we have opposite directions of flows for the fluids. The inlet of the hot fluid is at the same side as the outlet of the cold fluid, and the outlet of the hot fluid has the same positioning as the inlet of the cold fluid. In this type, the outlet temperature of the cold fluid can reach a higher amount than the outlet of the hot fluid.

Cross Flow Heat Exchanger

In a cross flow heat exchanger, we have a 90 angle in the intersection of fluids direction. This type can include many channels and tubes, which a flow with a 90 angle pass over them.

What are Cross Flow Exchangers

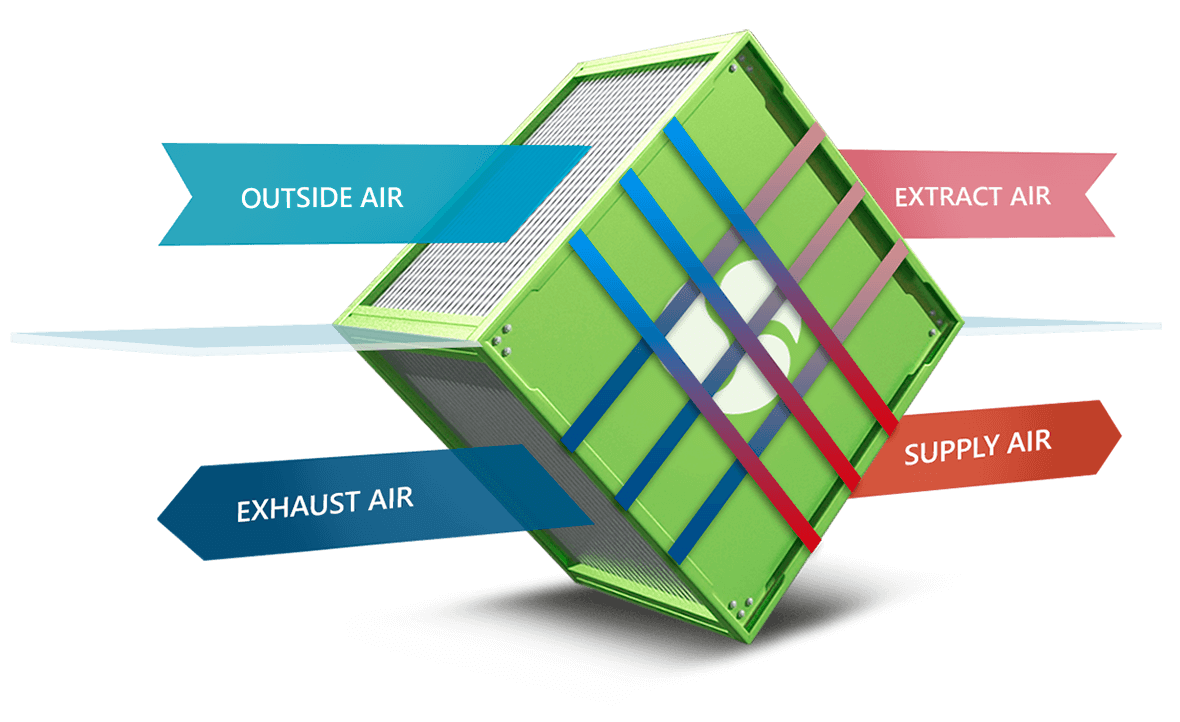

We have a perpendicular direction of flows in cross flow exchangers. An example of the cross flow is the shell and tube exchanger, in that one fluid flows in the tube side, and the other fluid passes around the tubes in the shell side. The flow around the tubes has a flow direction of 90 degrees compared to the flow in the tubes.

Cross flow exchangers, same as shell and tube, are usually used in the two-phase systems. An example of the application is a condenser in steam systems, in which steam passes over the tubes in the shell side and changes phase to the liquid water. Cold water passes through the tubes and absorbs the heat from steam. A large amount of steam condenses using this exchanger.

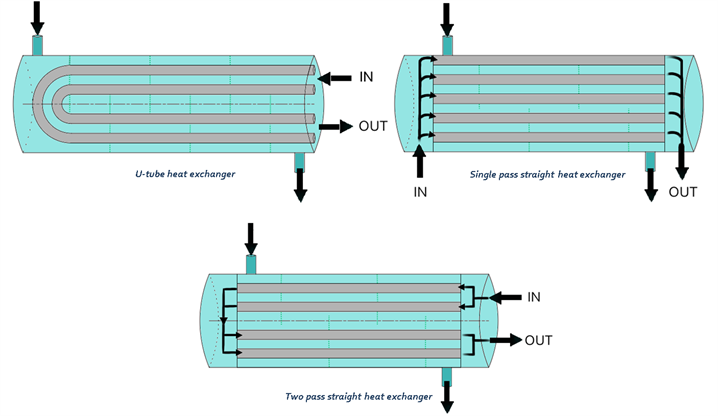

In the shell and tube heat exchanger, we can find all the parallel, counter flow, and cross flow. Types of the shell and tube illustrated in the following figure, we can see that the direction of the fluid includes cross flow types, while we use baffles inside the exchanger.

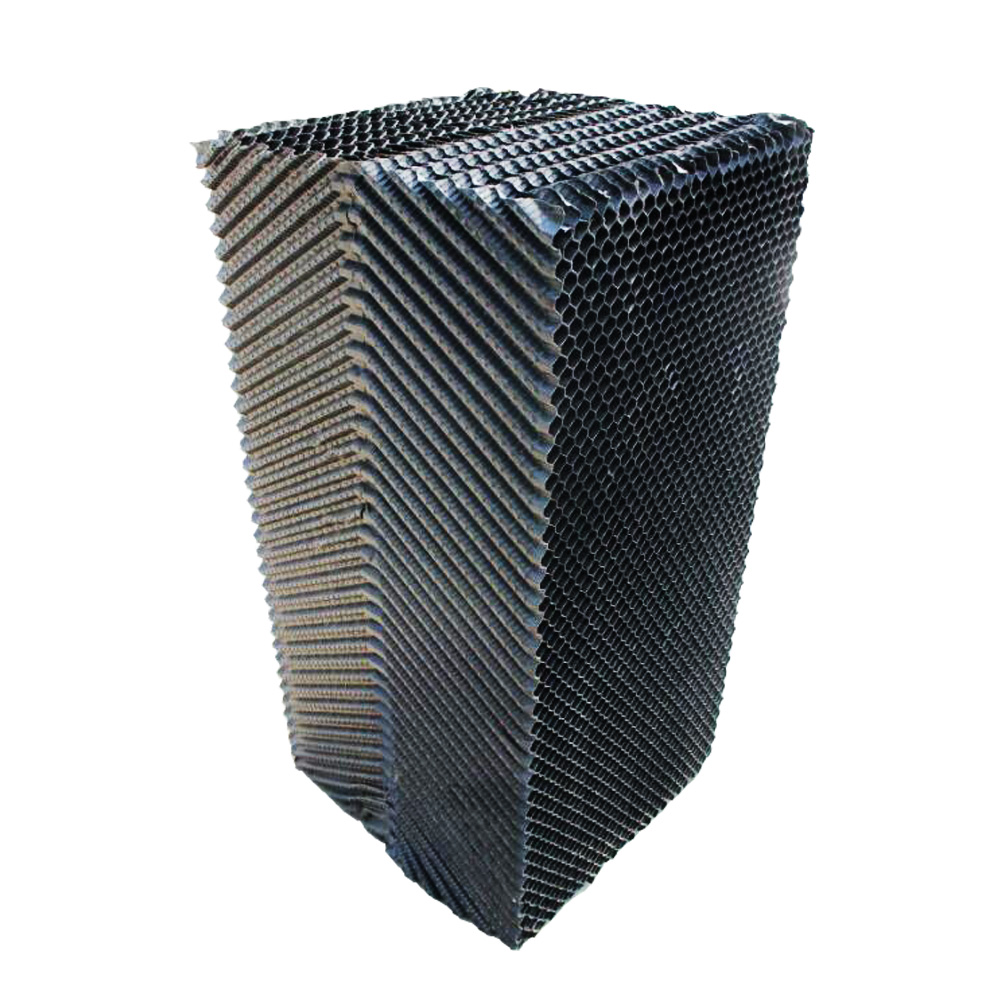

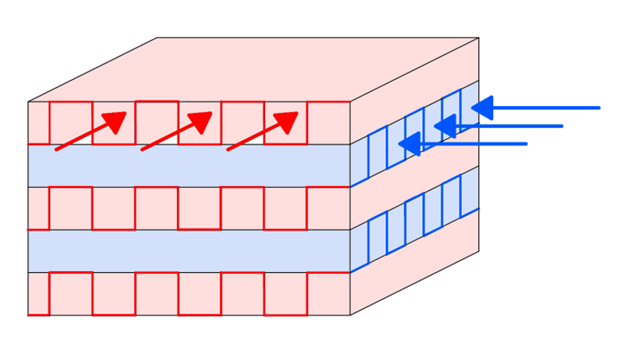

Another example for the cross flow heat exchanger is the plate-fin heat exchanger, and it is shown in the figure below. In the plate-fin heat exchangers, there are fins inserted between parallel plates, and the fluids flow through fins. Using these fins helps us to increase the heat transfer area. There are different shapes of fins, such as rectangular, triangular, wavy, or perforated.

Types of Cross Flow Heat Exchangers

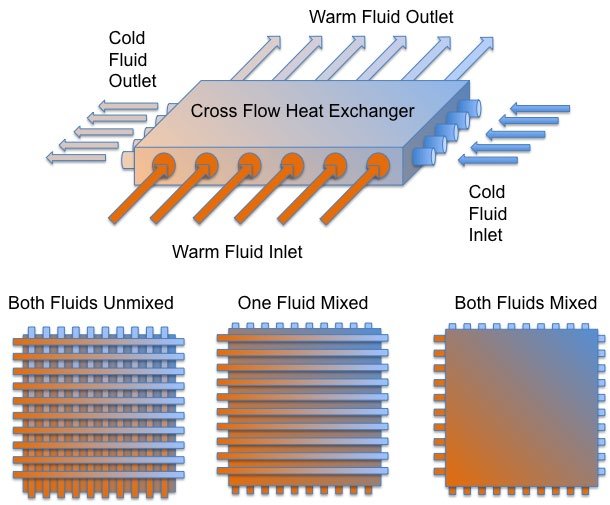

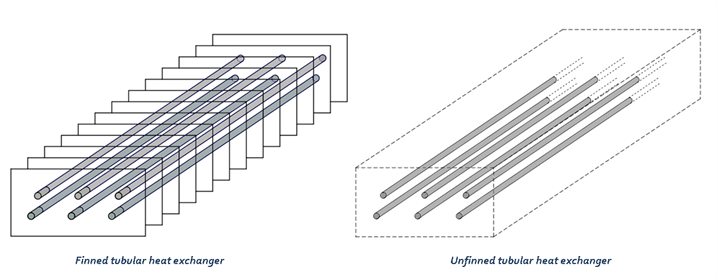

Cross flow heat exchangers are used in many different applications. Mixed and unmixed cross flow exchangers can be named as the types of cross flow heat exchangers based on the fins used in the system. The other names for them are finned and unfinned. The figure below shows these types.

Mixed Cross Flow Heat Exchangers

In this type, the fluid passes over the pipes in the shell side, and the flow is perpendicular to the pipes. The heat exchanger does not have any fins, as is shown in the figure. We can have turbulent flow in this type, and the pressure drop is less than the other one. Turbulent flow can significantly increase the heat transfer rate.

Unmixed Cross Flow Heat Exchangers

In the unmixed cross flow heat exchangers, we have fins around the pipes or separate channels for the flow to pass over the pipes. Using fins can increase the heat transfer due to the increase in the effective surface area of heat transfer. On the contrary, we have a larger pressure drop in the system. Also, the weight and the cost of these types increase because of adding fins to the exchanger.

Cross Flow Performance

The performance of the heat exchangers can be calculated using Logarithm Mean Temperature Difference (LMTD), and by increasing it, we can reach higher performances. These equations are the same for parallel, counter flow, and cross flow heat exchangers. Performance Equations for the exchangers are:

Q=UA \Delta T_{LM}

in which,

\Delta T_{LM}=\frac{\Delta T_{A}-\Delta T_{B}}{Ln(\frac{\Delta T_{A}}{\Delta T_{B}})}

and:

Q= heat transfer rate [BTU/hr]

U= Average thermal transmittance from one fluid to the other one [BTU/ft2-hr-F]

A= Heat transfer area in the exchanger [ft2] \Delta T_{LM} = Logarithm mean temperature difference between fluids. [F]

Advantages and Disadvantages of Cross Flow Heat Exchangers

In cross flow exchangers, the hot and cold fluids move perpendicular to each other. This is often a convenient way to physically locate the inlet and outlet ports in a small package, and moreover, this is an efficient design compared to the parallel heat exchanger.

Thermodynamically, the effectiveness of a cross flow heat exchanger is better than counter flow and parallel flow heat exchangers. Logarithmic mean temperature difference (LMTD) will always be greater for cross flow compared to a parallel flow heat exchanger. For a given flow rate and at the given inlet and outlet temperatures, a parallel flow heat exchanger requires maximum flow area, whereas a cross flow, heat exchanger, requires minimum flow area, and a counter flow heat exchanger area lies between two extreme limits.

For this reason, a parallel flow heat exchanger not commonly used in practice, and cross flow arrangement is preferred. Therefore cross flow arrangement is the most prevalent used exchanger because it is easier to provide inlet and outlet header connections with the cross flow rather than counter flow. A cross flow heat exchanger provides a compact design heat exchanger. Multi-pass cross flow heat exchangers can be simply manufactured compared to parallel and counter flow heat exchangers.

Download Cross Flow Heat Exchanger PDF

You can easily download this article as a PDF file so you can refer back to it whenever you want.

Read More In Linquip

- What is Scraped Surface Heat Exchanger? Find it Where it is used

- A Quick Guide to the Crossflow Cooling Tower

- Crossflow vs Counterflow Cooling Towers: Which to Use Where

- What is u-tube heat exchanger? An undeniable advantageous system

- Types of Heat Exchangers: An Introduction to All Essential about Specifications

- How to Calculate the Efficiency of Heat Exchangers?

- Heat Exchanger Design: How Is a Heat Exchanger Designed?

- What is u-tube heat exchanger? An undeniable advantageous system

- Working Principle of Plate Heat Exchanger

- Types of Shell and Tube Heat Exchanger

- What are Counter Flow Heat Exchangers and its Working Principles?

- The Complete Guide To Air Source Heat Pumps Disadvantages

- What are Double Pipe Heat Exchangers and Their Working Principles?

- Heat Exchanger Parts: Description of Configuration

- Advanced Guide: What Is Tube In Tube Heat Exchangers

- What is Plate Heat Exchanger?

- What is Scraped Surface Heat Exchanger? Find it Where it is used

- Types of Plate Heat Exchanger: Different Types with Wide Use

- Heat Exchanger vs. Chiller: Which One is the Best for You?

- Difference Between Heat Exchanger and Condenser: A thorough guide 2022

- Demystifying Heat Exchanger Sizing: A Comprehensive Guide