The crossflow cooling tower belongs to the family of mechanical drift cooling towers in which the upward flow of the air cools down the hot water raining down from the hot water basin at the top onto the cold water water basin at the bottom.

A fan is located on the roof of the device in order to induce airflow through the louvers and fills to be perpendicularly intercepted by the hot water rain drops. The drift leaves the tower at the top.

The crossflow cooling tower can operate with very much lower-than-design levels of flow, as little as 30%. Since the only mechanism pulling down the water through the nozzles is gravity, these towers can provide even water distribution across the fill.

Linquip is a proud supplier of cooling tower products, making possible a convenient interaction between the customers and manufacturers. To read more about the cooling parts and their function visit our post here.

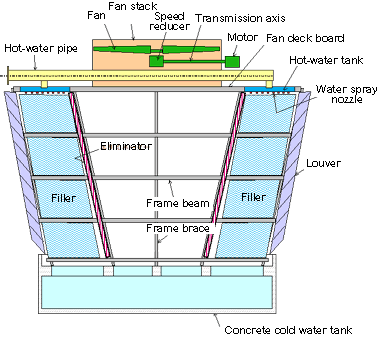

Crossflow Cooling Tower Diagram and Design

As can be seen in the diagram below, the water runs down the fills due to gravity in a vertical manner while the air comes in contact with it in a horizontal manner getting the name “crossflow”. It is clear that this design eliminates the need for the air to pass through the water distribution system which is the reason that there is no other mechanism necessary for the water to cascade down the cooling tower except for gravity.

In order for the water fall on the fill media to be evenly distributed, the use of a hot water basin is a standard practice for designing the crossflow cooling tower.

Working Principle

The working principle of the crossflow cooling tower is no different than what is generally true regarding cooling towers: Increasing the water surface area as it flows through the fills and water cool down via convective heat transfer to the passing air.

Crossflow Cooling Tower Parts

- Hot water basin : A container for widespread accumulation of hot water to be evenly passed into the nozzles.

- Spray nozzles : When water fills the surface of the hot water basin, it then drains down the holes spread throughout the basin’s surface into the spray nozzles.

- Fill : Panels onto which the water is sprayed and cascaded to increase its surface area and be interacted by the cooling air sucked into the tower through the fill.

- Cold water basin : The container placed at the bottom of the tower to accumulate the water cooled down through the fill media.

- Fan : A Device placed at the top of the crossflow cooling tower to induce airflow across the fills.

- Air inlet louvers : Air passages into the tower that keep outside bodies such as birds from entering the tower and prevent splashing out the cooling tower water.

- Drift Eliminator : Panels made from materials similar to that of fills in order to prevent water droplets entrained in the air stream (drift) to leave the tower, and therefore, prevent process water loss.

- Float : A Device that regulates the process water level lost due to drift.

- Makeup water inlet : Where the amount of water needed for maintaining proper process water levels in the basin enters it.

- Water outlet : The exit port for cooled down process water.

- Overflow : A Means of releasing extra levels of water in the basin.

- Drain : A Component for controlling the amount of mineral content in the basin accumulated during the operation cycles.

Crossflow Cooling Tower Advantages

The design of crossflow cooling towers, as might have been inferred from the diagrams, allows for a large plenum area. This means that an access door could be arranged for ease of inspection. In addition, the space inside these towers makes it possible for easy access to mechanical components inside the cooling tower.

Since the water flows down the fills by only enjoying the downward force of gravity, the operation would be possible for both low and high flows of hot water. This design has also made good operation in cold climates possible.

More on the Crossflow Cooling Tower

Click here for a detailed video of how the crossflow cooling towers work.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

- Cooling Tower Parts and Functions: A Concise 10,000-Foot yet Essential View

- Crossflow vs Counterflow Cooling Towers: Which to Use Where

- Types of cooling towers: an ultimate guide to knowing different types

- What is Cross Flow Heat Exchangers and its Working Principles?

- The Counterflow Cooling Tower: A Quick Intro

- Easy Guide to Cooling Tower Efficiency