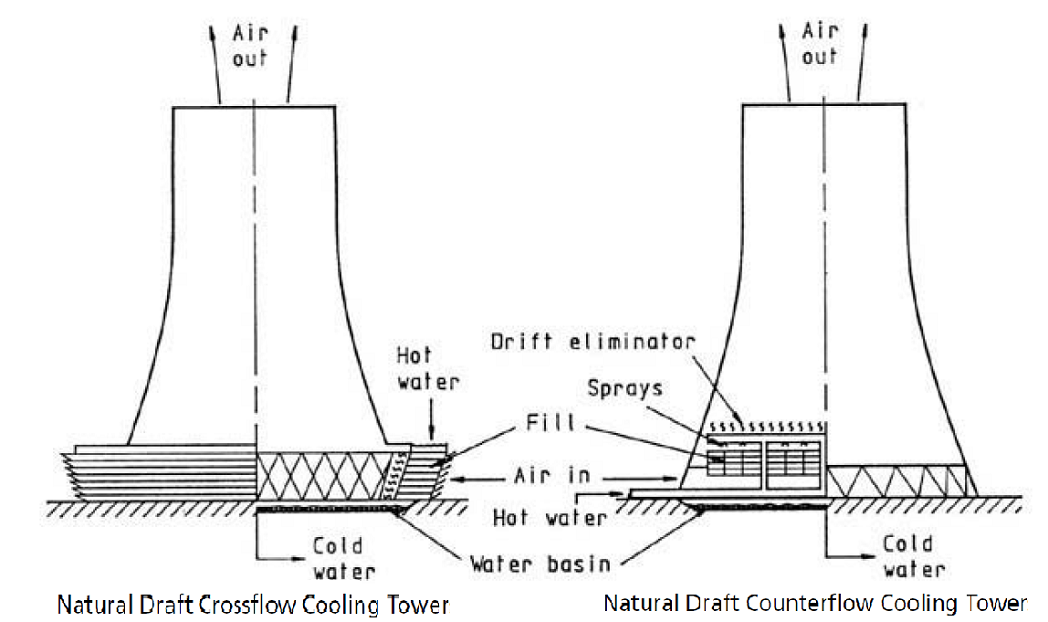

Comparing crossflow vs counterflow cooling towers is a common thing to do when choosing between cooling towers for a specific application. The most apparent distinction between crossflow towers and counterflow towers is that the airflow is perpendicularly contacted with the process water in the fill in crossflow while it comes into contact with the process water stream in the opposite direction for counterflow.

Linquip is a reliable supplier of cooling tower parts and products providing you with a variety of choices between different types and models to meet your needs and making possible a convenient interaction between the customers and manufacturers. To read more about the cooling parts and their function visit our post here.

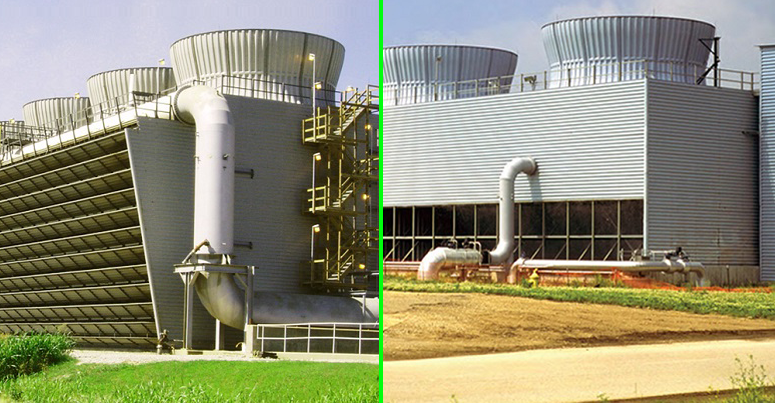

Crossflow Cooling Towers

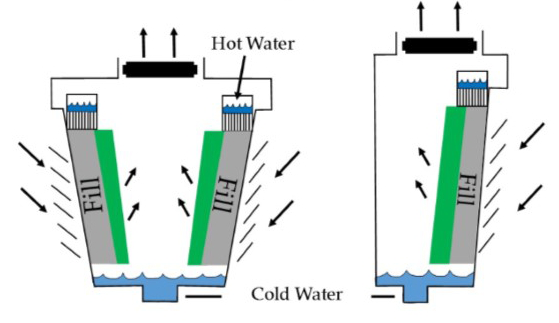

In order to compare crossflow vs counterflow cooling towers, we first turn our attention to the design of crossflow cooling towers. The arrangement of the fill in crossflow cooling towers is in a way that makes the hot process water vertically flow down the fill media due to the force of gravity while the air horizontally blows across the falling water cooling it down. This is the reason behind the naming convention for this design.

The important point about this design for crossflow cooling towers is that the water would require only gravity for flowing down the fill to reach the cold water basin due to the fact that no force is against its flow direction. In order for the water to be evenly distributed, hot water basins are placed above the fills, surface of which are covered by the hot water entering crossflow cooling towers.

Counterflow Cooling Towers

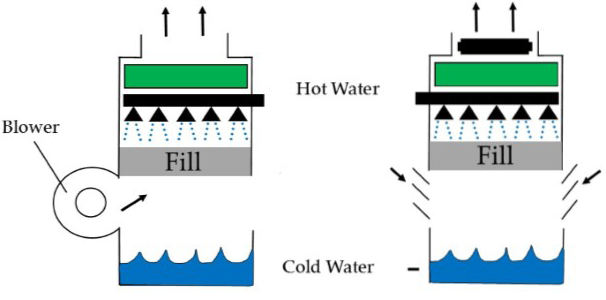

To continue comparing crossflow vs counterflow cooling towers, we may now know about the design of counterflow cooling towers. The hot process water is sprayed down on the fill media to vertically flow down and drain onto the cold water basin. Now, the air enters the tower in a lower section and flows upwards to pass through the water flowing the fill and cool it down.

The design here dictates that the water brought to the nozzles should be pressurized due to the fact that air flows opposite to the water, and to prevent a back-flow of the water into the nozzles, an extra downward force shall be provided. In order not to restrict any airflow in the tower, the set of pressurized pipes and nozzles are placed farther apart for counterflow cooling towers compared to the nozzles of crossflow towers.

Crossflow vs Counterflow Cooling Towers: What are the Differences?

When comparing crossflow vs counterflow cooling towers, some difference of performance and design stand out, which help find the best solution for your requirements. As was stated earlier, the most basic difference between the two is that the water flows at 90° to the airflow path for crossflow cooling towers, while it flows at 180° to the airflow path for counterflow cooling towers.

To be able to better compare crossflow vs counterflow cooling towers, let us see how they differ from each other with respect to various factors:

Foot print and height: Counterflow cooling towers generally require less ground space due to their higher profiles compared to crossflow cooling towers for the same capacity. On the other hand, the height of a crossflow cooling tower could be lower due to the vertical configuration of the fill. Space and height limitations could play a role when choosing between crossflow vs counterflow cooling towers.

Maintenance: crossflow cooling towers are easier to maintain as there is a possibility to have access into the plenum and conduct any repair for the internal equipment. Moreover, the nozzles located in the distribution basin are accessible at anytime.

Due to the configuration of crossflow cooling towers, one can easily enter the mid-plenum, even during the operation, and inspect the drift eliminators and mechanical equipment from below. Additionally, the nozzles can be reached, inspected, cleaned or even replaced if needed for the crossflow configuration of the cooling towers.

In case of counterflow cooling towers, accessing the sprayer nozzles is difficult and could only be done when the tower is not in operation so that one could go inside it. Checking the mechanical equipment and other parts such as drift eliminators for this configuration of cooling towers could only be possible when they are not in operation.

Climate conditions: Freezing of the water in the fills is a phenomenon that is highly detrimental to the performance and health of the system. The crossflow cooling towers are more suitable for cold climates due to the fact that the hydraulic load on those parts of the fill away from the fan become higher, which decreases the risk of water freezing in the fills. It means that the tower’s operation could also be more precisely anticipated for cold climates.

Algae growth: In the case of crossflow cooling towers, there is a part of plenum of the tower located beneath the fan, that receives sunlight (heating up inside the tower). It means that this moist environment paves the way for algae growth inside the tower, requiring an extra effort of chemical treatment inside the tower. Counterflow cooling towers, on the other hand, do not suffer from such problem making them a better solution for hot climates.

Noise emissions: The fall of water droplets on the surface of cold water basin in counterflow cooling towers emits noise. The level of noise can be reduced by means of installation of sound attenuators; however, crossflow cooling towers inherently produce quite lower levels of noise due to fact that the bottom surface of the fill is almost in contact with the surface of the cold water basin.

Process water output: Since crossflow cooling towers only use the gravitational force to move the water down the fill, it gives some sort of operational flexibility to the system: one could easily change the nozzles’ orifices to increase or decrease the process water output from the tower as per demand. In contrast, counterflow cooling towers do not provide such convenience for adjusting the flow through the nozzles as the access to the sprayer nozzles and sleeves is difficult.

Process water supply pressure: Due to the design of counterflow cooling towers, a pump is needed to pressurize the water supplied to the spray nozzles to account for the counter flow path of the water and the air. This means that crossflow cooling towers are slightly more efficient in terms of electrical power consumption.

Which one should you choose?

The most important point about crossflow cooling towers when comparing crossflow vs counterflow cooling towers is that they perform better in hot climates, and wherein low noise levels are required. On the other hand, while comparing crossflow vs counterflow cooling towers, counterflow cooling towers appear to have more acceptable configurations for applications where there is space limitation.

In general, the choice of crossflow vs counterflow cooling towers completely depends on the application and the characteristics of the intended site. We could help you identify the best solution for your requirements.

More on the the differences

To see a video comparing the crossflow vs. counterflow cooling towers click here.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip