Welcome to Linquip Blog. Today and in this article, we are going to deal with DC Motors vs. Servo Motors. The information in this article gives a significant collection of data you need to know about Differences between these two frequently used motors.

From security cameras and fans to DVD players and right down to the vibration in your phone, motors are practically all around us. With so many variables to consider, it is hardly surprising that many find it difficult to choose the right motor for their application and miss out on certain important parameters in the process. As such, we have put together a guide to help you with the selection process, so that you may pick the best motor for your application.

Our team gathered all of the necessary information on this topic to eliminate the need for reading diverse content on other websites. Stay with us until the end to find the answer to your question on this topic. We have a long journey ahead of us, so take a deep breath, sit back, and keep reading this article until the end.

To know what are the differences between DC Motors and Servo Motors, we should know what the reason behind the constructing each of these motors is, how they work and what they are useful for.

Therefore, in separate sections, we will deal with each of these cases separately.

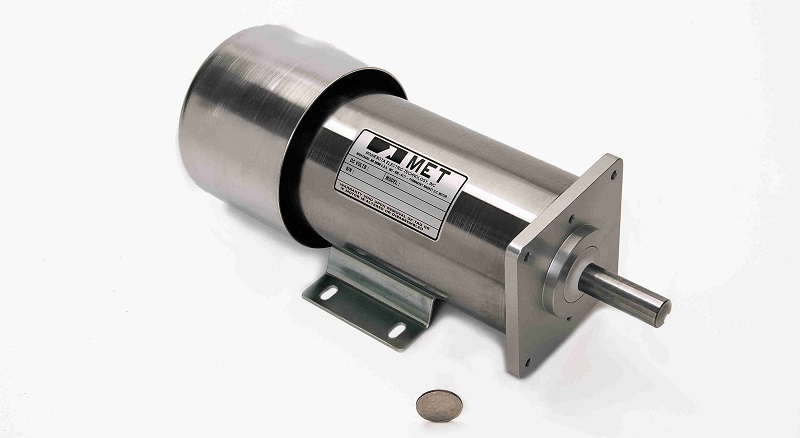

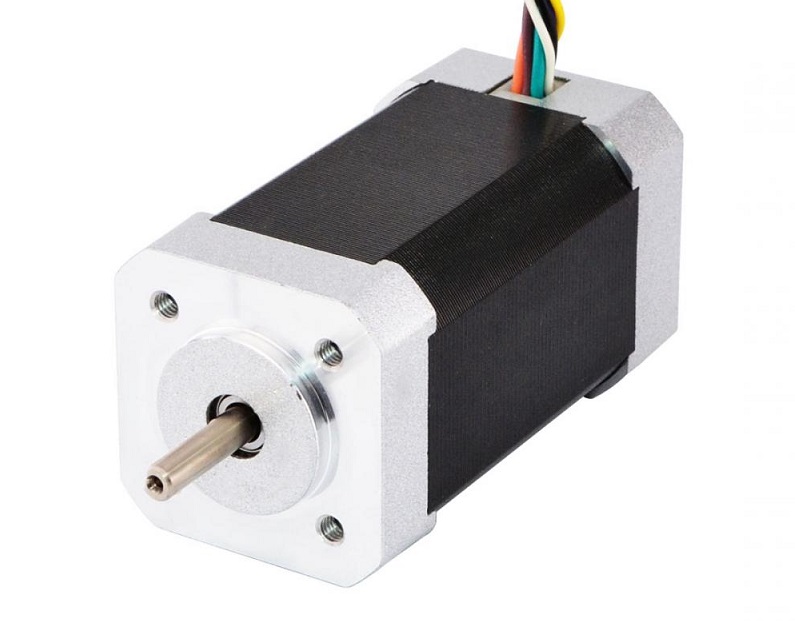

What Is a DC Motor?

DC (Direct Current) motors are two wire (power and ground), continuous rotation motors. When these wires are connected to power supplies, a DC motor starts to spin until that power is removed. Most DC motors run at a high RPM (revolutions per minute). DC motors could be used for computer cooling fans, radio-controlled cars or other automotive applications.

Mostly, speed of DC motors is controlled using pulse width modulation (PWM). Using this technique, we are rapidly pulsing the power on and off. The percentage of time spent cycling the on/off ratio determines the speed of the motor. For example, if the power is cycled at 50% (half on and half off), then the motor will spin at half the speed of your maximum speed (fully on). Each pulse is so rapid that the motor appears to be continuously spinning with no stuttering.

But how does a DC motor move? A DC motor only has one moving component – the rotor, which eliminates the complications caused by brushes in brushed motors. And also, unlike brushed motors, the rotor consists of a ring of permanent magnets, whereas the coils are stationary. This set-up eliminates the need for brushes.

The difficult part comes in controlling the polarity of the current flowing through the coils and keeping this in sync with the speed of the rotor. This can be achieved by measuring back EMF or using Hall effect sensors to directly measure the position of the magnets.

Due to this, brushless DC motors are typically more expensive and complex, in spite of the numerous advantages it has over brushed DC motors.

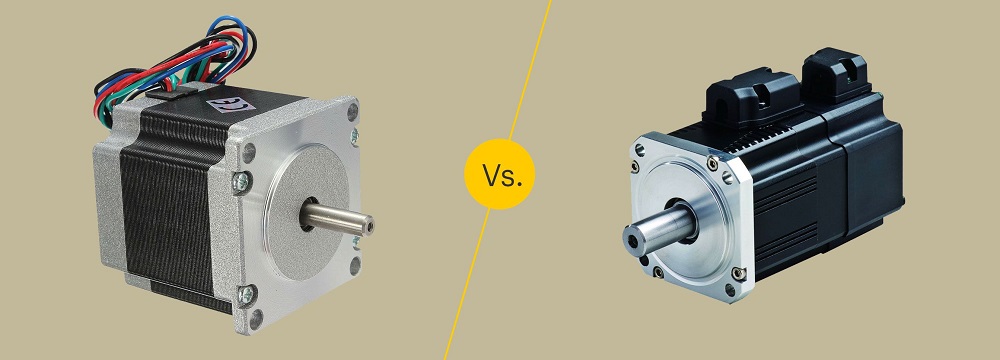

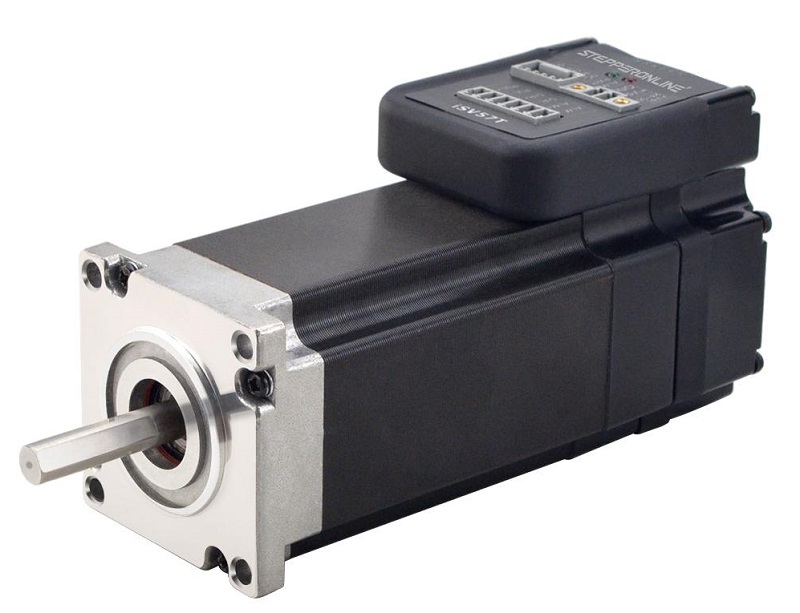

What Is a Servo Motor?

We can talk about servo motors as an assembly of four things: a DC motor, a gearing set, a control circuit and a position-sensor (usually a potentiometer).

In industry servo motors are known as motors that can be controlled most precisely. Comparing servo with standard DC motors, servos usually have three wires (power, ground and control). Power to servo motors is constantly applied. Servo controller regulates the current draw to drive the motor. These motors are designed for more specific tasks where position needs to be defined. Moreover, servo motors are used for accurate tasks, for example, to move robotic arm or robot leg within a certain range, move camera to certain object and etc.

Although we must mention that servo motors do not rotate freely like a standard DC motor unless it’s modified for continuous rotation, this type of motors do not have a limit on its range of motion and instead of having the input signal determine which position the servo should rotate to, the continuous rotation servo relates the input to the speed of the output and direction. However, for most of the servo motors the angle of rotation is limited to 180 degrees back and forth. Servo motor receives a control signal that represents an output position and applies power to the DC motor until the shaft turns to exact position, determined by the position sensor.

Unlike DC motors, to control servo motor PWM signal is used. The duration of the positive pulse that determines the position, rather than speed, of the servo shaft. A neutral pulse value dependent on the servo (usually around 1.5ms) keeps the servo shaft in the center position. Increasing that pulse value will make the servo turn clockwise, and a shorter pulse will turn the shaft anticlockwise. Servo control pulse is usually repeated every 20 milliseconds (depends from servo motor). We always must tell the servo where to go, even if that means remaining in the same position.

When a servo receives command to move, it will move to the position and will try to keep that position, even if external force pushes against it.

A Brief Comparison between DC Motors & Servo Motors

Servo motors are highly controllable. They were built with precision and accuracy in mind, and provide users with essentially infinite resolution on what the output angle can be. DC motors, while far less complex than servo motors are also easy to control; reverse the leads to change directions, and change the voltage to change the speed. These motors are both easily controllable, but their gap in complexity changes the resolution of control.

The torque or speed range of DC motors is increased by just how many types of DC motors exist. There is a good chance that, given a certain speed and torque need, a DC motor has been developed to fit the bill. However, servo motors combine this dynamic speed/torque range with the ability to modulate them at will. Their electronic feedback allows operators to set the desired speed and power, and the servo motor will comply. So, while there is a wider range of DC motors with differing torques/speeds on the market, the average servo motor can cover more of this range per unit.

The reliability of both of these motors comes down to failure rate and maintenance. When the brushes of DC motors are continuously serviced and used responsibly, they can last for long durations without losing their working characteristics. Though, even if they do break, their low cost allows buyers to simply replace the broken motor. Servo motors are not as disposable but are also more reliable per unit. It is important to note that when servo motors do break, the maintenance process is much more arduous. Since error-correction is paramount, the system must be adjusted for accuracy when a new component is added, which is time-consuming and often requires expert technicians to reconfigure the system.

The efficiency of DC motors suffers from heat loss from the brush contacts, but newer models are often rated with efficiencies up to 85% which is an impressive number. The servo motor will naturally beat the DC motor in terms of efficiency, as the precision electronics regulate the current and minimize losses. Even when a servo motor is not in use, it still pulls a current because of its feedback encoders, which means servo motors must always be powered to some capacity. This is usually not a problem, but servo motors will be harder to use if regular power-shutdown is needed.

DC motors win when it comes to sustained output. They are largely unaffected by running for extended periods of time (with maintenance) and can provide good torque during this duration. Servo motors are best used in intermittent applications, where the motor does not spin continuously for very long, as operators want to minimize the chances of failure. Servo motors can also only provide their peak torque for a small percentage of the operating time or they will be damaged, so they are best used as positioning motors and not for sustained rotation or spinning.

The cost of the common DC motor is its best chance to compete against this highly accurate contender. Not only are they cheaper per unit, but DC motors do not need the additional controllers, amplifiers, and sensors to function well. Servo motors and their accessories are more expensive to buy, install, maintain, and replace, making them a risky choice if long terms costs are of concern. While they provide excellent torque, speed, and position control, servo motors and their price tags might scare some buyers away depending on overall project cost targets.

Conclusion

The present article was an attempt to deal with DC Motors vs. Servo Motors and deliver all the essential information about how they are constructed and controlled, what their applications are, how their components cooperate with each other to do the jobs how much it cost to have each of these two amazing motors.

If you have any experience of using any of these two types of motors, we will be very glad to have your opinions about their performance in the comments on our website Linquip. Moreover, if you have any questions about this topic, you can sign up on our website and wait for our experts to answer your questions. Hope you enjoyed reading this article.

AC motor price

Thanks for visiting our website. You can visit our Industrial Equipment page, where you can find various AC Motors based on your application and demand. You can also visit our expert page and take advice from hundreds of professionals on your issue.

DC motor price

Thanks for visiting our website. You can visit our Industrial Equipment page, where you can find various DC Motors based on your application and demand. You can also visit our expert page and take advice from hundreds of professionals on your issue.