The major difference between petrol and diesel engine is their fuel combustion sequence. Diesel and petrol engines at first glance seem quite similar. The engines use chemical energy in the fuel to produce mechanical energy. However, a petrol engine is operated via the Otto cycle, while a diesel engine is operated via the Diesel cycle. Furthermore, these engines differ in terms of their structural components, types, and uses. One of the main characteristics used to classify them is their fuel type. The theory of heat transfer underlies the functioning of engines.

Basics of Petrol and Diesel Engine

Vehicles such as trucks, cars, and buses run on fossil fuels. Researchers have developed a variety of engines, and they can be found on the market. Petrol engines and diesel engines are the two most common types of engines. The majority of vehicles are powered by either petrol or diesel engines.

Diesel and petrol are both made from mineral oil, but the precise refinement methods differ. It is easier to refine diesel than gasoline, but diesel has more pollutants in it that must be extracted before it can produce the same amount of emissions as petrol. Diesel fuel contains more energy per liter than petrol, and the combustion process of the vehicle’s engine is more efficient, contributing to better fuel efficiency and fewer CO2 emissions.

Petrol Engine vs. Diesel Engine in Terms of Working Principle

In this section, petrol and diesel engines will be compared in terms of their internal structures and their operational stages.

Petrol Engine

Petrol engines have a wide range of applications, including cars, scooters, machines, etc. It is a spark-ignited internal combustion engine. Petrol engines are also known as petrol engines. The first petrol engine was invented in Europe in 1876. It was a petrol engine with very basic features. Many improvisations have been made since then and the present model is the most recent.

Fuel and air are mixed before compression in petrol engines, and an electric spark is used to ignite them. A carburetor previously handled the pre-mixing process, but now it involves an electronic fuel injection system, except for small engines where the cost and complexity of the electronics do not warrant additional engine efficiency. A diesel engine only compresses (and therefore heats) air and injects fuel into very hot air at the end of the compression stroke, which self-ignites.

The temperature of ignition is the lowest temperature at which a substance or fuel will ignite when heated. Petrol engines work based on the Otto cycle. In gasoline engines, the Otto cycle describes how chemical energy is converted into thermal energy, which then generates motion.

Compressing the mixture too much in a closed cylinder can result in an auto-ignition – or behave like a compression-ignition engine. Because petrol burns at a different rate from diesel, the timing of petrol engines is designed mechanically differently compared to diesel engines.

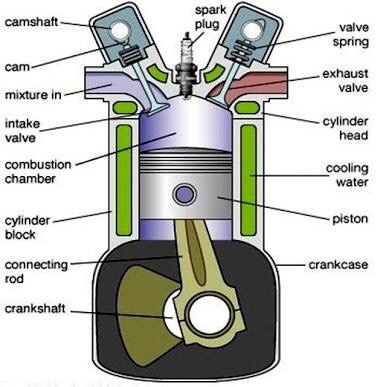

The following figure illustrates the internal structure of petrol engines.

A petrol engine works in the following sequential manner, as shown in the above schematic figure:

Intake

Air and fuel (petrol) are mixed in the cylinder.

Compression

Through crankshaft compression, petrol and air are compressed together.

Power

Spark is used to ignite the mixture, and the mixture forces the piston downward.

Exhaust

Gases are expelled from the exhaust valve.

Diesel Engine

Diesel engines are typically found in trucks and other heavy vehicles. The Diesel engine was developed in Germany by Rudolf Diesel in 1893. At that time, trains were mainly powered by diesel engines. This is also an internal combustion engine that runs on diesel energy.

In these engines, the air is compressed to a very high pressure, which causes it to become very hot, and then fuel (diesel) is injected into it. Due to the heat of compressed air, diesel reaches its ignition temperature. Diesel engines are also called compression ignition engines (CI engines). It is in contrast to engines that ignite the air-fuel mixture with spark plugs, such as petrol engines (gasoline engines) or gas engines, which use a gaseous fuel (e.g. natural gas) or liquefied petroleum gas.

Just prior to combustion, when fuel is injected into the air, the dispersion is uneven; this is termed a heterogeneous air-fuel mixture. The torque generated by a diesel engine is regulated by adjusting the air-fuel ratio (λ). During the combustion process, the air-fuel ratio equals the mass ratio of air to gaseous, liquid, or solid fuel; rather than throttling the air intake, a diesel engine adjusts the amount of fuel injected, and the air-fuel ratio is often high.

It is possible to design a diesel engine with a two-stroke or four-stroke cycle. Originally, they were intended to be a more efficient alternative to stationary steam engines. Since the 1910s, Submarines and ships have used these sources of power. Following that, the technology was used in locomotives, trucks, heavy machinery, agricultural equipment, and power plants. A few automobiles began using them in the 1930s. In the US, diesel engines have increasingly been used in large on-road and off-road vehicles since the 1970s.

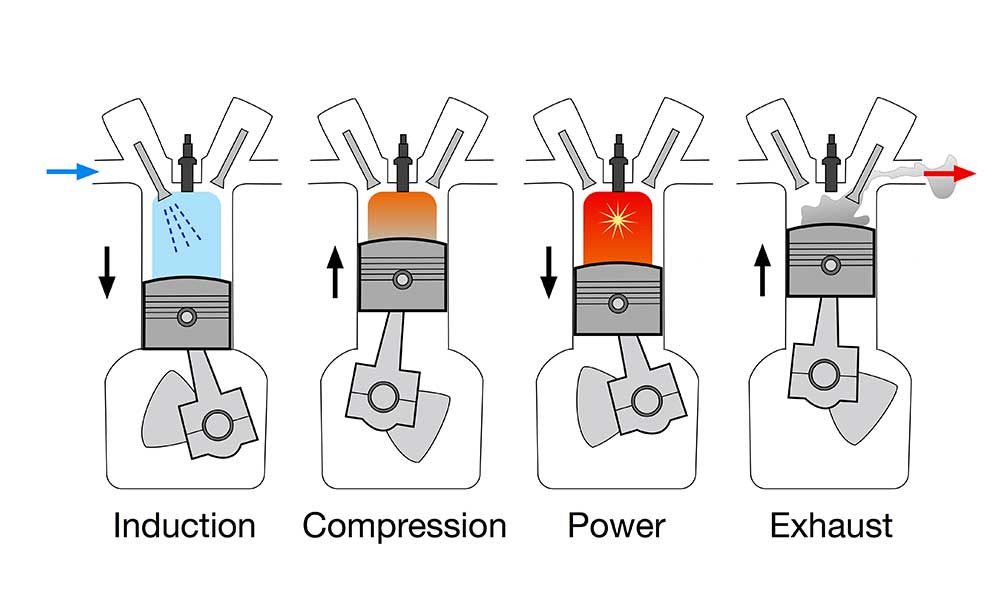

Induction

Air enters the engine’s cylinder when the piston goes down.

Compression

The piston goes up and compresses the air. The air is now getting hot.

Power

Fuel is now added to the cylinder.

Exhaust

The hot air provides the ignition temperature, causing fuel or diesel to burn. From the valve, smoke is emitted.

Petrol Engine vs. Diesel Engine in Terms of Working Cycles

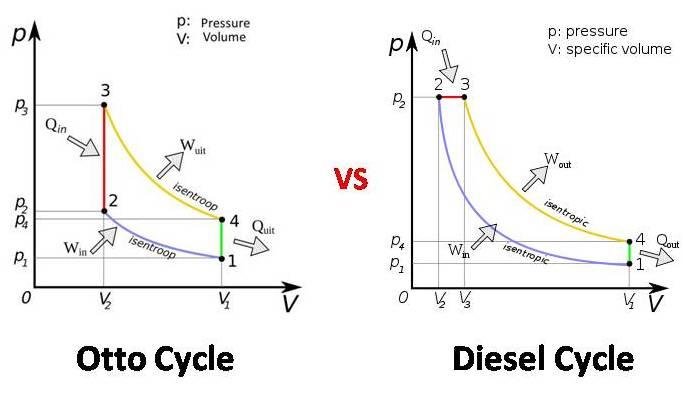

We will now discuss the difference between the Diesel cycle and the Otto cycle. Both of these cycles are air standard cycles for automobile engines. Diesel cycles are used for diesel engines, while Otto cycles are used for petrol engines.

It is critical to point out that there is a key difference between the Otto cycle and the Diesel cycle; in the Otto cycle, the heat is added at constant pressure, while in the Diesel cycle, the heat is added at constant volume.

Petrol Engine

Petrol engines work according to the Otto cycle, in which a carburetor is used to provide fuel to the combustion chamber. Nicolaus Otto introduced the Otto cycle in 1876. The Otto cycle ignites the mixture of air and fuel using spark plugs.

In the Otto cycle, four processes are involved: the intake stroke, the compression stroke, the expansion stroke, and the exhaust stroke. During the intake stroke, the cylinders pull in the charge. As the piston moves backward, adiabatic expansion takes place. It has a compression ratio between 7:1 and 10:1, which is lower than a diesel cycle. The heat addition in Otto cycles occurs at a constant volume. The piston in an Otto cycle is at the Top Dead Center (TDC) at the time of heat addition.

Diesel Engine

Dr. Rudolph Diesel proposed the diesel cycle in 1897. In the diesel cycle, the high compression ratio does not require a plug to ignite the engine, so there is no need for assistance to get the engine started. It has a relatively high compression ratio ranging from 11:1 to 22:1. Unlike gasoline engines, diesel engines work on the diesel cycle, which requires fuel injectors to supply fuel to the combustion chamber.

The diesel cycle consists of four processes: adiabatic compression, heat addition, adiabatic expansion, and heat rejection. Fuel is injected into the combustion chamber by an injector after air is drawn into it during the intake stroke. The heat is added under constant pressure. When the piston is retreating in the diesel cycle, at a portion of the piston stroke, heat is added. As soon as the heat addition is terminated in a diesel cycle, adiabatic expansion takes place.

Compared to an Otto cycle, this cycle has higher efficiency.

Petrol Engine vs. Diesel Engine in Terms of Fuels

Crude oil includes hundreds of different types of hydrocarbons mixed together, as well as varying levels of impurities depending on its source. Petrol, diesel, and other oil-based products need to be refined, which means that the hydrocarbons must be separated via refining processes.

Different hydrocarbon chains have different boiling points, so they can be separated by a process called fractional distillation. The distillation process involves heating crude oil in a distillation column, extracting hydrocarbon chains as vapors based on their vaporization temperatures then condensing those vapors.

Petrol Engine

The chemical composition of petrol is composed of alkanes and cycloalkanes, whose chain lengths range between five and twelve carbon atoms. Boiling occurs between 40°C and 205°C.

Diesel Engine

Diesel fuel is formed from alkanes with twelve or more carbon atoms. The boiling is between 250°C and 350°C.

Petrol Engine vs. Diesel Engine in Terms of Efficiency

Petrol engines generally have pistons with shorter strokes than diesel engines. Hence, a petrol engine’s piston usually completes its stroke in a shorter time than a diesel engine’s piston. However, petrol engines have lower efficiency than diesel engines due to their lower compression ratios. In general, petrol engines have thermal efficiencies of about 20%, nearly half that of diesel engines. Recent research reports that some newer engines are very efficient (thermal efficiency up to 38%) compared to previous spark-ignition engines.

Petrol Engine vs. Diesel Engine in Terms of Initial and Maintenance Costs

A diesel engine requires high initial and ongoing maintenance costs, while a petrol engine requires lower costs.

Petrol Engine vs. Diesel Engine in Terms of Fuel Consumption

Fuel consumption is lower for diesel engines than for petrol engines.

Petrol Engine vs. Diesel Engine in Terms of Applications

Generally, diesel engines are found in heavy vehicles like trucks and buses. In contrast, petrol engines are found in light vehicles such as motorcycles and cars.