The industrial world has advanced over the years with a wide range of measuring instruments suitable for industry and the laboratory. Although things used to be difficult to operate, today you can get fast and accurate measurement results. By using measuring tools you can save time, costs, prevent malfunctions and safety issues. They make our lives better and safer and improve quality and life expectancy. In this article, we will take a deeper look at the different type of Industrial measuring tools. Follow this new blog in Linquip to find out more.

Different Type of Industrial Measuring Tools

Here are some most commonly used measuring tools in industries.

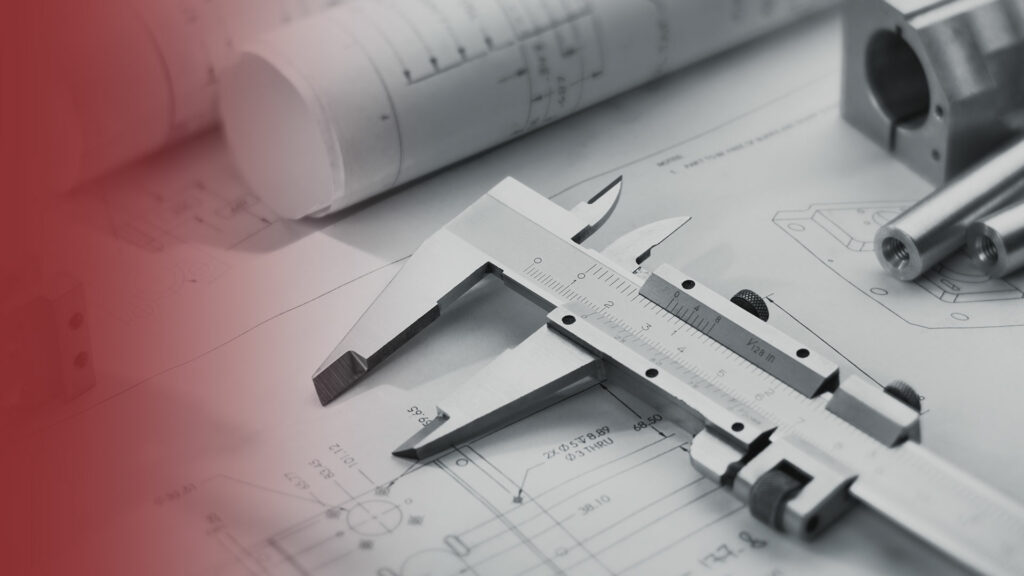

Caliper

Calipers are a common measuring tool that accurately measures the distance between two opposing sides of an object. A caliper will have two adjustable tips that can be pushed up against opposite sides of an object. When the caliper is removed from the object, the user can see from the affixed ruler which measurement was given between the two tips and would then know the object’s diameter.

The caliper has several types which are described below.

Vernier Caliper

Vernier Caliper is a widely used linear measurement instrument with the least count of 0.02 mm. It is used to measure linear dimensions like length, diameter and depth.

Inside Caliper

The inside caliper is used to measure the internal size of an object. It consists of two legs that are not inverted to each other and are connected using a screw and nut mechanism.

Outside Caliper

The Outside caliper is used to measure the external size or outer size of an object. It consists of two legs that are inverted to each other and are connected through a screw and nut mechanism.

Odd-Leg Caliper

Odd-Leg calipers, Hermaphrodite calipers, or Oddleg Jennys are generally used to scribe a line at a set distance from the edge of a workpiece. The bent leg is used to run along the workpiece edge while the scriber makes its mark at a predetermined distance, this ensures a line parallel to the edge.

Divider Caliper

In the metalworking field, a divider caliper, popularly called a compass, is used in the process of marking out locations. The points are sharpened so that they act as scribers; one leg can then be placed in the dimple created by a center or prick punch and the other leg pivoted so that it scribes a line on the workpiece’s surface, thus forming an arc or circle.

Dial Caliper

The dial caliper reads the final fraction of a millimeter or inch on a simple dial. In this instrument, a small, precise rack and pinion drive a pointer on a circular dial, allowing direct reading without the need to read a vernier scale. Typically, the pointer rotates once every inch, tenth of an inch, or 1 millimeter. This measurement must be added to the coarse whole inches or centimeters read from the slide.

Digital Caliper

A popular refinement replaces the analog dial with an electronic display that shows the reading as a numeric value. Rather than a rack and pinion, these calipers use a linear encoder. Most digital calipers can be switched between centimeters or millimeters, and inches. All provide for zeroing the display at any point along with the slide, allowing the same sort of differential measurements as with the dial caliper. Digital calipers may contain a “reading hold” feature, allowing the reading of dimensions after use in awkward locations where the display cannot be seen.

Micrometer

This is a measuring device commonly used in mechanical engineering. It works similarly to a caliper but can measure the length, depth, and thickness of an object. Like a caliper, the object to be measured is placed between two ends, but this is then measured not by a ruler, but by a calibrated screw. The spindle of the micrometer is moved until the object sits flush between the spindle and anvil, and then the measurement can be read.

Micrometers are available in two types: Inside micrometer (to measure inside diameter) and Outside micrometer (for measuring outside diameter).

Height Gauge

A height gauge is another type of industrial measuring tools used for determining the height of objects, and for marking items to be worked on. These measuring tools are used to either set or measure vertical distances; the pointer is sharpened to allow it to act as a scriber and assist in marking out workpieces.

Height gauges have several types that are mentioned below.

Digital Height Gauge

Digital height gauges allow for direct reading of the height or even setting zero locations at places other than the reference surface plate. They can be easier to read as the measurement is displayed and also, by pressing the inch/mm button, the distance can be read as metric or imperial.

Dial Height Gauge

Digital height gauges use a dial indicator to set the measurement height. These units feature a mechanical dial with a needle pointer that allows for easy reading.

Vernier Height Gauge

Vernier height gauge is used to measure vertical dimension from reference ground. Vernier Height Gauge consists of a graduated scale or bar that is held in a vertical position by a finely ground fixed base.

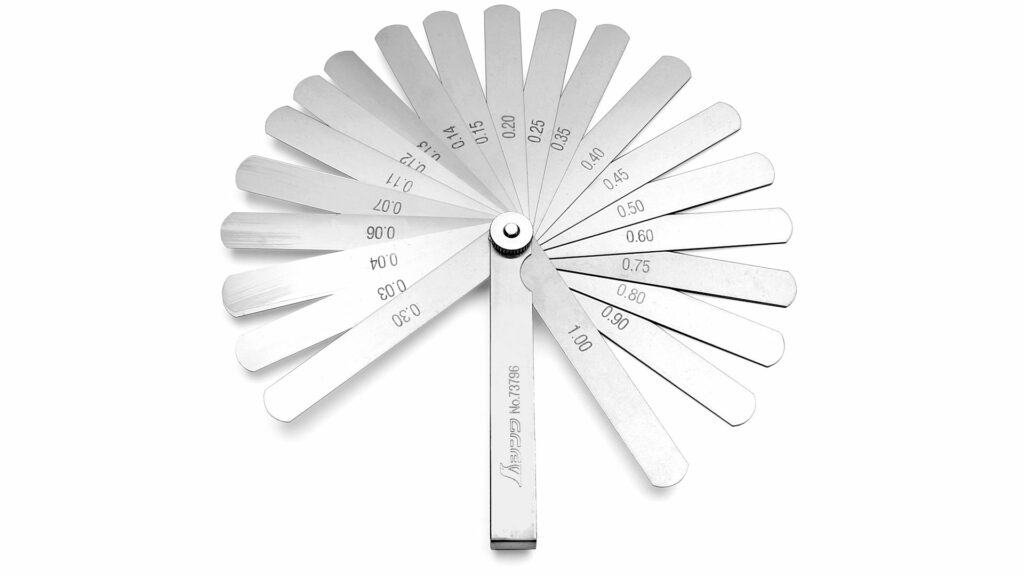

Feeler Gauge

It is also known as a thickness gauge. Feeler gauges are often used to measure the clearance between the components. These gauges are excellent for the measurement of narrow slots, measuring clearance, determining small spacing, and determining the fit between mating parts.

Pressure Gauge

Pressure gauges are common measuring tools used to measure the pressure of liquids and gases, such as water, air, or oil. They are important tools in industrial and commercial environments, where they help maintain the safety of a plant. They are also useful tools to use when pumping up bicycle tires or checking on the air pressure of the tires on your vehicle.

Angle Gauge

This tool is predominantly used by foresters to help with forest inventory. They are held at a set distance from the user’s eye to quickly establish whether a tree is within the boundary of a plot. The distance is usually determined by a string or chain held by the surveyor. Angle gauges can also be used in other professions where it is necessary to measure angles. They are available in both traditional metal formats, as well as digital types.

Radius Gauge

These gauge types are used to check the concave and convex radius on corners or shoulders. It is also useful for layout work and inspection of components in various industries. It is used as a template when grinding cutting tools.

Pin Gauge

Pin gauges are used to gauge bored features. They are especially useful for gauging the straightness of a relatively deep bore. Pin gauges are an integral part of the quality process that is used in the manufacturing industry to ensure the interchangeability of parts between processes or even between different manufacturers.

Ruler

Rulers, also known as a rule, or a line gauge, are the quintessential measuring tool. These tools are used for measuring relatively small distances to produce accurately sized technical drawings, as well as aiding in drawing perfectly straight lines.

Rulers are commonly used in geometry, construction, and engineering. Rulers can be made from plastic, wood, or metal. The profession they are intended to be used in will largely determine which type of material a ruler is made from. Metal rulers offer the best durability and, therefore, the longest lifespan, but they tend to be among the most expensive.

Square

A ruler can be used to draw straight lines but there is no guarantee that the line drawn is accurate and exactly straight, this is where the square is brought into use. It is going to come in handy when you are framing and when you need to find right angles. Everything from cutting lumber to making markings can be aided with the use of a square.

Tape Measure

Tape measures are probably the most commonly used measuring device of all measuring tools. These tools are simple yet effective and can be used to measure the length, width, height, or depth of almost any object. Their flexibility means they can also measure curves, or go around corners. One of the reasons they are so handy is that they are small and easily portable. Most tape measures have a clip on the back which means they can easily be attached to a belt loop on a pair of jeans or clipped onto a pocket.

Laser Measure

Laser measures are an alternative to traditional tape measures and are used to measure a length of space. They work by sending out a laser beam at the press of a button, which hits the desired target and can measure the distance based on the detected reflection. This is a very convenient method of measuring distance, able to determine the measurement in a few seconds by simply pressing a button.

They can calculate lengths as long as 650 feet, and with measurements of up to 300 feet, they boast an accuracy to within an eighth of an inch.

Level

Also known as a bubble level or a spirit level, these tools are used for measuring whether an angle is level and equally balanced. Levels come in various sizes, from short handheld versions to yard-long versions, which you will need to use on bigger projects. These tools work by one or more glass vials that are fixed into the level and filled with colored spirit or liquid. The liquid will be slightly too little to fill the vial, which means it will have an air bubble inside the glass.

Bubble Inclinometer

An inclinometer simply determines how steep a particular incline is. It works like a level normally would. You place it near the joint that you want to measure. Set the bubble inclinometer to zero, and then determine what the difference is as it goes through its changes. This may not be as simple to use as some of the other measurement tools due to the way that you have to read it, but it does work quite well.

Angle Locator

An angle locator is a manual tool with a digital display. You will need to position the two ruler-like ends of this angle locator and use the readings you get to determine your angle. This is going to work very well for determining an angle in cramped spaces.

Protractor

Protractor is a type of industrial measuring tools primarily used to measure angles. These convenient measuring tools are pretty simple to grasp yet they can help to make complex determinations possible. Most protractors that you will find on the market are simply made of plastic. Sometimes you will find more durable protractors that are made of metal.

One popular type of protractor used in industries is the digital protractor that measures an angle over 360 degrees with high accuracy of 0.1 degrees. Digital Protractor is very simple and easy to measure by just putting between levels or surfaces.

Speedometer

A speedometer is a measuring gauge that instantly determines the speed that a vehicle is traveling. For most of the 20th century, speedometers have been fitted as standard to motor vehicles, and it is now a requirement that all motor vehicles are universally fitted with. This is key for making the driver aware of the speed at which they are traveling, and therefore allowing them to be able to follow speed limits and ensure safer use of roads. Most speedometers have markings to measure both miles and kilometers.

Odometer

Odometers are used to determine how far something has traveled. You should have an odometer inside of your vehicle. This is the gauge that tells you how many miles or kilometers you have traveled. Odometers can also be mounted on bicycles to determine how far someone has traveled while on a bike.

Thermocouple

Thermocouples consist of two dissimilar conductor wires, made from different metals. These wires are welded together at one end, forming a junction used to measure temperature.

Thermistor

Thermistors have a high coefficient of resistivity. Thermistors are made of semiconductors of solid type. The suitable temperature measuring range for thermistors is -100 degrees Celsius to 300 degrees Celsius. Some special type thermistors can measure up to 600 degrees of temperature.

Galvanometer

In an electric circuit, even if the switch or loop is closed, it is difficult to know whether the current is flowing, hence for this purpose a galvanometer was introduced in the circuit.

Surface Plate

A surface plate also known as a granite inspection table is a solid, flat plate used as the main horizontal reference plane for precision inspection, marking out (layout), and tooling setup. Inspection tables are a common tool in the manufacturing industry and are often fitted with mounting points so that they can be an integrated structural element of a machine such as a coordinate measuring machine, precision optical assembly, or other high precision scientific and industrial machines. Plates are typically square or rectangular, (and less common, round) although they may be cut to any shape.

PH Meter

Another type of industrial measuring tools is a PH meter that is an instrument used to measure the acidity or alkalinity of a solution. The measurement range of the PH meter we measure always ranges from 0-14.

Borescope

A borescope is an optical tool used for viewing invisible areas. We get accurate results from it without destroying walls to see inside a wall or tunnel for example. Videoscope is an important tool for maintenance personnel in a variety of fields, it is a camera with a thin and flexible optical fiber that allows you to enter hidden places to locate faults, saves time and costs.

Torque Meter

Last but not least, a torque meter is a measurement instrument analog to a dynamometer, designed to operate in torsion. Existing applications in research and development, laboratory, quality, manufacturing, and field environment. Test units of torque measurements are most often Newtons or kilograms.

So, this was everything you needed to know about different type of industrial measuring tools. If you enjoy this article, let us know what you think by leaving a reply in the comment section. We will be more than glad to have your viewpoint on the article. Is there any question we can help you through? Feel free to sign up on Linquip where our experts are prepared to provide you with the most professional advice.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

List of Measuring Tools will have to neef