Ball bearings are rolling-element bearings that use rolling spheres held between inner and outer raceways to support radial and axial loads acting on rotating and reciprocating shafts. These bearings are used to provide smooth, low friction motion in rotary applications. They can provide high performance and a long lifetime to transfer the load from the balls to the inner races. In this article, we will discuss different types of ball bearings. Follow this new blog in Linquip to find out more.

Different Types of Ball Bearings

Common Designs

- Angular Contact Ball Bearing

- Single Row Angular Contact Ball Bearing

- Double Row Angular Contact Ball Bearing

- Four Points Angular Contact Ball Bearing

- Deep Groove Ball Bearing

- Single Row Deep Groove Ball Bearing

- Double Row Deep Groove Ball Bearing

- Thrust Ball Bearing

- Single Direction Thrust Ball Bearing

- Double Direction Thrust Ball Bearing

- Duplex Ball Bearing

Construction Types

- Conrad

- Slot-fill

- Self-aligning

- Linear ball Bearing

- Radial ball Bearing

- Relieved Race

- Fractured Race

- Flanged

- Caged

- Hybrid Ball Bearing

- Fully ceramic Bearings

Ball bearings can be classified into several types based on common design and construction. The common designs of ball bearings are described below. Read on to find out about different types of ball bearings and their uses.

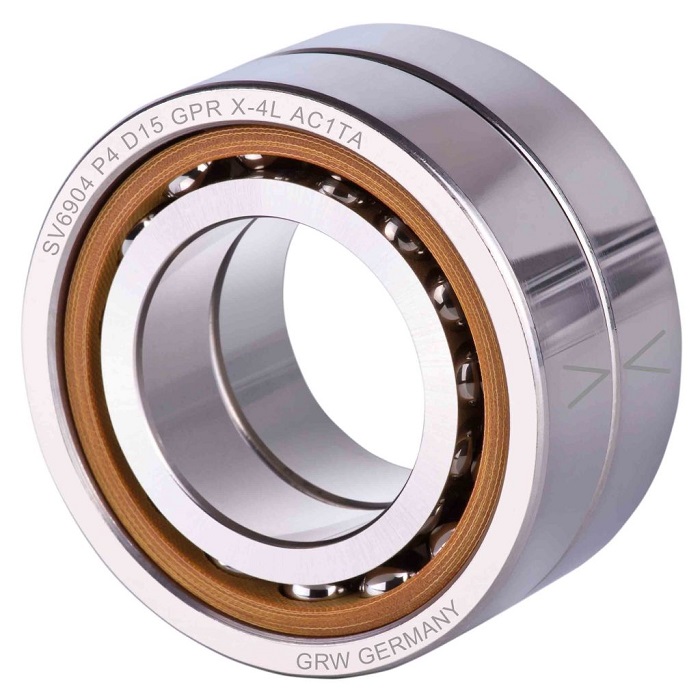

Angular Contact Ball Bearing

Angular contact ball bearings have inner and outer ring raceways that are displaced relative to each other in the direction of the bearing axis. This means that these bearings are designed to accommodate combined loads, i.e. simultaneously acting radial and axial loads.

These types of ball bearings can come in different design styles, with seals or shielding. These serve not only as protection from contamination but also as retainers for lubricants. These bearings can be made from stainless steel, ceramic hybrid materials, or plastic, and maybe plated with chrome, cadmium, or other materials. Also, they can be pre-lubricated, re-lubricated, or can feature solid lubrication.

Angular contact ball bearings are further classified into the following sub-types:

Single Row Angular Contact Ball Bearing

Incorporating a large number of balls to give it a relatively high load-carrying capacity, these bearings can accommodate axial loads in one direction only, are typically adjusted against a second bearing, and have non-separable rings.

The benefits of single row angular contact ball bearing include:

- High load-carrying capacity

- Good running properties

- Easy mounting of universally matchable bearings

Double Row Angular Contact Ball Bearing

With a design corresponding to two single row bearings arranged back-to-back, but where two single bearings take up too much axial space, they can accommodate radial and axial loads in either direction and tilting moments.

The benefits of double row angular contact ball bearing include:

- Less axial space

- Accommodates radial as well as axial loads in either direction

- Accommodates tilting moments

- Stiff bearing arrangement

Four Points Angular Contact Ball Bearing

Designed to support axial loads in both directions and have a high load-carrying capacity, these types of ball bearings can support a limited radial load for a given axial load, use less axial space than double row bearings, and are separable.

The benefits of four points angular contact ball bearing include:

- Accommodates axial loads in both directions

- Less axial space

- High load-carrying capacity

- Separable design

- Improved oil flow

- Limited inner ring deformation when subjected to high clamping forces

Deep Groove Ball Bearing

Deep groove ball bearings are the most commonly used types of ball bearings and can be purchased in seal, shield, and snap-ring arrangements. The race dimensions within these kinds of bearings closely match the dimensions of the balls that are contained. They are also well suited to the support of weighty loads. Deep groove bearings provide both radial and axial support. However, the contact angle can’t be adjusted to vary the relative levels of such loads.

Deep groove ball bearings are further classified into the following sub-types:

Single Row Deep Groove Ball Bearing

Single-row deep groove ball bearings are the most common type of ball bearings. Their use is very widespread. The raceway grooves on both the inner and outer rings have circular arcs of a slightly larger radius than that of the balls. In addition to radial loads, axial loads can be imposed in either direction. Because of their low torque, they are highly suitable for applications where high speeds and low power loss are required.

In addition, to open type bearings, these bearings often have steel shields or rubber seals installed on one or both sides and are pre-lubricated with grease.

Double Row Deep Groove Ball Bearing

Double row deep groove ball bearings correspond in design to single row deep groove ball bearings. Their deep, uninterrupted raceway grooves have a close osculation with the balls, enabling the bearings to accommodate radial loads and axial loads in both directions. These types of ball bearings are very suitable for bearing arrangements where the load-carrying capacity of a single row bearing is inadequate. For the same bore and outside diameter, double row bearings are slightly wider than single row bearings in the 62 and 63 series but have a considerably higher load-carrying capacity. Double row deep groove ball bearings are only available as open bearings (without seals or shields).

Thrust Ball Bearing

Thrust ball bearings are a special type of ball bearings designed specifically for axial loads. They cannot sustain radial loads at all. Thrust ball bearings exhibit low noise, smooth operation and are capable of high-speed applications.

They are available as single direction or double direction bearings and the selection relies on whether the load is unidirectional or bidirectional.

Single Direction Thrust Ball Bearing

Single direction thrust ball bearings are composed of washer-like bearing rings with raceway grooves. The ring attached to the shaft is called the shaft washer (or inner ring) while that attached to the housing is called the housing washer (or outer ring).

Double Direction Thrust Ball Bearing

In double direction thrust ball bearings, there are three rings with the middle one (center ring) being fixed to the shaft. There are also thrust ball bearings with an aligning seat washer beneath the housing washer to compensate for shaft misalignment or mounting error. Pressed steel cages are usually used in the smaller bearings and machined cages in the larger ones.

Duplex Ball Bearing

A combination of two angular contact ball bearings forms a duplex bearing. Possible combinations include face-to-face, which have the outer ring faces together (type DF), back-to-back (type DB), or both front faces in the same direction (type DT). DF and DB duplex bearings are capable of taking radial and axial loads in either direction. Type DT is used when there is a strong axial load in one direction and it is necessary to impose the load equally on each bearing.

Now that you got familiar with the common designs of ball bearings, let’s get to know the construction types of ball bearings.

Conrad Ball Bearing

These types of ball bearings are assembled by placing the inner ring into an eccentric position relative to the outer ring, with the two rings in contact at one point, resulting in a large gap opposite the point of contact. The balls are inserted through the gap and then evenly distributed around the bearing assembly, causing the rings to become concentric. Assembly is completed by fitting a cage to the balls to maintain their positions relative to each other.

Conrad bearings can withstand both radial and axial loads but have the disadvantage of lower load capacity due to the limited number of balls that can be loaded into the bearing assembly. Probably the most familiar industrial ball bearing is the deep-groove Conrad style. The bearing is used in most mechanical industries.

Slot-fill Ball Bearing

In a slot-fill radial bearing, the inner and outer races are notched on one face so that when the notches are aligned, balls can be slipped in the resulting slot to assemble the bearing. A slot-fill bearing has the advantage that more balls can be assembled, resulting in a higher radial load capacity than a Conrad bearing of the same dimensions and material type. However, a slot-fill bearing cannot carry a significant axial load, and the slots cause discontinuity in the races that can have a small but adverse effect on strength.

Self-aligning Ball Bearing

Self-aligning ball bearings have two rows of balls, a commonly sphered raceway in the outer ring and two deep uninterrupted raceway grooves in the inner ring. They are available open or sealed. These types of ball bearings are insensitive to angular misalignment of the shaft relative to the housing, which can be caused, for example, by shaft deflection.

The benefits of self-aligning ball bearings include:

- Accommodate static and dynamic misalignment

- Excellent high-speed performance

- Minimum maintenance

- Low friction

- Excellent light load performance

- Self-aligning ball bearings can reduce noise and vibration levels, for example, in fans.

Linear Ball Bearings

Linear ball bearings are designed to provide free motion in one direction. They are the most widely used variety of linear slides and ensure a smooth precision motion along a single axis linear design. Featuring self-lubrication technology, these ball bearings allow for optimum performance and reliability. They are comprised of two linear ball-bearing rows, integrated within four rods on alternate sides of the base.

Radial Ball Bearing

Suitable for a wide range of purposes, radial ball bearings offer exceptional levels of performance. These types of ball bearings have the capacity for either radial or axial loads as applied to the shaft. However, the combined application of such loads requires axial angular contact. Adjustment of the axial radial bearing angle allows for equal distribution of the axial and radial loads along with the angular contact ball bearings.

Relieved Race Ball Bearing

Relieved race ball bearings are ‘relieved’ as the name suggests by having either the OD of the inner ring reduced on one side of the ID of the outer ring increased on one side. This allows a greater number of balls to be assembled into either the inner or outer race, and then press-fit over the relief. Sometimes the outer ring will be heated to facilitate assembly. Like the slot-fill construction, relieved race construction allows a greater number of balls than Conrad construction, up to and including full complement, and the extra ball count gives extra load capacity. However, a relieved race bearing can only support significant axial loads in one direction.

Fractured Race Ball Bearing

Another way of fitting more balls into a radial ball bearing is by radially ‘fracturing’ one of the rings all the way through, loading the balls in, re-assembling the fractured portion, and then using a pair of steel bands to hold the fractured ring sections together in alignment. Again, this allows more balls, including full ball complement, however, unlike with either slot fill or relieved race constructions, it can support significant axial loading in either direction.

Flanged Ball Bearing

Bearings with a flange on the outer ring simplify axial location. The housing for such types of ball bearings can consist of a through-hole of uniform diameter, but the entry face of the housing must be machined truly normal to the hole axis. However such flanges are very expensive to manufacture. A more cost-effective arrangement of the bearing outer ring, with similar benefits, is a snap ring groove at either or both ends of the outside diameter. The snap ring assumes the function of a flange.

Caged Ball Bearing

Cages are typically used to secure the balls in a Conrad-style ball bearing. In other construction types of ball bearings, they may decrease the number of balls depending on the specific cage shape and thus reduce the load capacity. Without cages, the tangential position is stabilized by the sliding of two convex surfaces on each other. With a cage, the tangential position is stabilized by a sliding of a convex surface in a matched concave surface, which avoids dents in the balls and has lower friction.

Hybrid Ball Bearing

Ceramic bearing balls can weigh up to 40% less than steel ones, depending on size and material. This reduces centrifugal loading and skidding, so hybrid ceramic bearings can operate 20% to 40% faster than conventional bearings. This means that the outer race groove exerts less force inward against the ball as the bearing spins. This reduction in force reduces the friction and rolling resistance. The lighter balls allow the bearing to spin faster and use less power to maintain its speed.

Fully Ceramic Bearing

These bearings make use of both ceramic balls and race. These bearings are impervious to corrosion and rarely require lubrication if at all. Due to the stiffness and hardness of the balls and race, these bearings are noisy at high speeds. The stiffness of the ceramic makes these bearings brittle and liable to crack under load or impact. Because both ball and race are of similar hardness, wear can lead to chipping at high speeds of both the balls and the race, which can cause sparking.

So, this was everything you needed to know about different types of ball bearings and ball-bearing diagrams. Now that you know how many types of bearings are there, let us know what you think by leaving a reply in the comment section. We will be more than glad to have your viewpoint on the article. Is there any question we can help you through? Feel free to sign up on Linquip where our experts are prepared to provide you with the most professional advice.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Provider

Your content helps a lot to the new generation mechanical and automobile engineers. Keep rocking ?.

Thanks for visiting our website and leaving your comment, Jagan! You are encouraged to visit Linquip Tech News, where you can find similar posts.

You mention that double row deep groove bearings have a close osculation.

I think you meant to say oscillation. Good article. Informative