As you may know, bearing is an important part of contemporary machinery. Its main function is to support the mechanical rotating body, reduce the friction coefficient during its movement and ensure its accuracy. Although modern bearings are highly engineered components, their ultimate performance depends very much on how they are housed. Bearing housings are modular assemblies designed to make it easy to install bearings and shafts while protecting bearings, extending their operating life, and simplifying maintenance. This article will give you complete information on different types of bearing housing. Follow this new blog in Linquip to find out more.

At Linquip, you’ll find all the information about the bearing housing you need. If you have any bearing-related questions, we are here to help. Check out Linquip and explore the article “What Is Bearing?” for a basic understanding of these industrial devices.

Are you in need of a bearing? Browse our Bearing Products selection at Linquip for free to find the bearing you need. What type of bearing housing are you looking for? Linquip provides no-cost access to all available Bearing Devices for Sale. Linquip also allows you to submit an inquiry/request for quotes to all Bearing Suppliers and Companies free of charge if you are searching for bearing housing prices.

The Different Types of Bearing Housing

- Split Plummer block housing

- Non-split Plummer block housing

- Flanged housing

- Take-up housing

- Two-bearing housing

Housings are available in many sizes and generally fall into five standard categories: Split Plummer (or pillow) block housings, Non-split Plummer block housings, flanged housings, take-up housings, and two-bearing housings. These products can be designed to meet specific duty requirements such as load, speed and operating environmental conditions. Let’s get to know each type’s feature.

Read more about industrial bearings

Split Plummer Block Housing

In Split Plummer (or pillow) block housings, the housing body is split into an upper section and a lower section. This gives significantly simpler mounting and maintenance. The two halves of housing form a matched pair and must not be interchanged with parts from other housings.

Split Plummer block housings are an excellent choice for easy installation and maintenance as they not only accommodate pre-assembled shafts but also simplify bearing inspections and maintenance as the shaft does not need to be disassembled. These types of bearing housing are designed for self-aligning ball bearings, spherical roller bearings, and CARB toroidal roller bearings.

Non-split Plummer Block Housing

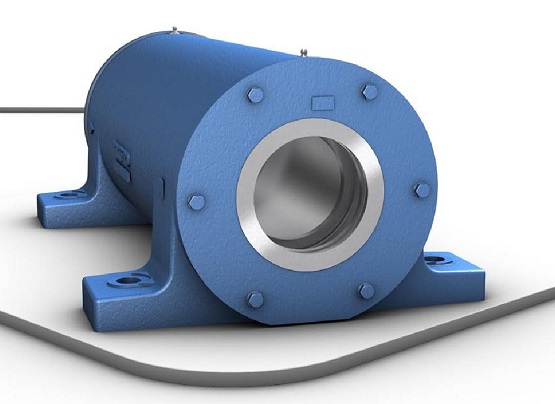

In the case of non-split Plummer block housings, the housing body is a single piece, so the bearing seat is free from parting lines. The non-split Plummer block housings also include Plummer block housing units VRE3. These are made available as completely assembled and greased bearing arrangement units comprising housing, seals, bearings, and shaft.

Non-split Plummer block housings are preferred when there are heavy loads acting in a direction other than toward the support surface. They are also used when the housing has to be mounted from the end of the shaft.

Flanged Housing

Flanged housings are well-proven machine parts that have a flange perpendicular to the shaft axis and thus offer the ideal adjacent construction for numerous machines and pieces of equipment where the use of Plummer block housings would be too demanding.

As mentioned above, these types of bearing housings provide a solution for applications that do not have a frame parallel to the shaft and are available in oval, circular, and square formats that accommodate bearing types similar to those of Plummer block housings. These housings provide simple, reliable housing in applications without horizontal frames. They enable the full-service life potential of the incorporated bearings to be exploited, but with reduced maintenance requirements.

Take-up Housing

Take-up housings were developed specifically for tensioner drum bearing arrangements in the belt conveyor plant. The housings are unsplit and there is a yoke-shaped drawbar eye for attachment to the tensioning device. Take-up housings are mounted onto a guide frame and are designed to accommodate heavy loads acting in different directions. These types of loads are typically encountered in conveyors, roller beds, and crushers.

Two-bearing Housing

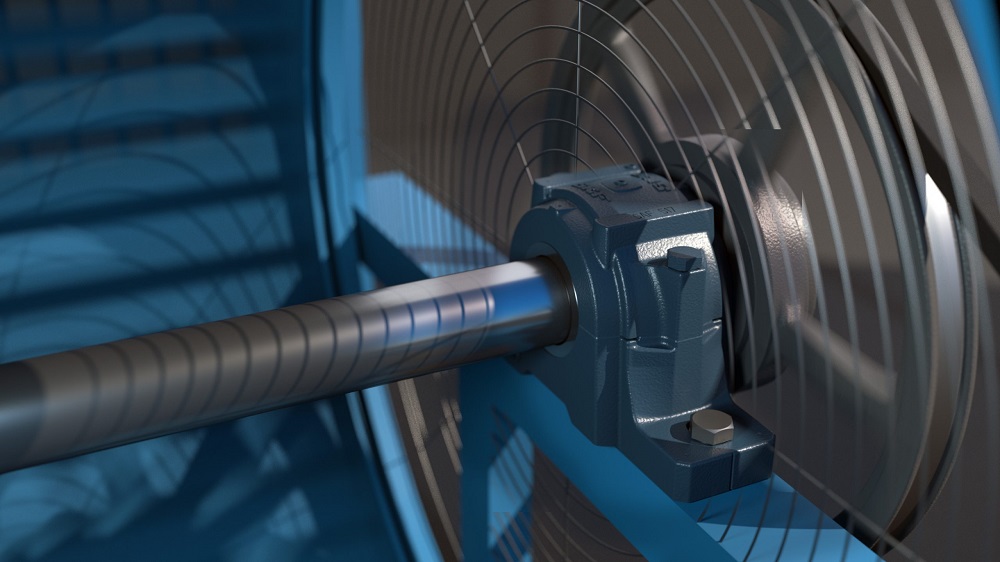

Two-bearing housings were originally developed for fan shafts with an overhung impeller, but are also suitable for other applications with similar shaft arrangements. These housings have intrinsically aligned bearing seats, which enable rigid bearings, such as deep groove ball bearings, angular contact ball bearings, and cylindrical roller bearings to be accommodated.

These types of bearing housing are typically used in applications with an overhanging load. Compared to the conventional shaft arrangement where two self-aligning bearings are mounted in separate pillow (Plummer) block housings, two-bearing housings provide several advantages including improved running accuracy and quieter operation.

In addition, non-standard bearing housing designs can also be supplied to particular customer requirements or to expand the scope of delivery where:

- Special technical requirements are present.

- The customer has particular specifications that must be fulfilled.

For example, where special shaft center heights, unusual sealing arrangements, or non-standard materials of construction may be specified.

Bearing Housing Selection

Appropriate housing seal selection will depend upon the operating conditions. These seals are available in a variety of designs, the most common being radial shaft seals. However, for extremely contaminated or wet environments it may be necessary to use an engineered seal comprising three- or even four-stage labyrinths in combination with an internal V-ring for additional sealing effect and efficient grease purging.

It must be noted that different types of bearing housing are generally supplied as standalone devices, requiring customers to specify all additional components separately. As this can be a time-consuming task, manufacturers offer complete pre-assembled bearing units or kits, which include the housing, bearing, seals, sensors, and locating rings necessary to create a working bearing system.

What Are Bearing Housings Made of?

Gray cast iron is a common material used for bearing housings. Metals of various grades can be used to make the same products, including ductile iron, steel, and stainless steel, as well as some types of thermoplastics and polyethylene-based plastics.

So, this was everything you needed to know about different types of bearing housing. Now that you know how many types of bearing housing are there, let us know what you think by leaving a reply in the comment section. We will be more than glad to have your viewpoint on the article. Is there any question we can help you through? Feel free to sign up on Linquip where our experts are prepared to provide you with the most professional advice.

Download Types of Bearing Housing PDF

If you prefer, you can download the PDF copy to your computer. Below is the download link.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Provider

Read More In Linquip

I only know the basic of Bearings but this blog really helps me understand the bearing housing concept. It is very helpful to me. Thank you so much and continue doing this.

Thanks for visiting our website and leaving your comment! We hope to hear from you again in our other posts.