A condenser in simple terms is a cooling device. Every refrigeration system and power plant use condensers to condense refrigerant vapors or steam and is known as a heat rejector. Actually, it turns superheated and highly-pressurized vapor into a subcooled liquid. What is exactly a condenser? was discussed in another article titled “A condenser; Parts, Functions, and types”.

There are three types of condensers, depending on the condensing medium used to extract heat from the system. Neither of the three types of condensers has a distinct advantage over the others. Each should be utilized correctly depending on the scenario. In the next sections, we’ll go through the functions of these three different types of condensers. Condensers are available from a variety of Suppliers and Companies, as well as various manufacturers and distributors, and there are several Condensers for Sale on Linquip.

There is a complete selection of condenser services on the Linquip platform that meets all of your needs. Linquip can connect you with a number of condenser service suppliers and experts who can help you. Linquip can connect you with Condensers Specialists and subject matter experts who can help you test your equipment.

In this article, we have collected a pile of useful information about the types of condensers. Linquip is going to have you acquainted with the various condenser types in a full detailed context. So follow us in the next sections of this article.

⇒ View a List of Condensers for Sale and Their Suppliers ⇐

How Does a Condenser Work?

Before we get acquainted with the different types of condensers, let’s have a brief look at how a condenser works. Again, we have to mention that a full description of the section was devoted to the topic of functions of a condenser in another article. Just in case you haven’t read that article, we deliver a gist of how a condenser works to make it easier for you to understand what different types of this equipment are.

Three different phases happen in every condenser. The first phase is called the desuperheating. The vapor entering into the condenser is already superheated and super pressurized in the evaporator and compressor. Desuperheating means to eject the heat from the vapor and turns it into liquid. The next level is changing or condensation state; losing more heat continues in this state where we reach into 10% of refrigerant as vapor and 90% as a liquid. The third and last phase is a sub-cooling state. The sub-cooling state is there so as to be sure that not even rising temperatures can bring the liquid refrigerant into vapor again.

Now that you have a general insight into how a condenser works, we can move safely forward to the next sections where we are going to get familiar with types of condensers step by step.

Three Main and Different Types of Condensers

- Air-cooled condenser

Natural Convection

Forced Convection

- Water-cooled condenser

Double Tube

Shell and Coil Condenser

Shell and Tube Condenser

- Evaporative Condenser

Condensers based on the condensing medium used to remove the heat from the system, include three different types. None of these three different types of condensers has particularly no advantages over the other. Depending on the situation, each one should be used appropriately. We are going to elaborate on the functions of these three condenser types in the following.

-

Air-cooled Condenser

Condensers of this type use air as the external fluid to reject the heat from the system. Air-cooled condensers usually have copper coils where refrigerant flows in. But this is not the whole story; this type is subcategorized into two subsets: natural convection and forced convection.

See All Air-Cooled Condenser for Sale

1.1. Natural Convection

In this type of condenser, air comes to contact with warm coils, absorbing the heat of refrigerant inside the coils, consequently the temperature of air increases. As the warm air is lighter, it goes up and the cold air replaces and again the cold air comes to touch warm coils to reject the heat. This natural cycle continues until the refrigerant loses its heat.

Since the flow rate of air is small and the radiation heat transfer is also not very high, the combined heat transfer coefficient in these condensers is small. As a result, a relatively large condensing surface is required to reject a given amount of heat. Hence these types of condensers are used for small capacity refrigeration systems like household refrigerators and freezers.

1.2. Forced Convection

One of the other types of condensers is forced-convection. A fan or a blower does play the most crucial role in removing heat from the refrigerant inside the coils. The fan blows the air into the finned coils. An important tip has to be noted here and it is that the fins of forced convection condenser are put tightly next to each other; so, if the dust and dirt fill the slight space between the fins, the air flowing and heat rejection faces big trouble.

Forced convection type condensers are commonly used in window air conditioners, water coolers, and packaged air conditioning plants.

-

Water-cooled condenser

As it can be guessed, this type of condenser uses water as fluid to remove heat from the refrigerant. It is obvious that water-cooled condensers are used where we have an adequate supply of water. This type, itself has three different kinds:

See All Water-Cooled Condenser for Sale

2.1. Double Tube

Double tube condensers have a tube of water inside a large refrigerant tube. The water absorbs most of the refrigerant heat, but as the refrigerant tube is in contact with the natural circulation of air, part of the cooling process is on natural convection. Although double-tube condensers commonly have been used in the past, the large number of gaskets and flanges used in these heat exchangers leads to maintenance problems.

2.2. Shell and Coil Condensers

In a shell-and-coil condenser, a welded shell contains a coil of finned water tubing. In this type of water-cooled condenser, the hot refrigerant flows in the shell while the cooling water circulates inside the coils and condenses the refrigerant. It is generally most compact and low in cost.

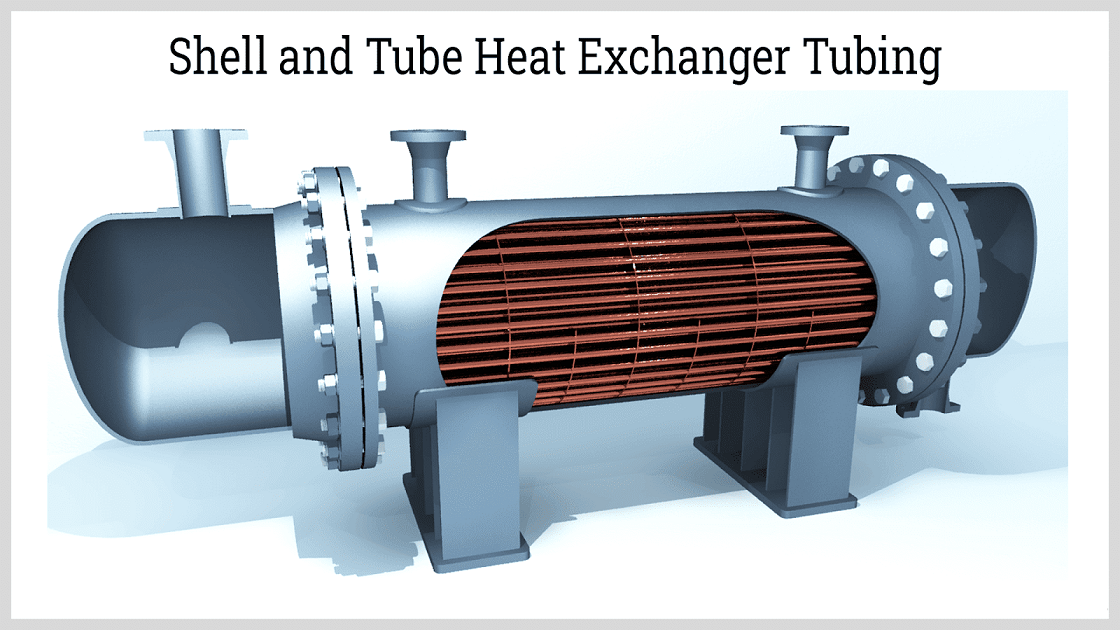

2.3. Shell and Tube Condensers

One of the types of condensers performs the process of rejecting heat by having a cylindrical shell consisting of water tubes. In a shell and tube condenser, water is pumped through the pipes while refrigerant flows in the shell. Installations of fins in pipes allows better heat transfer. The shell-and-tube condensers are generally low in cost and easy to maintain.

The most common type of shell and tube condensers is the horizontal shell type. However, vertical shell and tube condensers are usually used with ammonia in large capacity systems so that cleaning of the tubes is possible from the top while the plant is running.

-

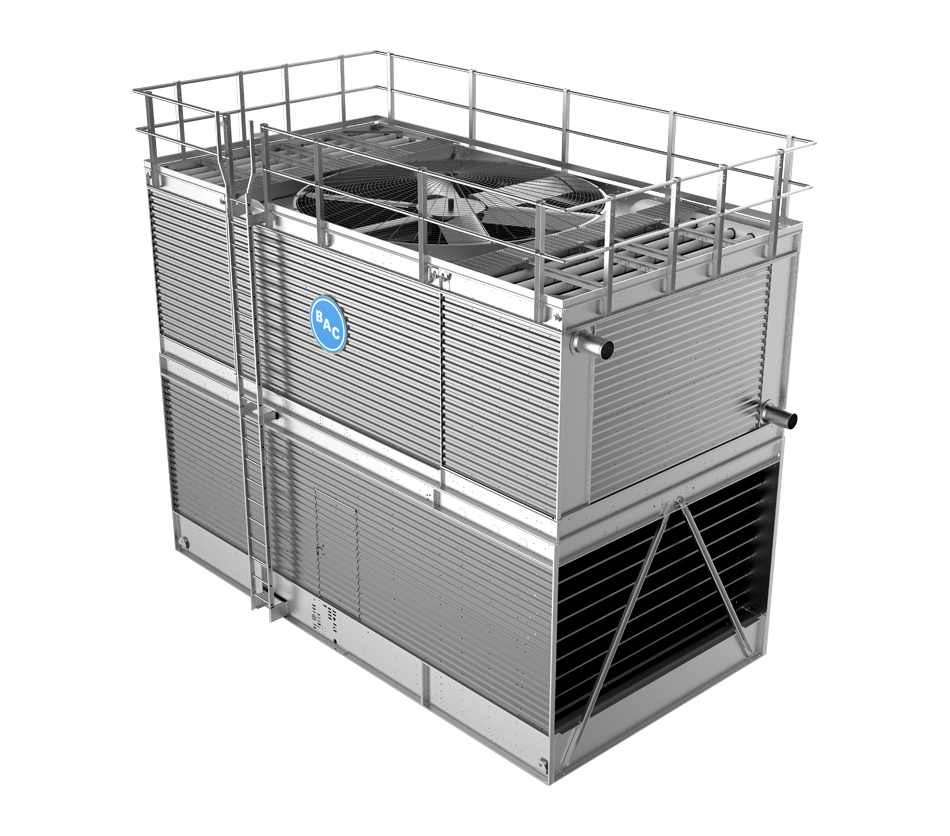

Evaporative Condensers

And finally, the last one of the types of condensers is the evaporative one. it is actually the mix of an air-cooled and water-cooled condenser. Evaporative condensers use air and water as the condensing medium. The condenser’s sump pumps the water to be sprayed over coils and simultaneously, a fan blows the air into the condenser. The sprayed water over coils evaporates and the required heat for the vaporizing water is taken from the heat of refrigerant. Some amount of water will be circulated by dropping into the sump but to make up the amount evaporated, an additional amount of water is added to the water supply of the sump.

See All Evaporative Condenser for Sale

Evaporative condensers are used in places where water is scarce. Since water is used in a closed-loop, only a small part of the water evaporates. Make-up water is supplied to take care of the evaporative loss. The water consumption is typically very low, about 5 percent of the equivalent water-cooled condenser with a cooling tower. However, since the condenser has to be kept outside, this type of condenser requires a longer length of refrigerant tubing, which calls for larger refrigerant inventory and higher pressure drops.

A Brief Comparison between these three types

- Evaporatives are often cheaper compared to water-cooled requiring a cooling tower.

- Evaporatives are used in places where we usually encounter a water supply shortage.

- Evaporatives are kept outside, so in cold seasons, the water pump is switched off so as to prevent freezing water.

Air-cooled condensers compared to water-cooled ones are simple in construction. Besides, access to air is always available. The maintenance cost of an air-cooled is low in comparison with a water-cooled.

Moreover, water-cooled types of condensers are more complex than air-cooled condensers as there are design considerations in water flow regulation and corrosion prevention. However, the advantages of water-cooled systems are that water has a higher exchange coefficient than air so heat transfer will be more efficient.

Conclusion

Knowing the types of condensers helps you have a better choice at the time of purchase. In this article we tried to inform you about the difference kinds of condensers, their unique functions, pros and cons.

If you have any experiences of using different types of condensers, or want to share your opinions about this topic to make this article a better source of information, feel free to write them down in comments. Experts in Linquip are ready to answer your various questions about condensers. So just sign up on our website and let us help you out.

Download Types Of Condensers PDF

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What Is a Condenser; Parts, Functions and types

- Difference Between Heat Exchanger and Condenser: A thorough guide 2021

- Water cooled condenser types: A go-to guide to choosing the right one

- Condenser water system: An overview of its components and more!

- Evaporative condenser: An easy to understand guide

- Difference Between Condenser and Capacitor in a nutshell 2021

- Types of Plate Heat Exchanger: Different Types with Wide Use

- Types of Heat Exchangers: An Introduction to All Essential about Specifications

- Types of boilers: Which one is the best?

- Types of Transformer: An Article About How Transformers Differ in Construction and Design

- 3 Types of Heat Pump + Working Principle ( Clear Guide)

- 5 Best Electric Boilers: A Practical Guide

- Common Problems with Solar Air Conditioners

- Your Complete Guide to Air Conditioner Replacement Cost

- Difference Between Condenser and Capacitor in a nutshell

- What is Coil Heat Exchanger? Design Example

- Advanced Guide: What Is Tube In Tube Heat Exchangers