Different Types of Fasteners – All kinds of common products are constructed using fasteners, which are essential. Using fasteners to complete DIY tasks is probably nothing new for you. We at All Points Fasteners are passionate about the usefulness of high-quality fasteners for both experts and do-it-yourself homeowners. Let’s define fasteners, go through some of the different types, and discuss some of the numerous applications for them.

On the Linquip website, among the many options available to you, you will find all the information you need to know about the Fasteners, as well as information regarding this marketplace. You can count on Linquip to provide you with as much general and reliable information about this topic, whether you’re a professional or a customer looking for a proper company. We recommend you review a list of all Fasteners Products available in Linquip. You can also be encouraged to visit Fasteners for Sale and find the most suitable device based on your applications and demands.

A Fastener: What Is It?

First, let’s establish what a fastener is. The name “fasteners” refers to a large group of instruments, such as screws, nuts, and bolts, that serve the common function of mechanically joining items. Yes, materials like glue can serve this purpose, but they are not fasteners. We must thus expand upon our definition. Objects are mechanically held together by hardware fasteners.

Fasteners often create a temporary junction. In other words, if you use a fastener to join two components, you can take the fastening out and the parts should separate without any harm. With a welded junction, for example, the situation would not be the same. Rivets, which come under the category of fasteners yet produce permanent joins, are the only exception to this rule.

Although the majority of fasteners create a non-permanent joint, this does not imply that you only use fasteners when you need to be able to disassemble something, and it does not in any way imply that the joint is weak. Fasteners are dependable for holding together things that may be subject to a lot of force. They provide adaptability for the project type you wish to utilize them for, making them an excellent option for both permanent and non-permanent connections.

Different Types of Fasteners

Permanent fasteners and Non-Permanent fasteners are the two basic categories into which fasteners may be divided. A permanent fastener creates a permanent joint, as its name suggests, whereas the latter creates a temporary junction. They are highly sought after because of their versatility in having several sorts of bolt heads. Commercially, mechanical fasteners come in a wide range of shapes and sizes. They come in a variety of sorts, each of which has several subcategories. The following list of popular fastener types includes:

- Screws: Screws are externally threaded fasteners with superior grip strength and great durability.

- Bolts: Also known as threaded bolts, a partly threaded fastener is used to join two components.

- Nuts: They fit into a bolt and are internally threaded to secure things and prevent slipping.

- Rivets: It creates strong connections between things and also includes pop rivets.

- Washers: Washers are flat discs used to distribute load when paired with a nut and bolt.

- Nails: Nails are long, thin metal pieces that are used to attach items together.

- Anchors: they are used to secure items to concrete surfaces.

All of the aforementioned fastener types have further subcategories and pertinent particular uses. Let’s get into the specifics of the various fastener types and examine their purposes.

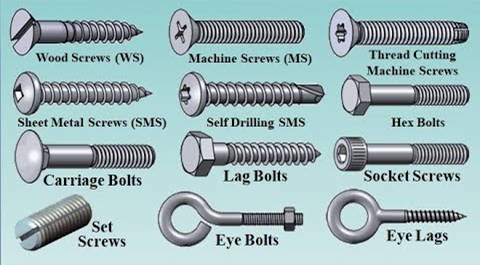

Screws

The most popular kind of fasteners are screw ones. They are extremely robust and adaptable. These socket screws have variously shaped heads and must repair internal threads that have deteriorated over their whole length. Internal threads in things are necessary for screws to keep them together. They create male threads that are placed into the item. Pre-tapping becomes less necessary as a result.

Commercially accessible screw fasteners come in a wide variety of forms, including slotted headless set screws, machine screws, deck screws, sheet metal screws, lock nuts, lock washers, and many more. A few of these are:

Machine Screws

Two metallic items are fastened together using machine screws. Machine screws are sometimes referred to as threaded fasteners since they are placed into existing threaded holes.

Screws for Decks

These wood screws have coarse threads and a tapered head, and they are sometimes referred to as screw fasteners. To prevent corrosion, they are utilized in timber products and outdoor decks.

Screw for Sheet Metal

To combine metal with other items, these teams use threads with sharp cutting edges. Their notched point can be cut through wood, plastic, and sheet metal. Typically, sheet metal screws bind better in nut-threaded or tapped holes.

Screw for Drywall

They may be put into drywall without causing damage because of their coarse threads and tapered heads with fine tips.

Screw With a Hex Head

Instead of using a screwdriver, a wrench is used to drive these massive wood screws. They are employed in demanding situations. Because they have a hexagonal head design, hex cap screws may generate more torque. It is for this reason that these hex-head bolts are regarded as the strongest metal fasteners. A wood screw is another name for a hex cap screw.

These are some of the most popular screws. Let’s move on to the many types of bolts and bolt heads.

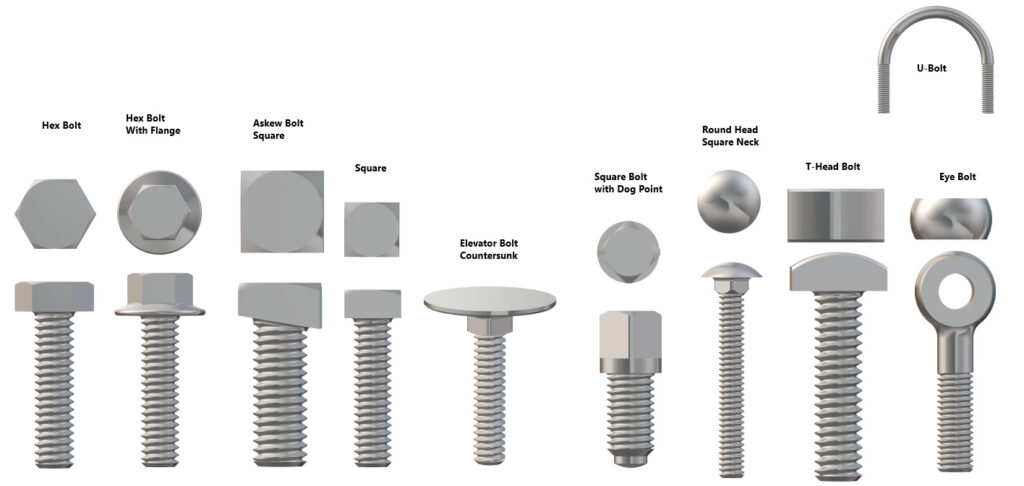

Bolts

Bolts are a different typical kind of fastener. Together, these two components keep unthreaded parts together. The bolt is a fastener that uses a nut and head with a straight, threaded shank to hold items together. Among the many different kinds of bolts and nuts are:

Bolts for Carriage

Carriage bolts, which are used to fasten wooden items, feature square necks, convex heads, and many threads.

The Allen bolts

For use with an Allen wrench, these bolts have a hexagonal socket in the head.

Bolts for Plows

These plow bolts are heavy-duty fasteners with a countersunk, square neck, and unified thread. They have a flat square head.

Bolts for Flanges

Under their heads, they have a circular flange in the shape of a U bolt that serves as a washer for load distribution. These fall under the category of U bolts.

Screwing Anchor Bolts In

Strong connections between the non-structured and structured parts are made by these anchor bolts.

Bolts with a Double End

As implied by the name, double-end bolts are used to attach two flanges together since they feature sharp threads on both sides.

As vital as screws are, we’ve quickly described some of the main varieties of bolts to explain how they work.

Nuts

A nut is a significant fastener that functions in tandem with a bolt. To boost grip and torque, it is internally threaded to fit with a bolt of the same size. Lock Nuts are attached in some fashion to a nut or tapped hole that has previously been established. The following are some examples of the several hex nut varieties:

Nuts on the Wheels

They are used to secure the wheels of cars and are likewise known as lug nuts.

Nuts on the Cap

By preventing their protrusion, socket cap nuts safeguard the fastener’s internally threaded anchors.

Nuts for Flanges

These nuts, which are frequently used in assembly lines, feature a big flange on one end. This secures the component and evenly distributes the pressure.

Nuts in a Coupling

An extended jam nut is what a coupling nut is for connecting threaded rods. They also enable rod extension.

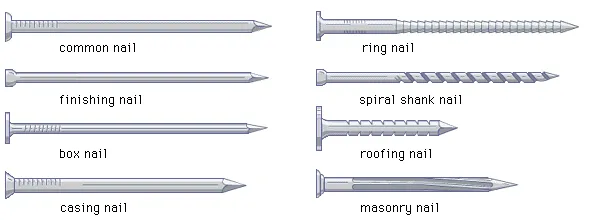

Nails

Nails are the oldest fastening known to man, and they are still employed in several applications today. Physically, a nail and a screw look quite similar, but you can tell them apart. The fact that screws have threading and nails don’t is one of the key distinctions between nails and self-tapping screws. Although a nail has a greater shearing capability than a screw, which makes it a viable choice in some situations, a screw undoubtedly offers a superior and stronger bond.

Here, we’ve covered several popular nail types:

Common Nails

This type of nail has a larger body shank, which makes a stronger joint between two or more items possible. A common nail’s larger shank is one of its biggest drawbacks since it is visible in the joint, drastically reducing the aesthetic value of the joint components.

Box Nails

Both a diamond point and a head-shaped tip are present on box nails. These are most frequently used when connecting steel structures.

Finishing Nails

Finishing nails are flat square head set screws that, when used in applications, blend in with the material being applied to and have a superior locking mechanism. This group of round, smooth-headed nails produces a tidy finish and is frequently used in complicated and precise design tasks.

Flooring Nails

This group of nails is utilized in flooring applications, as suggested by the name.

Flooring Nails

It is said that roofing nails, which look to have a large head, are corrosion-free nails.

Roofing Nails

These nails come in a wide variety of production styles and are frequently used in flush installation and related applications. They are very adept at stealth and camouflage.

These significant fastener types have therefore been briefly described above. You must be curious as to the composition of the nuts, screws, bolts, and structural washers. Let’s talk about the supplies needed to make plain washers and fasteners.

The Component Used To Create Sheet Metal Screws

The mechanical fastener’s production process is heavily influenced by the uses for which it is intended. The materials utilized in different types of fasteners range from aluminum and brass to different grades of steel. The choice of material has a significant impact on the qualities that are infused, including strength, corrosion resistance, and brittleness.

Let’s examine some of the materials that are often utilized in various sectors for fasteners.

Steel Fastener

The material that fasteners are most frequently made of is steel. Fasteners typically include 90% steel. Its popularity is due to the strength and longevity it gives the fasteners. They can be utilized as plain steel or steel with surface coatings like galvanization and zinc plating.

For fasteners, industries prefer employing carbon-containing steel, which comes in four common grades depending on their requirements.

Grade 2

Hardware frequently uses grade 2 steel fasteners, which are less expensive but less reliable.

Grade 5

Due to its increased strength from work-hardening, this one, also known as F grade, is frequently utilized in the automobile sector.

Grade 8

Fasteners in Grade 8 are more work-hardened than those in Grade 5, making them stronger than those in other grades and ideal for car suspensions.

Aluminized Steel

To increase steel’s strength, permit heat treatment at extremely high temperatures. They are robust yet might be fragile.

Fastener is Made of Stainless Steel

Low carbon steel grade and chromium are mixed to create the alloy known as stainless steel. Different qualities are imparted to the fasteners by these two main parts. High levels of corrosion resistance are provided by the chromium, whilst minimal levels of strength are provided by the low-carbon steel component. The stainless steel grades 18-8, 410, and 316 are some examples of those that are often used.

Altered Fastener

Lightweight aluminum has a high level of corrosion resistance. Because of this, aluminum fasteners maintain their characteristics even after being damaged in use. For the most part, producers mix aluminum with other materials like zinc, silicon, magnesium, iron, copper, etc. to create fasteners.

Various Coatings Available For Machine Screws

Fasteners may become less durable and corrosion-resistant when exposed to extreme weather conditions. The fasteners’ performance is enhanced and these effects are avoided by coating. There are several commercially available coatings that vary according to the different kinds of fasteners, some of which are listed below:

Zinc, Both Clear and Yellow

Zinc coatings are the most common since they are affordable. Fasteners made of clear zinc exhibit strong oxidation resistance. Fasteners with clear zinc or yellow zinc coating are both excellent choices for usage in moist situations.

Chrome and Nickel

Both increase corrosion resistance, but only when utilized to give the fasteners a nice look.

Brass and Bronze

Both of these metals are utilized to give finishing touches to the fasteners since they have excellent corrosion resistance and appealing aesthetics.

Because fasteners come in a variety of materials, they are also covered with a variety of coatings, sometimes to prevent corrosion and other times to create a stronger bond between two or more things.

What Advantages Do Small Fasteners Have in Manufacturing?

A lot of businesses, including manufacturing, use screw fasteners. Utilizing them in this context has several benefits, including:

Flexibility in design: When designing items, engineers and designers have additional alternatives because of fastener screws. For instance, businesses that produce electronic devices like laptops and tablets can reduce the cost of these products for consumers by joining certain parts and components using fasteners rather than welds and adhesives. These things are also simpler to fix thanks to screws.

Reduced waste: A lot of items need to be put together from various parts and pieces. Fasteners make it possible for businesses to finish the process with less waste and decrease manufacturing costs by allowing them to use fewer resources. To simplify the final assembly, manufacturers simply need to pre-drill a few tiny holes that will fit screws, nuts, and bolts.

Lower production costs: Lower production costs, improved aesthetics, and simpler handling and usage are driving a number of sectors to develop lighter, more agile goods. Small screws are ideal for these products since they satisfy the fundamental fastening needs while reducing the product’s weight.

How To Choose Different Types Of Fasteners

It’s crucial to pick the appropriate fastener for your intended purpose. When selecting the appropriate fastener types for your application, you should always ask these three questions:

- Which sort of fastener do you need?

- Which application calls for these fasteners?

- What qualities should your Jam nut possess?

- What is the true nature of your fastener requirement?

- What essential characteristics must your produced item possess?

You will know which threaded fasteners are ideal for your usage after you have the answers to these questions. By selecting the right characteristics for the fasteners, you can guarantee the good performance of your application. For instance, internally threaded fasteners are the finest option if you wish to link two produced pieces perpendicularly. The aforementioned discussion demonstrates how crucial it is to choose fasteners wisely.

In conclusion, mechanical fasteners may not seem important, yet they maintain the connection between two objects in a produced item. The selection of fasteners must take into account the necessary features of the produced item since there are several types of fasteners, such as lock nuts and screws, which also include various types of threaded hole bolts and hex nuts.

These fasteners all have various sorts of coatings on them, each with a particular function. Suitable instruction is also given on how to select fasteners. So all you need to know about mechanical fasteners is summarized in this post.

FAQs about Different Types of Fasteners

- How many types of fasteners are there?

Bolts, screws, and studs are the three basic categories of threaded fasteners.

- What is the most popular fastener?

The most popular kind of fasteners are bolts. These mechanical components are typically used to join two unthreaded parts. An external male thread and a hexagonal head are found on opposite ends of a bolt. On the opposite end of the bolt is often a nut that secures it.

- How do I identify a fastener?

Four or five characteristics—Type, Material, Diameter, Length, and Thread Pitch or Count—are used to categorize fasteners (machine thread fasteners only).

- What are engineering fasteners?

A fastener is a piece of hardware that attaches two or more items mechanically. Fasteners are typically utilized to form joins that are not permanent (can be removed or dismantled). Bolts, clips, latches, pins, sockets, nuts, washers, nails, and screws are a few examples of fasteners.

- What are the mechanical fasteners?

A tool used to mechanically attach (or fasten) two or more things together is known as a mechanical fastener. Although there are many distinct kinds of mechanical fasteners, they may generally be split into two groups: permanent and non-permanent fastening.

Conclusion

You may acquire all the details you want about the Fasteners and details about this market on the Linquip website, one of the numerous possibilities available to you. Whether you’re a professional or a client seeking for a reputable business, you can rely on Linquip to give you as much basic and trustworthy information on this subject. We advise you to look through the whole range of Fasteners Experts and take advice from our professionals. If you need any services required for your product, you can count on Linquip and visit Fasteners Services.

Download PDF for Different Types of Fasteners

You can download the PDF format of this post from the link provided here.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More On Linquip

- Top Fastener Suppliers & Manufacturing in 2022

- Different Types of Bolt Heads + Benefit of Bolts and Nuts

- Different 15 Types of Hand Saws: Clear Guide

- Different Types Of Screw Heads: A Practical Guide

- 12 Types of Industrial Sewing Machine + Advantages

- The 6 Best Industrial Sewing Machine

- 12 Types of Electric Saws: Clear Guide

- Types of Drill Bits for Metal: Comprehensive Guide

- Different Types of Socket Wrench: Clear Guide

- 42 Types of Wrenches + Guide for Choosing a Wrench

- Different Types of Socket Wrench: Clear Guide

- 13 Types of Adjustable Wrench: Clear Guide

- All 24 Types of Drill Bits + Video: Clear Guide

- 3 Types of Crimping Tools + Name & Their Uses

- 33 Types of Pliers & Their Names: A Comprehensive Explanation

- 53 Differents Tools for Construction Workers