Pressure sensors have been designed to measure the pressure of different liquids and gases! That would be the definition of a differential pressure sensor in a nutshell. But knowing that is not enough! That’s why in this article from Linquip, we want to dive into the world of differential pressure sensors and talk about what they are and how they work. Stay with us and keep on reading to enjoy gaining information about these amazing and life-saving pressure sensors.

Differential pressure sensors are one of the pressure sensor types that have been designed for pressure measurement. But first, we need to know what exactly pressure is. Pressure is an expression of the necessary force for stopping the expanding process of the fluid. These sensors, thus, have been designed for measuring this pressure and providing the necessary data relating to this parameter. They have many applications in our day-to-day life and are considered to be among the crucial parts for different applications. Among different types of pressure sensors, you can see the name of differential pressure sensors. Now let’s get into the details about this sensor type.

What are differential pressure sensors?

A differential pressure sensor is a device responsible for measuring the difference between two pressures. These two pressures are connected to each side of the differential pressure sensor. They also measure pressure drops across oil or air filters. They can measure fluid levels as well by measuring the pressure between the above and below the liquid. Another parameter that these sensors are able to measure is the flow rate of liquids.

When differential pressure sensors measure the changes in pressure, they can provide this parameter. These sensors contain an element that is sensitive to pressure and can detect, monitor, and measure the applied pressure at its ends. They also consist of electronic components for converting the calculated information into an output signal to provide the reader with the necessary information and to help with gathering the necessary data regarding the system.

How to calculate the pressure?

These sensors calculate the exerted force of gas or liquid to a unit of area and therefore, calculate the pressure and converting it into a signal that is readable to the reader. The equation for this calculation would be P=F/A.

How do differential pressure sensors work?

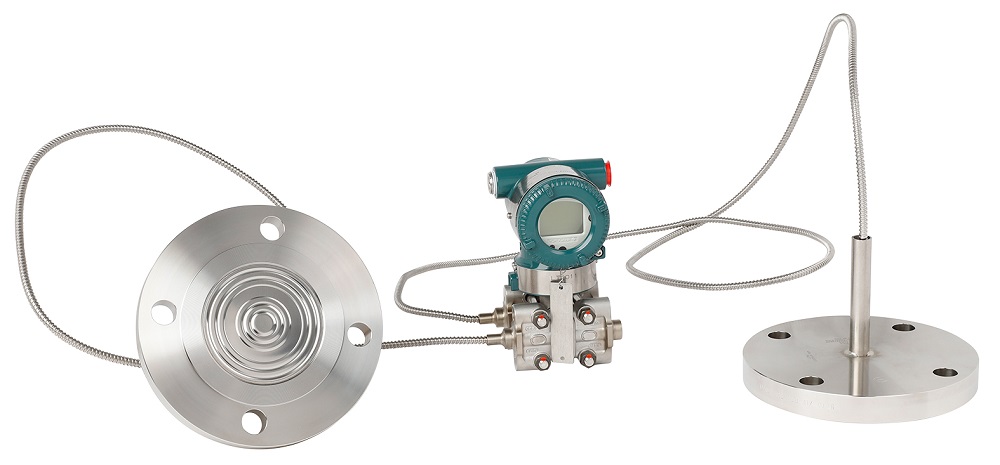

The opposite sides of a single diaphragm receive the two pressures that should be measured. The diaphragm’s deflection indicates the difference in the pressure, whether it be negative or positive with respect to the resting state. For industrial purposes, some sensors use two separate absolute sensors as well as a control system for measuring the desired parameters in the system.

In these systems, one can easily measure the pressure, flow, level, interface, and density of the liquid or gas. Another important application of these sensors is that they can detect a blockage or seized valve! By measuring the pressure and calculating the resulting number, it can easily show if there’s something that’s blocking the progress. If the pressure of a valve at the end side of the flow is higher than the opposite side (or the beginning of the valve), then it can probably be confirmed that there’s a blockage that needs to be taken care of.

The difference between differential pressure sensors and static pressure sensors is that the static type uses only one port to measure the pressure while the differential pressure sensors usually consist of two ports that host the attachment of the pipes.

Differential pressure sensors application

These pressure sensors are used in a wide variety of applications. You can find these sensors in many industrial environments where there’s a need to measure the pressure of a gas or liquid. For example, in systems that work by heating or cooling gases or liquids, the use of these sensors is usually necessary. You can also see differential pressure sensors in fire protector systems, inside their sprinkler unit. They are useful when the volume of a liquid in a closed vessel needs to be measured as well. The pressure, gravity, and liquid density can all help to measure the volume of the liquid (the height of the column of liquid). This is only true for situations when the temperature variation doesn’t change the fluid’s density.

There are also more important fields that use this sensor. With the advancement of technology in today’s world, our medical field has progressed even further than before but that doesn’t mean that small units such as pressure sensors can’t keep up with the field. In fact, these sensors are useful in the medical field and play a crucial role when it comes to saving our life. Respirator and breathing detection equipment, deep vein thrombosis, and also infusion pumps are among the places using the help of such pressure sensors. They can be used inside devices that cure diseases and also enable us to breathe etc.

That was all there is to know about differential pressure sensors and their important role in our life. Have you ever worked with one? Comment below and share your experience with us. And if you have any questions about your pressure sensor and need a solution, feel free to sign up on Linquip and our experts will answer all your questions.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More On Linquip

- Transducer vs. Sensor: Basic Differences & Advantages of Them

- Types of Sensors Detectors/Transducers: An Entire Guide

- Difference Between Actuator and Sensor: The Ultimate Guide

- 5 Types of Proximity Sensors (Application and Advantages)

- What is Humidity Sensor: Your go-to Guide on humidity Sensors!

- Temperature and Humidity Sensors: An Ultimate Guide

- Types of Humidity Sensors: A Full Explanation on The Most Common Types

- An Easy Overview of Types of Pressure Gauges

- How to Wire Up Piezoelectric Sensor? A Comprehensive Guide