Double Pipe Heat Exchangers- Heat exchangers are devices that transfer or exchange heat between two fluids without mixing and include various types depending on the design, application, required space, and the fluid flows in the system. All the heat exchangers have a barrier that separates the fluids and allows the heat transfer simultaneously. The double pipe heat exchanger is one of the basic kinds of exchangers with a very flexible configuration. There are two types of counterflow or parallel flow for this type that are the basis of design and calculation for determining pipe size, length, and a number of bends. In this article, we will examine different aspects of Double pipe heat exchangers.

A twin pipe heat exchanger is a heat exchanger that is made up of two concentric pipes separated by a mechanical closure. The use of Industrial HVAC Tools necessitates the use of Double Pipe Heat Exchangers. Several Suppliers And Companies, as well as other manufacturers and distributors, provide Double Pipe Heat Exchangers, and there are several Heat Exchangers For Sale on Linquip.

There is a complete list of double pipe heat exchangers services on the Linquip platform that covers all OEM fleets. Linquip vendors can assist you with this. Please contact Linquip’s Double Pipe Heat Exchangers Experts to learn more about how to connect with a diverse group of Service Providers who consistently deliver high-quality products.

⇒ View a List of Heat Exchanger for Sale and Their Suppliers ⇐

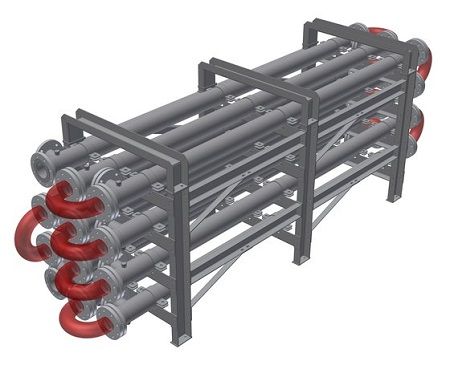

Double Pipe Heat Exchangers

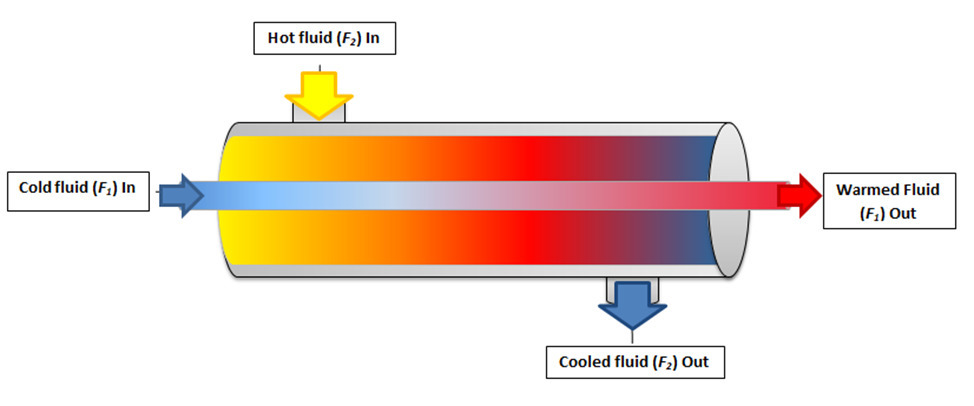

In double pipe heat exchangers, we have a large pipe with a small pipe inside it concentrically, and all the heat transfer process occurs inside the larger pipe. One fluid flows through the inner of a small pipe, and another fluid is between the two pipes, and that is how the inner pipe acts as a conductive barrier. The outside or shell side includes fluid flow passing on the inner side or tube side.

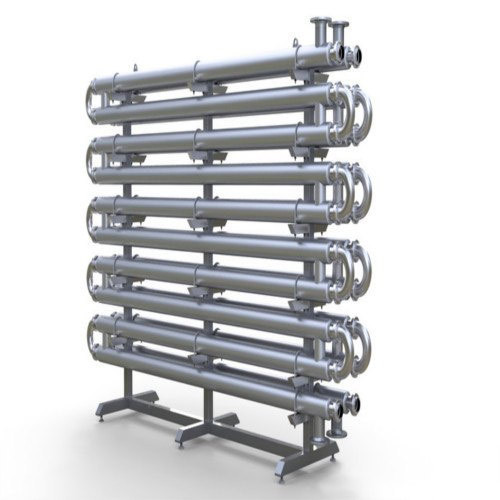

This type of heat exchanger is known as hairpin, jacketed pipe, jacketed u-tube, and pipe in pipe exchanger. They can contain one pipe or pipe bundle (less than 30), and the outer pipe must have a diameter of less than 200mm. In some cases, to increase the rate of heat transfer between working fluids, there are longitudinal fins in the inner tube.

Specification and Applications

One of the simplest heat exchangers is a double pipe heat exchanger. Figure 1 is a schematic of this type, and as shown, one pipe or shell is inside the other one. Because of the straightforward design, there are many options for a customer to choose from. Many custom heat exchangers are available in the market to satisfy industry and projects’ needs in various applications. It would be better to use this type in a low capacity application, while the heat transfer area is less than 45 square meters.

You should be aware of the fluid types in your system while using this exchanger. The viscous fluid should be used in the shell side due to the much more space available for the flow. As a result, if you are using steam as a fluid in the exchanger, it would be better to use pipes for flow.

Project specifications should be determined before choosing the proper exchanger. Inlet and outlet temperatures and the required heat transfer should also be defined. Providing these details makes it easier for you and a supplier to introduce available exchangers in the market or design the right pipe pairs for you. As discussed before, the design in double pipe heat exchangers is simple and modular, but you should know that you would pay high prices for the exchanger by increasing the surface area.

The applications of double pipe heat exchangers are a lot, and it is hard to encompass all, and it is all because of the practical, elegant, and simple design. A few of them are as below:

- Boilers and compressors as they have high temperatures and pressures

- Cooling and heating in process engineering systems

- Petroleum refining

- Refrigeration

- Sewage treatment

If the available space is important and you do not look for a complex heat exchanger, try double pipe heat exchangers for your project.

Types of Double Pipe Heat Exchangers

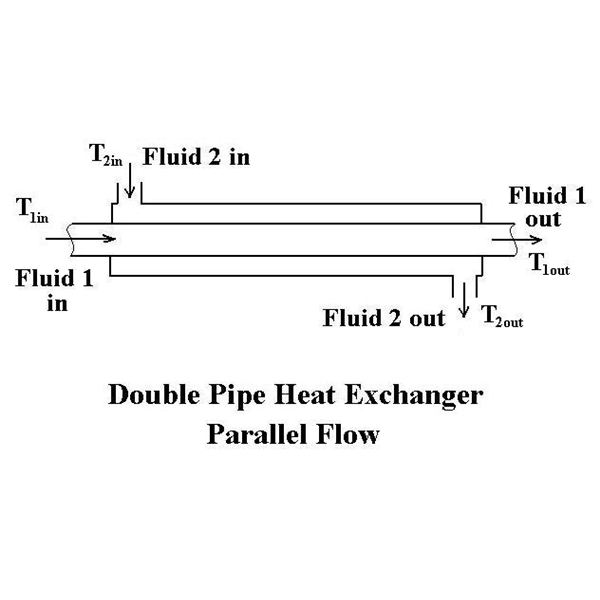

Double pipe heat exchangers can be categorized based on the flow direction. Parallel flow and counter flow can be deployed in these exchanges, and it is all about the position of inlets and outlets. Choosing the parallel and counter flow affect the heat transfer and the pressure drop in the system, by the way in some application you should choose one from other.

Counter Flow Double Pipe Heat Exchangers

The best design for a double pipe heat exchangers is counter flow. In this pattern, the heat exchanger has the optimum heat transfer coefficient and can cold or heat the outlets as we desire.

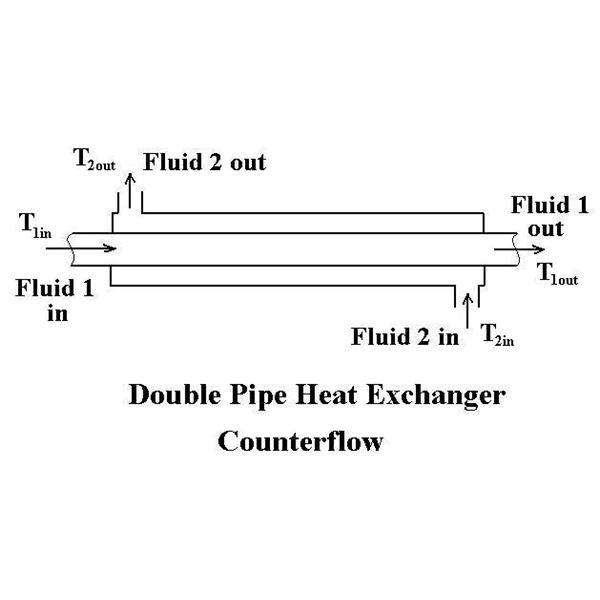

Figure 2 illustrates the position of the inlets and outlets. As it is shown in this type, the flows flow in the opposite direction of each other, and at the end in both heads, we have the maximum temperature difference between fluids. Examine the diagram for the counter flow and consider fluid 1is hot and fluid 2 is cold. Cold side temperature at the outlet (T2out) can obtain temperatures close to the T1in, and as we know, this temperature is greater than T1out. In this type, the clod fluid temperature can reach more than the hot side outlet, while in the parallel one, it is impossible.

Parallel Flow Double Pipe Heat Exchangers

Parallel flow is the type that the inlets and outlets are in one head. Heat transfer is less than the counterflow, and the efficiency is low; however, in some applications, we should choose this type.

Advantages and Disadvantages of Double Pipe Heat Exchangers

Double pipe heat exchangers have one of the most straightforward designs, and as a result, they are easy to be fabricated and repaired. All the devices have some advantages and disadvantages, and here we will show you if the double pipe heat exchangers are suitable for your application or not.

Advantages of Double Pipe Heat Exchangers

This type of exchanger has some unique advantages over other complicated heat exchangers. The main benefits of double pipe heat exchangers are listed below:

- You can provide good efficiency with lower capital costs.

- They are small compared to the shell and tube and do not need much space for maintenance, while the heat transfer is acceptable.

- As they are very popular, all the parts have been standardized, and it makes the repair and maintenance very easy.

- They have a flexible design, and other addition and removal parts can be done easily.

- You can use this type of exchanger at high pressure and temperature.

- The design of the exchanger allows more thermal expansion without any expansion joint.

Disadvantages of Double Pipe Heat Exchangers

You should be aware of the flaws of this type and its design, such as:

- They are usually used in counterflow designs and can not be used in some applications. It does not mean that they cannot be used in parallel flow.

- They have limitations in heat transfer rather than complicated designs and should be used in low heat duties.

- Leaking is more often in this type (paired with more units)

Double Pipe Heat Exchanger Design

By knowing some specifications of double pipe heat exchangers and your demands, design can be done by simple heat transfer equation as below:

where:

Q is the heat transfer rate between fluids, U is the heat transfer coefficient in the system, A is the surface of the heat transfer, and is the log mean temperature (can be calculated knowing the temperature of the inlet and outlet of fluids).

By knowing the required heat transfer area, we can choose the diameter and length of both inner and outer pipes. In the end, the length of the straight part and the number of bends can be selected.

What Are the Characteristics of Double Pipe Heat Exchanger?

It is made up of concentric pipes that are connected by mechanical closures. They are particularly tailored to high-temperature, high-pressure applications because of their comparatively tiny diameters. They are inexpensive, durable, and easy to maintain. The building of double pipe heat exchangers is straightforward.

Conclusion

Double pipe heat exchanger designs are the simplest type of exchangers suitable for high temperature and pressure applications. They are easy to repair, and due to the straightforward design, they are used widely in many applications and are the first choice for a lot of projects. They can be used in two types of counterflow, and parallel flow depends on the application, and the design of this type is straightforward.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Download Double Pipe Heat Exchanger PDF

Read More On Linquip

- Working Principle of Plate Heat Exchanger

- What is Cross Flow Heat Exchangers and its Working Principles

- Heat Exchanger Efficiency: Tips for Having an Efficient Heat Exchanging System

- Types of Shell and Tube Heat Exchanger

- Installing an Air Source Heat Pump: Everything You Need to Know

- Heat Exchanger vs. Chiller: Which one is the best?

- Difference Between Heat Exchanger and Condenser: A thorough guide 2022

- Tubular Heat Exchangers: Usage & Working Principle

- What is Coil Heat Exchanger? Design Example

- Advanced Guide: What Is Tube In Tube Heat Exchangers

- Heat Exchanger Parts: Description of Configuration

- What are Counter Flow Heat Exchangers and its Working Principles?

- Demystifying Heat Exchanger Sizing: A Comprehensive Guide

Thank you

We appreciate you stopping by our site and expressing your thoughts. In future articles, we welcome your feedback and comments.