The drift eliminator is one of the cooling tower parts that is used to minimize the amount of process water loss within the cooling tower for resource usage efficiency as well as keeping an eye on environmental concerns.

Here at Linquip, we have established a strong platform for the suppliers of cooling tower parts and products for the convenience of clients in their procurement process and management.

In what follows, some brief explanation regarding the types, manufacturing, and replacement of drift eliminators is presented.

What Is a Drift Eliminator?

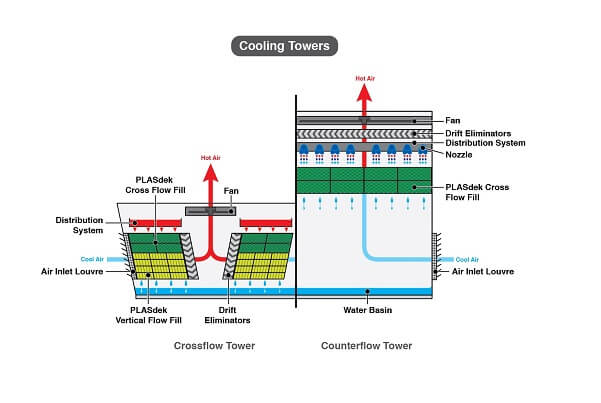

A by-product of intimate contact between water and air in the fill is the water droplets that have the same composition and quality of the circulating water flow through the tower. These (solid) droplets are called ‘drift’, and they are different from the pure water vapor in the effluent air stream or solid droplets formed by condensation of that vapor.

This water droplets or drift is hazardous for the environment and it is not desirable for the system to lose its process water circulating in it. Therefore a drift eliminator is used to prevent the drift from escaping.

Cooling Tower Fill Material: Gain a Deep Understanding

Drift Eliminator Function

A drift eliminator makes a sudden change of direction in the air stream. This sudden change of direction results in a centrifugal force that separates the drops from the air by depositing the drops on the eliminator’s surface. They would eventually drain back into the tower.

Drift Eliminator Material

The drift eliminator should be made from materials that are resistant to corrosion the same way it is the case for the fill. Therefore, they are typically made from the same material as the fill.

There are cases in which a certain type of treated wood is used as the eliminator’s material, but the most typically used materials for drift eliminators (as well as fills) include polyvinyl chloride (PVC) and polypropylene (PP) due to their cost-effectiveness, durability and cooling tower’s environmental compatibility. Drift eliminators could also be constructed from galvanized / stainless steel.

Drift Eliminator Types and Designs

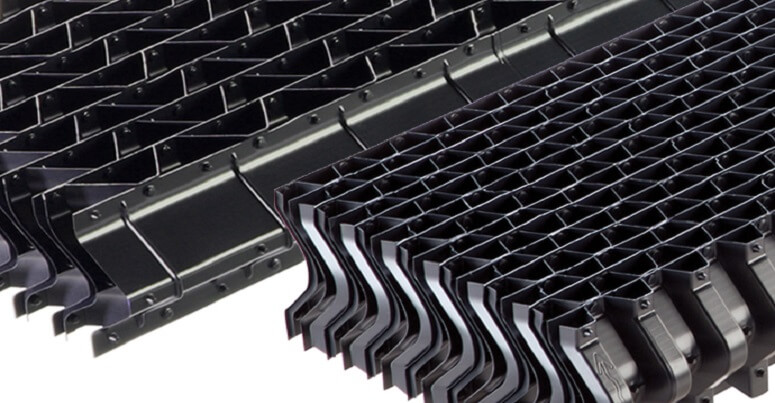

Drift eliminators can be categorized based on counterflow or crossflow types in compliance with the type of the cooling tower, and further based on their cellular (aka wave) or blade (aka fin) design.

in the design of drift eliminators, maximizing the efficiency of drift removal while minimizing the pressure drop across them should be considered.

Click here for a short graphical representation of drift eliminators and their assembly. (The eliminator in the video is of the blade type)

Cellular type

An alternating series of corrugated and wave sheets are assembled together to form closed cells. These cellular panels are called cellular drift eliminators that correspond to a high surface area of droplet capturing.

This type of drift eliminators is useful for low-drift-level applications.

Blade type

crossflow blade eliminators are designed for effective droplet capture and provide a cost-effective drift solution. The heavy gauge blades are held together with end caps to form a module that is lightweight yet strong enough to span up to 10 feet, saving material and labor costs.

Drift Eliminator Replacement

Scale and biological buildup result in deterioration and blockage of the eliminators over time. This means that airflow distribution through the panels would lose homogeneity and there would be excessive water loss. The energy use of the tower does not necessarily increase due to this problem, but its water use and chemical treatment of water will increase.

Finally, water stains or mineral deposits thrown around the tower as well as water-droplet falling in the tower discharge area are indications of the need for repair or replacement of the panels.