Dry cooling towers are among the cooling towers designed to achieve the same purpose as other towers: removing the excess heat as much as possible. The extra heat from machines and industrial processes can be harmful to the efficiency of the system and might even lead to danger and threat our own safety.

So it’s important to choose the right one for your specific application to not only ensure your safety, but also keep your system’s efficiency as high as possible and save money and time in the long run as well. In this article from Linquip, we will discuss the basics of dry cooling towers, where you can use them, how they operate, and so on.

What is a cooling tower?

Cooling towers are considered as devices that help reject the excess heat to the atmosphere. This process happens with the help of a water stream that acts as a medium to transfer the heat.

There are different types of cooling tower that can achieve such a purpose. Though the basics are the same for all of them, but each of them is unique for specific applications such as large scale or small scale, etc. Each cooling tower design belongs to a specific category. This categorization can be based on different parameters such as shape, heat transfer method, etc. and Dry cooling towers also belong to a particular category.

The dry cooling system belongs to which cooling tower category?

Dry cooling towers are one of the types under the heat transfer method category. They are known for their specific way of transferring the heat. There are also other types in this section such as wet cooling towers, but we want to focus on dry ones here.

Dry cooling towers definition

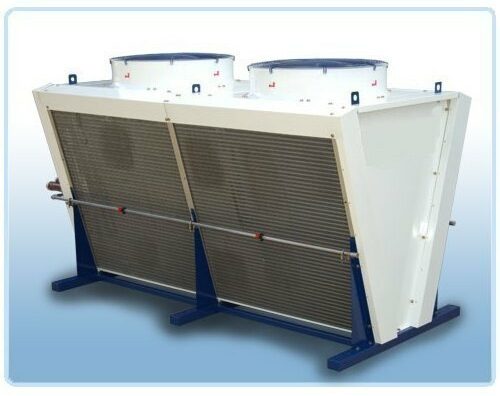

This tower is a closed-circuit cooling tower that operates by heat transfer to remove the excess heat from the system.

Dry cooling tower working principle

“How does a cooling tower work?” If you already know the answer to this question, understanding the working principle for dry ones shouldn’t be too hard for you. They operate by heat transfer through a surface separating the ambient air from the working fluid. The medium used in dry cooling towers is either water or a mixture of water-glycol. The principle of heat transfer is used in this system which takes place by a heat exchanger with extended fins. In dry cooling towers, the air can be introduced by natural draft or mechanical draft to move the air through the air-cooled heat exchangers/ACC.

Unlike other towers, they don’t use evaporation and as a result, the consumption of makeup water in these systems is minimal; plus, the fan in this system uses an electric motor to run, so it’s another plus point for this type. This system functions with air cooling technology and the circulation of hot water from the condenser through thin tubes enables the heat exchange since the tubes are exposed to ambient air flowing around them. The low air temperature absorbs the heat from the water to cool it down to the desired degree.

The increase of volumetric flow rate of the air through the heat exchangers has an improving effect on the performance, which depends on the air dry-bulb temperature. But one of the disadvantages of such devices is their lower efficiency when the ambient air temperature is high.

In order to provide uniform heat transfer and a smooth and clean inner tube surface for water pressure-drop, this tower has been designed with controlled expansion between the tube and fin. Plus, to keep the efficiency high, the motors are designed to withstand rain, moisture, and dust. And the low speed of the motor helps increase the efficiency and minimizes the noise.

Dry cooling towers application

There are different performance ranges for this system, and you can choose the right one for your specific application. It is ranged from approximately 5 to 2,000 kW performances. These systems have different noise levels and should be used for outside installation.

Dry cooling towers can be used for the solar industry, plastic industry, data center cooling, factory cooling, power plant, and many other applications.

You can use dry coolers in computer room air conditioning systems, in cooling production equipment systems, in water-cooled chilled water air conditioning systems, in storage refrigeration systems, and also in cooling diesel generator sets.

This tower type works amazing for places where water resources are limited. They can easily help to eliminate the excess heat without damaging the outside environment and ensure your safety and your devices’ safety all year long.

Keep in mind that you need to set an appointment for regular maintenance to make sure your dry cooling tower works well and enables you to get the most out of your system. Regular maintenance is necessary to avoid any damage in the future and also avoid small problems turning into big disasters by solving them at the right time. The regular maintenance helps avoid compressor failure too. Plus, when the system is efficient, the costs of energy consumption and maintenance will decrease over time while maintaining high efficiency. On the other hand, their simplistic design as well as other points that we mentioned above, are the reasons that this type is popular for both residential and industrial uses.

Now that you’ve read this article, you can easily talk about dry cooling towers, how they operate, and where they’re used. You can easily realize what the difference between this one and the other counterparts is and whether it suits your needs or not. Do you have anything to add up to this article? Don’t hesitate to leave a comment below and share your experience with us. And if you have any questions about this tower or any other industrial units, sign up on Linquip and ask our experts… We will solve your problems in no time!

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

We Have a 750 kw emergency generator the the main and jacket water coolers have to many leaks to repair cost effectively any recommendations

Thank you for your review. To recive complete information on your issue, please sign up on Linquip where our experts are prepared to provide you with the professional advice you need.